- DL manuals

- Panasonic

- Air Conditioner

- CS-G125KE CU-G125KE

- Service Manual

Panasonic CS-G125KE CU-G125KE Service Manual

1

Features

2

2

Functions

3

3

Product Specifications

8

4

Dimensions

12

5

Refrigeration Cycle Diagram

14

6

Block Diagram

15

7

Wiring Diagram

16

8

Operation Details

18

9

Operating Instructions

48

© 2000 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D) All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-G95KE CU-G95KE

CS-G125KE CU-G125KE

10 Installation Instructions

72

11 Servicing Information

81

12 Technical Data

94

13 Exploded View

97

14 Replacement Parts List

98

15 Exploded View

99

16 Replacement Parts List

100

17 Electronic Parts List

101

18 Electronic Circuit Diagram

103

Room Air Conditioner

CONTENTS

Page

Page

Order No: MAC0010056C2

Summary of CS-G125KE CU-G125KE

Page 1

1 features 2 2 functions 3 3 product specifications 8 4 dimensions 12 5 refrigeration cycle diagram 14 6 block diagram 15 7 wiring diagram 16 8 operation details 18 9 operating instructions 48 © 2000 matsushita air-conditioning corp. Sdn. Bhd. (183914d) all rights reserved. Unauthorized copying and ...

Page 2: 1 Features

• product − powerful mode for quick cool/heat − compressor operating frequency control to maintain desired room temperature − automatic restart after power failure − washable front panel − power monitor display − standby control − high cop (new compressor and indoor heat exchanger) − vertical and ho...

Page 3: 2 Functions

2 functions remote control operation off / on off / on i room temperature setting temp. Operation mode selection • a automatic operation mode • heat heating operation mode • cool cooling operation mode • dry soft dry operation mode • fan fan operation mode time / timer setting • hours and minutes se...

Page 4

Indoor unit power monitor display * * * * * • lights up during compressor operation. Airflow direction control * * * * * automatic switch • press for operation mode. (used when the remote control cannot be used.) • press continuosly for 5s or operate forced cooling operation at compressor rated freq...

Page 5

Deodorizing control * * * * * room temperature control * * * * * indoor power relay control * * * * * anti-dew formation control * * * * * sensible heat control * * * * * cooling / soft dry operation anti-fog discharge control * * * * * anti freezing control * * * * * quiet operation * * * * * opera...

Page 6

Fan operation heating operation anti-cold draft control * * * * * high pressure control * * * * * hot start * * * * * intake air temperature control * * * * * standby control * * * * * deice operation * * * * * automatic operation 6 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 7

Outdoor unit forced operation 30 seconds * * * * * time delay safety control * * * * * high pressure control * * * * * (for cooling / soft dry) outdoor fan motor • 6 poles induction motor, 1 speed. Deice operation * * * * * standby control * * * * * compressor overheating protection * * * * * ipm (p...

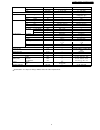

Page 8: 3 Product Specifications

3 product specifications unit cs-g95ke cu-g125ke cooling capacity kw kcal/h 2.6 (0.70 - 3.00) 2,240 (600 - 2,580) heating capacity kw kcal/h 3.6 (0.63 - 5.00) 3,100 (540 - 4,300) moisture removal l/h pint/h 1.6 3.4 power source phase v cycle single 230 50 airflow method outlet intake side view top v...

Page 9

Dimensions height inch (mm) 10 - 31/32 (279) 21 - 9/32 (540) width inch (mm) 31 - 15/32 (799) 27 - 17/32 (699) depth inch (mm) 7 - 27/32 (199) 11 - 7/32 (285) net weight lb (kg) 20 (9.0) 86 (39) compressor type — rotary (2 cylinders) rolling piston type motor type — induction (4-poles) rated output ...

Page 10

Unit cs-g125ke cu-g125ke cooling capacity kw kcal/h 3.45 (0.74 - 4.00) 2,970 (640 - 3,440) heating capacity kw kcal/h 4.80 (0.70 - 6.50) 4,130 (600 - 5,590) moisture removal l/h pint/h 2.0 4.2 power source phase v cycle single 230 50 airflow method outlet intake side view top view air volume indoor ...

