- DL manuals

- Panasonic

- Blu-ray Player

- DMP-BD75GA

- Service Manual

Panasonic DMP-BD75GA Service Manual

Summary of DMP-BD75GA

Page 1

©panasonic corporation 2011. Unauthorized copying and distribution is a violation of law. Order no.Chm1104017ce blu-ray disc player model no. Dmp-bd75ga dmp-bd75gc dmp-bd75gn dmp-bd75gt dmp-bd75gw dmp-bd75pu vol. 1 colour (k).......................Black type.

Page 2

2.

Page 3: Table of Contents

3 table of contents page page 1 safety precautions----------------------------------------------- 4 1.1. General guidelines ---------------------------------------- 4 1.2. Caution for fuse replacement--------------------------- 4 2 warning ------------------------------------------------------------...

Page 4: 1 Safety Precautions

4 1 safety precautions 1.1. General guidelines 1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit. 2. After servicing, see to it that all the protective devices such as insulation barriers, ins...

Page 5

5 1.2.1. Micro fuse conducting check this unit uses the micro fuse. Check the micro fuse conducting using the tester at the check points below..

Page 6: 2 Warning

6 2 warning 2.1. Prevention of electrostatic discharge (esd) to electrostatic sensitive (es) devices some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called elec- trostatic sensitive (es) devices. Examples of typical es devices are in...

Page 7

7 2.2. Precaution of laser diode.

Page 8

8 2.3. Service caution based on legal restrictions 2.3.1. General description about lead free solder (pbf) the lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this equipment in considering the globally environmental conservat...

Page 9: 3 Service Navigation

9 3 service navigation 3.1. Service information.

Page 10

10 3.2. Combination of multiple pressing on the remote control press multi-buttons (in combination) on the remote control simultaneously for operations, such as initialization or service mode, etc. There are no multiple pressing functions on the previous remote controls, thus, please be sure to use ...

Page 11

11 3.3.2. Nondisclosure mode 1 (combination of multiple pressing: [6] [7] [yellow]) press and hold [6] [7] [yellow] on the remote control simultaneously for 5 sec., then [50 ret] is displayed on fl display window. 3.3.3. Nondisclosure mode 2 (combination of multiple pressing: [5] [9] [red]) press an...

Page 12: 4 Specifications

12 4 specifications power supply: ac220v-240v, 50/60hz (bd75ga/gc/gw) ac110v, 60hz (bd75gt) ac220v-240v, 50hz (bd75gn) ac110v-240v, 50/60hz (bd75pu) power consumption: approx. 12w (bd75ga/gc/gn/gt/gw) approx. 14w(bd75pu) in standby mode: approx. 0.2w (bd75ga/gc/gn/gw/pu) approx. 0.1w(bd75gt) in quic...

Page 13

13 bd-rom(sl/dl): (sl:single layer/dl;dual layer) compliant ver.1.3 bd-re(sl/dl): (sl:single layer/dl;dual layer) bd-mv bd-r(sl/dl): (sl:single layer/dl;dual layer) bd-mv dvd-rom(sl/dl): (sl:single layer/dl;dual layer) dvd-video dvd-r: dvd-video dvd-vr dvd-r(dl): dvd-video dvd-vr dvd-rw: dvd-video d...

Page 14

14 5 location of controls and components.

Page 15: 6 Operating Instructions

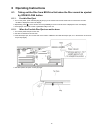

15 6 operating instructions 6.1. Taking out the disc from bd-drive unit when the disc cannot be ejected by open/close button 6.1.1. Forcible disc eject 1. Turn on the power, press and hold [ok], [b] and [y] on the remote control at the same time for more than 5 seconds. -"00 ret" is displayed on the...

Page 16: 7 Service Mode

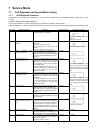

16 7 service mode 7.1. Self-diagnosis and special mode setting 7.1.1. Self-diagnosis functions self-diagnosis function provides information for errors to service personnel by “self-diagnosis display” when any error has occurred. U** and f** are stored in memory and held. You can check latest error c...

Page 17

17 f58 drive hardware error when drive unit error is detected, the event is saved in memory. No display no display f74 hdmi device key communica- tion error. This error is displayed when the information error is occurred at hdmi device key loading. No display f75 hdmi incompatible error (hdmi incomp...

