Summary of ES-5000

Page 1

1 es-5000 service manual pressure sealer es-5000

Page 2: Table Of Contents

2 table of contents 1. Introduction 2. Installation 3. Features 1) specifications 2) general views 4. How to operate 1) form preparation 2) loading forms 3) start 4) fold setting 5) operator panel 6) manual feed 5. Maintenance 1) general cleaning 2) paper dust 3) cleaning pickup and fold rollers 4) ...

Page 3

3 1. Introduction es-5000 produces folded and sealed single mail pieces with cut-sheet pressure seal forms. Pressure activated adhesive applied forms provide and instantly secure seal on all sides of the form, whether use a “c”, “v”, “z” or “double” fold. Names of each part 2. Pressure sealer es-500...

Page 4

4 2. Installation locate the box right next to the location where the machine will be set up and operate. open box, remove the operators guide and set aside. Grasp the two shipping straps and remove the unit from the box. remove all packing materials from around the unit and place the folder o...

Page 5

5 1) features 1) specifications processing speed 4,200 forms per hour automatic jam recovery system no adjustment required for varying paper thickness fold plate setting can be changed in seconds manual feeder for single form processing folding unit slides out for easy access and mainten...

Page 6

6 2.3) exit tray 2.4) label & fuse 2.5) how to open the fold unit (please follow the pictures below in order) ac socket 5 amp 250v mini fuse in a 1/4 turn fuse holder manufacturer’s label with serial no. Folding unit pulls out by grasping the hand hold and pull out stopper for exit tray pressure sea...

Page 7

7 2.6) how to open the fold drum (please follow the pictures below in order) folding drum handle in the unlock(down) position folding drum in the partially open position folding drum in the open position. Access the folding drum for clearing jams pressure sealer es-5000

Page 8

8 3. How to operate 1) form preparation forms must be fanned properly on both sides to separate and eliminate any static that may have been induced by the laser printer 2) loading forms place the paper in the paper tray in the correct orientation as indicated in the chart below. The paper tray can h...

Page 9

9 4) fold setting 4.1) standard folding drum 4.1.1) unlock the green release lever to set the fold position 4.1.2) move the red arrow, first fold on the red knob to the fold position required according to the manual on the fold drum 4.1.3) move blue arrow, second fold according to the manual on the ...

Page 10

10 5) operator panel 5.1) power switch: power on/off 5.2) reset: reset button will clear the display count 5.3) start/stop: start/stop button will start or stop the feed cycle 5.4) counter: display will show the total page count/resettable as well as firmware rev. Level at start-up, fold unit open a...

Page 11

11 5. Maintenance 1) general cleaning be sure that the room is well ventilated, switch off the mains power and unplug or disconnect from the mains, pull out the fold drum and the fold unit, remove as much paper dust as possible using a soft brush 2) paper dust with general use, paper dust will build...

Page 12

12 4) cleaning press rollers with general use, toner will build up on the press rollers. Check the rollers for build up and clean on a regular basis with roller cleaning fluid. Depending on the type of laser printer, toner and fuser, the degree of build up will vary. Clean both upper & lower press p...

Page 13

13 6. Trouble shooting 1) paper jam 1.1) feeding unit jam do not pull the document backward in the event of jam in the infeeder. Open the fold drum unit by pushing down the fold drum handle as the direction of the red arrow in the picture on the right pull the paper to the direction of the red arrow...

Page 14

14 1.3) press unit jam fully extend the folding unit to the direction of the red arrow in the picture on the right use the jam removal tool to rotate the rollers by placing the tool into the jam removal holes as shown in the picture on the right turn it downward. Remove the jam as shown in the pictu...

Page 15

15 2) double feed 2.1) clean the pickup rollers and pad with an alcoholic solution(in case the problem persists, then go to 2.2) 2.2) slide in-feed tray tension adjusters upwards (manufacturer’s default position: middle). Both tension adjusters must be in the same position as shown in the picture on...

Page 16

16 4.7) clean the fold rollers with an alcoholic solution 4.8) examine and replace any folding roller with imperfections such as flat spots or swelling 4.9) replace or exchange from side to side the folding roller compression springs pressure sealer es-5000

Page 17

17 2. Replacement and assemblies 1) folding unit side covers 1.1) fully extend the fold unit on its rails 1.2) remove the circled 2 screws from the outside cover as shown in the picture on the right 1.3) remove the circled 1 screw from the inside as shown in the picture on the right 1.4) remove cove...