Page 11

Dimensions height inch (mm) 10 - 31/32 (279) 21 - 9/32 (540) width inch (mm) 31 - 15/32 (799) 27 - 17/32 (699) depth inch (mm) 7 - 27/32 (199) 11 - 7/32 (285) net weight lb (kg) 20 (9.0) 95 (43.0) compressor type — rotary (2 cylinders) rolling piston type motor type — induction (4-poles) rated outpu...

Page 12: 4 Dimensions

4 dimensions 12 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 13

13 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 14

5 refrigeration cycle diagram 14 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 15: 6 Block Diagram

6 block diagram 15 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

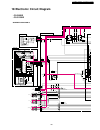

Page 16: 7 Wiring Diagram

Resistance of outdoor fan motor windings connection cwa95384 ( Ω ) blue - yellow 264.1 yellow - red 304.8 resistance of compressor windings connection 2rd132x5bb03 ( Ω ) u - v 0.8 u - w 0.8 v - w 0.8 7 wiring diagram 16 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 17

Resistance of outdoor fan motor windings connection cwa95380 ( Ω ) blue - yellow 234.1 yellow - red 263.5 resistance of compressor windings connection 2rd132x5ba03 ( Ω ) u - v 0.8 u - w 0.8 v - w 0.8 17 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 18: 8 Operation Details

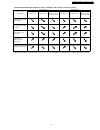

1. Temperature shift (i) cooling, soft dry shift amount cs-g95ke cs-g125ke 38°c outdoor air temperature -1.0°c -1.0°c 30°c outdoor air temperature 38°c -0.5°c -1.0°c 23°c outdoor air temperature 30°c 0.0°c 0.0°c outdoor air temperature +1.0°c +1.0°c cooling dry heating powerful -4.0°c -3.0°c +6.0°c ...

Page 19

2. Cooling operation a. Room temperature control (i) when the remote control setting temperature is less than 24°c (ii) when the remote control setting temperature is 24°c and above • compressor off temperature = compressor on temperature. • the operation frequency can be changed every 30 seconds. •...

Page 20

B. Deodorizing control • this control is available during automatic fan speed for cooling and soft dry operation. It is not available during anti- freezing control. • when the compressor is in operation, the deodorizing status starts from 1 → 2 → 3. • when the compressor stops operation, the deodori...

Page 21

3. Soft dry operation a. Room temperature control at the start of operation, cooling operation is running until the intake air temperature is 0.5°c higher than internal setting temperature, then the operation will shift to soft dry with indoor fan speed slo. • compressor off temperature = compressor...

Page 22

B. Deodorizing control • this control is available during automatic fan speed for cooling and soft dry operation. It is not available during anti- freezing control. • when the compressor is in operation, the deodorizing status starts from 1 → 2. • when the compressor stops operation, the deodorizing...

Page 23

4. Heating operation a. Room temperature control • during heating operation, the room temperature control depends on intake air temperature and internal setting temperature. Basically it can be divided into 2 periods as shown below: (i) when indoor fan speed is medium of above. 23 cs-g95ke cu-g95ke ...

Page 24

(ii) when indoor fan speed is lower than medium. 24 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 25

• compressor off temperature = compressor on temperature. • the operation frequency changes every 30 seconds. • when the difference of the intake air temperature and internal setting temperature is -1.5°c or more, compressor will operate at fh continuously for 3 minutes and then change over to fhmax...

Page 26

(a) manual fan speed control (auto airflow direction control) (b) auto fan speed control (auto airflow direction control) (manual airflow direction control) (manual airflow direction control) b. Anti cold draft control (i) indoor fan control indoor fan speed and airflow direction varies in accordanc...

Page 27

(ii) hot start • at the start of heating operation, the indoor fan stops and compressor operates at fhmax frequency 99hz (cs-g95ke) or 115hz (cs-g125ke). This is to heat up the indoor heat exchanger in order to avoid cold air discharged. • hot start ends when a. Indoor heat exchanger temperature rea...

