- DL manuals

- Panasonic

- Air Conditioner

- CS-A28BKP5

- Service Manual

Panasonic CS-A28BKP5 Service Manual

1

Features

2

2

Functions

3

3

Product Specifications

6

4

Dimensions

8

5

Refrigeration Cycle Diagram

9

6

Block Diagram

10

7

Wiring Diagram

11

8

Operation Details

12

9

Operating Instructions

22

10 Installation Instructions

42

© 2002 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D) All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-A28

BKP5/CU-A28BKP5

11 3-way Valve

51

12 Servicing Information

58

13 Troubleshooting Guide

62

14 Technical Data

64

15 Exploded View

67

16 Replacement Parts List

68

17 Exploded View

69

18 Replacement Parts List

70

19 Electronic Parts List

71

20 Electronic Circuit Diagram

72

Room Air Conditioner

CONTENTS

Page

Page

Order No:TAC0204001C2

Summary of CS-A28BKP5

Page 1

1 features 2 2 functions 3 3 product specifications 6 4 dimensions 8 5 refrigeration cycle diagram 9 6 block diagram 10 7 wiring diagram 11 8 operation details 12 9 operating instructions 22 10 installation instructions 42 © 2002 matsushita air-conditioning corp. Sdn. Bhd. (183914d) all rights reser...

Page 2: 1 Features

• high efficiency • high efficiency airflow circuit • compact design • auto restart after power failure • long piping up to 30m • catechin deodorizing air filter • deodorizing control during operation • cold draught control 1 features 2 cs-a28 bkp5/cu-a28bkp5.

Page 3: 2 Functions

2 functions remote control operation off / on off / on i room temperature setting temp. • temperature setting (16˚c to 30˚c) • automatic operation m / n 2˚c lower than standard n standard n - o 2˚c higher than standard operation mode selection • auto automatic operation mode • heat heating operation...

Page 4

Indoor unit auto restart control • operation is restarted after power failure at previous setting mode. Anti-freezing control • anti-freezing control for indoor heat exchanger. (cooling and soft dry) sleep mode auto control • indoor fan operates at low fan speed. • operation stops after 8 hours. Ind...

Page 5

Outdoor unit 4-way valve control • when the unit is switched to “off” during heating operation, 4-way valve stays at heating position for 5 minutes. 60 secs. Forced operation control • once the compressor is activated, it does not stop for 60 secs. (stops imme- diately with remote control stop signa...

Page 6: 3 Product Specifications

3 product specifications unit cs-a28 bkp5 cu-a28 bkp5 cooling capacity kw btu/h 7.92 - 7.80 27,000 - 26,600 heating capacity kw btu/h 8.35 - 8.25 28,500 - 28,200 moisture removal l/h pint/h 4.6 9.7 power source phase v cycle single 230 - 220 50 airflow method outlet intake side view top view air vol...

Page 7

Power cord length number of core-wire m 2.1 3 (2.5 mm 2 ) — — dimensions height inch (mm) 14 - 9/16 (370) 26 - 31/32 (685) width inch (mm) 48 - 1/32 (1,220) 34 - 21/32 (880) depth inch (mm) 8 - 21/32 (220) 13 - 19/32 (345) net weight lb (kg) 40 (18) 150 (68) compressor type — scroll type motor type ...

Page 8: 4 Dimensions

4 dimensions 8 cs-a28 bkp5/cu-a28bkp5 cs-a28bkp5/ cu-a28bkp5.

Page 9: Dimensions

Cs- a 28bk p 5 / cu- a 28bk p 5 5 refrigeration cycle diagram 9 cs-a28 bkp5/cu-a28bkp5 cs- a 28bk p 5 / cu- a 28bk p 5 dimensions cs-a28bkp5/cu-a28bkp5 cs-a28 bkp5/cu-a28bkp5.

Page 10: 6 Block Diagram

6 block diagram 10 cs-a28 bkp5/cu-a28bkp5 cs-a28bkp5/cu-a28bkp5.

