- DL manuals

- Panasonic

- Air Conditioner

- CS-D34DTQ

- Service Manual

Panasonic CS-D34DTQ Service Manual

© 2006 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

Order No. MAC0603021C3

Air Conditioner

CS-D34DTQ CU-D34DBQ7

CS-D43DTQ CU-D43DBQ7

CS-D50DTQ CU-D50DBQ7

TABLE OF CONTENTS

PAGE

PAGE

1 Service Information---------------------------------------------- 3

1.1. Example of trouble at test operation ------------------ 3

1.2. Caution of test operation--------------------------------- 3

1.3. Caution during automatic address setting----------- 3

1.4. Operation range-------------------------------------------- 4

2 Features ------------------------------------------------------------- 5

2.1. Ceiling Type------------------------------------------------- 5

2.2. Outdoor Unit ----------------------------------------------- 5

2.3. Wired Remote Control------------------------------------ 7

2.4. Wireless Remote Control --------------------------------7

2.5. Group Control Equipment--------------------------------8

3 Product Specification ------------------------------------------- 9

3.1. CS-D34DTQ CU-D34DBQ7 (50Hz) ------------------- 9

3.2. CS-D34DTQ CU-D34DBQ7 (60Hz) ----------------- 10

3.3. CS-D43DTQ CU-D43DBQ7 (50Hz) ----------------- 11

3.4. CS-D43DTQ CU-D43DBQ7 (60Hz) ----------------- 12

3.5. CS-D50DTQ CU-D50DBQ7 (50Hz) ----------------- 13

3.6. CS-D50DTQ CU-D50DBQ7 (60Hz) ----------------- 14

Summary of CS-D34DTQ

Page 1

© 2006 panasonic ha air-conditioning (m) sdn bhd (11969-t). All rights reserved. Unauthorized copying and distribution is a violation of law. Order no. Mac0603021c3 air conditioner cs-d34dtq cu-d34dbq7 cs-d43dtq cu-d43dbq7 cs-d50dtq cu-d50dbq7 table of contents page page 1 service information-------...

Page 2

2 3.7. Safety devices -------------------------------------------- 15 4 dimensions ------------------------------------------------------- 16 4.1. Indoor unit ------------------------------------------------- 16 4.2. Outdoor unit ----------------------------------------------- 17 5 refrigeration cyc...

Page 3: 1 Service Information

3 1 service information the new cassette / new outdoor models are possible to have address setting for twin control or group control by auto- matic when main power supply is switched on. (manual address setting is also possible by using dip switch on indoor unit p.C. Board.) however, this address se...

Page 4

4 1.4. Operation range 1.4.1. Power supply the applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be bal- anced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of th...

Page 5: 2 Features

5 2 features 2.1. Ceiling type 2.1.1. Easier maintenance and cleaning • anti-mould long life air filter. • 3-direction pipe lead-out. 2.1.2. Wide air discharge, comfortable control • wide-angle airflow — 100 degrees horizontal. • auto swing louver. 2.2. Outdoor unit 2.2.1. Flexible installation in s...

Page 6

6 • long pipe design with maximum piping length of 40m (50hz), 50m (60hz). • flexible 4-way piping. • centralized drain method gathered multiple outdoor unit’s drain pipes into a single drain pipe to make installation easier and also improve appearance. • side-by-side continuous installation is poss...

Page 7

7 2.3. Wired remote control 1. The new design includes an easily-visible red pilot lamp. The power can be turned on and off at a single touch, without open- ing the cover. 2. Has a build-in thermistor, allowing indoor temperature detection in accordance with indoor conditions by switching with main ...

Page 8

8 2.5. Group control equipment wired remote control group control by one remote control • all air conditioner units are controlled as a whole by remote control. • all indoor units operate in the same mode. • a maximum of 16 units can be con- nected together (sequential starting) [remote side] • opti...

Page 9: 3 Product Specification

9 3 product specification 3.1. Cs-d34dtq cu-d34dbq7 (50hz) 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) electrical data (50 hz) indoor unit outdoor unit item...

Page 10

10 3.2. Cs-d34dtq cu-d34dbq7 (60hz) 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) electrical data (60 hz) indoor unit outdoor unit item / model main body cs-d...

Page 11

11 3.3. Cs-d43dtq cu-d43dbq7 (50hz) 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) electrical data (50 hz) indoor unit outdoor unit item / model main body cs-d...