Page 28

Deice operation time chart • compressor frequency is set at 40hz (cu-g95ke) or 49hz (cu-g125ke) when the deice operation starting signal is generated. • 30 seconds later deice operation starting signal is generated, indoor fan, outdoor fan, 4-way valve are turned off and compressor operates at 40hz ...

Page 29

D. Standby control (a) the purpose of standby control is to warm up the compressor when outdoor temperature is low. The standby control will be activated when all of the followings occur. (i) main power is supplied. (ii) unit is not operating. (iii) outdoor ambient temperature is below 3°c. (iv) com...

Page 30

5. Fan operation 6. Automatic operation this operation is enable the fan operation without compressor running. Timer operation is valid for fan operation. When the automatic mode is selected, the operation mode is decided in accordance to remote control setting temperature, intake air temperature an...

Page 31

(c) when setting temperature of remote control is 23°c ~ 26°c. (d) when setting temperature of remote control is 27°c and above. Setting temp. °c t1 t2 t3 18 and below +10 +8 -5 19 - 22 +8 +7 -7 23 - 26 +7 +6 -7 27 and above +6 +5 -8 note: base temperature for t1 is 29°c base temperature for t2 is 2...

Page 32

• when the operation mode is changed over, the value for t1, t2 and t3 are shifted as below: cooling/soft dry → heating: - 2°c heating → cooling/soft dry: + 2°c • when the indoor intake air temperature is lower than 16°c, heating operation is immediately started. • when the outdoor air temperature i...

Page 33

7. Indoor fan speed control fan voltage voltage cooling heating speed supply to supply to soft remarks remarks no. Dc (v) dc (v) manual auto dry manual auto cs-g95ke cs-g125ke 0 off off off off off • hot start control 1 2 15.6 16.3 slo • deodorizing control • sleep mode (soft dry) • slo: hot start c...

Page 34

(a) cooling automatic fan speed the automatic fan speed for cooling operation is shown as below: (i) when automatic fan speed is selected (ii) when automatic fan speed and powerful mode are selected note: the fan speed will change every 10 seconds and it will be repeated from a to h every 80 seconds...

Page 35

8. Outdoor fan control (c) cooling operation at shi speed during cooling operation, indoor fan speed is set at shi when the following conditions occur: • outside air temperature is 30°c or above • compressor operates at 50hz (cu-g95ke) or 70hz (cu-g125ke) and above • remote control setting fan speed...

Page 36

9. Airflow direction a. Vertical airflow direction • vane angle setting operation vane angle 1 2 3 4 5 heating airflow direction auto indoor heat exchanger temperature c 33° b 70° a 15° airflow direction manual - 13° 33° 46° 57° 70° cooling airflow direction auto - 7° ~ 36° anti-dew formation contro...

Page 37

(a) vertical airflow direction manual by pressing the remote control vertical airflow direction setting switch, the vane will move to the indicated angle (1, 2, 3, 4, 5) as shown in the table. When the remote control off/on switch is pressed to stop the unit, the vane will move to the close position...

Page 38

Wide spot 3 2 for all operations 10. Quiet operation (b) manual horizontal vane angle setting • by pressing the remote control horizontal airflow direction setting switch, the vane will move to the indicated position (1, 2, 3, 4, 5, 6, 7) as shown in the table. • horizontal van angle position 1 2 3 ...

Page 39

11. Powerful mode operation 12. Sleep mode operation when the powerful mode is selected, the internal setting temperature will shift to achieve the setting temperature quickly. (a) cooling operation (b) soft dry operation (c) heating operation (a) cooling operation / soft dry operation • when the sl...

Page 40

13. Delay on timer control (a) cooling/soft dry 14. Auto restart control (b) heating (b) heating operation • when the sleep button is pressed, the remote control setting temperature will decrease 2°c after 1 hour or when the remote control setting temperature is reached. After another hour, 3°c will...