Page 11: 7 Wiring Diagram

7 wiring diagram 11 cs-a28 bkp5/cu-a28bkp5 cs-a28bkp5 / cu-a28bkp5.

Page 12: 8 Operation Details

Cooling in operation according to remote control setting. Time delay safety control (3 minutes) 7 minutes time saved control anti-freezing control • if the temperature of the indoor heat exchanger falls continuously below 2°c for 4 minutes, the compressor turns off to protect the indoor heat exchang...

Page 13

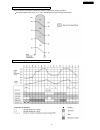

Automatic fan speed mode cooling operation time diagram when automatic fan speed is selected at remote control during cooling operation. • fan speed rotates in the range of hi to me. • deodorizing control. 13 cs-a28 bkp5/cu-a28bkp5.

Page 14

Time delay safety control anti-freezing control automatic fan speed mode 8.2. Soft dry mode operation • the unit starts cooling operation until the room temperature reaches the setting temperature set on the remote control, and then soft dry operation will start. • during soft dry operation, the ind...

Page 15

Soft dry operation time diagram 15 cs-a28 bkp5/cu-a28bkp5.

Page 16

• heating in operation according to remote control setting. Time delay safety control 30 minutes time saved control overload protection control 4-way valve control hot start control hot start is completed when indoor heat exchanger reaches 42°c. Maximum hot start duration = 4 minutes. After 4 minute...

Page 17

Automatic fan speed mode heating operating time diagram when automatic fan speed is selected at remote control during heating operation. • fan speed rotates in the range of hi → slo according to the heat exchanger temperature. 17 cs-a28 bkp5/cu-a28bkp5.

Page 18

Deicing control a) normal deicing time diagram deice starts to prevent frosting at outdoor heat exchanger. • normal deicing deice operations detection commences in heating operation starts or 60 minutes after previous deice operation. If the outdoor piping temperature drops to -4°c for 50 sec. Conti...

Page 19

Operation higher standard lower mode (+2°c) (±0°c) (-2°c) cooling 27°c 25°c 23°c soft dry 24°c 22°c 20°c heating 23°c 21°c 19°c b) overload deicing time diagram 8.4. Automatic mode operation 1. When the automatic mode operation is selected, the indoor fan operates at slo fan speed for 20 seconds to ...

Page 20

Cooling or soft dry operation when you press the sleep mode, the following movement will start to avoid overcooling. • the fan speed refer to indoor fan motor control. • the setting temperature will be risen by 0.5°c at the start of operation and by 0.5°c one hour later. • the operation will stop af...

Page 21

Airflow direction auto-control • when set a airflow direction auto-control with remote control, the louver swings up and down as shown in the diagram. • the louver does not swing when the indoor fan stops during operation. • when stopped with remote control, the discharge vent is closed with the lou...

Page 22: 9 Operating Instructions

9 operating instructions ■ do not install, remove and reinstall the unit yourself. Improper installation will cause leakage, electric shock or fire. Please consult an authorized dealer or specialist for the installation work. To prevent personal injury, injury to others and property damage, the foll...

Page 23

Operation precautions ■ insert the power plug properly. Heat generated by a loose power plug could cause electric shock or fire. Electrical outlet and power plug shall be easily accessible. ■ do not modify the length of the power cord or use an extension cord. It could cause electric shock or fire. ...

Page 24

■ switch off the power supply if the unit is not going to be used for a long period of time. If dust accumulates on the plug, it will generate heat and this could cause a fire. ■ do not place combustor in the path of the airflow from the unit. Incomplete combustion could cause toxic gas (co) poisoni...

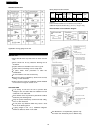

Page 25: Name of Each Part

Name of each part indoor unit operation indication lamps (led) (rear) (side) outdoor unit air intake vents air outlet vents drain hose piping ground terminal (inside cover) front panel air intake vent air outlet vent panel opener horizontal airflow direction louver (manually adjusted) vertical airfl...

Page 26

Off/on sleep pm mode temp. Fan speed manual swing air swing dry cool heat auto am on-tim er off-tim er °c auto fan c h j k m n o separate displays and functions are available when the door is opened. Remote control two r03 dry-cell batteries or equivalent air purifying filters (with deodorizing func...

