- DL manuals

- Panasonic

- Fax Machine

- DP-8025

- Service Manual

Panasonic DP-8025 Service Manual

Order Number: MGCS080801C0

H21

Digital Imaging Systems

DP-8032 / 8025

[ Version 1.2 ]

This service information is designed for experienced repair technicians only and is not intended for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt within this service information by anyone else could result in serious injury or death.

WARNING

© Panasonic Communications Co., Ltd. 2008.

Unauthorized copying and distribution is a violation of law.

Summary of DP-8025

Page 1

Order number: mgcs080801c0 h21 digital imaging systems dp-8032 / 8025 [ version 1.2 ] this service information is designed for experienced repair technicians only and is not intended for use by the general public. It does not contain warnings or cautions to advise non-technical individuals of potent...

Page 2

2.

Page 3

3.

Page 4: Important Notice

4 important notice please read this notice completely before installing any optional accessories. As failure to properly install the additional board or connector with the power on (only the front power switch off) could damage the copier’s spc or sc board. Please follow the instructions below: 1. I...

Page 5

5 hinweis:.

Page 6: Precautions

6 precautions power and ground connection cautions ensure that the plug connection is free of dust. In a damp environment, a contaminated connector can draw a significant amount of current that can generate heat and eventually cause fire if left unattended over an extended period of time. Always use...

Page 7

7 once a month, unplug the machine and check the power cord for the following. If you notice any unusual condition, contact your authorized panasonic dealer . The power cord is plugged firmly into the receptacle. The plug is not excessively heated, rusted, or bent. The plug and receptacle are free o...

Page 8

8 operating safeguards do not place a magnet near the safety switch of the machine. A magnet can activate the machine accidentally, resulting in injuries. Do not use a highly flammable spray, or solvent near the machine. It can cause fire. When copying a thick document, do not use excessive force to...

Page 9

9.

Page 10

10

Page 11

11.

Page 12

12 memo.

Page 13

Table of contents 13 specifications table ............................ 15 1.1. Copy function.........................................15 1.2. Fax, printer and internet fax functions ................................................24 1.3. System combination...............................32 1.4. Option...

Page 14

Table of contents 14 8.17. Installing the automatic document feeder (da-as201) and the inverting automatic document feeder (da-ar251) ......................................... 304 8.18. Installing the platen cover (da-uc200) ......................................... 310 8.19. Installing the key coun...

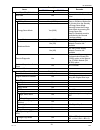

Page 15: 1 Specifications Table

15 dp-8032/8025 2008 ver. 1.2 1 specifications table 1.1. Copy function items description remarks dp-8032 dp-8025 basic specifications 1 type desktop 2 platen fixed 3 original position platen left / rear adf / i-adf left / center 4 recording paper path center 5 face up / face down face down 6 drum o...

Page 16

16 dp-8032/8025 2008 ver.1.2 capacity 550 sheets x 2 usa and canada ltr : 20 lb (75 g/m 2 ) other destinations a4 : 80 g/m 2 auto size setting no low level warning empty only bypass capacity 50 sheets auto size setting yes paper capacity (std. Configuration) 1,150 sheets 18 acceptable paper weight p...

Page 17

17 dp-8032/8025 2008 ver. 1.2 stand for 3-paper tray configuration option low plain stand stand for 2-paper tray configuration option high plain stand 3 platen cover option for eu and other destinations free stop yes from 30 to 70 degrees. 4 adf single side type option for eu and other destinations ...

Page 18

18 dp-8032/8025 2008 ver.1.2 multi tray function yes max. 3 way using optional exit tray (inner) and exit tray (outer) or finisher. Shift tray function yes staple function yes no manual stapling. Not available with rotation. Not available with inv, inv-r, a5, a5-r or b5-r. Stapler capacity 3,000 pin...

Page 19

19 dp-8032/8025 2008 ver. 1.2 auto paper tray selection yes auto start yes reservation while power on initial energy saver automatically enters the sleep or shutdown mode after 15 minutes from the standby or energy saver mode. Manually enters the energy saver mode by pressing the energy saver key. S...

Page 20

20 dp-8032/8025 2008 ver.1.2 4 in 1 yes 6 in 1 yes for usa and canada 8 in 1 yes for eu and other destinations booklet mode yes copy from four 1-sided pages to 1 booklet mode sheet. Duplex copy 1 →2 yes 2 →1 yes available only when using the i-adf. 2 →2 yes book →2 yes 1st page blank yes 1 → 2/2 → 1...

Page 21

21 dp-8032/8025 2008 ver. 1.2 3 control panel display wide touch panel lcd status lamp yes green : scanning / printing red : alarm / warning key original size yes copy size yes keypad yes clear yes stop yes start yes energy saver yes multi size feed no sort / finish no function mode yes original det...

Page 22

22 dp-8032/8025 2008 ver.1.2 add paper (under 50 sheets) no paper jam indication yes paper jam location yes service alert call yes user error yes machine error yes history of jam errors yes 4 main unit total counter yes (standard) mechanical counter max. Weight of documents on the platen glass 11.02...

Page 23

23 dp-8032/8025 2008 ver. 1.2 packing configuration 1 packing dimension 28.58 x 32.91 x 42.91 in (726 x 836 x 1090 mm) 2 packing weight 218.26 lb (99 kg) 3 accessories process unit yes developer no toner no toner waste container no outer tray no option operating instructions yes power supply 1 power...

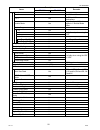

Page 24

24 dp-8032/8025 2008 ver.1.2 1.2. Fax, printer and internet fax functions 1.2.1. Fax function items description remarks dp-8032 dp-8025 main specifications 1 compatibility g3 itu-t std & non-std 2 pstn line port yes 1-line only 3 leased line port no 4 v.24 line port no 5 modem speed 33.6 - 2.4kbps t...

Page 25

25 dp-8032/8025 2008 ver. 1.2 5 effective scanning width ldr ( 10.7 in ) / a3 (292 mm) 6 a3 size tx/rx yes conforms to itu-t a3 7 reduction xmt yes a3 to b4 / a3 to a4 / b4 to a4 8 adf capacity 50 sheets face-up, feed from top page 9 collation stack yes face down printer mechanism 1 recording method...

Page 26

26 dp-8032/8025 2008 ver.1.2 8 direct dialing (monitor dialing) yes voice mode 9 automatic redialing yes up to 15 times at 0 to 15 min. Intervals 10 manual redialing yes pressing the redial/pause button 11 line monitor speaker yes 12 chain dialing (hybrid dial) yes in monitor dialing mode only 13 pu...

Page 27

27 dp-8032/8025 2008 ver. 1.2 7 90 degree rotation reception yes 8 duplex printing yes polling 1 polling yes 2 turnaround polling no 3 multi-station polling yes max. 270 stations 4 deferred polling yes max. 50 timers 5 deferred multi-station polling yes max. 50 timers / 270 stations 6 direct polling...

Page 28

28 dp-8032/8025 2008 ver.1.2 1.2.2. Printer function 5 confidential xmt / polling no 6 confidential center no 7 mailbox xmt / polling no 8 mailbox center no 9 file xmt no 10 fax forward yes received file transfer (only with internet fax option) 11 sub-address xmt yes t. Routing 12 sub-address rcv no...

Page 29

29 dp-8032/8025 2008 ver. 1.2 1.2.3. Network scanner function 9 pdl (pcl6) yes requires optional pcl6 emulation kit. 10 pdl (ps3) yes requires optional ps / pcl6 emulation kit 11 duplex printing yes custom size/post card size is not available. 12 collation stack yes 13 network printing yes 14 device...

Page 30

30 dp-8032/8025 2008 ver.1.2 1.2.4. Internet fax function 8 file format mult-page tiff / pdf tiff can also be converted to pdf with the pdms software 9 completion notice yes auto pop-up on the pc screen (requires network status monitor - installed with pdms software) 10 protocol tcp/ip, non-std item...

Page 31

31 dp-8032/8025 2008 ver. 1.2 8 fax forward yes received file transfer, only with internet fax option 9 sub-address rcv yes inbound routing, only with internet fax option 10 mail header email header print selection yes all or from / to / subject only subject line random entry lan features 1 internet...

Page 32

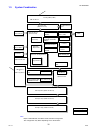

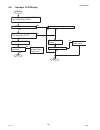

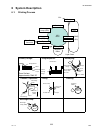

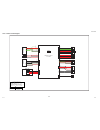

32 dp-8032/8025 2008 ver.1.2 1.3. System combination document sensor motor scanner unit (sdr pc board) expansion board main pc board (sc pc board) image memory electronic sorting memory dual-path exit guide unit paper transport unit 2nd paper tray (cst2 pc board) 3rd paper tray (cst3 pc board) 4th p...

Page 33

33 dp-8032/8025 2008 ver. 1.2 1.4. Options list 1. Options 2. Supplies note: pcl6 is a page description language of the hewlett-packard company. Ps3 is a page description language of the adobe systems company. The part number(s) may differ for other than pu (usa/canada, etc.) destinations. Please as...

Page 34

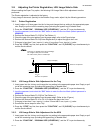

34 dp-8032/8025 2008 ver.1.2 1.5. External view 1. Standard configuration 2. With optional system console configuration 33.86 in (860 mm) 27.44 in (697 mm) 23.58 in (599 mm) 27.83 in (707 mm) manufacturer's name and address factory id product complies with dhhs rules 21 cfr subchapter j in effect at...

Page 35

35 dp-8032/8025 2008 ver. 1.2 3. Space requirements with options main unit + finisher main unit + outer exit tray main unit 27.83 in (707 mm) 27.83 in (707 mm) 14.92 in (379 mm) 14.92 in (379 mm) 3.94 in (100 mm) 3.94 in (100 mm) 10.83 in (275 mm) 14.84 in (377 mm) 9.88 in (251 mm) 3.46 in (88 mm) 3...

Page 36

36 dp-8032/8025 2008 ver.1.2 1.5.1. Serial number contents the contents of the 11-digit serial number is as follows: 2 3 4 5 6 1 sequential production number 5-digit sequential production number 00001 ~ 99999 = 1 ~ 99,999 units a0001 ~ y9999 = 100,000 ~ 329,976 units (letters “i” and “o” are skipped...

Page 37

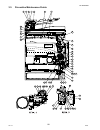

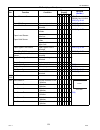

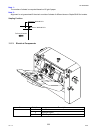

37 dp-8032/8025 2008 ver. 1.2 1.6. Control panel 1.7. Fans and motors dp-8032 scanning motor (201) lvps fan (322) lsu fan (315) main motor (907) adf motor (1801) transport motor (1320) toner motor (958) lift dc motor (1152) fan (459).