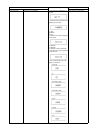

Page 18

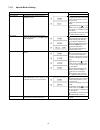

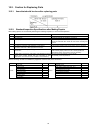

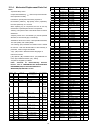

18 7.1.2. Special modes setting item fl display key operation mode name description front key rating password the audiovisual level setting password is initialized to level 8. While the unit is on, press and hold [ok], [b] and [y] on the remote control at the same time for more than 5 seconds. - "00...

Page 19

19 aging perform sequence of modes as * aging description shown below continually. Display following the then mode. Turn the power on. Press the [5] [9] and [r] button simultaneously for five seconds, then [70 ret] is displayed on fl. Press the [ ] button to select until [81 aig] is displayed on fl....

Page 20

20 demonstration lock/unlock ejection of the disc is prohibited. The lock setting is effective until unlocking the tray and not released by main unit initialization of service mode. *when lock the tray. “lock” is displayed for 3 seconds. When the power is on, press and hold [ok], [b] and [y] on the ...

Page 21

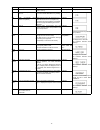

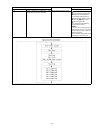

21 7.1.3. Service modes at a glance information necessary for service can be displayed. Service mode setting: 1. Turn the power on. 2. Press the [5] [9] and [r] button simultaneously for five seconds, then [70 ret] is displayed on fl. 3. Press the [ ] button to select until [80 srv] is displayed on ...

Page 22

22 bd drive last error bd drive error code display. 1. Error number is displayed for 5 seconds. 2. Time when the error has occurred is display for 5 seconds. Yy: year mm: month dd: day 3. Last drive error (1/2) is displayed for 5 seconds. 00 : bad disc 03 : bad disc 04 : bad disc or drive malfunctio...

Page 23

23 6. Disc maker id is displayed for 5 seconds. 7. Factor of drive error (hexadeci- mal) occurring is left displayed. In case that the maker cannot be identified, display is blackout. Item fl display key operation mode name description (remote controller key).

Page 24

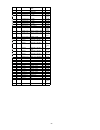

24 8. When the last error doesn't exist . Cec (h) output the cec terminal high output of hdmi. Press [5] [5] in service mode. Cec (l) output the cec terminal low output of hdmi. Press [5] [6] in service mode. Manufacturing date read out the manufacturing date of the unit. Yy: year mm: month dd: day ...

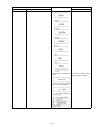

Page 25: 8 Service Fixture & Tools

25 8 service fixture & tools * the above parts are supplied by avc-csc-spc. Part number description pcs compatibility rfkz0216 extension cable ( digital p.C.B. - power p.C.B. / 23 pin) 1 same as bd60 series rfkz03d01ks lead free solder (0.3mm/100g reel) same as bd60 series rfkz06d01ks lead free sold...

Page 26

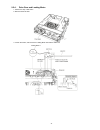

26 9 disassembly and assembly instructions 9.1. Unit 9.1.1. Disassembly flow chart the following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing. To assemble the unit, reverse the steps shown in the chart below. 9.1.2. P.C....

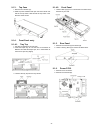

Page 27

27 9.1.3. Top case 1. Remove the 3 screws (a) . 2. Slide top case rearward and open the both ends at rear side of the top case a little and lift the top case in the direction of the arrows. 9.1.4. Front panel ass’y 9.1.4.1. Tray top 1. Put deck so that bottom can be seen. 2. Insert the paper clip, e...

Page 28

28 9.1.7. Bd drive 1. Remove the opu ffc, and isolate it with an esd prevention bag (rpfc0114) to prevent the laser diode from the esd damage. Do not touch the opu ffc conductive surface. 2. Remove the 3 ffcs. 3. Remove the 4 screws (a ) to remove bd drive. 9.1.8. Digital p.C.B. 1. Remove the 2 scre...

Page 29

29 notes when attaching the tray: 1. Be sure to leave the opu at the inner limited posts. 2. Push slide cam to the left side slightly, and make sure the tray band is between the two posts of slide cam when attaching the tray. 9.2.2. Pulley gear, belt 1. Perform the step “ tray ”. 2. Push the post to...

Page 30

30 3. Pull the hooks at both sides to remove the side post on the mid base. 4. Slide the slid cam in the direction as shown, and then take the front post out of the slide cam track. 5. Take the damper out of the mecha chassis and remove the drive ass’ y. 6. Remove the slide cam..

