- DL manuals

- Panasonic

- Amplifier

- MINAS-BL GP series

- Instructions Manual

Panasonic MINAS-BL GP series Instructions Manual

• Thank you very much for your

purchase of Panasonic product.

• Please read this instruction

manual carefully for proper use.

• In particular, be sure to read

Safety precautions (P.2 to 5)

before use for safety.

• Keep this manual with care after

reading, and read as necessary.

Technical Instructions (Overall)

MINAS-BL GP series

Be sure to give this Instruction manual to an end user.

Safety precautions ......................................2

Introduction .................................................6

Checking the model ....................................6

Name of part ...............................................8

Installation ..................................................9

Caution .....................................................11

System configuration and wiring...............12

Wiring .......................................................14

How to use Digital key pad (option) ..........18

Test run .....................................................26

Checking load and use condition ................28

Assembling of gear head ..........................30

Maintenance/ inspections .........................31

Protective functions ..................................32

Parameter .................................................38

List of parameters .....................................46

Detail of parameters .................................47

Outline of PANATERM for BL ...................59

Example setting of motion pattern ............60

Communication.........................................68

Conformance to EC directive and UL standard ...92

Specifications ...........................................96

Options ...................................................102

List of peripheral equipments .................108

Cautions for proper use ..........................109

After-sale service (Repair) .........Back cover

page

page

• Label of safety precaution is affixed to the product.

・

This product is for industrial

equipment. Don't use this

product at general household.

Summary of MINAS-BL GP series

Page 1

• thank you very much for your purchase of panasonic product. • please read this instruction manual carefully for proper use. • in particular, be sure to read safety precautions (p.2 to 5) before use for safety. • keep this manual with care after reading, and read as necessary. Technical instruction...

Page 2: Danger

- 3 - - 2 - danger do not touch the rotating part of the motor while operating. The failure could result in injuries. Ground the earth of the brushless motor and brushless amplifier. The failure could result in electric shocks. Do not expose the cables to sharp objects, excessive pressing or pinchin...

Page 3: Caution

- 5 - - 4 - caution do not subject the brushless amplifier, motor or shaft to high impact. The failure could result in malfunction. If trip occurs, remove the causes of the trip and secure the safety before restarting. The failure could result in injuries. Execute the trial-operations with the motor...

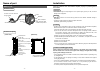

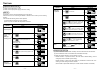

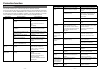

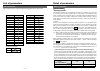

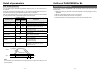

Page 4: After Unpacking

- 6 - - 7 - model no. Voltage input output phase f.L.C freq. Power 200-240v 1ø/3ø 1.5a/0.7a 50/60hz 0-240v 3ø 0.8a 0-267hz 130w ser.No. P12120001 brushless amplifier mbeg1e5bcv made in china 20121201 合格 model no. Input/output voltage input/output phase rated input/output current input/output frequen...

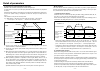

Page 5: Name of Part

- 9 - - 8 - safety precaution label is affixed to the product. Connector for motor cable and cs signal cable ground terminal oil seal output shaft safety precaution label is affixed to the product. O-ring (not provided on a round shaft model) motor nameplate bracket b frame [front view] [side view] ...

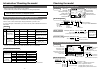

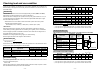

Page 6: Installation

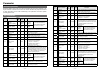

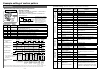

- 11 - - 10 - installation environmental condition item condition ambient temperature brushless motor –10 ℃ to 40 ℃ (free from freezing) *1 brushless amplifier 0 ℃ to 50 ℃ (free from freezing) *1 digital key pad (option) ambient humidity 20% to 85% rh (free from condensation) storage temperature at ...

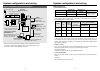

Page 7: Wiring Equipment

- 13 - - 12 - digital key pad connecting cable (option) connector for ser. It cannot be used simultaneously. Digital key pad (option) digital display console. It enables change of parameter. (refer to p.18) rs485 communication software panaterm for bl please download from our web site change of para...

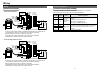

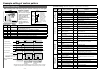

Page 8: Wiring

- 15 - - 14 - wiring brushless amplifier • in case of 3-phase 200 v power supply input l1 l2 l3 1 5 6 10 be sure to ground the grounding terminal. Mccb molded case ( circuit breaker ) in wiring to power supply (outside of equipment) from mccb, use an electric wire of 1.6 mm diameter (2.0 mm 2 ) or m...

