- DL manuals

- Panasonic

- Air Conditioner

- CS-A12CTP

- Service Manual

Panasonic CS-A12CTP Service Manual

1

Functions

2

2

Product Specifications

5

3

Dimensions

11

4

Refrigeration Cycle Diagram

13

5

Block Diagram

15

6

Wiring Diagram

17

7

Operation Details

19

8

Operating Instructions

35

9

Installation Instructions

39

10 Servicing Information

50

© 2003 Matsushita Industrial Corp. Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-A12CTP CU-A12CTP5

CS-A18CTP CU-A18CTP5

CS-A24CTP CU-A24CTP5

11 Troubleshooting Guide

51

12 Technical Data

53

13 Exploded View

55

14 Replacement Parts List

56

15 Exploded View

57

16 Replacement Parts List

58

17 Exploded View

59

18 Replacement Parts List

60

19 Electronic Circuit Diagram

61

Room Air Conditioner

CONTENTS

Page

Page

Order No. MAC0301002C8

Summary of CS-A12CTP

Page 1

1 functions 2 2 product specifications 5 3 dimensions 11 4 refrigeration cycle diagram 13 5 block diagram 15 6 wiring diagram 17 7 operation details 19 8 operating instructions 35 9 installation instructions 39 10 servicing information 50 © 2003 matsushita industrial corp. Sdn. Bhd. (11969-t). All r...

Page 2: 1 Functions

1 functions mode sleep fan speed reset timer auto manual aut auto hea heat cool cool dr dry fan an speed speed h h off off on on a b a b temp off/on air swing select set/cancel remote control operation off / on room temperature setting temp. Operation mode selection • auto automatic operation mode •...

Page 3

Indoor unit sleep mode auto control • indoor fan operates refer to indoor fan speed. • operation stops after 8 hours. Indoor fan speed control • high, medium and low. • automatic fan speed mode – heating : fan speed varies from me → sslo in accordance with indoor heat exchanger. – cooling : fan rota...

Page 4

Outdoor unit cu-a12ctp5 • to protect compressor from reverse rotation when there is a instantaneous power failure. 60 secs. Forced operation control • once the compressor is activated, it does not stop within the first 60 secs. However, it stops immediately with remote control stop signal. Overload ...

Page 5: 2 Product Specifications

2 product specifications unit cs-a12ctp cu-a12ctp5 power source phase v cycle single 220 - 230 50 cooling capacity kw btu/h kcal/h 3.52 - 3.52 12,000 - 12,000 3,030 - 3,030 heating capacity kw btu/h kcal/h 4.00 - 4.00 13,600 - 13,600 3,440 - 3,440 moisture removal l/h pint/h 2.0 4.2 airflow method o...

Page 6

Unit cs-a12ctp cu-a12ctp5 heat exchanger description evaporator condenser tube material copper copper fin material aluminium aluminium (blue coated) fin type louver fin corrugated fin row / stage (plate fin configuration, forced draft) 2 × 12 2 × 24 fpi 20 16 size (w × h × l) mm 857 × 252 × 25.4 720...

Page 7

Unit cs-a18ctp cu-a18ctp5 power source phase v cycle single 220 - 230 50 cooling capacity kw btu/h kcal/h 5.30 - 5.30 18,100 - 18,100 4,560 - 4,560 heating capacity kw btu/h kcal/h 6.00 - 6.00 20,500 - 20,500 5,160 - 5,160 moisture removal l/h pint/h 2.9 6.1 airflow method outlet intake side view to...

Page 8

Unit cs-a18ctp cu-a18ctp5 heat exchanger description evaporator condenser tube material copper copper fin material aluminium aluminium (blue coated) fin type louver fin corrugated fin row / stage (plate fin configuration, forced draft) 2 × 12 + 1 × 10 2 × 26 fpi 20 16 size (w × h × l) mm 857 × 252 ×...