Page 41

15. Power monitor display 16. Remote control signal receiving sound on/off 17. Indoor power relay control power monitor led lights on when the compressor is in operation. The number of the led lights on is in accordance to the compressor operating frequency. Model display a a, b a, b, c a, b, c, d a...

Page 42

1. Protection control for all operations model no. Cu-g95ke cu-g125ke i1 (a) 6.1 9.2 i2 (a) 7.3 10.8 8.2. Protection a. Time delay safety control • the compressor is not restarted for 3 minutes after stop of compressor. B. 30 second forced operation • once the compressor is on, it will not turn off ...

Page 43

2. Dc peak current control • when the electric circuit to the ipm (power transistor) exceeds the set value, dc 27 ± 4a, the compressor stops. The compressor restarts after 3 minutes. • if within 30 seconds the set value is exceeded again, the compressor will stop for 1 minute. If this condition repe...

Page 44

G. Minimum frequency operation protection • when the compressor operates at less than 31 hz for 40 minutes, the operating frequency will increase to 31 hz for 2 minutes. H. Low frequency operation protection indoor intake air temp. (°c) 30°c or 28°c or outdoor air temp. (°c) 38°c or 24°c or indoor h...

Page 45

2. Protection control for cooling & soft dry fan speed shift hi 2 rank down me+ 3 rank up me unchange me - unchange lo 2 rank up a. Anti-freezing control • when the temperature of the indoor heat exchanger becomes low, the compressor operating frequency is reduced and stopped when the temperature fa...

Page 46

C. Anti-fog discharge control • the compressor operating frequency is regulated by operation time to prevent fog discharged from indoor until as shown in the table below. Compressor operating frequency operation time, t (min) 0 t 50hz 70hz 30 t 46hz 64hz t 90 43hz 58hz model no. Cu-g95ke cu-g125ke n...

Page 47

3. Protection control for heating operation a. Intake air temperature control • when the intake air temperature is 10°c or above and remote control setting fan speed is less than me - , the compressor operates maximum at 71 hz (cu-g95ke) or 90 hz (cu-g125ke). • when the intake air temperature is 30°...

Page 48: 9 Operating Instructions

9 operating instructions ■ this room air conditioner must be earthed. Improper grounding could cause electric shock. ■ do not install the unit in a place where there may be explosive gas leaks. Gas leaks near the unit could cause fires. ■ ensure that drainage piping is connected properly. Otherwise,...

Page 49

■ do not damage the power cord or use an unspecified power cord. A damaged/unspecified power cord could cause elec- tric shock or fire. ■ do not insert finger, sticks or other objects into the units. It could lead to physical injury and cause damage to the units. ■ do not try to repair the unit your...

Page 50

■ do not remove the power plug by pulling the cord. Hold the plug when disconnecting the plug from the wall outlet. ■ do not use for other purposes. Do not use for preservation purposes. It will affect food quality, animals or plants. ■ do not wash the unit with water. It could cause an electric sho...

Page 51

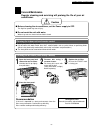

Power low high sleep timer powerful power monit or power low high sleep timer powerful power monitor indoor unit tab for front panel signal receptor receives signal from the remote control. ( s i g n a l - r e c e i v e d sound: one short beep or one long beep.) front panel air intake vent panel ope...

Page 52

When back cover is open operation display sleep mode operation button on-timer button off-timer button airflow direction selection button fan speed selection button open the remote control door operation mode selection button clock button wide/spot operation button reset points diagnostic terminals ...

Page 53

Power low high sleep timer powerful power monit or insert the power supply plug into an electri- cal outlet and open the front panel. Preparation (indoor unit • remote control) 1 indoor unit ■ ensure that the power supply plug is securely inserted. A loose plug may cause a fire or an elec- tric shoc...

Page 54

B rem ote co ntr oll er a operating the remote control ● the maximum distance at which signals can be received is about 10 m. ● aim the remote control at the signal receptor on the room air conditioner when operating. ● make sure that the signal path is not obstructed. Batteries power low high sleep...