Page 12

12 3.4. Cs-d43dtq cu-d43dbq7 (60hz) 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) electrical data (60 hz) indoor unit outdoor unit item / model main body cs-d...

Page 13

13 3.5. Cs-d50dtq cu-d50dbq7 (50hz) 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) electrical data (50 hz) indoor unit outdoor unit item / model main body cs-d...

Page 14

14 3.6. Cs-d50dtq cu-d50dbq7 (60hz) 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) electrical data (60 hz) indoor unit outdoor unit item / model main body cs-d...

Page 15

15 3.7. Safety devices indoor unit outdoor unit 1mpa=10.2kgf/cm 2 indoor unit cooling only model cs-d34dtq cs-d43dtq cs-d50dtq for fan motor protection internal off °c 135 135 135 protector (49f) on °c 86 86 86 for condesation temperature protection control off °c 58 58 58 heater exchanger thermisto...

Page 16: 4 Dimensions

16 4 dimensions 4.1. Indoor unit.

Page 17

17 4.2. Outdoor unit.

Page 18: 5 Refrigeration Cycle

18 5 refrigeration cycle 5.1. Cs-d34dtq cu-d34dbq7.

Page 19

19 5.2. Cs-d43dtq cu-d43dbq7 cs-d50dtq cu-d50dbq7.

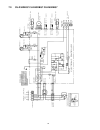

Page 20: 6 Block Diagram

20 6 block diagram 6.1. Cs-d34dtq cs-d43dtq cs-d50dtq 6.2. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7.

Page 21: 7 Wiring Diagram

21 7 wiring diagram 7.1. Cs-d34dtq cs-d43dtq cs-d50dtq.

Page 22

22 7.2. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7.

Page 23: 8 Operation Instructions

23 8 operation instructions 8.1. Wired remote control (optional part) name and function of each part notes • ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct. • the illustration above is for explanatory purposes only. The ap...

Page 24

24 8.2. Remote control - display.

Page 25

25 8.3. Remote control - panel.

Page 26

26 8.4. How to set remote control day and time • the day and time needs to be set when you turn on the power for the first time or after a long time has elapsed since the power was last turned on. • the day and time becomes the standard time for all the timer operations. • set the day and time accur...

Page 27

27 clock display (to set current day and time) note: • the above display is shown if no valid timer setting is made. • if valid timer setting is made. - and setting will be displayed. - if you want to check the current time and day, press “mode button” once. (however, after a few seconds, the displa...

Page 28

28 final display of daily timer: 8.7. Weekly timer setting • display • how to set weekly timer - you can set the timer for 1 week (monday to sunday) with 6 programs per day. - on-timer can be set together with your desired temperature. However, this temperature will be used continuously. - cannot se...

Page 29

29 note: • timer that has setting nearest to current time and day will be activated first. • to check the setting timer, press “select button”, then “up or down button” to select day. The display will show each program for the selected day. • to reset the setting for all, press “select button”, then...

Page 30

30 8.8. Wireless remote control (optional part) name and function of each part notes • ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct. • the illustration above is for explanatory purpose only. The appearance will be differ...

Page 31: 9 Operation Details

31 9 operation details 9.1. Cooling operation • cooling operation can be set using remote control. • this operation is applied to cool down the room temperature reaches the setting temperature set on the remote control. • cooling operation time diagram. 9.2. Soft dry operation • soft dry operation c...

Page 32

32 9.5. Operation control 9.5.1. Thermostat control • depending on differences between room temperature and setting temperature, compressor operation is decided and starts oper- ation. • if temperature difference matches values shown below, thermostat switches off. 9.5.2. Indoor fan control • manual...

Page 33

33 9.5.5. Dew form prevention control • during cooling operation, dew form prevention control activates if: - indoor temperature falls between 24ºc and 30ºc. - compressor and thermostat is on. - indoor fan speed is low speed. - setting temperature is less than 25ºc. • during dew form prevention cont...

Page 34

34 9.5.9. Energy save control • during cooling operation, press "economy" button at remote control to enable energy saving operation • the air conditioner judges the stable condition, where the different between indoor suction temperature and setting temperature is 1°c for 30 minutes and moderately ...

Page 35

35 9.7. Pump down • to enable pump down operation, at outdoor pcb, set the ds1 to off position. • press test run button for 1 second. • during pump down operation, push the test run button again for 1 second to stop the pump down operation. • the pump down operation run for 10 minutes..