Page 9

Unit cs-a24ctp cu-a24ctp5 power source phase v cycle single 220 - 230 50 cooling capacity kw btu/h kcal/h 6.40 - 6.40 21,800 - 21,800 5,500 - 5,500 heating capacity kw btu/h kcal/h 7.50 - 7.50 25,600 - 25,600 6,450 - 6,450 moisture removal l/h pint/h 3.5 7.4 airflow method outlet intake side view to...

Page 10

Unit cs-a24ctp cu-a24ctp5 heat exchanger description evaporator condenser tube material copper copper fin material aluminium aluminium (blue coated) fin type louver fin corrugated fin row / stage (plate fin configuration, forced draft) 2 × 12 + 1 × 10 2 × 26 fpi 20 16 size (w × h × l) mm 857 × 252 ×...

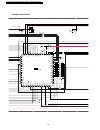

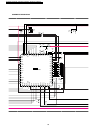

Page 11: 3 Dimensions

3 dimensions 11 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 12

12 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

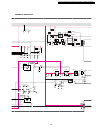

Page 13

4 refrigeration cycle diagram 13 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 14

14 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

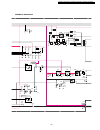

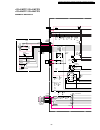

Page 15: 5 Block Diagram

5 block diagram 15 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 16

16 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

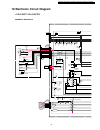

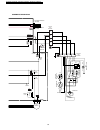

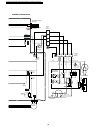

Page 17: 6 Wiring Diagram

6 wiring diagram 17 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 18

18 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 19: 7 Operation Details

Cooling in operation according to remote control setting. Time delay safety control (3 minutes) 7 minutes time save control anti-freezing control • if the temperature of the indoor heat exchanger falls continuously below 2°c for 4 minutes or more, the compressor turns off to protect the indoor heat ...

Page 20

Compressor protection control automatic fan speed mode • after the compressor starts for 50 seconds but the outdoor fan motor is still off, the compressor will stop and restart automatically. (time delay safety control is valid). • if the above phenomenon is repeated for 3 times, the compressor will...

Page 21

Cooling operation time diagram 21 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 22

Time delay safety control anti-freezing control compressor reverse rotation protection control compressor protection control anti-dew formation control automatic fan speed mode 7.2. Soft dry mode operation • the unit starts cooling operation until the room temperature reaches the setting temperature...

Page 23

Soft dry operation time diagram 23 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 24

Heating in operation according to remote control setting. Time delay safety control 30 minutes time save control overload protection control compressor reverse rotation protection control 7.3. Heating mode operation • when the compressor is stopped by remote control, it restarts after 3 minutes when...

Page 25

4-way valve control outdoor fan motor control indoor fan motor control hot start control anti cold draft control • 4-way valve always on during heating operation. (except deicing operation) • when the unit is switched to “off” during heating operation, 4-way valve stay at heating position for 5 minu...

Page 26

Automatic fan speed mode heating operating time diagram when automatic fan speed is selected at remote control during heating operation. • fan speed rotates in the range of me → slo according to the heat exchanger temperature. • if use manual fan speed, at above diagram will operate with setting fan...

Page 27

Deicing control 1) a12ct deice starts to prevent frosting at outdoor heat exchanger. • normal deicing deice operations detection commences after 30 minutes of heating operation starts or 60 minutes after previous deice operation. If the trs (thermal reed switch) senses the outdoor piping temperature...

Page 28

Normal deicing time diagram overload deicing time diagram 28 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 29

A) normal deicing time diagram 2) a18ct, a24ct deice starts to prevent frosting at outdoor heat exchanger. • normal deicing deice operation detection commences in heating operation starts or 60 minutes after previous deice operation. If the outdoor piping temperature drops to -4°c for 50 sec. Contin...

Page 30

(b) overload deicing time diagram 7.4. Automatic mode operation 1. When the automatic mode operation is selected, the indoor fan operates at slo fan speed for 25 seconds to sense intake air temperature and determine the 1st operation mode. If indoor intake air temperature is less than 16°c, heating ...

Page 31

Cooling or soft dry operation purpose is to obtain a comfortable room temperature while sleeping. When you press the sleep mode, the following movement will start to avoid overcooling. • sleep shift operation starts, when the room temperature reaches the setting temperature or after 1 hour of operat...

