This operator’s book has important information for the use and safe operation of this machine. Read this book carefully before starting the machine. Keep this book and tell all operators to read the book. If you do not follow the instructions, you can cause an injury or damage equipment, furniture o...

2 safety instructions 1) you must have training in the operation of the machine before using it. Read the instruction book. If you do not understand any instruction, ask your supervisor. 2) make sure all labels, decals, warnings, cautions and instructions are fastened to the machine. 3) read the lab...

Symbols used on the automatic scrubber water valve indicator brush drive motor control switch vacuum motor control switch squeegee lift lever indicator battery charge indicator water flow control indicator traction drive speed control forward - reverse traction drive switch 3.

Machine preparation 1. Unpacking the machine a.Take off the outer packaging b. The machine is fastened to the pallet with wooden wedges that block the wheels. Remove tie down straps c. Using a ramp, pull the machine off the pallet 2. Battery installation a. Remove the squeegee hose from the recovery...

Machine preparation 4. Squeegee assembly installation the squeegee is assembled to the machine by lifting the locking latches and sliding the squeegee assembly onto the 2 posts at the rear of the squeegee swing arm. Push the locking latches down. Lower the squeegee and install vacuum hose over vacuu...

6 machine preparation 7. Recovery tank open the lid and confirm the following connections are secure: a. The vacuum cover is securely attached. Align the notches and rotate the cover clockwise to close. The vacuum hose must also be attached b. Confirm that the squeegee hose is properly connected c. ...

10. Splash guard installation a. Wrap splash guard around the brush deck base b. Place band clamp over the front band clamp stud c. Pull band clamp around brush deck base and place and clamp spring over rear band clamp stud d. Repeat process on opposite side of brush deck base machine operation 1. C...

Machine operation 5. Adjust the flow rate of the cleaning solution with lever. Moving the solution flow control lever downward increases the flow rate and raising the lever decreases the flow rate. There should be enough solution to wet the floor uniformly, but not so much that the water gets past t...

10. Over fill protection the machine is equipped with a float that stops the vacuum exhaust air flow when the recovery tank is full. Vacuum motor does not stop operating but the vacuum exhaust air flow rate is greatly reduced. When this occurs, empty the recovery tank by removing the drain plug on t...

Upon completion of machine use 5. Switch off main power key switch 6. Switch off the water solenoid valve switch 7. Switch off the brush motor switch 8. Switch off the vacuum motor switch 9. Transport the machine to the location where the recovery tank should be emptied 10. Remove the drain hose at ...

2. Cleaning the vacuum filter a. Lift the cover b. Take off the vacuum cover by rotating it counter-clockwise c. Remove the filter and its housing d. Use clear water to clean the walls and the bottom of the filter e. Remove the filter and its housing f. Wash all components thoroughly g. Reassemble r...

Daily machine maintenance 5. Brush / pad driver removal a. Lift the brush base by depressing the foot level at the rear of the machine b. The photo shows the directions to rotate the brushes to unlock them from the auto scrubber. Clean the brushes with clear water weekly machine maintenance 1. Clean...

Weekly machine maintenance 2. Solution tank cleaning a. Remove the fill cap from the solution tank b. Rinse with clear water c. Remove the solution tank drain hose and cap at rear of machine and empty the solution tank warning: use gloves for protection from contact with dangerous solution 3. In-lin...

Water solenoid maintenance in the event that the water solenoid begins to leak when turned off, debris must be cleared at the valve seat. To gain access the water solenoid the scrub deck most be disassembled from the lifting arms. Remove the 3 bolts shown in the photo to release the scrub deck troub...

4. Excessive foam production a. Check that a low foaming detergent has been used. If required, add a small quantity of defoamer liquid to the recovery tank. More foam is generated when a floor is lightly soiled. Use less detergent if this is the case trouble shooting guide 15.

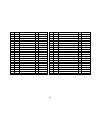

23 22 17 18 17 16 15 24 25 26 19 20 15 21 27 8 7 28 44 43 42 41 40 20 38 39 15 38 37 36 35 34 33 32 29 31 30 13 11 14 13 12 11 10 6 9 13 29 27 13 8 7 6 5 2 4 3 2 1 16 z210 traction auto scrubber - brush deck assembly.

17 item part # description qty note item part # description qty note 1 964103 hex bolt-full m8x45 zinc 2 zinc 23 843324 fitting 1 2 980684 m8 washers flat l zinc 2 zinc 24 849404 solenoid valve 1 3 841102 wheel bushing 2 brass 25 843323 fitting barbed 1 4 849701 wheel 2 26 842003 hose clamp 1 ss 5 9...

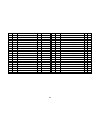

18 1 2 3 4 5 6 7 6 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 8 30 29 24 35 19 20 36 20 31 38 39 40 41 23 24 25 26 27 28 31 32 23 24 33 34 z210 traction auto scrubber - brush base assembly.