Page 38

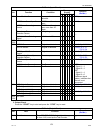

38 dp-8032/8025 2008 ver.1.2 1.8. Clutches and switches 1.9. Pc boards ils pcb (19124) (front cover sensor) paper feed roller clutch (1105) paper feed roller clutch (1105) intermediate roller clutch (957) sheet bypass feed roller clutch (957) registration roller clutch (957) adf roller clutch (1788)...

Page 39: 2 Disassembly Instructions

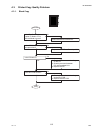

39 dp-8032/8025 2008 ver. 1.2 2 disassembly instructions 2.1. General disassembly pertinent disassembly instruction sections are shown below..

Page 40

40 dp-8032/8025 2008 ver. 1.2 2.2. Disassembly instructions 2.2.1. Inverting-automatic document feeder (i-adf) unit (1) open the adf cover (1831). (2) remove 4 silver screws (b1). (3) lift the adf input tray (1604). (4) slightly pull the right edge of the adf rear cover upward. (5) release the latch...

Page 41

41 dp-8032/8025 2008 ver. 1.2 (15) remove the snap ring (s9). (16) remove the pin (744). (17) remove the adf shaft (1724). (18) remove the adf roller (1728). (19) remove the snap ring (s9). (20) remove the pre-feed roller shaft (1730). (21) remove the pre-feed roller (1731). (22) remove 1 silver scr...

Page 42

42 dp-8032/8025 2008 ver. 1.2 (30) disconnect all connectors on the adf pc board. (31) remove 2 screws (19). (32) remove the adf pc board (1907). (33) remove 2 screws (24). (34) remove the adf motor (1801). (35) remove 6 screws (19). (36) remove the sensor bracket (1663). (37) remove 4 screws (19). ...

Page 43

43 dp-8032/8025 2008 ver. 1.2 2.2.2. Control panel unit and feed 2 roller> (1) open the adf cover (1831). (2) clean the adf roller (1728), pre-feed roller (1731), drive roller (1872) and the feed 2 roller (1753) with a soft cloth, saturated with isopropyl alcohol. (3) lift the adf input tray (1604)....

Page 44

44 dp-8032/8025 2008 ver. 1.2 (3) remove 6 silver screws (b1). (4) remove the left platen cover (514) and the right platen cover (516). (5) remove 2 silver screws (b1). (6) slightly lift the control panel assembly. (7) disconnect 4 harnesses on the pnl1 pc board (cn220, cn221, cn222 and cn224). (8) ...

Page 45

45 dp-8032/8025 2008 ver. 1.2 (10) disconnect 4 harnesses on the pnl1 pc board (cn223, cn225, cn229 and cn230). (11) remove 4 screws (f10). (12) remove the pnl1 pc board (1908). (13) remove 7 screws (f10). (14) disconnect the harness on the pnl2 pc board (cn251). (15) remove the pnl2 pc board (123)....

Page 46

46 dp-8032/8025 2008 ver. 1.2 (19) remove 2 screws (p5). (20) release 2 latch hooks and remove the upper control panel cover (122). (21) remove 1 screw (p5). (22) remove the pnl4 pc board (114). (23) remove 4 screws (p5). (24) remove the pnl3 pc board (113). (25) remove 2 screws (h4). (26) remove 2 ...

Page 47

47 dp-8032/8025 2008 ver. 1.2 2.2.3. Scanner unit (28) remove the touch panel (127). (1) remove the left and right platen covers (514, 516) and the control panel assembly. (refer to 2.2.2.) (2) remove 2 screws (19). (3) remove the glass assembly (557). (4) remove the glass s (559). (5) holding by th...

Page 48

48 dp-8032/8025 2008 ver. 1.2 (6) remove 4 screws (19). (7) remove the f/r scanner frame (240). (8) remove 2 screws (19). (9) remove the 2 lamp plate springs (232). (10) disconnect the harness on the lfb pc board (cn181). (11) remove the scanning lamp (204). (12) remove 2 mirror plate springs (230)....

Page 49

49 dp-8032/8025 2008 ver. 1.2 (17) remove 2 screws (19). (18) remove the inverter pc board (268). (19) remove 2 red screws (d24). (20) remove the fpc cable holder a (215) assembly. (21) holding by the center, slowly move the lamp base assembly towards the left of the scanner base frame. (22) disconn...

Page 50

50 dp-8032/8025 2008 ver. 1.2 (27) remove 4 silver screws (s6). (28) open the rear cover. (29) remove 4 silver screws (s6). (30) remove the rear right cover (507) and the right rear cover (518). (31) remove the e-ring (5y). (32) remove the synchro belt (208). (33) remove the mxl34 pulley (217). (34)...

Page 51

51 dp-8032/8025 2008 ver. 1.2 (39) remove 2 screws (36). (40) remove the scanning motor (201). (41) disconnect the harness on the sc pc board (cn106). (42) release 2 latch clips and remove the ferrite core. (43) remove 3 red screws (d24). (44) remove the ccd assembly (207). Note: when reinstalling t...

Page 52

52 dp-8032/8025 2008 ver. 1.2 (45) remove 1 screw (6p). (46) remove the cn bracket (511) assembly. (47) remove 2 screws (19). (48) remove the sdr pc board (1903). (49) remove 6 screws (19). (50) remove the f/r scanner frame (240). (51) remove 2 red screws (d24). (52) remove the rear lamp belt lock (...

Page 53

53 dp-8032/8025 2008 ver. 1.2 (55) remove the 3 sliders (211). (56) remove 2 screws (18). (57) remove the rear mirror belt lock (238). (58) remove the front mirror belt lock (236). (59) remove the mirror 2 bracket (233) assembly. (60) remove the 4 mirror 2 plate springs (206). (61) remove the two mi...

Page 54

54 dp-8032/8025 2008 ver. 1.2 bracket assembly> (1) remove 2 screws (19). (2) remove the right scanner frame (242). Note: when reinstalling the right scanner frame, tighten the 2 screws after reinstalling both sides of the f/r scanner frame. (3) install the mirror 2 bracket (233) assembly. (4) reins...

Page 55

55 dp-8032/8025 2008 ver. 1.2 2.2.4. Process unit (7) while holding each side of the bracket against the notch, secure the rear lamp belt lock (228) and the front lamp belt lock (227) with 2 red screws (d24). (8) clean the mirror 1 (264), the mirror 2 (265), and the multi beam sensor. Note: 1. Do no...

Page 56

56 dp-8032/8025 2008 ver. 1.2 (7) disconnect the harness. (8) loosen the process unit screw (743). (9) slide the process unit out. Caution: to prevent damage to the process unit, ensure the right cover is still open before pulling the process unit out. Caution: exercise caution not to scratch the su...

Page 57

57 dp-8032/8025 2008 ver. 1.2 (15) remove the harness from clamp, disconnect the connector. (16) remove 2 screws (51) and 1 snap ring (g6). (17) remove the hopper unit. Note: when reinstalling the hopper unit, insert the hooks into the recessed holes on the developer unit as illustrated. (18) releas...

Page 58

58 dp-8032/8025 2008 ver. 1.2 (22) shake the developer bottle thoroughly (approx. 30 seconds). (23) pour the appropriate developer evenly into the developer unit. Make sure to empty the bottle. (24) close the developer cover. Note: when reinstalling the developer cover, ensure that 2 magnet roller s...

Page 59

59 dp-8032/8025 2008 ver. 1.2 (29) remove the cleaning roller (706). (30) remove 2 bias charge roller holder (728) assemblies. Note: when reinstalling the bias charge roller holder assembly on the rear side, install the bias charge roller holder (728) first and then the bias charge roller bushing (7...

Page 60

60 dp-8032/8025 2008 ver. 1.2 2.2.5. Fuser unit caution: to prevent from getting burned, do not install, remove, clean or make adjustments when the fuser unit is hot. (1) open the right cover (1201). (2) remove 1 screw (6p). (3) remove the harness cover (1525). (4) unlock the angled rear arm (1218) ...

Page 61

61 dp-8032/8025 2008 ver. 1.2 (10) disconnect the 3 harnesses on the terminals of fuser unit. Note: when reinstalling, make sure that the 3 harnesses are connected correctly as illustrated. (11) disconnect 2 harnesses. (12) remove 4 screws (4n). (13) remove the fuser unit. (14) remove 4 screws (6p)....

Page 62

62 dp-8032/8025 2008 ver. 1.2 (17) clean the feed roller (1510) with a soft cloth, saturated with isopropyl alcohol. (18) remove 3 screws (4n). (19) remove 1 screw (6p). (20) remove the lower fuser cover (1003). (21) remove 2 screws (21) and 1 screw (19). (22) disconnect the harness. (23) remove the...

Page 63

63 dp-8032/8025 2008 ver. 1.2 (24) remove 1 screw (21). (25) remove the rear web bracket (1071). (26) remove the cleaning web roller (1083) and web pressure roller (1080). (27) remove 2 screws (36). (28) remove the thermostat (1038). (29) remove 2 screws (36). (30) remove the thermal fuse (1040). (3...

Page 64

64 dp-8032/8025 2008 ver. 1.2 (36) remove 1 screw (21). (37) remove the rear lamp holder (1021). (38) remove 2 screws (16). (39) remove 1 screw (21). (40) remove the front lamp holder (1018). (41) remove 2 fuser lamps (1043 and 1044). Note: make sure to check the wattage of each fuser lamp when repl...

Page 65

65 dp-8032/8025 2008 ver. 1.2 note: 1. When reinstalling, route the harnesses along the hooks as illustrated. 2. Be sure to install the longer harness to the gear side and the shorter harness to the other side. 3. Make sure that the 600w fuser lamp (white harness) is plugged into the upper left slot...

Page 66

66 dp-8032/8025 2008 ver. 1.2 (45) remove the 2 c-rings (1078). (46) remove the e40 heat roller gear (1014). (47) remove the plate spacer (1023). (48) remove the 2 insulation bushings (1006). (49) remove the 2 bearings (1046). Note: 1. The plate spacer is installed only to the non-gear side. 2. Do n...

Page 67

67 dp-8032/8025 2008 ver. 1.2 2.2.6. Drive unit (57) remove 5 upper fingers (1067). (58) remove the pressure roller (1027). Caution: when disassembling, exercise care not to damage the pressureroller (1027). Clean the surface of the pressure roller with a soft cloth, saturated with isopropyl alcohol...