Page 55: Automatic

Automatic • heating • cooling • soft dry • fan 1 3 2 to set the temperature • increases or decreases by 1°c when pressed. • the temperature can be set between 16°c and 30°c. (not adjustable during fan operation.) press off/on button again to stop operation (power led lights off). Press off/on button...

Page 56

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 19 18 17 16 outdoor temp.˚c indoor temp. ˚c c o o l i n g auto restart control automatic operation ● if there is a power failure, operation will be automatically restarted under the previous operation mod...

Page 57

■ auto vertical airflow direction control heating when the discharge air temperature is low such as at starts of heating op- eration, the air blows at horizontal level. As the temperature rises, the hot air blows in a downwards direction. Cooling ● soft dry the louver swings up and down automaticall...

Page 58: Wide / Spot

Louver adjustment range wide / spot convenient control of horizontal airflow direction. Auto auto fan fan speed wide/spot air swing timer clock 1 2 3 wide on off set cancel sleep mode auto ■ press wide/spot button to select wide or spot airflow direction. Display when pressed, the display changes in...

Page 59: Setting The Timers

Setting the timers set the on to the time at which you want heating or cooling to begin. Set the off to the desired stop time. Use both timers together for maximum comfort and efficiency. 1 2 3 press on button display ex: set the on timer for 7:00am. Press or to set the time ● increases or decreases...

Page 60

● when you sleep set the time at which you will go to sleep with the off . This prevent wasting of electricity. ● when you return set the time at which you will return with the on . Set the time at which you will go to sleep with the off . This will make the temperature pleasant when you return, and...

Page 61: Powerful

Powerful • sleep powerful and sleep modes are available for automatic operation, heating, cooling and soft dry. Powerful mode operation • used in winter to warm yourself quickly upon returning home (heating + powerful). • used in summer to cool yourself after a hot bath (cooling + powerful). Press p...

Page 62

Pow er lo w high sle ep tim er pow erful po wer monit or do not overcool! A difference of 6°c or less between the outdoor and indoor temperatures during cooling is ideal. Anything cooler may harm your health. Adjust your curtains and blinds adjust curtains and blinds to prevent sunlight from enterin...

Page 63: Care and Maintenance

Care and maintenance regular cleaning and servicing will prolong the life of your air conditioner. ■ before cleaning the air conditioner, set the power supply to off. The high fan speed may cause injury. ■ do not wash the unit with water. Water may cause a short circuit or electric shock. Cleaning t...

Page 64

Cleaning the front panel (must be removed before washing) ■ do not leave water on the panel after cleaning. Dry thoroughly to prevent elec- tric shock. ■ stand on a flat surface when removing the front panel. ■ do not touch the indoor unit’s metal portions after removing the front panel. ■ removing ...

Page 65: Care and Maintenance

1 care and maintenance ■ replacing the air purifying filters ● do not reuse dirty filters. Consult the nearest authorized dealer. Air purifying filter no. Cz-sfd50n. ● these filters function effectively for no longer than three months. ● if the air conditioner operates with dirty filters: • air is n...

Page 66

■ are the remote control bat- teries dead? If the remote control display flashes, replace the batteries. (page 9) ■ is the discharge air cold (warm)? Operation is normal if, 15 min- utes after the start of operation, the temperature difference be- tween the air intake and outlet vents is 8°c or abov...

Page 67: Troubleshooting

Troubleshooting (before calling your dealer, refer to the checklist) problem? Check power low high sleep timer powerful power monitor check! Off off ■ has a circuit breaker been tripped or a fuse blown? ■ is the power supply plug disconnected from the outlet? ■ is the timer being used correctly (pag...

Page 68

Power low high sleep timer powerful power monitor ● at cooling • soft dry (auto fan speed) air will not be discharged for approximately 40 seconds. The unit is designed to prevent tobacco, cooking and body odors from being discharged together with the cool air. ● at heating (power led blinks) this i...

Page 69: Is There A Problem?

Is there a problem? Call the dealer immediately if any of the following occurs. Call the dealer immediately circuit breaker trips or fuse blows frequently. A smell of burn- ing is emitted. Power supply cord and plug become unusually warm. Abnormal noise during operation. Switches or buttons not func...