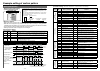

Page 9: Wiring

- 17 - - 16 - wiring photo-coupler internal power supply (+5 v) i 1, i 2, i 3, i 4 gnd gnd 01, 02 vce max dc30 v ic max 50 ma 1 kΩ input circuit output circuit connector for motor connection (motor) connector on amplifier side: parts no. 5569-08a1-210 (molex inc.) or equivalent. (mating connector: h...

Page 10: Using The Digital Key Pad

- 19 - - 18 - how to use digital key pad (option) function of digital key pad • monitoring of rotation speed (actual speed) and load factor, etc. • display detail of trip, and trip history. Trip reset by pressing and . • parameter setting, initialization, and copying function. • teaching function (t...

Page 11: Monitor Mode

- 21 - - 20 - how to use digital key pad (option) • trip can be reset by pressing and switch at the same time. Display shifts to monitor screen after resetting. • shifts to parameter number made when switch is pressed. Monitor mode parameter number mode trip detail display mode parameter setting mod...

Page 12: Point Number Mode

- 23 - - 22 - how to use digital key pad (option) monitor mode hold down for 4 seconds. Mode [caution] • in teaching mode, displayed present position is set as target position. • set the point coordinate setting to absolute travel. (pr02, 0a, 12, and 1a). When the point coordinate setting is set to ...

Page 13: Parameter Copy Function

- 25 - - 24 - how to use digital key pad (option) parameter copy function parameter copy function (digital key pad ←→ brushless amplifier) can be used by pr77. • initializing the data of the digital key pad eeprom installed onboard the digital key pad is initialized (data cleared). When reading is d...

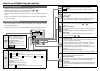

Page 14: Test Run

- 27 - - 26 - test run description of operation 1.Turn on power 2.Set the action pr4e setting of ( teaching speed ) 3.Return to monitor mode. Operation panel switch led display press press and choose parameter 4e (teaching speed). (initial setting: 50) press press and change the teaching speed to 30...

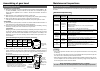

Page 15: Standard Life

- 29 - - 28 - checking load and use condition check the use condition for extended use of the product. Particular use conditions may lead to heating or damage to the shaft. Fully check use conditions, and use the motor in a permissible range. Standard life standard life is 10,000 hours for the motor...

Page 16: Assembling of Gear Head

- 31 - - 30 - assembling of gear head assembling of gear head • preparation for assembling [1] gear head applicable to the motor described in this instruction manual is mb8g □ bv (for 50w) and mb9g □ bv (for 90 w and 130 w). Never use a combination of gear heads other than applicable ones. Failure t...

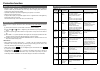

Page 17: What Is Protective Function?

- 33 - - 32 - what is protective function? • brushless motors, brushless amplifier minas-bl gp series have various protective functions. When they are activated, the motor stops under a tripping state, which turns off (opens) trip output. (factory default) • trip detail is displayed only when the di...

Page 18: Protective Function

- 35 - - 34 - display on the digital key pad trip number (rs485) protective function causes countermeasure 8 * overcurrent error (e-oc) the motor trips when the motor current exceeds specified current. [1] excessive acceleration/ deceleration setting is pos- sible. Set longer accelera- tion/ deceler...

Page 19: Protective Function

- 37 - - 36 - protective function troubleshooting if any trouble should be found, follow the steps below to determine the fault. If you cannot find out the cause, we recommend that you use the digital key pad (option) or communication software “panaterm for bl” (download from our web site) to check ...

Page 20: Parameter

- 39 - - 38 - parameter overview of parameter brushless amplifier of this series has various parameters that are used for adjusting or set- ting the features or functions of the motor. This section describes the purpose and function of these parameters. Ensure a full understanding of the parameters ...

Page 21: Parameter

- 41 - - 40 - parameter parameter no. (pr □□ ) name of parameter effective after power resetting setting range default description 1b the 4th point the 4th setting speed 0 to 4000 2000 you can set the speed moving to the 4th point. Setting unit [r/min] 1c the 4th acceleration time 1 to 30000 200 you...