Page 68

68 dp-8032/8025 2008 ver. 1.2 (5) remove 2 silver screws (b1). (6) remove the lower rear cover (506). (7) remove 1 screw (24). (8) remove 5 fly wheels (922). (9) remove the process unit. (refer to 2.2.4.) (10) remove 3 screws (21). (11) remove the hvps unit. (12) disconnect the mt harness (1926) on ...

Page 69

69 dp-8032/8025 2008 ver. 1.2 (19) remove 4 screws (6p). (20) remove the rd cover (411). (21) remove 1 screw (6p) and 2 screws (19). (22) remove the 1st tray drive bracket (939). (23) remove 3 screws (19). (24) remove the motor bracket (908)..

Page 70

70 dp-8032/8025 2008 ver. 1.2 2.2.7. Right cover (1) open the right cover (1201). (2) remove 1 screw (6p). (3) remove the harness cover (1525). (4) unlock the angled rear arm (1218) and the front arm (1217). (5) hook the angled rear arm (1218) into the lower hook hole. Clean the sensor on the cds pc...

Page 71

71 dp-8032/8025 2008 ver. 1.2 (11) remove 1 screw (19). (12) remove the registration pinch roller (1222). Clean the surface of the registration pinch roller with a soft cloth, saturated with isopropyl alcohol. (13) remove the roller cleaner (1229). Note: when installing the roller cleaner, make sure...

Page 72

72 dp-8032/8025 2008 ver. 1.2 2.2.8. Sheet bypass (16) remove the btr gear (1234). (17) remove the bias transfer roller (1221). Clean the surface of the bias transfer roller only with a soft dry cloth. Caution: when reinstalling the right cover, make sure the harness is not nipped by the cover. (1) ...

Page 73

73 dp-8032/8025 2008 ver. 1.2 (9) remove 1 screw (x6). (10) remove the reverse roller guide (1294). (11) remove the reverse roller (1291) assembly. (12) remove the bushing (1286). (13) remove the washer (1288). (14) remove the e-ring (j7). (15) remove the reverse roller (1291). Clean the surface of ...

Page 74

74 dp-8032/8025 2008 ver. 1.2 2.2.9. Paper feed module (1) remove the process unit. (refer to 2.2.4.) (2) remove the clutch (1105). (refer to 2.2.6.) (3) remove the snap ring (s9). (4) remove the registration roller (1121). Clean the surface of the registration roller with a soft cloth, saturated wi...

Page 75

75 dp-8032/8025 2008 ver. 1.2 (11) remove the reverse clutch (1132) and spring d (1178). (12) remove the c25 gear roller (1145). Clean the surface of the c25 gear roller with a soft cloth, saturated with water. (13) slide the 2nd paper tray out. (14) open the jam access cover (2307). (15) remove 2 s...

Page 76

76 dp-8032/8025 2008 ver. 1.2 2.2.10. Lsu unit (1) remove the process unit. (refer to 2.2.4.) (2) slide the 1st paper tray out. (3) remove 1 screw (19) and 2 screws (6p). (4) remove the front left cover (534). (5) remove the blind cover (530). (6) remove 2 screws (s6). (7) remove the s inner cover (...

Page 77

77 dp-8032/8025 2008 ver. 1.2 2.2.11. Paper transport unit (1) open the right cover (1201). (2) remove the fuser unit. (refer to 2.2.5.) (3) remove 4 silver screws (s6). (4) open the rear cover (302). (5) remove 4 silver screws (s6). (6) remove the rear right cover (507), and the right rear cover (5...

Page 78

78 dp-8032/8025 2008 ver. 1.2 (10) remove 1 screw (6p). (11) remove the fan assembly. (12) remove the exfc harnesses 2 from the 2 harness clamps. (13) disconnect the exfc harnesses from the exfc harnesses 2. (14) remove 5 screws. (15) remove the paper transport unit. (1) remove the inner tray (1522)...

Page 79

79 dp-8032/8025 2008 ver. 1.2 2.2.12. Pc board (2) push to open the paper transport jam cover (1302). (3) clean 6 pinch rollers (1518) with a soft cloth saturated with water. (1) remove 7 screws (6p). (2) disconnect all the harnesses on the sc pc board. (3) remove the sc pc board (1901). (4) remove ...

Page 80

80 dp-8032/8025 2008 ver. 1.2 (7) remove 2 shoulder silver screws (l8: upper) and 2 silver screws (s6: lower). (8) remove 2 screws (6p). (9) open the lvps cover (301). (10) remove 6 screws (6p). (11) disconnect all the harnesses on the acd pc board. (12) remove the acd pc board (1904). (13) remove 2...

Page 81

81 dp-8032/8025 2008 ver. 1.2 (16) remove 9 screws (6p). (17) remove all the harnesses on the lvps (18) remove the lvps (1910)..

Page 82

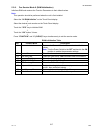

82 dp-8032/8025 2008 ver. 1.2 2.3. Screw identification template ref. No. Part no. Figure remark 16 xyn3+j8fj screw 18 xyn3+j6fj screw 19 xtb3+8jfj screw 20 xtb3+8ffj screw 21 xtb3+6ffj screw 23 xyn3+f8fj screw 24 xyn4+f8fj screw 36 xyn3+f6fj screw 51 xtb3+10ffj screw 62 xtb3+6jfj screw 64 xwg3fj wa...

Page 83

83 dp-8032/8025 2008 ver. 1.2 7b xtb26+6jfj screw b1 dzpb000007 silver screw b4 xtb3+8jfi black screw c2 dzpb000020 screw c8 xtw3+8sfj screw d24 xtb3+8jfj-r red screw d25 xtb3+8jfj-b bule screw e5 xtb3+32jfj screw e6 xtb3+24jfj screw e8 xtw3+10sfj screw f4 dzpa000063 screw f6 dzpk000021 washer f7 xs...

Page 84

84 dp-8032/8025 2008 ver. 1.2 j7 xuc4vm e-ring j8 xuc7vm e-ring l7 xuc2vm e-ring l8 dzpb000031 shoulder screw l9 xtb3+4ffj screw m2 dzpa000064 thumb screw n3 xtb4+10ffj screw p1 xtb3+6ffj-rp screw p2 xtb3+12jfj screw p5 xtn3+8gfn screw p7 ffpfa0152 screw s6 dzpa000086 screw s8 xtb3+12ffj screw s9 dz...

Page 85

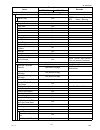

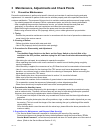

85 dp-8032/8025 2008 ver. 1.2 3 maintenance, adjustments and check points 3.1. Preventive maintenance preventive maintenance is performed at specific intervals and consists of machine cleaning and parts replacement. It is essential to perform these service activities properly and at the specified in...

Page 86

86 dp-8032/8025 2008 ver.1.2 2. The service mode is used by service technicians to perform maintenance and/or repairs, as well as to maintaining security of the machine. Service technicians must not leave the machine in the service mode after servicing the unit. 3. Service technicians are required t...

Page 87

87 dp-8032/8025 2008 ver. 1.2 3.2. Required tools 3.2.1. Preventive maintenance method no. Tools no. Tools 1 soft cloth 7 pliers 2 isopropyl alcohol 8 cotton swab 3 phillips screwdriver (#2) 9 brush 4 stubby phillips screwdriver (#2) 10 ks-660 - conductive grease (available from shin-etsu silicones ...

Page 88

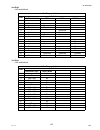

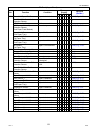

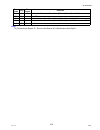

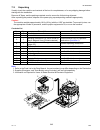

88 dp-8032/8025 2008 ver.1.2 3.3. Preventive maintenance points 5 7 7 6 47 8 11 20 45 46 45 21 44 43 43 detail b 16 18 13 17 12 14 15 19 13 12 14 15 12 14 12 14 10 4 3 1 2 9 47 detail a 25 29 24 26 27 28 23 22 42 32 40 34 33 30 31 38 37 35 36 41.

Page 89

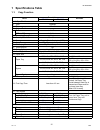

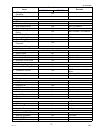

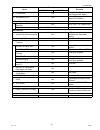

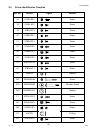

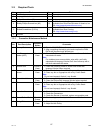

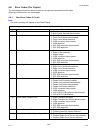

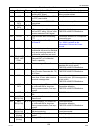

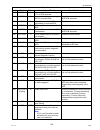

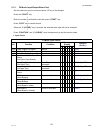

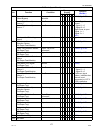

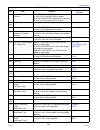

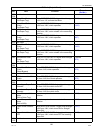

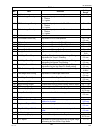

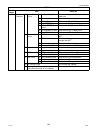

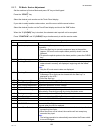

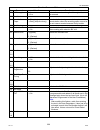

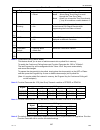

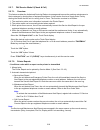

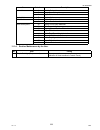

89 dp-8032/8025 2008 ver. 1.2 3.4. Preventive maintenance check list no. Mechanical parts ref. No. Cleaning replacement/adjustment ref. Counter cycle (sheet) method cycle (sheet) procedure i-adf/adf unit 1 adf roller 1728 60k water 1 120k refer to 2.2.1. F7-02-03 2 pre feed roller 1731 60k water 1 1...

Page 90

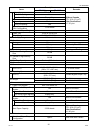

90 dp-8032/8025 2008 ver.1.2 note: 1. Clean all rollers and separation rubber with a soft cloth saturated with water. For stubborn toner accumulation, wipe with a soft cloth saturated with isopropyl alcohol first, then follow up with a soft cloth saturated with water. 2. The maintenance cycle is bas...

Page 91

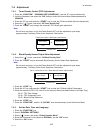

91 dp-8032/8025 2008 ver. 1.2 3.5. Resetting the p/m (preventive maintenance) counter when the machine reaches the preset p/m cycle, it will show “call for p/m” or “replace the toner waste container” on the lcd display. The pm counter can be reset by following the procedures below. 3.5.1. “call for ...