Page 70: Helpful Information

Helpful information remote control fails to function 1 if the remote control fails to function or has been misplaced, carry out auto operation. Auto opera- tion settings are automatic; the temperature can- not be adjusted. Turn the power supply to on press the auto operation button the power led bli...

Page 71

! Warning 1) this appliance must be earthed. 2) if the supply cord is damaged or need to be replaced, it must be replaced by the manufacturer or its service agent or a similarly qualified person in order to avoid a hazard. 3) remove power plug or disconnect from the mains before servicing this appli...

Page 72

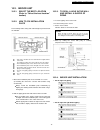

10 installation instructions required tools for installation works 1. Phillips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 42 n.M (4.2 kgf.M) 55 n.M (5.5 kgf.M) 3. Electric drill, hole core drill (ø...

Page 73

1. Grounding is necessary. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in installati...

Page 74

Attached accessories applicable piping kit cz-3f5, 7aen cz-4f5, 7, 10an select the best location indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place ...

Page 75

10.2.1. Select the best location (refer to “select the best location” section) 10.2.2. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. : unit centre should be at more than 450 mm at right and left of the wall. The height should be more tha...

Page 76

3. For the embedded piping (this can be used for left rear piping and left bottom piping also.) 76 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 77

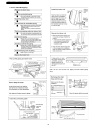

10.2.5. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × 1.5 mm 2 flexible cord, type designation h05 rn-f or hea...

Page 78

How to take out front grille please follow below steps to take out front grille if necessary such as when servicing. 1. Set the vertical airflow direction louver to the horizontal position. 2. Slide down the two caps on the front grille as shown in the illustration below, and then remove the two mou...

Page 79

Cutting and flaring the piping 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping and down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut ...

Page 80

Disposal of outdoor unit drain water • if a drain elbow is used, the unit should be placed on a stand which is taller than 3 cm. • if the unit is used in an area where temperature falls below 0°c for 2 or 3 days in succession, it is recommended not to use a drain elbow, for the drain water freezes a...

Page 81: 11 Servicing Information

1. Rated frequency operation 11 servicing information 11.1. Troubleshooting during troubleshooting and servicing, rated compressor operating frequency must be obtained in order to check the specification and technical data. Below are the methods used to obtain rated compressor operating specificatio...

Page 82

2. Troubleshooting air conditioner refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a ...

Page 83

1. Relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditoner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refrigerant ...

Page 84

11.2. Self diagnosis display the diagnostic display can be seen on the receiver of the front grille. • when an abnormality occurs, the unit automatically stops, and the timer led blinks to indicate a malfunction. At the same time, the type of abnormality will be indicated on the receiver as shown in...

Page 85

Diagnosis display abnormality / protection control abnormality judgement temporary operation primary location to verify h11 indoor / outdoor abnormal communication 1 min after starting operation - • internal / external cable connections • indoor / outdoor pcb h14 indoor intake air temperature sensor...

Page 86

(a) current transformer defective when the current transformer (ct) is an open circuit, total running current is less than 1.88a and the indicated frequency is 53 hz (cu-g95ke) or 74 hz (cu-g125ke) or above. If this condition continues for 20 seconds, the abnormality signal is sent from outdoor to i...

Page 87

A. Remote control reset when the batteries are inserted for the first time, or the batteries are replaced, all the indications will blink and the remote control might not work. If this happens, remove the back cover of the remote control and you will find a resetting terminal, and by shorting it wit...

Page 88

1. Remove the front grille fig. 1 2. Remove the indoor control board fig. 3 fig. 2 fig. 4 11.4. Disassembly of parts a. Indoor control board removal procedure 88 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 89

Fig. 5 fig. 7 fig. 9 fig. 6 fig. 8 fig. 10 a. Removal of electronic controller procedure 89 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 90

Fig. 11 fig. 13 fig. 15 fig. 12 fig. 14 c. Indoor fan motor removal procedure 90 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 91

Fig. 16 fig. 17 fig. 19 fig. 18 d. Cross flow fan removal procedure 1. Remove discharge grille 1. Remove cross flow fan 91 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 92

D. Outdoor electronic controller removal procedure 1. Remove the top pane and front panel fig. 20 2. Remove the outdoor electronic controller fig. 22 caution! When handling electronic controller, be careful of electrostatic discharge. • be save to return the wiring to its original position • there a...