Page 27: Preparation Before Operation

2 3 preparation before operation before operating the unit ■ open the front panel. ■ remove air filter. ■ insert air purifying filter. Insert the air filters. Hold the tab to raise up slightly and then pull down. Hold the panel openers at both sides and pull up the front panel. Air filter ■ connect ...

Page 28

O p e n e r e r open how to insert batteries operating the remote control gently press the place marked [open] and slide the cover toward you. Er be sure that the (+) and (–) directions are correct. Pull out the power plug or turn off the power breaker when: ■ the air conditioner is not going to be ...

Page 29: How to Operate

Recommended temperature for health and comfort. ■ if there is a power failure, operation will be automatically restarted after 3 minutes when the power is resumed with previous operation mode and airflow direction. (when the operation is not stopped by re- mote control.) ■ if you do not intend to co...

Page 30

Heat – heating operation ■ defrosting operation depend on the outdoor temperature, the opera- tion occasionally stops to melt the frost on the outdoor unit. ■ heat is obtained from outdoor air to warm up the room. When the outdoor ambient air temperature falls, the heating capacity of the unit might...

Page 31: Setting The Timer

Regarding remote control. ■ if the current time is not set correctly, correct timer setting will not be possible. ■ when the timer is set, the current time display will vanish. ■ [reset] points will clear the memory once they are shorted. ■ [b ↔ a] switch is used when two air conditioners units have...

Page 32

■ setting the off timer. ■ setting the on timer. Timer ■ the on timer and off timer can only be set once during a day. ■ the operation will start before the actual setting time with on timer setting. This is to allow time to attain your desired set temperature. If the air conditioner is set before y...

Page 33: Convenient Operation

Convenient operation sleep mode this is to gain a comfortable room temperature while sleeping. Sleep mode operation. ■ when the room temperature reaches the setting temperature or after 1 hour of operation, sleep shift operation starts and the airflow volume will automatically change to low. ■ sleep...

Page 34

When the remote control cannot be used test run button. (use when installing and moving) auto operation button. ■ when the remote control cannot be used, press auto operation button to run automatic operation. (airflow direction setting will be automatic.) off/on remote control signal receiving soun...

Page 35: Operation Hints

Operation hints ■ adjust room temperature properly. Set the temperature 1°c higher (cooling operation) or 2°c lower (heating operation) than actu ally desired. Approximately 10% of electricity costs can be saved. ■ prevent wastage with the timer. Use timer when sleeping or going out to save electric...

Page 36

■ make sure that the doors and windows are shut. Otherwise, cooling and heating per formance will be reduced and electricity cost is wasted. ■ proper airflow direction adjustment. Set the airflow direction louvers horizontal for cool ing operation and downwards for heating operation. Operation resul...

Page 37: Better Care and Maintenance

Regular care and maintenance will extend the life of the air conditioner and prevent wastage of electricity. Before performing any maintenance procedure, be sure to switch off the main power supply. Once every 2 weeks is recommended. ■ clean the air filters. ■ to remove the dust adhering to the filt...

Page 38: Pre-Season Inspection

3 filters ■ is the discharge air cold (warm)? Operation is normal if, 15 min- utes after the start of operation, the temperature difference be- tween the air intake vent and outlet vent is 8°c or above for cooling and 14°c or above for heating. ■ are the air outlet vents and air intake vents obstruc...

Page 39: Troubleshooting

Normal operation ? Z z z during soft dry mode operation, the air condi- tioner stops. Q is it okay? A this is the answer. Air conditioner has been re- started, but does not operate for 3 minutes. During automatic airflow volume setting, indoor fan stops occasionally. Operation stops for about 12 min...

Page 40

Abnormal operation the air conditioner does not operate. The air conditioner does not cool effectively. Air conditioner operation noise too loud. ■ has the temperature been set incorrectly? ■ are the filters dirty? ■ are the intake or outlet vents of the outdoor unit obstructed? ■ are all windows an...