Page 92

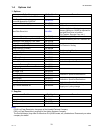

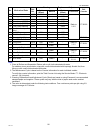

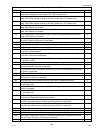

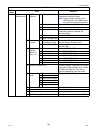

92 dp-8032/8025 2008 ver.1.2 3.6. Lubrication point list this information is used for routine preventive maintenance (pm) calls to ensure the highest degree of reliability. Inspect the following areas and lubricate as required. The inspection interval is usually 120k copies or more, however the inte...

Page 93

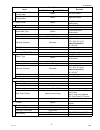

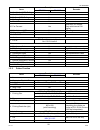

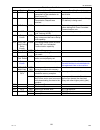

93 dp-8032/8025 2008 ver. 1.2 roller shaft 1313 em-50l pinch roller 1518 paper transportation drive roller 1314 em-50l p6l8 bushing 1322 roller shaft 1313 em-50l hp-300 pinch roller 1518 automatic duplex unit bias transfer roller (btr) 1221 em-50l ks-660 registration pinch roller 1222 front bushing ...

Page 94

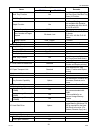

94 dp-8032/8025 2008 ver.1.2 roller shaft 1313 em-50l pinch roller 1518 drive roller 1409 em-50l p6l5 bushing 1150 pinch spring 1411 em-50l pinch roller 1518 mechanical parts ref. No. Grease lubrication point.

Page 95

95 dp-8032/8025 2008 ver. 1.2 3.7. Updating the firmware the quickest and most easiest method of updating the firmware is to use the network firmware update tool using ethernet lan port and a crossover cable. The network firmware update tool version must be 3.20 or higher. 3.7.1. Firmware configurat...

Page 96

96 dp-8032/8025 2008 ver.1.2 (2) for pcl option the pcl control program (2) must be written into the 4 mb onboard, which is assigned as rom code (b). The pcl control program (3) and pcl font data (4) are written into the 8 mb in the slot 1. The firmware (3) and (4) are assigned as rom code (c). When...

Page 97

97 dp-8032/8025 2008 ver. 1.2 cd-rom to the firmware data folder in your pc, or access the service web site to download the latest firmware code. When performing the self-extraction wizard for preparing the firmware code file, make sure and agree with the license agreement, then input the password “...

Page 98

98 dp-8032/8025 2008 ver.1.2 3.7.3. Updating through usb port (alternate method) if the device is not connected to the lan, upgrade the firmware code using the usb port. 1) install the local firmware update tool to your pc the tool can be downloaded from your sales company’s web site, or the pcc ser...

Page 99

99 dp-8032/8025 2008 ver. 1.2 note: 1. While updating the firmware code, the display may become garbled, however, it will return to normal upon completion of the firmware update. 2. Please refer to the firmware update tool oi for additional details. 3. The suffix "_xx" for the folder name or file na...

Page 100

100 dp-8032/8025 2008 ver.1.2 2) preparing the firmware code double click the appropriate destination shortcut batch file, and copy the firmware code file on the cd-rom to the firmware data folder in your pc, or access the service web site to download the latest firmware code. When performing the se...

Page 101

101 dp-8032/8025 2008 ver. 1.2 4. Press the “function”, “original size (ledger/a3)”, and the “3” keys simultaneously. 5. Input the password, and select the “ok” button to enter the service mode (default password is 00000000). 6. Perform the service mode f9-09 (update program card). 7. After the flas...

Page 102

102 dp-8032/8025 2008 ver.1.2 3.7.9. Firmware version sc : pnl : spc : sfd-l80 a a vxxxxx pu destination code (copier) pu : usa/canada pb : uk destination code (fax) au : usa/canada ab : uk firmware version (vxxxxx) language code a : a-english, c-french & spanish firmware type a : standard b, c, d, ...

Page 103

103 dp-8032/8025 2008 ver. 1.2 3.8. Adjusting the printer registration, lsu image side to side when installing the paper tray option, the following lsu image side to side adjustment must be performed. The printer registration is adjusted at the factory. If copy image is abnormal, specially in the ro...

Page 104

104 dp-8032/8025 2008 ver.1.2 3. Input the password, and select the “ok” button to enter the service mode (default password is 00000000). 4. Perform the service mode f1-06 (print test pattern 4). 5. Check the gap of the print pattern from the paper edge. (refer to the “3.8.2. ”) 6. Perform the servi...

Page 105

105 dp-8032/8025 2008 ver. 1.2 5. Perform the service mode f2 (single copy test). 6. Check the image size of the copy and the original as portrait. 7. Perform the service mode f6-93 (adf 100% image 1-sided), to adjust the side to side to be the same. 8. If the image is smaller than the original, inp...

Page 106

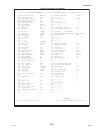

106 dp-8032/8025 2008 ver.1.2 3.10. Glossary of electrical abbreviations signal name function +12v +12 vdc power supply +24v +24 vdc power supply +24vd1 +24 vdc power supply +24vd2 +24 vdc power supply +24vhl +24 vdc power supply +24vfb +24 vdc power supply +24vfl +20/+24 vdc power supply +24vfp +24...

Page 107

107 dp-8032/8025 2008 ver. 1.2 gopsw1 developer missing detection hsync horizontal synchronous signal humsn temp humidity sensor signal iicscl iic transmission clock iicsda iic transmission signal iouta motor control signal ioutb motor control signal iprxd finisher ipc reception iptxd finisher ipc t...

Page 108

108 dp-8032/8025 2008 ver.1.2 ldupl photo sensor dc drive voltage ldupl2 photo sensor dc drive voltage ldupl3 photo sensor dc drive voltage ldupl4 photo sensor dc drive voltage ldwtd photo sensor dc drive voltage leda select sensor signal ledc select sensor signal ledx select sensor signal ledy sele...

Page 109

109 dp-8032/8025 2008 ver. 1.2 ncst4 4th paper tray detection signal ncstop 2nd paper feed module detection signal ncstop4 4th paper feed module detection signal ncton ring detection signal ndadfon adf option detection signal ndoor paper transport unit open detection signal nduack duplex print ackno...

Page 110

110 dp-8032/8025 2008 ver.1.2 nmmrdy main motor ready signal nmrclh3 3rd paper tray intermediate roller clutch drive signal nmrclh4 4th paper tray intermediate roller clutch drive signal noe output enable (image data) nop2way 2way unit detection signal nop3enb option feed fifo enable nop3fck option ...

Page 111

111 dp-8032/8025 2008 ver. 1.2 p/s motor start/stop padf2 2nd paper tray feed roller drive signal pblkclp afe black level clamp switch signal pcmld line switching relay drive signal pfclcnt paper feed clutch drive signal pflon inverter ground plift2 2nd paper tray lift motor signal plift4 4th paper ...

Page 112

112 dp-8032/8025 2008 ver.1.2 thermb1 fuser thermistor b1 thermb2 fuser thermistor b2 tr0 transfer control transfer output tr1 transfer control cleaning output txclkout+ image data transmission clock + txclkout- image data transmission clock - txout0+ image data out 0 + txout0- image data out 0 - tx...

Page 113: 4 Troubleshooting

113 dp-8032/8025 2008 ver. 1.2 4 troubleshooting 4.1. Initial troubleshooting flowchart start plug in the power cord, and then turn the power switches on. Does the lcd display function correctly? Does the original document feed through correctly? Does the recording paper exit the unit? Troubleshoot ...

Page 114

114 dp-8032/8025 2008 ver.1.2 4.2. Improper lcd display replace the sc pcb. Is the trouble resolved? Replace the low voltage power supply unit. Is the trouble resolved? Check connectors: cn52 (sc pcb), and cn220 (pnl1 pcb). Is led/lcd displayed? Does the display appear normal? Replace the lcd module...

Page 115

115 dp-8032/8025 2008 ver. 1.2 4.3. Printed copy quality problems 4.3.1. Black copy start yes no check the scanner mechanism. Is the ps normal? Is the spc pcb normal? Is the opc drum/developer unit operational? Replace the opc drum/developer unit. 1. Check all connectors, and voltages on the ps. 3. ...

Page 116

116 dp-8032/8025 2008 ver.1.2 4.3.2. Blank copy start end check the scanner mechanism. Are there any foreign particles, or stains in the charge unit? Is the opc drum/developer unit operational? Is the ps normal? No yes yes yes no no replace the opc drum/developer unit. Yes no 1. Clean the charge wir...

Page 117

117 dp-8032/8025 2008 ver. 1.2 4.3.3. Vertical white lines start end replace the recording paper. Yes no replace the drum/developer unit. Are there any foreign particles, or stains blocking the laser beam path? No yes no clean, or replace the rollers. Yes no check the scanner mechanism. No yes yes i...

Page 118

118 dp-8032/8025 2008 ver.1.2 4.3.4. Ghost images start end yes no check the scanner mechanism. Is the opc drum/developer unit operational? No yes are the fuser and pressure roller surfaces clean? Is the recording paper damp? No yes yes no replace the recording paper. Replace the opc drum/developer ...

Page 119

119 dp-8032/8025 2008 ver. 1.2 4.3.5. Vertical dark lines start yes no check the scanner mechanism. Is the opc drum/developer unit operational? Yes no replace the opc drum/developer unit. Is the lsu normal? No yes replace the lsu. End no yes clean, or replace the rollers. Paper travel p are the fuse...

Page 120

120 dp-8032/8025 2008 ver.1.2 4.3.6. Horizontal dark lines start yes no replace the opc drum/developer unit. Yes no check the scanner mechanism. Is the opc drum/developer unit operational? Is the lsu normal? Yes replace the lsu. Is the ps normal? 1. Check all connectors, and voltages on the ps. 2. C...

Page 121

121 dp-8032/8025 2008 ver. 1.2 4.3.7. Dark background is the lsu normal? No yes replace the lsu. Start yes no check the scanner mechanism. Is the opc drum/developer unit operational? No yes is the recording paper damp? Yes no replace the recording paper. Replace the opc drum/developer unit. Is the p...

Page 122

122 dp-8032/8025 2008 ver.1.2 4.3.8. Light print end no yes start yes no is the test pattern printout in copier f1 mode, or fax service mode 3 normal? Check the scanner mechanism. No yes is the opc drum/developer unit operational? Is the recording paper damp? Yes no replace the paper. Are there any ...

Page 123

123 dp-8032/8025 2008 ver. 1.2 4.3.9. Horizontal white lines end no yes clean, or replace the rollers. Start yes no check the scanner mechanism. Is the opc drum/developer unit operational? No yes is the recording paper damp? Yes no replace the recording paper. Replace the opc drum/developer unit. Is...