Page 93

Fig. 24 f. Outdoor fan motor removal procedure fig. 26 fig. 26 fig. 25 fig. 27 f. Propeller fan removal procedure 93 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 94: 12 Technical Data

12 technical data 94 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 95

95 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 96

230v outdoor temp. (°c) indoor wet bulb temp. 30 35 40 46 tc shc ip tc shc ip tc shc ip tc shc ip 17.0°c 2.58 1.96 0.67 2.41 1.88 0.72 2.24 1.80 0.77 2.04 1.71 0.83 19.0°c 2.60 0.73 19.5°c 2.83 2.05 0.68 2.65 1.97 0.73 2.46 1.89 0.78 2.24 1.80 0.85 22.0°c 3.09 2.12 0.69 2.88 2.04 0.75 2.68 1.97 0.80...

Page 97: 13 Exploded View

13 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 97 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

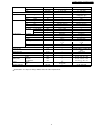

Page 98: 14 Replacement Parts List

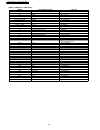

14 replacement parts list no. Description & name q’ty cs-g95ke cs-g125ke remarks 1 chassy complete 1 cwd50c338 ← 2 fan motor 1 cwa98244 ← 0 3 cross flow fan 1 cwh02c060 ← 4 bearing 1 cwh64k007 ← 5 evaporator 1 cwb30c271 ← 6 flare nut (1/2”) or (3/8”) 1 cwt25005 (3/8”) cwt25007 (1/2”) 7 flare nut (1/...

Page 99: 15 Exploded View

15 exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 99 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 100: 16 Replacement Parts List

16 replacement parts list no. Description & name q’ty cu-g95ke cu-g125ke remarks 1 chassy complete 1 cwd50k660a ← 2 fan motor bracket 1 cwd54254 cwd54255 3 fan motor 1 cwa95384 cwa95380 0 4 screw - fan motor 4 cwh55406 ← 5 compressor 1 2rd132x5bb03 2rd132x5ba03 0 6 sound proof material 1 cwg302029 ←...

Page 101: 17 Electronic Parts List

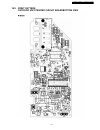

17 electronic parts list symbol description & name part no. Bz1 buzzer a48040 d1, d2, d4, d5, d7, d8 diode a541ss355t d3, d6, d9 diode a54d1f60 db1 diode bridge a54d3sba60f1 fuse1 fuse xbacw067 ic1 integrated circuit a5278366f114 ic2 integrated circuit a52br9020f ic3 integrated circuit a52mpc393g22 ...

Page 102

Symbol description & name part no. C-fm capacitor - fm a31735 ct1 current transformer a40260 d1 diode a54au02zv0 d17, d18, d20 diode a54ra15-06v3 d19 diode a54ra15-10v3 d2, d3, d4, d5, d8 diode a54ra22-04v3 d6 diode a541ss136t d9 ~ d16 diode a54ma165ta5 fuse1, fuse2 fuse xbacw067 ic1 integrated circ...

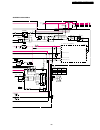

Page 103

18 electronic circuit diagram • cs-g95ke • cs-g125ke schematic diagram 1/3 d103 a54lnk5372 cn-stm1 1 2 3 4 5 5 4 3 2 1 (mx-5) (zh5) 4 3 2 1 cn-th 8 3 1 5 6 4 2 7 rst cs busy sck d0 d1 cs dl s1 s0 sck 4 8 3 2 1 5 6 7 com d101 1 2 3 4 5 6 7 cn-disp1 d102 a54lnk4183b a54lnm23301a 1 2 3 cn-rcv2 2 (mx-3)...