Page 32

Heating operation purpose is to obtain a comfortable room temperature while sleeping. When you press the sleep mode, the following movement will start to avoid overheating. • sleep shift operation starts, when the room temperature reaches the setting temperature or after 1 hour of operation. • the s...

Page 33

1. Manual operation when the airflow direction adjustment button of the remote control is pressed, the louver moves up/down in the movable range shown in the diagram at right, and can be stopped at the required position. Only the up/down louvers are adjustable from the remote control. 2. Automatic a...

Page 34

7.11. Soft starter (applicable only for australia market) a. Purpose to reduce starting current lower than 45a. B. Basic operation (a18ctp, a24ctp) 1. When indoor relay is turn on, starting capacitor will be turn on through ry-c for ~ 1 second. After that reactor will be turn off through ry-l and in...

Page 35: 8 Operating Instructions

8 operating instructions ■ installation precautions ! Warning ● this room air conditioner must be earthed. Improper grounding could cause electric shock. ● ensure that the drainage piping is connected properly. Otherwise, water will leak out. ● do not install the unit in a potentially explosive atmo...

Page 36

Name of each part ■ remote control ● remote control signal. • make sure it is not obstructed. • maximum distance : 10 m. • signal received sound. One short beep or one long beep. ● notes for remote control. • do not throw or drop. • do not get it wet. • certain type of fluorescent lamps may affect s...

Page 37

■ setting the fan speed • press 4 to select:- fan – low fan speed fan – medium fan speed fan – high fan speed auto fan – automatic fan speed the speed of the indoor fan is adjusted automatically according to the operation. The indoor fan stops occasionally during cooling operation. ■ vertical airflo...

Page 38

■ pre-season inspection ● clean the air filters, re-insert and operate the air conditioners. ● is the discharged air cold / warm? Operation is normal if 15 minutes after the start of operation, the difference between the air intake and outlet vents temperature is:- ● are the air intake or outlet ven...

Page 39

9 installation instructions required tools for installation works 1. Philips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 55 n.M (5.5 kgf.M) 65 n.M (6.5 kgf.M) 3. Electric drill, hole core drill (ø70...

Page 40

10. • when connecting the piping, do not not use any existing (r22) pipes and flare nuts. Using such same may cause abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. Use only r410a materials. • thickness of copper pipes used with r410a must be...

Page 41

Select the best location indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place where drainage can be easily done. • a place where noise prevention is t...

Page 42

Installation on the ceiling 9.2. Indoor unit 9.2.1. Select the best location (refer to “select the best location” section) 9.2.2. How to fix installation parts • measure and mark the position for the suspension bolts and the piping hole. • drill the hole for anchor nut on the ceiling. • drill the pi...

Page 43

1. Insert the piping sleeve to the hole. 2. Fix the bushing to the sleeve. 3. Cut the sleeve until it extrudes about 15 mm from the wall. Caution when the wall is hollow, please be sure to use the sleeve for tube ass’y to prevent dangers caused by mice biting the connecting cable. 4. Finish by seali...

Page 44

Piping and drainage 9.2.5. Connect the cable to the indoor unit 1. Open the control box at the bottom end of the chassis and connect the cable through the hole. • connect the wires to the terminals on the control board individually according to the outdoor unit connection. • ensure the color of wire...

Page 45

At the best location, start installation according to indoor- outdoor unit installation diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2. When installing at roof, please consider strong wind. Please fasten the installation stand firmly with bolt or ...

Page 46

1. Remove the service port caps from both 3-way valves. 2. Connect the manifold gauge set to the service port of liquid side 3-way valve. 3. Connect the charging cylinder to the manifold gauge set and open the valve of the cylinder. 4. Open the low pressure side valve of the manifold gauge for appro...

Page 47

The remaining air in the refrigeration cycle which contains moisture may cause malfunction on the compressor. 1. Remove the caps from the 2-way and 3-way valves. 2. Remove the service-port cap from the 3-way valves. 3. To open the valve, turn the valve stem of 2-way valve counter-clockwise approx. 9...