Page 124

124 dp-8032/8025 2008 ver.1.2 4.3.10. Improper fusing (printed image does not bond to the paper) note: replace the entire fuser unit when the thermostat and/or the thermistor fail (open-circuit). End is the fuser unit normal? No yes replace the fuser unit. (see note) start no yes is the recording pa...

Page 125

125 dp-8032/8025 2008 ver. 1.2 4.3.11. Voids in solid areas 4.3.12. Black dots end no yes clean, or replace the rollers. Start no yes is the recording paper damp? Replace the recording paper. Is the opc drum/developer unit operational? Yes no replace the opc drum/developer unit. P paper travel are t...

Page 126

126 dp-8032/8025 2008 ver.1.2 4.3.13. Recording paper creases start no yes is the recording paper damp? Replace the recording paper. End are the fuser, and pressure roller surfaces soiled, or are there any foreign particles, or stains in the fuser unit? 2. Clean, or replace the rollers. 1. Remove an...

Page 127

127 dp-8032/8025 2008 ver. 1.2 4.3.14. Poor printed copy quality start is the test pattern printout in copier f1 mode, or fax service mode 3 normal? 1. Replace the spc pcb. 2. Replace the lsu. 3. Replace the ps. 4. Replace the developer unit. End perform a receiving test with the reference fax unit....

Page 128

128 dp-8032/8025 2008 ver.1.2 4.3.15. Document skewing 4.3.15.1. Lsu skew adjustment (1) open the front cover and the right cover. (2) slide the process unit out. (refer to 2.2.4.) caution: exercise caution not to scratch the surface of the opc drum (green), and not to touch it with bare hands. (3) ...

Page 129

129 dp-8032/8025 2008 ver. 1.2 4.3.16. Abnormal printing start is the recording paper loaded in the paper tray properly? 1. Adjust the paper width guide. 2. Adjust the paper length guide. Is panasonic toner being used? Yes no is the recording paper size, and thickness within specification? Yes no ye...

Page 130

130 dp-8032/8025 2008 ver.1.2 4.3.17. Scanned copy quality problems start no yes is the scanning lamp abnormal? Replace the scanning lamp. End are the transmitting rollers dirty? Are there any foreign particles, or paper pieces in the scanning area? Yes no remove the foreign particles, or paper piec...

Page 131

131 dp-8032/8025 2008 ver. 1.2 4.3.18. Print skew adjustment for platen glass scanning follow the procedures below to adjust for the skewing when scanning original(s) from the platen glass. (1) make sure that the scanner unit is in the standby mode. (2) remove 3 screws and the left platen cover. (3)...

Page 132

132 dp-8032/8025 2008 ver.1.2 4.4. Document feeder (adf) 4.4.1. No document feed is the document set properly? Adjust, or replace the actuator. Is the document thickness, or size within specifications? Does the lcd activate when a doument is set? Check the harness of the adf motor. Does the adf roll...

Page 133

133 dp-8032/8025 2008 ver. 1.2 4.4.2. Document jam remove any obstacles blocking the path. Is the trouble resolved? Is the trouble resolved? Are there any obstacles in the document path? Does the adf roller rotate? Check the adf motor connector. Replace the adf motor, or the adf pcb. Replace the adf...

Page 134

134 dp-8032/8025 2008 ver.1.2 4.4.3. Document skew remove any obstacles from the document path. Are there any obstacles in the document path? Are the components of the feeder unit operational? Does the np sensor actuator move smoothly? Are the pre-feed, and adf rollers operational? Replace the pre-f...

Page 135

135 dp-8032/8025 2008 ver. 1.2 4.4.3.1. Adf / i-adf feed skew adjustment 1. Front page skew adjustment using a lined original (about 20 lb (80 g/m 2 ) weight pager), make a copy from the adf / i-adf to check for feeding alignment. Adjust the feed skew adjustment "a" downwards and recheck the feeding...

Page 136

136 dp-8032/8025 2008 ver.1.2 2. Back page skew adjustment (i-adf only) using a lined original (about 20 lb (80 g/m 2 ) weight pager), make a copy from the i-adf to check for feeding alignment. 4.4.4. Adf / i-adf free stop adjustment follow the procedure below to adjust the free stop function, if ne...

Page 137

137 dp-8032/8025 2008 ver. 1.2 4.5. Troubleshooting the lan interface 4.5.1. Checking network configuration start from the dos prompt, enter the following command-line utility: ipconfig /all locate a pc connected to the same subnet mask as the unit does the displayed network configuration, match the...

Page 138

138 dp-8032/8025 2008 ver.1.2 4.5.2. Testing the tcp/ip network it is beyond the scope of this service manual to cover networking in detail, there are many excellent manuals on this subject, but we hope the information in this section will aid with your troubleshooting efforts. In most cases, the ne...

Page 139

139 dp-8032/8025 2008 ver. 1.2 settings of the unit: default gateway ip address: dns server ip address: subnet mask: (whether it is valid) for windows 98 / me / 2000 / nt / xp the following example shows the output after you type "ipconfig /all" at a command prompt: from the above examples, you know...

Page 140

140 dp-8032/8025 2008 ver.1.2 pinging the default gateway (default router ip address) pinging the smtp/pop server if for some reason, the physical connection is missing, the echo reply will not be received from the destination and the following output is displayed: if the physical destination is far...

Page 141

141 dp-8032/8025 2008 ver. 1.2 router hop along with the ip address of each router crossed. If a fqdn (fully qualified domain name) is available, it will be displayed as well. This utility is useful for two diagnostic purposes: a. To detect whether a particular router is malfunctioning along a known...

Page 142

142 dp-8032/8025 2008 ver.1.2 some are shown below: • mask if this switch is present, the next parameter is interpreted as the netmask parameter. • netmask if included, specifies a sub-net mask value to be associated with this route entry. If not specified, it defaults to 255.255.255.255. • gateway ...

Page 143

143 dp-8032/8025 2008 ver. 1.2 (to leave from this menu, type "exit" on the command-line.) 7. Testing unit using the telnet command telnet is a terminal emulation protocol. Telnet enables pcs and workstations to function as dumb terminals in sessions with hosts on internet works. From windows 98/me/...

Page 144

144 dp-8032/8025 2008 ver.1.2 4.6. Error codes (for copier) the self-diagnostic functions detect troubles in the important components of the copier. When any trouble occurs, the copier stops. 4.6.1. User error codes (u code) note: uxx and a message will appear on the panel display. User error codes ...

Page 145

145 dp-8032/8025 2008 ver. 1.2 4.6.2. Jam error codes (j code) u13 add toner 1. Toner bottle incorrectly installed. 2. Low toner. 3. Toner sensor disconnected. 4. Toner sensor defective. 5. Spc pcb connector disconnected. 6. Spc pcb defective. U14 replace toner waste container 1. Toner waste contain...

Page 146

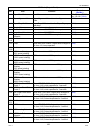

146 dp-8032/8025 2008 ver.1.2 • j code log view mode the 5 most recent j codes can be displayed on the panel display by pressing "function" and "3" keys in standby mode. Note: if the machine is jammed, follow the procedure below. 1. Turn the power switch on the left side and the main power switch on...

Page 147

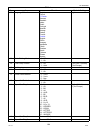

147 dp-8032/8025 2008 ver. 1.2 • jam sensor location of printer 2nd paper tray sheet bypass automatic duplex unit sensor 4 automatic duplex unit sensor 3 automatic duplex unit sensor 1 registration sensor 2nd registration sensor 3rd registration sensor 4th registration sensor automatic duplex unit s...

Page 148

148 dp-8032/8025 2008 ver.1.2 • jam sensor location of finisher • jam sensor location of i-adf • jam sensor location of adf jam error codes (j code) table code contents section j00 the registration sensor does not detect paper within a predetermined time after the paper starts feeding. (sheet bypass...

Page 149

149 dp-8032/8025 2008 ver. 1.2 j07 the registration sensor does not detect paper within a predetermined time after the paper starts feeding from 2nd feeder unit. (2/3/4 feeder unit) c, d2 j08 the registration sensor did not detect paper within a predetermined time after the paper feed roller started...

Page 150

150 dp-8032/8025 2008 ver.1.2 j62 the finisher registration sensor does not go off within a predetermined time after the sensor is activated. A j63 the finisher registration sensor detects paper at the time of the initials. A j64 the finisher exit sensor does not detect paper within a predetermined ...

Page 151

151 dp-8032/8025 2008 ver. 1.2 4.6.3. Mechanical error codes (e code) e1: optical unit error code function possible cause(s) e1- 01 abnormal platen glass scanning 1. Home position sensor connector disconnected. 2. Home position sensor defective. 3. Scanner motor connector disconnected. 4. Scanner mo...

Page 152

152 dp-8032/8025 2008 ver.1.2 e2: lift dc motor error code function possible cause(s) e2- 01 lift motor rotation (1st paper tray) 1. Level sensor connector disconnected. 2. Level sensor defective. 3. Lift mechanism defective. 4. Lift motor connector disconnected. 5. Lift motor defective. 6. Spc pcb ...

Page 153

153 dp-8032/8025 2008 ver. 1.2 e3: development system error code function possible cause(s) e3- 01 toner bottle motor rotation 1. Toner bottle motor connector disconnected. 2. Toner bottle motor defective. 3. Toner bottle motor drive mechanism defective. 4. Toner bottle installed incorrectly. 5. Spc...

Page 154

154 dp-8032/8025 2008 ver.1.2 e5: system error code function possible cause(s) e5- 05 vp (+24v, scanner) 1. Sdr pcb connector disconnected. 2. Sdr pcb defective. 3. Spc pcb connector disconnected. 4. Spc pcb defective. 5. Lvps defective. E5- 11 printer engine communication abnormal 1. Spc pcb connec...

Page 155

155 dp-8032/8025 2008 ver. 1.2 note: these error codes will appear only when the optional accessories are installed. Refer to the appropriate optional unit service manual. Technician warning: the following message will be displayed in the event that the required additional sort memory to operate the...

Page 156

156 dp-8032/8025 2008 ver.1.2 4.7. Information codes table (for facsimile) fax information codes code mode phase description of problem possible cause(s) 012 rcv c, d the length of the received document is over 2 m. 030 xmt b read point sensor does not activate within 4 seconds after the document st...