Page 22: Parameter

- 43 - - 42 - parameter parameter no. (pr □□ ) name of parameter effective after power resetting setting range default description 37 gain switching time 0 to 10000 50 when the gain switching mode is set to auto- matic switching, after the output of instruc- tion, the 2nd gain (in running) changes t...

Page 23: Parameter

- 45 - - 44 - parameter no. (pr □□ ) name of parameter effective after power resetting setting range default description 50 i 1 function selection ○ 0 to 15 8 you can assign functions to i1 through i 4. 0: forced trip 1: instantaneous stop, 2: deceleration stop 3: homing start*, 4: forward jog* 5: r...

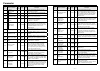

Page 24: List of Parameters

- 47 - - 46 - list of parameters detail of parameters list of parameters figures displayed on the 7 segment display of the digital key pad are shown below. A b c d e f g h i k l n o p q r alphanumeric led display s t u v y 0 1 2 3 4 5 6 7 8 9 alphanumeric led display no • example of led display p.Pr...

Page 25: Detail of Parameters

- 49 - - 48 - detail of parameters [2] sequential run (using sequential run start signal) set pr50 to 53 as follows, and assign the function of signal input. Of signal inputs 1 to 4 ( i 1 to i 4), set the input parameter used for run start at “9” (sequential run start). Positioning point number is i...

Page 26: • Jog Operation

- 51 - - 50 - • jog operation the motor runs in one direction at a specified speed as long as the signal is on. Jog operation is allowed even when homing is not completed. Set pr50 to 53 as follows, and assign the function of signal input. Of signal inputs 1 to 4 ( i 1 to i 4), set the input used fo...

Page 27: • Homing Operation

- 53 - - 52 - (1) change the homing start signal (or run start signal (when pr48 is 2)) from contactoff to the status of connection to gnd (on). It activates operation. Even when homing has been completed, if homing is started, the homing completion signal turns off. (2) make sure that in-motion sig...

Page 28: Detail of Parameters

- 55 - - 54 - detail of parameters e.G. 2: when homing consists of home sensor only. Home sensor mechanical end starting point starting point home home (1) when the starting point is other than home sensor. (2) when the starting point is upon the home sensor. Coordinate system(+) homing direction(−)...

Page 29: Detail of Parameters

- 57 - - 56 - detail of parameters signal input and signal output choosing function • signal input choosing function function can be assigned to signal input i 1 to i 4 by pr50 to 53. Function number assignment function description of function 0 forced trip when preset signal input is turned on, the...

Page 30: Detail of Parameters

- 59 - - 58 - detail of parameters gain switching function you can switch the gain parameter automatically while the motor is in run-command and is at standstill. During the automatic gain switching (pr36 = 2), the 2nd gain is applied while the motor is in runcommand, and the 1st gain is applied whi...

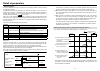

Page 31: Indexing

- 61 - - 60 - example setting of motion pattern indexing (feeding by fixed length) • when feeding by fixed length of travel indexing conveyor • every time i 1 is turned on, the motor runs for fixed travel distance. • homing operation is executed and the home is set when i 1 is turned on just once af...

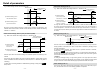

Page 32: Reciprocating

- 63 - - 62 - reciprocating • when executing reciprocating run between fixed positions slider • every time i 1 is turned on, feed action → return action → feed action is repeated in turn. • when power is on, homing operation is executed and home is set by i 1. Coordinate system + direction depends o...

Page 33: Automatic Reciprocating

- 65 - - 64 - automatic reciprocating • when executing fixed reciprocating sequence operation with single run start signal workpiece lifter • when i 1 is turned on, the unit moves to target position (feed position), waits for a specified time, and returns to original position (return position). • wh...

Page 34: Automatic Door

- 67 - - 66 - • coordinate system + direction depends on configuration of gear head and machine. When setting the rotation direction ccw of motor shaft to +, set pr23 at "0", and when setting cw to +, set pr23 at "1". • when setting the mechanical end offset value to –144, the home is the point whic...

Page 35: Communication

- 69 - - 68 - communication communication overview of communication with the upper host controller, which can be connected with 31 brushless amplifiers at the maximum via serial communication conforming to rs485, enables the following: 1. Rewriting parameters 2. Browsing and clearing status and hist...