Page 31

31 9.2.4. Drive gear and loading motor 1. Perform the step “ slide cam ”. 2. Remove the drive gear. 3. Loosen the hooks, and remove the loading motor unit and the sw p.C.B..

Page 32

32 9.3. Disassembly from the traverse unit, assembly of the optical pick-up unit, and precautions on esd-preventive 9.3.1. Disassemly 1. Before removing the optical pick-up unit, please apply an esd prevention bag(rpfc0114) to the opu ffc, and weld the short-circuit solder. A. Set the temperature of...

Page 33

33 note: in this action, finger stab needs to be put on. Do not touch any parts other than the positions marked in the figure. 9.3.2. Assembly 1. Insert the shaft into the shaft hole of the base, install the opu to the auxiliary shaft, and then attach the nut piece unit onto the screw stem. 2. Assem...

Page 34

34 d. Welding should be applied less than 3 times. 4. Apply the lubricants to the 7 points as shown in figure..

Page 35

35 9.3.3. How to clean the lens of optical pick-up.

Page 36

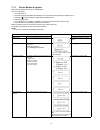

36 9.4. Repair flowchart and analysis procedures 9.4.1. Repair flowchart note: when digital p.C.B., drive unit and opu ass’y are replaced, adjustment value initialization is not required..

Page 37

37 9.4.2. Distinction analysis 9.4.2.1. Analysis procedures 1. Confirmation of pointed symptom -1 • confirm the pointed symptom of bd player occurs again after cleaning the lens. 2. Replacement of digital p.C.B. With the normal p.C.B. • replace the failed digital p.C.B. With the normal p.C.B. 3. Con...

Page 38

38 10 measurements and adjustments 10.1. Service positions note: for description of the disassembling procedure, see the section 9. 10.1.1. Checking and repairing of power p.C.B..

Page 39

39 10.1.2. Checking and repairing of digital p.C.B. Module.

Page 40

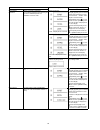

40 10.2. Caution for replacing parts 10.2.1. Items that should be done after replacing parts 10.2.2. Standard inspection specifications after making repairs after making repairs, we recommend performing the following inspection, to check normal operation. Use the following checklist to establish the...

Page 41

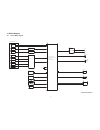

41 11 block diagram 11.1. Overall block diagram traverse mechanism unit optiacl pick-up unit usb port x56501 ic55004 ic55005 ic51001 servo controller/ av decoder/ system controller optical disc controller/ mixl ic54004 mixr overall block diagram key led laser diode motor drive focus coil beam expand...

Page 42

42 11.2. Power supply block diagram 1 2 3 4 2 5 4 5 n a 2 1 6 4 5 11 12 10 9 8 7 ac socket p1001 f1001 va1001,l1001 surge suppressor and surge absober d1006, c1014 rectifier t1001 power transformer ic1021 (switching ic) fb/olf vcc q1022 (feed back) d1110 4 3 ic1102 (error voltage det.) p_on_h from/t...

Page 43

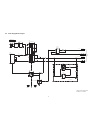

43 12 schematic diagram 12.1. Interconnection schematic diagram digital p.C.B. Bd drive power p.C.B. P55001 2 1 3 4 p1102 p58001 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 2 1 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 2 1 3 4 p1001 n a dmp-bd75ga/gc/gn/gt/gw/pu interconnection...

Page 44

44 12.2. Power supply schematic diagram power_p section f e d 1 c b a 9 8 7 6 5 4 3 2 dmp- bd75ga/gc/gn/gt/gw/pu schematic diagram 1 2 4 3 2 1 4 3 va1001 erzv05z471cs (bd75ga/gc/gn/gt/gw) erzv10d471c2 (bd75pu) c1001 0.068 l1001 g0b233d00005 d1006 b0edkt000009 2 ! ! ! ! P1001 k2aa2b000011 f1001 k5g20...

Page 45

45 12.3. Led section schematic diagram f e d 1 c b a 9 8 7 6 5 4 3 2 led section schematic diagram dmp-bd75ga/gc/gn/gt/gw/pu dig6 dig5 dig4 dig3 g f b k a dig2 d c e dig1 14 13 12 11 10 9 8 7 6 5 4 3 2 1 1 p led_txd 2 p led_clk 3 p led_cs p pw_led5v p key2 p key1 p key3 p pw_xn3.3v p remocon p key_p...