Page 104

Schematic diagram 2/3 c6 0.01 µ 10 µ c37 r29 100k + – c22 1.5 µ 16v (t) o i g ic4 a52pst600d c21 0.01 µ c11 0.01 µ r45 374 r44 137 r28 10k r59 5.49k + – c12 1 µ 50v r58 49.9k d2 + – c44 1 µ 50v 1/4 w 13.7k r80 c43 a52mpc393g22 ic3 x1 4mhz (27pf x 2) r42 150k 10k 4.7k 4.7k 10k r63 1k c18 0.022 µ c17 ...

Page 105

Schematic diagram 3/3 1 cn-pwr 0.01 µ c13 10k r47 cn-pwr c5 2200p r70 200k r73 1k znr2 erzva9v271 r76 15k 2w sw4 3 2 1 cn-mtr (xh3) 18 7 16 10 9 l2 l3 r48 1k bz bz1 + – c1 100 µ l4 5v g o i c3 0.01 µ + – c35 470 µ (fc) r23 10k d3 a54d1f68 d1 a541ss355t r72 2.4k r74 47k 510k r82 ac 230v znr1 erzveav5...

Page 106

Schematic diagram 1/3 1 2 3 cn-ac 1 2 3 (red) ac4 1 2 cn-s (nh-2) cn-tank (nv-2) 1 2 cn-th 1 2 4 3 pipe temp. Sensor (4.96k, 3800) (15k, 3950) sensor air temp. Compressor temp. Sensor (50k, 3975) cn-hot 1 2 3 hot (blue) (vh-3) blu red yel fan motor c-fm (wht) (wht) ry-fm outdoor terminal + – c39 22 ...

Page 107

Schematic diagram 2/3 c26 2200p r46 2.2k 15k 4.7k r40 560 r39 560 r38 560 r37 560 r36 560 1 2 pc6 tlp521-igh r35 560 r67 560 + – c7 270 µ 25v (sxe) – + – + 2 1 16 4 3 15 5 6 8 7 d2 a54ra22-04 d3 ebr43-02 d4 ebr43-02 12 13 9 11 d1 a54au02zv8 r2 27 3/4w + – c1 470 µ 25v + – c2 10 µ 25v 5v i o g regula...

Page 108

Schematic diagram 3/3 p u 3 2 1 vin vcc vfo gnd gnd vsen vout ct ct vout vsen gnd gnd vfo vcc vin 4 5 6 v ct vout vsen gnd gnd vfo vcc vin 7 8 9 w ct vout vsen gnd gnd vfo vcc vin 12 n ct vout vsen gnd gnd vfo vcc vin 13 ct vout vsen gnd gnd vfo vcc vin 15 14 10 11 630v 1 µ c40 (ecqe) q8 (ecqv) 50v ...

Page 109

109 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

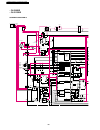

Page 110

How to use electronic circuit diagram timer table test mode name time (when test point short-circuited) 4 way valve abnormality 4 min. 2.4 sec. Outdoor air temp. For hz no. Decision 30 min. 0 sec. Anti-dew formation control 20 min. 0 sec. Anti-freezing control 6 min. 0 sec. Themo off delay 3 min. 0 ...

Page 111

Timer table test mode name time (when test point short-circuited) dc peak 30 sec. 3 sec. 120 min. 24 sec. Deice detection 80 min. 16 sec. 40 min. 8 sec. 40 min. 8 sec. Deice forced completion 11 min. 66 sec. Hz lock time 30 sec. 0 sec. Outdoor fan delay operation control 30 sec. 3 sec. 4 way valve d...

Page 112

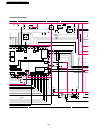

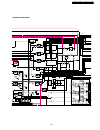

18.1. Print pattern indoor unit printed circuit board 112 s-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 113

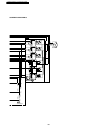

18.2. Print pattern outdoor unit printed circuit boardbottom view 113 cs-g95ke cu-g95ke / cs-g125ke cu-g125ke.

Page 114

114 s-g95ke cu-g95ke / cs-g125ke cu-g125ke [macc] printed in malaysia.