Page 157

157 dp-8032/8025 2008 ver. 1.2 406 rcv (password comm.) b xmt-password mismatched. Rcv- password mismatched. Selective rcv incomplete. Xmt, rcv password does not match. Last 4 digits of tsi does not match with the last 4 digits of auto dial telephone number. 407 xmt d transmitter received no respons...

Page 158

158 dp-8032/8025 2008 ver.1.2 421 rcv b busy tone is detected after sending nsf signal. Remote station disconnected the line. Wrong number dialed. 422 xmt b content of nsf (or dis) or nsc (or dtc) was invalid. Incompatible content 427 g3 rcv b dcn received to nsf/csi/dis transmitted. Interface is in...

Page 159

159 dp-8032/8025 2008 ver. 1.2 540 xmt ecm b no response after transmitting 3rd ctc or dcn received. Incompatible interface. 541 xmt ecm d no response after transmitting 3rd eor or received dcn. Faulty line. Mjr pcb abnormal. 542 xmt ecm d no response to the 3rd rr transmitted or received dcn. Remot...

Page 160

160 dp-8032/8025 2008 ver.1.2 638 xmt pstn lan power turned off with applicable data in memory or during communication. Power switched off. Power failure occurred. 700 xmt rcv pstn lan communication terminated by operator pressing the "stop" key. 712 xmt lan unknown email address replied from the ma...

Page 161

161 dp-8032/8025 2008 ver. 1.2 730 rcv lan unable to program the internet parameters or the autodialer via email from a pc. Verify that the fax parameter #158 is set to valid. 731 rcv lan dialer full while relayed transmission request was received. Dial buffer for manual number dialing (70 stations)...

Page 162

162 dp-8032/8025 2008 ver.1.2 4.8. Diagnostic codes (for facsimile) the 13-digit diagnostic code is provided for the service engineer to analyze how the communication was performed. The code is recorded on the journal. Journal example 1st digit: manufacturer code -: not used/defined fax diagnostic c...

Page 163

163 dp-8032/8025 2008 ver. 1.2 2nd digit -: not used/defined 3rd digit -: not used/defined fax diagnostic codes data definition id (tsi, csi, cig) rtn dcn stop button 0 - - - - 1 received - - - 2 - received - - 3 received received - - 4 - - received - 5 received - received - 6 - received received - ...

Page 164

164 dp-8032/8025 2008 ver.1.2 4th digit -: not used/defined 5th digit -: not used/defined fax diagnostic codes data definition scanning rate resolution 0 20 ms/line std 1 5 ms/line std 2 10 ms/line std 3 - std 4 40 ms/line std 5 - std 6 - std 7 0 ms/line std 8 20 ms/line fine 9 5 ms/line fine a 10 m...

Page 165

165 dp-8032/8025 2008 ver. 1.2 6th digit -: not used/defined 7th digit -: not used/defined fax diagnostic codes data definition polling xmt/rcv selective comm. Password comm. 0 - rcv off off 1 yes rcv off off 2 - xmt off off 3 yes xmt off off 4 - rcv on off 5 yes rcv on off 6 - xmt on off 7 yes xmt ...

Page 166

166 dp-8032/8025 2008 ver.1.2 8th digit -: not used/defined 9th digit -: not used/defined fax diagnostic codes data definition advanced comm. Cover sheet xmt 0 - - 1 report xmt - 2 check & call - 3 - - 4 memory transfer - 5 - - 6 - - 7 - - 8 - yes 9 report xmt yes a check & call yes b - yes c memory...

Page 167

167 dp-8032/8025 2008 ver. 1.2 10th digit -: not used/defined 11th digit -: not used/defined fax diagnostic codes data definition coding ecm 0 mh - 1 mr - 2 mmr - 3 jbig - 4 - - 5 - - 6 - - 7 - - 8 mh yes 9 mr yes a mmr yes b jbig yes c - yes d - yes e - yes f - yes fax diagnostic codes data definit...

Page 168

168 dp-8032/8025 2008 ver.1.2 12th digit -: not used/defined 13th digit -: not used/defined fax diagnostic codes data definition modem speed modem speed (v.34) 0 2400 bps - 1 4800 bps 2400 bps 2 7200 bps 4800 bps 3 9600 bps 7200 bps 4 tc 7200 bps 9600 bps 5 tc 9600 bps 12000 bps 6 12000 bps 14400 bp...

Page 169

169 dp-8032/8025 2008 ver. 1.2 4.9. Troubleshooting (for printer) 4.9.1. Checking the basics this section explains how to solve problems including error messages, or unexpected printing results. If the printing system is not printing or working as expected, and if you are not sure what to do, start ...

Page 170

170 dp-8032/8025 2008 ver.1.2 4.9.4. Error message appears on the unit 4.9.5. System error (cd drive related error during installation) error message cannot complete print job; image memory overflow • there may not be enough sort memory available in the panasonic device to complete the print job. Ei...

Page 171: 5 Service Modes

171 dp-8032/8025 2008 ver. 1.2 5 service modes 5.1. Service modes (for copier) these service modes are provided to assist the technician in checking for abnormalities in the copier and a means of making adjustments to the input/output of major components. Caution: the factory default parameters are ...

Page 172

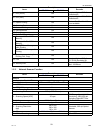

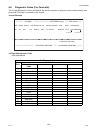

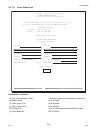

172 dp-8032/8025 2008 ver.1.2 f5 / f6 information list (sample) * * * * * * * * * * - f 5 / f 6 i n f o r m a t i o n l i s t - * * * * * * d a t e m m m - d d - y y y y * * * t i m e 1 2 : 0 1 * * * p . 0 1 f5-00 country version usa/can f5-50 auto contrast adjust. Yes f5-01 frequency desired 60hz f...

Page 173

173 dp-8032/8025 2008 ver. 1.2 2.Firmware version sc : aav0000xpu 1.Machine information machine name : dp-xxxx mac address : 08002312137e sc boot : m13 pnl : aav0000xpu spc : 30cpm v0000x finisher : ver 6d01 fax modem : pdl font1 : sc2 : 3.Memory capacity page memory : 32 mb sort memory : 16 mb fax ...

Page 174

174 dp-8032/8025 2008 ver.1.2 f7 total counter list (sample) f7-01 key operator id code : 0000 f7-02 maintenance count total count : 295 pm count : 295 scanner pm count : 61 adf count : 26 opc drum count : 295 process unit count : 295 adf pm count : 50 fuser web count : 295 developer count : 295 avg...

Page 175

175 dp-8032/8025 2008 ver. 1.2 5.1.3. F4 mode: input/output status test set the machine to service mode and press “4” key on the keypad. ↓ press the “start” key. ↓ enter the number to activate the test then press “start” key. ↓ press “stop” key to cancel the test. ↓ when the “c (clear)” key is touch...

Page 176

176 dp-8032/8025 2008 ver.1.2 004 fuser unit paper exit sensor paper is detected. 0 (1045) fig.10 g4 dual-path exit guide unit detection sensor unit is connected. 0 --- adu detection sensor unit is connected. 0 --- jam access cover open detection sensor (2nd paper feed module) cover is open. 0 (1045...

Page 177

177 dp-8032/8025 2008 ver. 1.2 008 bottom sensor (sheet bypass) home position is detected. 1 (1045) fig.12 d7 front / right cover open sensor 2 see remarks. * front / right cover is closed. Signal 1 = 0 signal 2 = 0 right cover is open. Signal 1 = 1 signal 2 = 1 (461) front / right cover open sensor...

Page 178

178 dp-8032/8025 2008 ver.1.2 013 paper entrance sensor paper is detected. 1 1-bin finisher (fs300). No. 013-014 (2525) fig.28 h1 paper exit sensor paper is detected. 1 (2525) fig.29 h6 home position sensor home position is detected. 1 (2525) fig.29 i6 paper level sensor paper hold sensor paper hold...

Page 179

179 dp-8032/8025 2008 ver. 1.2 2. Output check press the “start” key to start and press the “stop” key to reset. 021 home position sensor home position is detected. 1 (270) adf/platen cover open sensor adf/platen cover is open. 1 (1903) adf/platen cover angle sensor adf/platen cover is open more tha...

Page 180

180 dp-8032/8025 2008 ver.1.2 041 key counter / card counter when spc pcb cn726-2 signal level changes to 0v from +24v, count up the key counter. When spc pcb cn726-6 signal level changes to 0v from +5v, count up the card counter. --- 042- 049 not used 050 main motor when spc pcb cn723-2 signal leve...

Page 181

181 dp-8032/8025 2008 ver. 1.2 073- 074 not used 075 paper feed motor (3rd paper tray) when cst3 pcb cn805-4 signal level changes to 0v from +5v, activate the motor. (2402) 076 paper feed roller clutch (3rd paper tray) when cst3 pcb cn806-2 signal level changes to 0v from +24v, clutch operates. 1 mi...

Page 182

182 dp-8032/8025 2008 ver.1.2 110 paper feed motor feed motor rotates. 1bin finisher (fs300) no. 110-116 (3014) 111 paper alignment motor paper alignment motor drives the alignment plate. (2931) 112 paper tray lift motor paper tray lift motor drives the paper tray up and down. (2511) 113 stapler mot...

Page 183

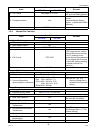

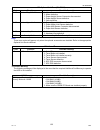

183 dp-8032/8025 2008 ver. 1.2 5.1.4. F5 mode: function parameters (for copier) set the machine to service mode and press “5” key on the keypad. ↓ press the “start” key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number, scroll the menu with the...

Page 184

184 dp-8032/8025 2008 ver.1.2 07 language default english french c.French german swedish italian dutch portugal spanish norway danish finnish turkish english polish hungary japanese czech russian greek chinese taiwan korean english 08 batch printing mode 0 : off 1 : on 1 09 fuser lamp control 0 : of...

Page 185

185 dp-8032/8025 2008 ver. 1.2 17 paper size tray 4 same as f5-14 18-19 not used 20 adf 0 : no 1 : auto 1 21 finisher 0 : no 1 : auto 1 22 system console 0 : no 1 : auto 1 23 paper transport unit 0 : no 1 : auto 1 24 not used 25 digital quantum 0 : off 1 : on 1 26 2-sided unit 0 : no 1 : auto 1 27-2...

Page 186

186 dp-8032/8025 2008 ver.1.2 45 dept code reentry again 0 : no 1 : yes 1 46-47 not used 48 th sensor (dev) 0 : no 1 : mid 2 : large 1 49 not used 50 auto contrast adjust 0 : no 1 : yes 1 51 dept. Counter (copy) 0 : no 1 : yes 1 52 dept. Counter (fax) 0 : no 1 : yes 0 53 2-sided auto shift 0 : no 1 ...