Page 36: 10 Installation Instruction

36 10 installation instruction 10.1. Pipe length • correction of cooling capacity 1. Correction of cooling capacities according to the connecting pipe length. The data of cooling capacities (marked on the name plate) are based on 7.5 meters connecting pipe and horizontal installa- tion. For other pi...

Page 37

37 10.2. Refrigerant additional charge 1. Piping installation by standard piping • at the time of shipment from the factory, this unit is charged with enough refrigerant for an equivalent pipe length of 30m. (refer the following table) but when the piping length exceeds 30m, additional charge is req...

Page 38

38 10.4. Indoor unit installation • precautions shown here are differentiated between warnings and cautions. Those that have much chance for leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling them especially into th...

Page 39

39 10.4.1. Accessories packed in the indoor unit container 10.4.2. Selecting the location for indoor unit provide a check port on the piping side ceiling for repair and maintenance. • install the indoor unit once the following conditions are satisfied and after receiving the customer approval. 1. Th...

Page 40

40 note • study thoroughly the following installation locations. 1. In places such as restaurants and kitchens, considerable amount of oil steam and flour adhere to the fan, and the fin of the heat exchanger may result in heat exchange reduction, spraying or dispersing of water drops, etc. In these ...

Page 41

41 1. Open the inlet grille, and remove the side cover fixing screw (right and left) from the internal part of the unit. 2. Move the side cover to about 15mm forward to remove it. Use the packing material (styrene foam) to support, when you reverse the top and bottom of the indoor unit. 3. Remove th...

Page 42

42 1. Insert the hanging bracket fastening bolts and both sides of the unit into the hanging brackets, and slide the unit to the rear. Fasten the bolts. 2. Tighten the slip prevention screws (m5) for brackets to prevent the unit from shifting. 3. To ensure correct drainage, after hanging the unit, u...

Page 43

43 10.4.5. Indoor unit drain piping • be sure to use the drain hose provided (accessory item.) • drain piping must have down-slope (1/50 to 1/100): be sure not to provide up-and-down slope to prevent reversal flow. • during drain piping connection, be careful not to exert extra force on the drain po...

Page 44

44 2. Precautions in high humidity circumstance. This air conditioner has been tested according to the “jis standard conditions with mist” and have been confirmed that there is no form of any faults. However, if it is operated for a long time in high humid atmosphere (dew point temperature: more tha...

Page 45

45 • remove a two mounting screw, remove the control box cover, and then connect the wires by following the procedure given in the illustration. 10.4.8. Settings • all sets in the group which uses the same remote controller thermistor settings can be controlled by the same remote controller thermist...

Page 46

46 (remote control address setting) (refer to the operation manual which is provided with the remote controller for details.) • two remote controllers (including the wireless remote controller) can be connected. However, remote control thermistor setting is not possible. • as for [master/slave] sett...

Page 47

47 10.4.11. Check the following items when installation is complete • after completing work, be sure to measure and record trial run properties, and store measuring data, etc. • measuring items are room temperature, outside temperature, suction temperature, blow out temperature, wind velocity, wind ...

Page 48

48 10.5. Outdoor unit installation • precautions shown here are differentiated between warnings and cautions. Those that have much chances for leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling them especially into ...

Page 49

49 10.5.1. Accessories supplied with outdoor unit • the following parts are supplied as accessories with each outdoor unit. Check that all accessory parts are present before installing the outdoor unit. 10.5.2. Regarding handling handling the unit by hold the handle at compressor side and hold the b...

Page 50

50 10.5.3. Selecting the outdoor unit installation locations • select location which satisfies the following condition, and then confirm with the customer that such a place is satisfactory before installing the outdoor unit. Maintain sufficient space above the unit. Values inside brackets indicate d...

Page 51

51 • the distance given above are the minimum distance required in order to maintain proper performance. Allow as much space as possible in order to get the best performance from the units. 10.5.4. Transporting and installing the outdoor unit • transporting 1. The outdoor unit should be transported ...

Page 52

52 2. Local pipes can project in any of four directions. • make holes in the pipe panels for the pipes to pass through. • be sure to install the pipe panels to prevent rain from getting inside the outdoor unit. [removing the service panel]. 3. Notes when connecting the refrigerant pipes. • use clean...

Page 53

53 10.5.6. Heat insulation 10.5.7. Charging with refrigerant • at the time of shipment from the factory, this unit is charged with enough refrigerant for an equivalent pipe length of max charge- less lenght. (refer table below) if the equivalent pipe length will be up to max charge-less length, no a...