19 item part # description qty note item part # description qty note 1 964003 screw flat head torx drive m8x45 1 zinc 23 964116 hex bolt m6x20 zinc 4 zinc 2 980668 washer - wide m16x56x3thk 1 24 980665 m6 flat washer zinc 8 zinc 3 840303 idler arm 1 epoxy paint 25 964084 hex bolt-full m8x50 zinc 1 z...

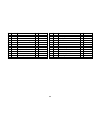

20 1 2 2 2 3 4 5 6 6 7 7 7 8 8 8 14 9 9 10 11 11 12 12 12 13 13 14 14 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 41 13 30 31 32 33 34 35 36 37 20 38 39 40 42 z210 traction auto scrubber - main frame assembly.

21 item part # description qty note item part # description qty note 1 964007 hex bolt m8x40 zinc 1 zinc 21 842306 pedal cover 1 2 980684 m8 washers flat l zinc 5 zinc 22 964400 flat head soc hex screw m6x16 zinc 1 zinc 3 840301 brush deck lift idler arm 1 zinc 23 842701 metal disc 1 zinc 4 980676 m...

22 1 2 3 4 5 5 5 6 7 8 8 9 10 11 11 11 12 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 2 3 30 31 32 33 21 z210 traction auto scrubber - squeegee frame assembly.

23 item part # description qty note item part # description qty note 1 842407 squeegee lift cable 1 18 842405 squeegee lift cable 2 2 845001 adjustment knob 3 19 964225 hex bolt m5x20 zinc 2 zinc 3 920649 hex nut m8 zinc 3 zinc 20 920615 hex nut m5 zinc 2 zinc 4 924033 nyloc hex nut m8 zinc 1 zinc 2...

24 1 2 2 3 4 5 6 7 8 9 10 10 11 12 14 13 15 16 17 17 18 19 20 21 23 22 24 z210 traction auto scrubber - squeegee assembly.

25 item part # description qty note item part # description qty note 1 964103 hex bolt-full m8x45 zinc 2 zinc 14 964004 hex set screw m6x8 2 black oxide 2 980679 m8 washer flat zinc 4 zinc 15 841304 squeegee attachment block 2 zinc 3 889742 wheel 45 dia 2 16 845105 squeegee attachment block latch 2 ...

26 1 2 3 5 6 7 7 8 9 11 10 10 12 13 14 15 16 17 18 19 20 19 21 22 23 24 25 26 27 28 29 29 30 31 32 33 34 35 36 37 37 38 39 40 8 42 43 44 45 z210 traction auto scrubber - solution tank assembly.

27 item part # description qty note item part # description qty note 1 846403 plate wire retaining 3 23 848302 spring 1 zinc 2 964228 m3x9.5 pan head plastite screw 6 zinc 24 920615 hex nut m5 zinc 1 zinc 3 964398 hex bolt full-thd m6x25 ss 1 ss 25 885044 knob 1 5 843406 conical tank gasket 1 26 843...

28 1 2 3 4 6 7 8 8 8 9 10 11 12 13 14 15 15 16 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 31 32 32 33 34 35 36 z210 traction auto scrubber - recovery tank assembly.

29 item part # description qty note item part # description qty note 1 845110 z series recovery tank cover label 1 20 883446 gasket 1 2 842304 z210 recovery tank cover 1 21 886841 filter cover 1 3 964231 st m4.2x12 pan hd pl zinc 2 zinc 22 883441 gasket 1 4 882440 hook 1 ss 23 844101 z210 recovery t...

30 1 2 3 4 4 5 6 3 7 7 7 8 8 8 9 9 10 11 12 13 14 14 14 14 14 15 15 16 16 16 16 16 16 16 16 16 16 16 17 18 19 19 20 21 21 21 22 23 24 25 26 27 28 29 30 z210 traction auto scrubber - vacuum assembly.

31 item part # description qty note item part # description qty note 1 843901 connector handle 1 18 845002 lever arm knob 1 zinc 2 964422 screw m4x20 pan hd pl zinc 2 zinc 19 964423 hex bolt m6x12 zinc 5 zinc 3 911186 plug - charge 2 20 840805 bracket-weldment 1 epoxy paint 4 920033 m4 hexagon lock ...

1 2 3 2 4 7 6 5 9 10 11 4 15 17 29 18 20 13 28 27 17 26 25 24 23 22 16 12 12 8 21 19 24 30 14 32 z210 traction auto scrubber - switch box assembly.

33 item part # description qty note 1 920658 nut flange m5 zinc 1 zinc 2 980685 m5 washer flat zinc 2 zinc 3 964237 set screw socket m5x30 zinc 1 4 964228 m3x9.5 pan head plastite screw 6 zinc 5 911419 brush motor relay 1 6 964182 screw m4x10 pan head zinc 2 zinc 7 846406 strap-wire retaining 2 8 91...

34 z210 traction auto scrubber - wiring diagram.

Warranty policy auto scrubber, z210 traction the pacific z210 traction auto scrubber has been manufactured, tested and inspected in accordance with specific engineering requirements. This machine is warranted to be free from defects in workmanship and materials for periods as follows from the date o...