Page 187

187 dp-8032/8025 2008 ver. 1.2 68 cover mode default 0 : f, blank 1 : f, copy 2 : fb, blank 3 : fb, copy 0 69 reduce n in 1 space 0 : no 1 : yes 0 70 pm cycle 0 : no 1 : 1.5 k 2 : 2.5 k 3 : 5 k 4 : 10 k 5 : 15 k 6 : 20 k 7 : 30 k 8 : 40 k 9 : 60 k 10 : 80 k 11 : 90 k 12 : 120 k 13 : 150 k 14 : 200 k...

Page 188

188 dp-8032/8025 2008 ver.1.2 82 manual skyshot mode 0 : off 1 : m1, on 2 : m2, on 3 : m1, m2, on 0 83 digital skyshot mode 0 : no 1 : normal 2 : quality 1 84 paper tray priority 0 : s > c > b 1 : c > s > b 1 85 side void setting (adf) 0 : none 1 : yes 0 86 pm cycle (optics) 0 : no 1 : 40 k 2 : 60 k...

Page 189

189 dp-8032/8025 2008 ver. 1.2 5.1.5. F6 mode: adjust parameters (for copier) set the machine to service mode and press “6” key on the keypad. ↓ press the “start” key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number, scroll the menu with the a...

Page 190

190 dp-8032/8025 2008 ver.1.2 17 charge roller voltage charge voltage compensation adjustment. -76 ~ +76 2.60 v 18 standard laser power laser power compensation adjustment. -29 ~ +25 19 std bias dc voltage adjustment of bias standard voltage. -76 ~ 76 2.60 v 20 not used 21 tdc gain voltage adjustmen...

Page 191

191 dp-8032/8025 2008 ver. 1.2 48 not used 49 t mode image density image density adjustment for text mode. (-) : darker. (+) : lighter. -99 ~ +99 50 t/p mode image density image density adjustment for text/ photo mode. (-) : darker. (+) : lighter. -99 ~ +99 51 p mode image density image density adju...

Page 192

192 dp-8032/8025 2008 ver.1.2 80 quantum photo mode read value of quantum gamma table for photo mode. +1 ~ +5 (read only) 81 quantum halftone read value of quantum laser duty of check pattern. +127 ~ +255 (read only) 82 quantum black read value of quantum laser duty of black pattern. +127 ~ +255 (re...

Page 193

193 dp-8032/8025 2008 ver. 1.2 5.1.6. F7 mode: electronic counter set the machine to service mode and press “7” key on the keypad. ↓ press the “start” key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number, scroll the menu with the arrow buttons...

Page 194

194 dp-8032/8025 2008 ver.1.2 f7 electronic counters 03 paper feed count 04 4th paper tray count total count of paper fed from the 4th paper tray. 05 not used 06 2-sided count total count of 2-sided print. 07 a4 / letter count total count of a4 / letter print. 08 a4r / letter r count total count of ...

Page 195

195 dp-8032/8025 2008 ver. 1.2 5.1.7. F8 mode: service adjustment set the machine to service mode and press “8” key on the keypad. ↓ press the “start” key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number, scroll the menu with the arrow buttons...

Page 196

196 dp-8032/8025 2008 ver.1.2 20 tdc check operation adjustment of tdc sensor. 21-46 not used 47 adf continuous test press start key to begin. 48 platen continuous test press start key to begin. 49-54 not used f8 mode no. Item remarks.

Page 197

197 dp-8032/8025 2008 ver. 1.2 5.1.8. F9 mode: unit maintenance set the machine to service mode and press “9” key on the keypad. ↓ press the “start” key. ↓ select the desired code number on the touch panel display. ↓ if you wish to select another code number, scroll the menu with the arrow buttons. ...

Page 198

198 dp-8032/8025 2008 ver.1.2 f9 unit maintenance 06 ram initialize 00 parameter initialize resets the fax and function parameters to default values. Note: turn the power switch to the off and back to the on position to enable the parameter settings. 01 all job clear clears all jobs stored in flash ...

Page 199

199 dp-8032/8025 2008 ver. 1.2 5.2. Service modes (for facsimile) caution: the factory default parameters are preset (country dependent) for optimum performance and in compliance with the local telecommunication regulations/standards, and do not need to be changed. Changing some of these parameters ...

Page 200

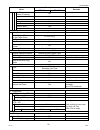

200 dp-8032/8025 2008 ver.1.2 5.2.3. Fax service mode 1 (function parameter setting) use the following procedure to change the function parameters. Select the “01 function param. Setting” on the touch panel display. ↓ select the desired code number on the touch panel display. ↓ if you wish to select...

Page 201

201 dp-8032/8025 2008 ver. 1.2 005 destination code 000 : austria 001 : u.K. 002 : canada 003 : denmark 004 : taiwan 005 : finland 006 : germany 007 : netherlands 008 : italy 009 : spanish 010 : hong kong 011 : australia 012 : switzerland 013 : norway 015 : portuguese 016 : ireland 017 : belgium 018...

Page 202

202 dp-8032/8025 2008 ver.1.2 012 dtmf level 00 = 0 dbm ~ 15 = -15 dbm selects the dtmf output level, 0 to -15 dbm in 1 dbm steps. 013 g3 rx eql 1 = 0db 2 = 4db 3 = 8db 4 = 12db selects the cable equalizer for g3 reception mode, 0db, 4db, 8db or 12db. 014 g3 tx eql 1 = 0db 2 = 4db 3 = 8db 4 = 12db s...

Page 203

203 dp-8032/8025 2008 ver. 1.2 025 comm. Start-up 1 = first 2 = second selects the communication start-up condition (xmt and polling). (used when echo suppression is disabled.) 026 non-standard 1 = off (invalid) 2 = on (valid) selects own mode (panafax mode). 027 short protocol b 1 = off (invalid) 2...

Page 204

204 dp-8032/8025 2008 ver.1.2 045 ring detect count 1 = 1 ring ~ 9 = 9 rings selects the ring detection count from 1 to 9 rings in 1 ring step intervals. 046 on-hook time 0 = 0 sec. ~ 90 = 90 sec. Selects the on-hook time between sequential communication calls in 1 second step intervals. 047 respons...

Page 205

205 dp-8032/8025 2008 ver. 1.2 068 nyse fax forward (usa and canada only) 1 = off 2 = on selects whether the machine will forward the incoming and outgoing faxes to a specified station. Note: once this parameter is activated, fax forwarding via fax parameter 054 is automatically disabled, an access ...

Page 206

206 dp-8032/8025 2008 ver.1.2 082 jam length 1 = 1 m 2 = 2 m selects the maximum length of the original that can be scanned. 083 not used 084 line as no paper 1 = ring (ring) 2 = busy (keep line busy) selects whether to ring or send a busy tone to the remote station when the recording paper runs out...

Page 207

207 dp-8032/8025 2008 ver. 1.2 note 1: continuous polling (station mode) this feature allows you to store or add documents into a polled file in memory. To enable the continuous polling feature set function parameter no. 003 to "2:station". The last program key will be assigned with the "store 4 pol...

Page 208

208 dp-8032/8025 2008 ver.1.2 5.2.4. Fax service mode 3 (printout of lists, reports and test results) from this service mode you can print the function parameter list, page memory test, printer report, all document file, protocol trace and the toner order form. 5.2.4.1. Function parameter list a lis...

Page 209

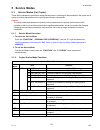

209 dp-8032/8025 2008 ver. 1.2 function parameter list (sample) ************* -function parameter- ************* date mmm-dd-yyyy ***** time 12:07 ***p.01 -panasonic - ******************************** - - ****** -12345678901234567890- ********* 000 monitor/tel dial monitor 050 ring detect mode norma...

Page 210

210 dp-8032/8025 2008 ver.1.2 note: 1. The contents of the function parameter list may vary depending on the country’s regulations. 2. “ * ” mark will be shown on the left side of number when setting was changed from default. Function parameter list (sample) ************* -function parameter- ******...

Page 211

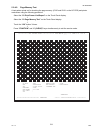

211 dp-8032/8025 2008 ver. 1.2 5.2.4.2. Page memory test a test pattern prints out for checking the page memory (ic120 and ic121 on the sc pcb) and printer mechanism using the following procedure. Select the “03 print param. List/report” on the touch panel display. ↓ select the “03 page memory test”...

Page 212

212 dp-8032/8025 2008 ver.1.2 5.2.4.3. Printer report all printer errors are logged on the printer report which can be printed by the following procedure. Select the “03 print param. List/report” on the touch panel display. ↓ select the “04 printer report” on the touch panel display. ↓ touch the “ok...

Page 213

213 dp-8032/8025 2008 ver. 1.2 5.2.4.4. All document files print the document files from the flash memory. Select the “03 print param. List/report” on the touch panel display. ↓ select the “05 all document files” on the touch panel display. ↓ touch the “ok” button 3 times. ↓ press “function” and “c ...

Page 214

214 dp-8032/8025 2008 ver.1.2 5.2.5. Fax service mode 4 (modem test) 5.2.5.1. Binary signal this service mode is used to check the binary signal output. Signals can be output to the line using the following procedure. Select the “04 modem tests” on the touch panel display. ↓ select the “01 binary si...

Page 215

215 dp-8032/8025 2008 ver. 1.2 5.2.5.3. Dtmf signal this service mode is used to check the dtmf (dual tone multi frequency) signal output. The dtmf signal can be generated using the following procedure. • dtmf single tone select the “04 modem tests” on the touch panel display. ↓ select the “03 dtm s...

Page 216

216 dp-8032/8025 2008 ver.1.2 5.2.5.4. Binary signal (v.34) this service mode is used to check the binary signal output. Signals can be output to the line using the following procedure. (v.34) select the “04 modem tests” on the touch panel display. ↓ select the “05 v34 modem” on the touch panel disp...

Page 217

217 dp-8032/8025 2008 ver. 1.2 5.2.6. Fax service mode 6 (ram initialization) initializes ram and restores the function parameters to their default values. Note: this operation should be performed when the unit is first installed. Select the “06 ram initialize” on the touch panel display. ↓ select t...

Page 218

218 dp-8032/8025 2008 ver.1.2 5.2.7. Fax service mode 8 (check & call) 5.2.7.1. Overview this feature enables the authorized servicing dealers to manage and improve the machine maintenance to their customers by alerting them of equipment problems. It also can be used as a supply sales tool by alerti...