Page 41: Important

(1) remove power plug or disconnect from the mains before servicing this appliance. (2) this appliance must be earthed. (3) the appliance is not intended for use by young children or infirm persons without supervision (4) young children should be supervised to ensure that they do not play with the a...

Page 42

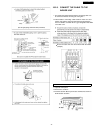

10 installation instructions required tools for installation works 1. Phillips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 65 n.M (6.5 kgf.M) 3. Electric drill, hole core drill (ø70 mm) 7. Reamer 11...

Page 43

1. Grounding is necessary. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in installati...

Page 44

Attached accessories applicable: flaring piping kit cz-52f select the best location indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place where air dra...

Page 45

10.2.1. Select the best location (refer to “select the best location” section) 10.2.2. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. : unit centre should be at more than 700 mm at right and left of the wall. The height should be more tha...

Page 46

(this can be used for left rear piping and left bottom piping also.) 46 cs-a28 bkp5/cu-a28bkp5.

Page 47

10.2.5. Connect the cable to the indoor unit 1. The inside and outside indoor/outdoor connecting cable can be connected without removing the front grille. 2. Indoor/outdoor connecting cable between indoor unit and outdoor unit shall be approved polychorprene sheathed 5 × 2.5 mm 2 flexible cord 245 i...

Page 48

How to take out front grille please follow below steps to take out front grille if necessary such as when servicing. Remove the grille from the chassis. 1. Set the up-and-down air direction louver to open position (horizontally) by finger pressure. 2. Open the three screw covers as shown in the illu...

Page 49

Cutting and flaring the piping 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut ...

Page 50

10.3.6. Pipe insulation 1. Please carry out insulation at pipe connection portion as mentioned in indoor/outdoor unit installation diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2. If drain hose or connecting piping is in the room (where dew may form), p...

Page 51: 11 3-Way Valve

11 3-way valve 3-way valve (liquid side) 3-way valve (gas side) works shaft position service port shaft position service port shipping close closed closed closed (with valve cap) (with cap) (with valve cap) (with cap) evacuation closed open closed open (installation and (clockwise) (connected manifo...

Page 52

11.1. Evacuation of installation required tools: hexagonal wrench, adjustable wrench, torque wrenches, wrench to hold the joints, gas leak detector, and charging set. 1. Connect a charging hose with a push pin to the low and high sides of a charging set and the service ports of a 3-way valve. • be s...

Page 53

11.2. Pumping down 1. Confirm that both the 3-way valves are set to the open position. • remove the valve stem caps and confirm that the valve stems are in the open position. • be sure to use a hexagonal wrench to operate the valve stems. 2. Operate the unit for 10 to 15 minutes. 3. Stop operation a...

Page 54

11.3. Evacuation of re-installation when reinstalling an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. 1. Connect a charging hose with a push pin to the low and high sides of a charging set and the service port of the 3-way valve. • be sure...

Page 55

1. Confirm that both the 3-way valves are set to the open position. 2. Connect the charge set to the 3-way valve’s service port. • leave the valve on the charge set closed. • connect the charge hose with the push-pin to the service port. • confirm whether the pressure indicates more than 0.1 mpa (1 ...

Page 56

1. Connect the vacuum pump to the charge set’s centre hose. 2. Turn on the vacuum pump to evacuate the unit. • confirm that the gauge needle has moved toward -76 cmhg (-0.1 mpa). • apply the vacuum for approximately 1 hour (vacuum of 4 mmhg or less). 3. Close the valve (low side and high side) on th...

Page 57

1. Connect the charge hose to the charging cylinder. • connect the charge hose which was disconnected from the vacuum pump to the valve at the bottom of the cylinder. 2. Purge the air from the charge hose. • open the valve at the bottom of the cylinder and use a screwdriver to press the check valve ...

Page 58: 12 Servicing Information

• inspection points for the indoor electronic controller 1. The electronic controller, a signal receiver and an indicator can be seen by removing the front grille and control board cover, as shown in the . • indoor fan motor removal procedure:- 1. Remove the connector cn-c of fan motor and connector...