Page 54

54 earth lead wire shall be longer than other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage. 1. Connect the power supply line to a 3-phase/220v (or single-phase 220) power sup- ply. 2. The equipment shall be connected to a suit...

Page 55

55 • power supply specifications please follow below table. 10.5.9. Connecting power supply cables caution • for three phase model, never operate the unit by pressing the electromagnetic switch. • never correct the phase by switching over any of the wires inside the unit. Model name leakage current ...

Page 56

56 10.5.10. Precautions with regard to test operation (must first select “cooling” mode.) when operation mode changes, the compressor stops operation momentary. • use only insulation tool to the switch on the microswitch on the electric circuit board. (do not use finger or a metallic object.) • do n...

Page 57

57 10.5.11. As to making the inspection after completion of work fully understood • at the time when the work has been completed, measure and record the characteristics of test run without fail and keep the mea- suring date, etc. • carry out the measurement regarding room temperature outside air tem...

Page 58

58 10.6. Wired remote control installation wired remote control installation manual • before installing the wired remote controller, be sure to thoroughly read the “notes with regard to safety” section of the installa- tion manual provided with the indoor unit. • after installing the wired remote co...

Page 59

59 • connect the indoor unit and the remote controller as shown in the illustration below. • the remote control cable is non-polar. • at the time of shipment from the factory, the connector cable used to connect the terminal block and connector cn1 is discon- nected. When connecting the remote contr...

Page 60

60 • strip the end of the remote control cable which is to be connected to the remote controller. (refer to the illustration below) • route the remote control cable inside the lower case in accordance with the intended feeding- out direction. (refer to the illustra- tion below.) securely connect con...

Page 61

61 10.6.4. Settings • up to two remote controllers can be installed for a single indoor unit, and either remote controller can be used to operate the indoor unit. • the indoor unit can be operated with the last switch pressed having priority. 1. Decide which is to be the master and which is to be th...

Page 62

62 • all in group will be remote controller thermistor setting when using the remote controller thermistor. • up to a maximum of 16 indoor units can be connected at the time of group control. (do not connect heat pump unit with cooling only unit.) • indoor unit no. Is possible to set automatically a...

Page 63

63 • the temperature detection thermistor can be switched between the thermistor at the indoor unit and the thermistor at the remote controller. However, do not switch to the remote controller thermistor if using two remote controllers. 1. When operation is stopped, press for 5 seconds, continue the...

Page 64

64 • if the “check” display on the wired remote controller is not blinking, press the check switch continuously for 5 seconds or more to display the problem details for the last problem or the problem before that. • you can then switch between the display for the previous problem and the problem bef...

Page 65

65 10.7. Wireless remote control installation manual wireless remote control installation manual • before installing the wireless remote controller, be sure to thoroughly read the “notes with regard to safety” section of the instal- lation manual provided with the indoor unit. • after installing the...

Page 66

66 • installing the wireless remote controller to a wall (for remote control storage). • if using a single remote controller to operate several air conditioners, address setting will be required. (refer to later in this man- ual.) • for twin and triple types, install to the main unit only. (accordin...

Page 67

67 1. Route the joint cord for wiring as shown in the figure (figure of the back of decorative panel) below. Pass the cord through the hook of the decorative panel, taking care that the cord does not run on the heat insulator, etc. 2. Remove the control box cover by removing the two fixing screws an...

Page 68

68 receptor unit (for ceiling type) assembly procedure 1. Route for wiring the cord as shown in the figure to the right. 2. Remove the control box cover by removing the two fixing screws and connect the joint cord to p.C.B terminal in the control box. 1 attach the receptor unit onto the indoor main ...

Page 69

69 10.7.4. Address setting for wireless remote controller and receptor unit (only when using more than one indoor unit) • only the air conditioner units which receptor unit address numbers match the remote controller address number can be oper- ated. • at the time of shipment from the factory, the a...

Page 70

70 note • if the batteries are replaced or the remote controller is reset, the address setting will return to address1, so you will need to repeat the address setting again. All setting details which are stored in memory will be cleared, so you will need to repeat the setting. • if the address is se...

Page 71

71 10.7.5. Emergency operation • if you do not have the wireless remote controller (because the batteries are weak, or some other reason prevents the wireless remote controller from being used), emergency operation can be carried out at receptor unit. • press the auto switch to start emergency opera...