Page 219

219 dp-8032/8025 2008 ver. 1.2 note: tx (transmission) report: s = service alert report, m = maintenance alert report error code log tx report remarks ex-xx o s refer to the mechanical error code (e code) table. (sect. 4.6.3.) e13 o out of toner. Jxx o refer to the jam error code (j code) table. (se...

Page 220

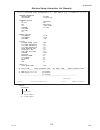

220 dp-8032/8025 2008 ver.1.2 5.2.7.3. Service alert report format explanation of contents (1) customer id (2) firmware version (3) counter information (4) print error last 30 records (latest on top) (5) serial number *************************************************** date mmm-dd-yyyy ***** time 03...

Page 221

221 dp-8032/8025 2008 ver. 1.2 5.2.7.4. Maintenance alert report format explanation of contents (1) low toner message (fixed) “machine is running out of toner” (2) customer id up to 16 characters (user identification code) (3) firmware version (4) transmission / reception / copy / print counters (5)...

Page 222

222 dp-8032/8025 2008 ver.1.2 5.2.7.5. Toner order form explanation of contents (1) low toner message (fixed) “the toner supply in your machine is running low” (2) dealer name up to 25 digits (3) toner order tel # up to 36 digits (4) toner order fax # up to 36 digits (5) customer id up to 16 charact...

Page 223

223 dp-8032/8025 2008 ver. 1.2 5.2.7.6. Call counter report explanation of contents (1) customer id (2) firmware version (3) counter information (4) call counter pre-set value (5) serial number *************************************************** date mmm-dd-yyyy ***** time 03:47 ******** ***********...

Page 224

224 dp-8032/8025 2008 ver.1.2 5.2.8. Service mode 9 (system maintenance) 5.2.8.1. Overview this service mode is used to maintain the machine. Use the following procedure for system maintenance. Select the “09 system maintenance” on the touch panel display. ↓ select the “01 send rcv’d file”. The disp...

Page 225: 6 System Description

225 dp-8032/8025 2008 ver. 1.2 6 system description 6.1. Printing process exit paper feed toner photo electric conversion (+dc) (gnd) developer transfer separation cleaning discharge lamp (led) charger laser exposure fusing opc drum adu (-dc) magnetic roller primary charge: drum surface approximatel...

Page 226

226 dp-8032/8025 2008 ver.1.2 6.2. Precaution with consumables (1) photoreceptor (opc) drum • exercise caution not to scratch the surface of the opc drum (green), and not to touch it with bare hands. • be careful not to smear the surface with saliva, water, oil, etc. • do not store in places where t...

Page 227

227 dp-8032/8025 2008 ver. 1.2 6.3. New image stabilizing technology to improve the copy quality, a new toner density controller (quantum ii system) is developed. The most important aim was to stabilize the toner density under various office environments. Up to now, the control method was controlled...

Page 228

228 dp-8032/8025 2008 ver.1.2 3. Control method 4. Quantum adjustment compensation values after dp-8032 / 8025 adjustment reference for dp-8060 / 8045 / 8035 f5-25 quantum on f6-80: quantum exposure voltage f6-81: quantum bias dc voltage f6-82: quantum charge voltage print density data print density...

Page 229

229 dp-8032/8025 2008 ver. 1.2 5. Installing / replacing developer 6. Installing / replacing opc drum & sensor replacement 7. Service parameters for copy image compensation after f8-09 => f6-21: tdc gain voltage (0.1% / step) f6-26: tdc judgement level + tdc adjustment quantum control f8-09 toner de...

Page 230

230 dp-8032/8025 2008 ver.1.2 6.4. Mechanical operation 6.4.1. Scanning mechanism (flatbed) 1. Scanning mechanism the scanning mechanism consisting of lens, ccd pcb assy (207), mirrors, xenon lamp (204), lamp base bracket (224) and mirror 2 bracket (233), is used to scan originals. • the mirror 1 (2...

Page 231

231 dp-8032/8025 2008 ver. 1.2 detection sensor (270) stepping motor (201) when scanning originals when returning to standby position drive shaft (256) lamp base bracket (224) rear mirror clamp (235) rear lamp belt lock (226) mirror 2 bracket (233).

Page 232

232 dp-8032/8025 2008 ver.1.2 6.5. Automatic document feeder the adf (automatic document feeder) automatically feeds paper into the unit, one original at a time. Its main features are: 1. Place originals face-up 2. Correct order stacking (collation mode) 3. Paper feed mechanism with pre-feed roller ...

Page 233

233 dp-8032/8025 2008 ver. 1.2 mark on the front of the original after the document is successfully transmitted or stored. It consists of the stamp head (1636) and stamp solenoid (1635). The exit roller (1751) feeds and ejects the original out of the adf. If there are additional originals on the adf...

Page 234

234 dp-8032/8025 2008 ver.1.2 side of the original. After the back side is scanned, the original is transported through the duplex 2 guide, through the inverting 1 guide and is carried beyond the inverting feed roller and lower pinch rollers (1838) this time, into the sub tray, again stopping 10 to ...

Page 235

235 dp-8032/8025 2008 ver. 1.2 6.6. Receive mechanism 6.6.1. Paper feed modules 1. Paper feed module (1st/2nd/3rd/4th) a. The np actuators (1133) attached to the paper feed blocks no.1, 2, 3 and 4 determine if there is paper in the paper tray. B. The paper in the paper tray lifts up the np actuator,...

Page 236

236 dp-8032/8025 2008 ver.1.2 a. When the printing operation begins, the main motor (907) starts driving the gears. B. The clutch (1105) is energized for a specified period of time and turns on. This activates the paper feed roller (1144). The paper is separated into individual sheets by the c25 gea...

Page 237

237 dp-8032/8025 2008 ver. 1.2 a. When the printing operation begins, the main motor (907) and the drive motor (2402) start driving the gears. B. The clutch (1105) is energized for a specified period of time and turns on. This activates the paper feed roller (1144). The paper is separated into indiv...

Page 238

238 dp-8032/8025 2008 ver.1.2 a. When inserting the paper tray into the machine, the np sensor (1045) activates. At the same time, the lift plate (2009) is combined with the coupling which drives the lift plate of the machine. The lift plate rotates, lifting the bottom plate (2008) and the recording...

Page 239

239 dp-8032/8025 2008 ver. 1.2 a. The recording paper size in the paper feed module is set on the touch panel. 2. Sheet bypass a. The np actuator attached to the paper feed unit determines if there is paper in the paper tray. B. The paper in the paper tray lowers the np actuator and the np sensor (1...

Page 240

240 dp-8032/8025 2008 ver.1.2 c. The paper is transported to the registration roller (1121), activating the registration sensor (1045). D. After a specified period of time, the clutch (1105) is turned on and the registration roller (1121) and the registration pinch roller start rotating. The paper i...

Page 241

241 dp-8032/8025 2008 ver. 1.2 6. F- θ lens this amorphous plastic, molded lens is designed to provide parallel laser light across the surface of the drum, providing a constant scanning speed. 7. Cover glass this prevents a particle of dust invading into the lsu. 6.6.3. Fuser operation the paper pas...

Page 242

242 dp-8032/8025 2008 ver.1.2 this converted pfa tube silicon rubber roller applies pressure to the fuser roller, assisting in bonding the toner to the paper. Cleaning web roller (1083) the cleaning web roller (1083) is installed in the fuser unit, which keeps cleaning the surface of the fuser rolle...

Page 243: 7 Installation

243 dp-8032/8025 2008 ver. 1.2 7 installation 7.1. Precautions during set up before you begin the installation, read these entire instructions. You must locate an appropriate site (firm, and leveled surface) for the installation. Reading this section assists you with the decision making process. Mac...

Page 244

244 dp-8032/8025 2008 ver.1.2 space requirements for copier, and options main unit + finisher main unit + outer exit tray main unit 27.83 in (707 mm) 27.83 in (707 mm) 14.92 in (379 mm) 14.92 in (379 mm) 3.94 in (100 mm) 3.94 in (100 mm) 10.83 in (275 mm) 14.84 in (377 mm) 9.88 in (251 mm) 3.46 in (...

Page 245

245 dp-8032/8025 2008 ver. 1.2 7.2. Unpacking visually check the condition and contents of the box for completeness, or for any shipping damage before starting with the installation. Remove all tapes, and the packing materials used to secure the units during shipment. After unpacking the product, di...

Page 246

246 dp-8032/8025 2008 ver.1.2 7.3. Installation procedure caution: 1. Refer to each individual installation instructions when installing stands, or other options. 2. The following machine illustrations/lcd/firmware, depict a sample unit with the usa/canadian standard configuration, in details may di...

Page 247

247 dp-8032/8025 2008 ver. 1.2 note: to release the handle, pushing the release latch toward the machine, pull out then lift up the handle into the machine. (3) open the right front handle cover, and swing the handle downwards to lock it in place. Note: to release the handle, pushing the release lat...

Page 248

248 dp-8032/8025 2008 ver.1.2 note: to release the handle, pushing the release latch toward the machine, push down the handle into the machine. (5) lift, and place the machine on a suitable stand / paper tray, aligning with front, and side covers. Deluxe stand:(da1d320 / da1d310/da1d230) usa only pa...

Page 249

249 dp-8032/8025 2008 ver. 1.2 (15) open the 1st paper tray. (16) store the shipping metal bracket, and the blue screw into the space provided in the 1st paper tray. (17) close the 1st paper tray. (18) open the right cover. (19) to unlock the pressure roller, using a stubby phillips screwdriver, tig...

Page 250

250 dp-8032/8025 2008 ver.1.2 (28) carefully remove the packing tape and protective sheet from the opc drum assembly. (29) turn the opc drum assembly in the direction of the arrow, and remove. Caution: exercise caution not to scratch the surface of the opc drum (green), and not to touch it with bare...

Page 251

251 dp-8032/8025 2008 ver. 1.2 note: before installing the process unit into the machine, ensure that the shutter's alignment guide is positioned as illustrated. (37) open the front cover wide. (38) remove 1 screw. (39) remove the connector cover (clear blue). (40) install the process unit. Caution:...

Page 252

252 dp-8032/8025 2008 ver.1.2 caution: exercise caution not to scratch the surface of the opc drum (green), and not to touch it with bare hands. (41) fasten the process unit with 1 screw. (42) connect the harness, and reinstall the connector cover and 1 screw. Caution: when reconnect the harness, ma...

Page 253