Page 48

1. If you may connect an additional drain hose, the end of the drain-outlet should keep distance from the ground. Caution (do not dip it into water, and fix it on the wall to avoid swinging in the wind.) in case of the outdoor unit is installed below position of the indoor unit. 2. Tape the pipings,...

Page 49

Check the drainage • connect the drain hose, as described below. • pour water into the drain pan to ensure that water is drained smoothly through the drain hose. Auto switch operation the below operations will be performed by pressing the “auto” switch. 1. Auto operation mode the auto operation will...

Page 50: 10 Servicing Information

• remote control reset when the batteries are inserted for the first time, or the batteries are replaced, all the indications will blink and the remote control might not work. If this happen, you will find a resetting terminal, and by shorting it with a minus screwdriver, it will return to normal. •...

Page 51: 11 Troubleshooting Guide

11.1. Refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air te...

Page 52

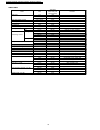

11.1.1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditoner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refrige...

Page 53: 12 Technical Data

12 technical data 53 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 54

230v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 3.49 2.65 1.04 3.26 2.54 1.12 3.03 2.44 1.20 2.76 2.32 1.30 19.0°c 3.52 1.14 19.5°c 3.83 2.77 1.06 3.58 2.66 1.14 3.33 2.56 1.22 3.03 2.44 1.32 22.0°c 4.18 2.87 1.08 3.90 2.76 1.17 3.63 2.67 1.25...

Page 55: 13 Exploded View

13 exploded view 55 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 56: 14 Replacement Parts List

14 replacement parts list ref no. Description & name qty. Cs-a12ctp cs-a18ctp cs-a24ctp remarks 1 chassy complete 1 cwd50c1258 ← ← 2 fan motor 1 cwa921172 ← cwa921158 o 3 supporter fan motor 2 cwd932270 ← ← 4 blower wheel assy 2 cwh01k1014 ← ← 5 air guider b.W. 2 cwd321046 ← ← 6 control board assy 1...

Page 57: 15 Exploded View

15 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 57 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 58: 16 Replacement Parts List

16 replacement parts list ref. No. Part name & description qty. Cu-a12ctp5 remarks 1 chassy ass’y 1 cwd50k2074 2 sound proof material 1 cwg302110 3 fan motor bracket 1 cwd541030 4 screw - fan motor bracket 2 cwh55413 5 fan motor 1 cwa951121 0 6 screw - fan motor mount 3 cwh55406 7 propeller fan ass’...

Page 59: 17 Exploded View

17 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 59 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 60: 18 Replacement Parts List

18 replacement parts list ref. No. Part name & description qty. Cu-a18ctp5 cu-a24ctp5 remarks 1 chassy ass’y 1 cwd50k514b ← 2 sound proof board 1 cwh15223 ← 3 fan motor bracket 1 cwd54237 ← 4 screw - fan motor bracket 4 cwh55027 ← 5 fan motor 1 cwa921182 cwa921081 0 6 screw - fan motor mount 4 cwh55...

Page 61

19 electronic circuit diagram schematic diagram 1/4 • cs-a12ctp / cu-a12ctp5 7 6 5 4 3 1 2 cn-rmt 4 3 1 2 cn-ha (xh4) 7 6 5 4 3 1 9 8 2 cn-disp (ph9) 3 4 5 6 7 9 1 2 8 cn-disp (ph9) 5 4 3 1 2 5 4 3 1 2 cn-stm (ph5) r67 c30 0.01 µ r63 10k c29 0.01 µ r62 10k r65 100k c31 0.01 µ r64 100k r18 620 r17 62...

Page 62

Mn101c309 ic01 p74 p75 p76 p77 p87 p86 led5 led4 led3 led2 p81 p80 vref- an0 an1 an2 p50 p24 p23 irq2 irq1 irq0 p14 p13 p12 p11 p10 nrst buzzer p05 p04 p03 an4 an3 an6 an5 an7 vcd vref+ osc2 vss osc1 x0 x1 mm0d sbi0 sbt0 sbo0 46 41 42 43 44 45 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 40...