Page 72

72 10.8. Twin operation • simultaneous air conditioning of wide spaces and corners is possible. Indoor units with same horsepower can be used in combi- nation. • master unit and slave-units can be set automatically in twin systems. No address setting is necessary. • 2 indoor units can be operated si...

Page 73: 11 Troubleshooting Guide

73 11 troubleshooting guide if test operation does not proceed correctly if the following symptoms occur after turning on the power, check the wiring connections once more. 11.1. For standard installation system example 1. The main power is turned on while the indoor-outdoor transmission wires are n...

Page 74

74 outdoor unit: led2, 4, 6 on p.C.B flashes (when remote control display shows “power supply”) clock setting, and no timer setting (when remote control display shows “no power supply”).

Page 75

75 11.2. During twin operation system example 1. The main power is turned on while the transmission wires between the indoor units are not connected. (open circuit at a or b) symptom remote control unit: “check” flashes error code: f30-01 (connected indoor capacity error) indoor unit no. 1: led1 on ...

Page 76

76 4. The main power is turned on and the connection wire is all ok. If operation starts in this condition, combination of the d50dbq7 outdoor unit and d24dtq6 indoor unit will result in abnormal operation. Symptom remote control unit: “check” flashes error code: f30-01 (connected indoor capacity er...

Page 77

77 11.3. During group control operation system example 1. The main power is turned on while the transmission wires between the indoor units are not connected. (open circuit at a or b or c) symptom operation of indoor unit no.1 and no.3 is possible. However “check” flashes in the remote control displ...

Page 78

78 11.4.2. Test operation from the outdoor unit during emergency operation or when test operation is carried out, the led on the p.C.B. Will turn on. 11.4.3. Test operation using the wired remote control 1. Check that “cool” is displayed on the lcd, and then press the off/on button to start test ope...

Page 79

79 11.4.4. Self-diagnosis function the wired remote control display and the self-diagnosis leds (green) on the outdoor unit printed circuit board indicate where the abnormality has occurred. Recalling the error display. The air conditioner no.”01” appears during normal installation and use. When usi...

Page 80

80 11.4.5. Test operation using the receiver auto button (if using wireless remote controller).

Page 81

81 11.5. Emergency operation when using the wireless remote control and losing the remote controller, emergency operation can be operated by pressing auto button in the receiver. • press the auto button continuously within 5 seconds if there is an abnormality in the temperature thermistor (disconnec...

Page 82

82 during outdoor unit emergency operation or test operation, the led on the p.C.B. Will flash. 80 - 2.5 6.3 - 90 - 1.9 4.7 - 100 - 1.4 3.5 - resistance value (k Ω)±5%.

Page 83

83 11.6. Self-diagnosis error code table • the display screen on the wired remote control unit and the self-diagnosis leds (green) on the outdoor unit printed circuit board in the outdoor unit can be used to indicate where the location of a problem is. Refer to the table below to remove the cause of...

Page 84: 12 Technical Data

84 12 technical data 12.1. Cooling capacity performance data tc: cooling capacity shc: sensible heat capacity ipt: cooling power consumption ambient temperature air entering condenser ( °c d.B.) model power return 25 °c 30 °c 35 °c 40 °c 43 °c (cs-) source air tc shc ipt tc shc ipt tc shc ipt tc shc...

Page 85

85 tc: cooling capacity shc: sensible heat capacity ipt: cooling power consumption ambient temperature air entering condenser ( °c d.B.) model power return 25 °c 30 °c 35 °c 40 °c 43 °c (cs-) source air tc shc ipt tc shc ipt tc shc ipt tc shc ipt tc shc ipt d.B. W.B. Kw kw kw kw kw kw kw kw kw kw kw...

Page 86

86 tc: cooling capacity shc: sensible heat capacity ipt: cooling power consumption ambient temperature air entering condenser ( °c d.B.) model power return 25 °c 30 °c 35 °c 40 °c 43 °c (cs-) source air tc shc ipt tc shc ipt tc shc ipt tc shc ipt tc shc ipt d.B. W.B. Kw kw kw kw kw kw kw kw kw kw kw...

Page 87

87 12.2. Capacity and power consumption 12.2.1. Cs-d34dtq model cooling capacities are based on conditions cs-d34dtq single phase, 50hz 220v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 10.0kw outdoor temp. 35 °c d.B. Standard air volume 28.9 m 3 /min.