Page 59

3. Remove the discharge grille. Remove the discharge grille and then pull the discharge grille in a down and forward direction. 4. Remove the indoor fan motor. Loosen the fan mounting screw at the junction with cross flow fan. Loosen the screw at the left side of the evaporator. Pull off the bearing...

Page 60

• cross flow fan removal procedure. 1. (refer to no. 4 of indoor fan motor the removal procedure) loosen the screw at the right side of the evaporator. 2. Pull the left side of the evaporator forward slightly and remove the cross flow fan. (b) disassembly of the parts (outdoor unit) • inspection poi...

Page 61

(c) remote control transmission setting • remote control reset when the batteries are inserted for the first time, or the batteries are replaced, all the indications will blink and the remote control might not work. If this happen, remove the back cover of the remote control and you will find a rese...

Page 62: 13 Troubleshooting Guide

In order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air temperature and pressure of the ref...

Page 63

13.1.1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditoner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refrige...

Page 64: 14 Technical Data

14 technical data 64 cs-a28bkp5 cs-a28 bkp5/cu-a28bkp5.

Page 65

65 cs-a28 bkp5/cu-a28bkp5 cs-a28bkp5 / cu-a28bkp5.

Page 66

66 cs-a28 bkp5/cu-a28bkp5 cs-a28bkp5 / cu-a28bkp5.

Page 67: 15 Exploded View

15 exploded view 67 cs-a28bkp5 cs-a28 bkp5/cu-a28bkp5.

Page 68: 16 Replacement Parts List

Cs-a28bkp5/cu-a28bkp5 (note) no description & name qty cs-a28bkp5 remarks 1 chassis complete 1 cwc5239-970 ● 2 fan motor 1 cwc4301-370 ■ ● 3 cross flow fan complete 1 cwc5707-260 ● 4 bearing ass’y 1 cwc4059-190 ● 5 screw (cross flow fan) 1 cwc4582-660 ● 6 evaporator complete ass'y 1 cwc6325-300 ● 7 ...

Page 69: 17 Explodedview

17 explodedview 69 cu-a28bkp5 cs-a28 bkp5/cu-a28bkp5.

Page 70: 18 Replacement Parts List

18 replacement parts list • “ ■ ” marked parts are recommended to be kept in stock. • “ ● ” marked parts are supplied from tamaco, taiwan. • “ ▲ ” marked parts are supplied from macc, malaysia. 70 cs-a28bkp5/cu-a28bkp5 no description & name qty cu-a28bkp5 remarks 1 chassis ass’y 1 cwc5244-200a ● 2 s...

Page 71: 19 Electronic Parts List

19 electronic parts list note electronic controller: c3919-420a (cs-a28bkp5) symbol description & name part no. Ic1 integrated circuit c4083-910 ic2 integrated circuit c4083-450 ic3 integrated circuit c4083-860 ic4 integrated circuit c4083-730 ic5 integrated circuit c4083-720 pc1 photo coupler c4094...

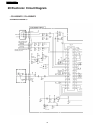

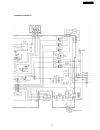

Page 72

20 electronic circuit diagram • cs-a28bkp5 / cu-a28bkp5 schematic diagram 1/3 72 cs-a28 bkp5/cu-a28bkp5.

Page 73

Schematic diagram 2/3 73 cs-a28 bkp5/cu-a28bkp5.

Page 74

Schematic diagram 3/3 74 cs-a28 bkp5/cu-a28bkp5.

Page 75

75 cs-a28 bkp5/cu-a28bkp5.

Page 76

How to use electronic circuit diagram timer table test mode name time (when test point remarks short-circuited) sleep mode waiting 1 hr. 6 sec. Sleep mode operation 8 hrs. 48 sec. 1 hr. 1 min. Real timer 10 min. 10 sec. 1 min. 1 sec. Time delay safety control 3 min. 0 sec. Forced operation 60 sec. 0...

Page 77

20.1. Remote control 77 printed in taiwan cs-a28 bkp5/cu-a28bkp5.