Page 18

18 3) main side cover 3.1) fully extend the folding unit on its rails 3.2) remove the 2 screws as indicated in the picture on the right 3.3) remove the 1 screw in the back of the unit as shown in the picture on the right 3.4) lift up on the cover to unlock the “hidden” screw in keyway. 3.5) remove t...

Page 19

19 4) top cover 4.1) remove the main side covers as indicated in the chapter 7-3 4.2) remove the circled 4 screws on each side as shown in the picture on the right note: screw in upper corner is longer as it has to pass through to layers of metal 5) main drive belt 5.1) to tighten the drive belt, us...

Page 20

20 6.5) remove the bushings from both ends of shaft 6.6) remove shaft note: the direction of feed roller rotation (one way bearing) makes sure the new roller rotates in the same way direction 6.7) with feed roller removed you can now remove the separator(pad base) note: it’s orientation in the machi...

Page 21

21 8) folding unit drum (new type) 8.1) fully extend the folding unit on its rails 8.2) unlock the folding drum assembly 8.3) rotate the folding drum all the open 8.4) by moving the release catch towards the left (direction of arrow) as shown in the picture on the right. The drum should release from...

Page 22

22 10) folding rollers & rubber roller replacement 10.1) remove the white gear from the side as well as the black gear on the back side 10.2) after removing the bearing on the front side, push down the main rubber roller and take the roller out through the large hole as shown in the picture below. F...

Page 23

23 12) operator panel pcb replacement 12.1) remove operator side of main cover 12.2) remove the circled six screws that hold pcb in place as shown in the picture on the right 12.3) remove pcb 12.4) reinstall in reverse order pressure sealer es-5000

Page 24

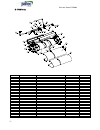

24 8. Diagram & part list 1) infeed tray 020 010 030 060 040 070 080 090 100 110 120 025 140 130 150 150 160 111 011 no part number part name unit remark 10 wel-b250-00 assy:tray plate 1 11 wel-f200-00 tray:cigal plate 1 20 adn-c048-01 guide:right 1 25 adn-c048-00 guide:left 1 30 wel-b271-00 plate s...

Page 25

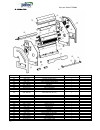

25 2) fold drum 2 3 0 2 2 0 1 9 0 2 0 0 1 7 0 1 8 0 1 8 5 1 7 3 1 9 1 2 4 0 2 4 5 2 5 0 2 6 0 2 5 3 2 6 1 2 2 2 2 1 1 2 1 0 1 7 1 1 7 2 2 5 1 1 7 4 1 8 1 2 0 1 2 6 1 2 2 2 2 2 1 1 7 1 2 0 2 2 5 2 1 7 0 no part number part name unit remark 170 adn-d200-01 frame:cassette 2 171 wel-s110-00 spring:v-fol...

Page 26

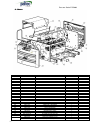

26 3) folder unit no part number part name unit remark 270 ez5-1127 cover:front:folder 1 271 pm5-1125 folder frame:front 1 280 ez5-1128 cover:rear:folder 1 281 pm5-1116 assy:folder frame:rear 1 282 wel-f488-01 gear:double 1 283 wel-f489-00 gear:24t 1 290 pm5-1446 guide:folder:ent 1 291 adn-d019-01 a...

Page 27

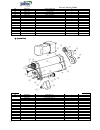

27 4) frame no part number part name unit remark 500 pm5-1105 cover:front 1 510 pm5-1201 label:op:pm-5 1 515 pm5-1202 op cover 1 520 pm5-5000 pwb:op 1 530 pm5-1123 support frame:front 1 531 pm5-1124 support frame:rear 1 540 pm5-5526 micro s/w 1 550 lca-0010 b/k:i/l:2nd folder 1 560 pm5-1331 assy:fra...

Page 28

28 770 pm5-1203 shaft:support 2 780 pm5-1109 shield;left 1 790 pm5-1104 cover:top 1 800 pm5-1103 frame:rear 1 810 pm5-1205 cord bracket 1 820 fra-0003 power:inlet 1 821 pm5-5524 fuse holder(r3-11) 1 830 pm5-1106 rear cover 1 840 pm5-5522 s/w (r9d2kkft00f1-r19-2) 1 850 pm5-5523 ssr(240vac 15a) 2 851 ...

Page 29

29 1045 pm5-1217 mb belt:320mb 1 1050 ben010dj bearing:f688 3 1060 pm5-4455 pulley:v-belt:large 1 1070 pm5-1215 timing belt:b60s3m252 1 1080 pm5-4450 pulley:s3m56t 1 1090 pm5-6223 key:6 x 6 x 12 1 1091 pm5-6222 key:6 x 6 x 25 2 pressure sealer es-5000