Page 63

Schematic diagram 3/4 4.7k 10k b e c r49 1k r07 1k r50 100k r51 10k q03 ssr01 rx1 q02 jx4 r42 10k r39 10k r13 10k r74 1k jx1 r31 20k jx2 jx8 jx3 jx7 jx6 r40 39k r41 51k r48 1k c22 0.1 µ c13 0.1 µ c14 0.01 µ c e b c e b r54 6.2k r53 10k r52 6.2k zd01 c21 10 µ 50v q05 q06 + 4.7k 10k b e c ssr02 1 3 2 ...

Page 64

5 4 3 1 2 cn-fm fan motor cr01 fm(blu) ry-pwr ac(wht) ac 220-240v 50/60 hz hot(red) air temp. Sensor (15k 3950) (20k 3950) pipe temp. Sensor 1 2 4 3 cn-th (ph4) fuse 250v 2a 511u c-fm znr01 c11 0.047 µ c12 0.047 µ l01 125 µh r01 39k/2w ssr01 znr03 511u outdoor unit terminal indoor unit terminal 1 2 ...

Page 65

Schematic diagram 1/4 • cs-a18ctp / cu-a18ctp 5 • cs-a24ctp / cu-a24ctp5 7 6 5 4 3 1 2 cn-rmt 4 3 1 2 cn-ha (xh4) 7 6 5 4 3 1 9 8 2 cn-disp (ph9) 3 4 5 6 7 9 1 2 8 cn-disp (ph9) 5 4 3 1 2 5 4 3 1 2 cn-stm (ph5) r67 c30 0.01 r63 10k c29 0.01 r62 10k r65 100k c31 0.01 r64 100k r18 620 r17 620 r16 620 ...

Page 66

Mn101c309 ic01 p74 p75 p76 p77 p87 p86 led5 led4 led3 led2 p81 p80 vref- an0 an1 an2 p50 p24 p23 irq2 irq1 irq0 p14 p13 p12 p11 p10 nrst buzzer p05 p04 p03 an4 an3 an6 an5 an7 vcd vref+ osc2 vss osc1 x0 x1 mm0d sbi0 sbt0 sbo0 46 41 42 43 44 45 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 40...

Page 67

Schematic diagram 3/4 4.7k 10k b e c r49 1k r07 1k r50 100k r51 10k q03 ssr01 rx1 q02 jx4 r42 10k r39 10k r13 10k r74 1k jx1 r31 20k jx2 jx8 jx3 jx7 jx6 r40 39k r41 51k r48 1k c22 0.1 c13 0.1 c14 0.01 c e b c e b r54 6.2k r53 10k r52 6.2k zd01 c21 10 50v q05 q06 + 4.7k 10k b e c ssr02 1 3 2 cn-fb (p...

Page 68

5 4 3 1 2 cn-fm fan motor cr01 fm(blu) ry-pwr ac(wht) ac 220-240v 50/60 hz hot(red) air temp. Sensor (15k 3950) (20k 3950) pipe temp. Sensor 1 2 4 3 cn-th (ph4) fuse 250v 2a 511u c-fm znr01 c11 0.047 c12 0.047 l01 125 h r01 39k/2w ssr01 znr03 511u outdoor unit terminal indoor unit terminal 1 2 3 4 1...

Page 69

How to use electronic circuit diagram 69 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 70

Timer table test mode name time (when test point remarks short-circuited) real timer 1 hr. 1 min. 10 min. 10 sec. 1 min. 1 sec. Time delay safety control 2 min. 58 sec. 0 sec. Forced operation 60 sec. 0 sec. Time save control 7 min. 4.2 sec. Anti-freezing 4 min. 0 sec. Auto mode judgement 25sec. 0 s...

Page 71

19.1. Remote control 71 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 72

19.2. Print pattern indoor unit printed circuit board 72 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5.

Page 73

73 cs-a12ctp cu-a12ctp5 / cs-a18ctp cu-a18ctp5 / cs-a24ctp cu-a24ctp5 [maico] printed in malaysia.