Page 88

88 model cooling capacities are based on conditions cs-d34dtq single phase, 60hz 220v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 10.8kw outdoor temp. 35 °c d.B. Standard air volume 28.9 m 3 /min.

Page 89

89 12.2.2. Cs-d43dtq model cooling capacities are based on conditions cs-d43dtq single phase, 50hz 220v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 12.5kw outdoor temp. 35 °c d.B. Standard air volume 33 m 3 /min.

Page 90

90 model cooling capacities are based on conditions cs-d43dtq single phase, 60hz 220v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 13.5kw outdoor temp. 35 °c d.B. Standard air volume 33 m 3 /min.

Page 91

91 12.2.3. Cs-d50dtq model cooling capacities are based on conditions cs-d50dtq single phase, 50hz 220v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 13.1kw outdoor temp. 35 °c d.B. Standard air volume 33 m 3 /min.

Page 92

92 model cooling capacities are based on conditions cs-d50dtq single phase, 60hz 220v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 14.1kw outdoor temp. 35 °c d.B. Standard air volume 33 m 3 /min.

Page 93

93 12.3. Reaching distance cs-d34dtq.

Page 94

94 cs-d43dtq.

Page 95

95 cs-d50dtq.

Page 96

96 12.4. Sound measuring point 12.4.1. Indoor unit 12.4.2. Outdoor unit.

Page 97

97 12.5. Sound data.

Page 98

98.

Page 99

99.

Page 100

100 12.6. Fan performance cs-d34dtq cs-d43dtq item/model indoor unit outdoor unit cs-d34dtq cu-d34dbq7 mode hi me lo hi air volume m 3 /min 29 27 25 103 running current a 0.84 0.70 0.56 1.20 power consumption kw 0.19 0.15 0.12 0.27 fan speed r/min 1130 1010 890 770 item/model indoor unit outdoor uni...

Page 101

101 cs-d50dtq item/model indoor unit outdoor unit cs-d50dtq cu-d50dbq7 mode hi me lo hi air volume m 3 /min 33 31 29 103 running current a 0.96 0.82 0.67 1.20 power consumption kw 0.21 0.18 0.15 0.27 fan speed r/min 1300 1180 1030 770

Page 102

102 12.7. Discharge and suction pressure saturation temperature of discharge and suction pressure cooling 12.8. Operating characteristics cooling only model main power compressor motor indoor unit outdoor unit electrical data (60hz) model source fan motor fan motor voltage frequency s.C. R.C. (a) ip...

Page 103

103 13 exploded view (indoor unit) 13.1. Cs-d34dtq cs-d43dtq cs-d50dtq.

Page 104

104 13.2. Cs-d34dtq cs-d43dtq cs-d50dtq.

Page 105

105 13.3. Cs-d34dtq cs-d43dtq cs-d50dtq.

Page 106

106 14 replacement part list (indoor unit) no. Part description qty. Cs-d34dtq cs-d43dtq cs-d50dtq 1 cabinet top plate 1 cwe001016 ← ← 2 cabinet front plate 1 cwg07k1008 ← ← 3 cabinet side plate (l) 1 cwd63k1003 ← ← 4 vane supporter (l) 1 cwg071144 ← ← 5 catcher 1 cwh601005 ← ← 6 cabinet side plate ...

Page 107

107 all parts are supplied from phaam, malaysia (vendor code: 061) 64 cabinet side cover (l) 1 cwe041025 ← ← 65 flexible pipe-accessory 1 cwh82c1308 ← ← 66 wired remote control co. (acces- sory) 1 cwg50c2604 ← ← 67 wired remote control co. 1 cwa75c2586 ← ← 68 wireless remote control comp. 1 cwa75c27...

Page 108

108 15 exploded view (outdoor unit) 15.1. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7.

Page 109

109 15.2. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7.

Page 110

110 15.3. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7.

Page 111

111 16 replacement part list (outdoor unit) 16.1. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7 all parts are supplied from phaam, malaysia (vendor code: 061) ref. No. Part description qty. Cu-d34dbq7 cu-d43dbq7 cu-d50dbq7 1 base pan ass’y 1 cwd52k1103 ← ← 2 compressor dc 280v 1 jt125ga jt160ga jt170ga 3 anti-vi...

Page 112: 17 Print Pattern

112 17 print pattern 17.1. Indoor unit printed (main).

Page 113

113 17.2. Indoor unit printed (indicator) 17.3. Outdoor unit (main) [phaam] printed in malaysia ssbz0603-00