Page 46

46 12.4. Power sw schematic diagram f e d 1 c b a 9 8 7 6 5 4 3 2 power_sw section schematic diagram dmp-bd75ga/gc/gn/gt/gw/pu gnd 2 3 key_power 1 pj7551 to p7004 power p.C.B. Vee1j93 evq11a05r s7551.

Page 47

47 13 printed circuit board 13.1. Power p.C.B. And power sw p.C.B. P1001 f1001 va1001 c1001 l1001 za1001 nk1 1 3 c1007 r1006 c1005 d1023 c1024 ip1024 r1022 w5 r1031 r1111 r1121 c1121 d1111 9 8 7 6 f 5 4 3 2 1 e d c b a dmp- bd75ga/gc/gn/gt/gw/pu power p.C.B. Power sw p.C.B. (vep70390b) ( bd75ga/gc/g...

Page 48

48 14 appendix for schematic diagram 14.1. Voltage and waveform chart note: circuit voltage and waveform described herein shall be regarded as reference information when probing defect point, because it may differ from an actual measuring value due to difference of measuring instrument and its measu...

Page 49

49 14.1.3. Abbreviations initial/logo abbreviations a a0~up aclk ad0~up adata ale amute areq arf asi aso async address audio clock address bus audio pes packet data address latch enable audio mute audio pes packet request audio rf servo amp inverted input servo amp output audio word distinction sync...

Page 50

50 initial/logo abbreviations t te tibal tid tin tip tis tpsn tpso tpsp trcrs tron trson tracking error balance control balance output 1 balance input balance input balance output 2 op amp input op amp output op amp inverted input track cross signal tracking on traverse servo on initial/logo abbrevi...

Page 51

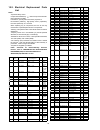

51 15 exploded view and replacement parts list 15.1. Exploded views 15.1.1. Casing parts & mechanism section 11 24 45 46 47 2 40 4 3 31 32 33 35 36 34 42 43 44 48 3-1 3-4 3-5 3-2 3-3 13 17 23 18 14 19 21 20 22 1 37 38 39 12 16.

Page 52

52 15.1.2. Mechanism section 101 118 102 119 107 115 113 120 116 138 139 140 112 126 127 128 129 104 133 134 135 136 144 144-1 144-2 144-5 144-6 144-3 144-4 137.

Page 53

53 15.1.3. Packing & accessories section a6 pc4 pc5 pc3 pc2 a4-1 a4 pc1 a7 pc7(bd75gc) (bd75pu) (bd75gt) a2 a3 (bd75ga/gc/gn/gw/gt) a16 pc6 a10 (bd75pu) (bd75ga/gc/gn/gw/pu) (bd75gt) (bd75gc) a1.

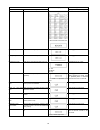

Page 54

54 15.1.4. Mechanical replacement parts list notes: *important safety notice: components identified by mark have special character- istics important for safety. Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors), etc. ...

Page 55

55 144-6 xtn2+4ffj stepping motor screw 1 accessory a1 k2cq2ca00007 ac cord 1 bd75pu/ ga/gc/ gw a1 k2cj2da00014 ac cord 1 bd75gn a1 k2ca2ca00027 ac cord 1 bd75gt a1 k2cp2ca00001 ac cord 1 bd75ga a1 k2cz3yy00005 ac cord 1 bd75gc a2 k1ha19da0007 hdmi cable 1 bd75pu a3 k2kyyyy00048 av cord 1 bd75ga/ gc...

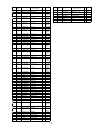

Page 56

56 15.2. Electrical replacement parts list notes: *important safety notice: components identified by mark have special character- istics important for safety. Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors), etc. Ar...

Page 57

57 q1022 b3pba0000454 transistor 1 e.S.D. Q14301 b1chrd000024 transistor 1 e.S.D. Bd75pu r1006 d0bf685ja030 1/2 6.8m 1 bd75pu/ ga/gc/ gn/gw r1021 d0gzr27ja027 1/2w 0.27 1 bd75gt r1021 d0gzr47ja027 1/2w 0.47 1 bd75ga/ gc/gn/ gw r1021 d0gzr24ja027 1/2w 0.24 1 bd75pu r1022 d0gzr27ja027 1/2w 0.27 1 bd75...

Page 58

58 16 schematic diagram for printing with a4 size.