Page 36: Communication

- 71 - - 70 - communication list of data number related to communications 1) communication parameter address pr no. Parameter name range of setting default function/description 8060h 60 device number 80h(128) to 9fh(159) 81h(129) set the device number of amplifier in com- munication (amplifier id). ...

Page 37: Communication

- 73 - - 72 - communication transmission sequence • handshake code for line control, following codes are used: name code functions description soh 01h heading start start code of communication data, which is followed by address. Stx 02h text start start code for sending command data. Etx 03h text en...

Page 38: Communication

- 75 - - 74 - communication • transmission procedure $p/$s: data writing/parameter writing command (1) host → amplifier (data writing) soh stx $ p * * * * * * * * etx bcc amplifier id host id command data number (parameter address) data (parameter value) (2) amplifier → host (result response) soh ac...

Page 39: Communication

- 77 - - 76 - communication see “$r: data reading/parameter reading command” on p.74. 3. When the status of amplifier changes (1) host → amplifier (request for sending) soh enq amplifier id host id (2) amplifier → host (request of data) soh stx # c 8 1 0 3 * * * * etx bcc host id amplifier id comman...

Page 40: • Example of Trip Reset

- 79 - - 78 - • example of trip reset shown below is communication data in chronological order when executing trip reset. This is an example where trip reset of all amplifiers connected by host id = 01h (1). Data is represented by ascii character. (data in parenthesis is hexadecimal ascii code.) soh...

Page 41: Communication Timing

- 81 - - 80 - communication timing t3 0 to 2 ms t1 or above t1 or above t2 t3 0 to 2 ms t3 0 to 2 ms data transfer eot ack/nak request for sending t3 0 to 2 ms amplifier bus occupied host → amplifier amplifier → host symbol name value t1 communication response time (amplifier) set by pr63. T2 commun...

Page 42: Communication

- 83 - - 82 - • $s: parameter writing command (with eeprom writing function) received data (host → amplifier) soh stx $ s 8 0 p1 p2 p3 p4 etx bcc amplifier id host id command parameter address parameter value • when the device number set on the amplifier (value of pr60) matches with the amplifier id...

Page 43: 8112H: Internal Dc Voltage

- 85 - - 84 - 8112h: internal dc voltage • $r: internal dc voltage reading request command received data (host → amplifier) soh stx $ r 8 1 1 2 0 0 0 0 etx bcc amplifier id host id command data number data value • enter request for sending after execution of this command, the internal dc voltage (vo...

Page 44: Communication

- 87 - - 86 - 8115h: present position (rotation number), 8116h: present position (pulse) • $r: present position reading request command received data (host → amplifier) soh stx $ r 8 1 1 0 0 0 0 etx bcc amplifier id host id command data number data value • enter request for sending after execution o...

Page 45: Communication

- 89 - - 88 - • #r: input terminal status response command transmission data (amplifier → host) soh stx # r 8 1 3 0 d1 d2 d3 d4 etx bcc host id amplifier id command data number data value • when the amplifier receives request for sending after normal completion of input terminal status reading reque...

Page 46: 8190H: Trip Reset

- 91 - - 90 - 8190h: trip reset • $p/$s: trip reset command received data (host → amplifier) soh stx $ p 8 1 9 0 0 0 0 1 etx bcc amplifier id host id command data number data value • when data value is set at ‘0001’ and this command is executed during trip, trip reset is executed. • when data value ...

Page 47: Noise Filter

- 93 - - 92 - configuration of peripheral equipment power supply ・ 100 v system: single phase 100 v to 120 v ± 10%, 50/60 hz 200 v system: single phase 200 v to 240 v ± 10%, 50/60 hz ・ use the equipment under the environment of overvoltage category ii specified by iec60664-1. ・ in order to obtain ov...

Page 48: Surge Absorber

- 95 - - 94 - conformance to ec directive and ul standard • dv0p4190 • dv0p1450 circuit diagram 1 ø4.2±0.2 41±1 ul-1015 awg16 28±1 5.5 ±1 11 ±1 28.5±1 4.5 ±0.5 200 +30 −0 2 3 [unit: mm] circuit diagram ø4.2±0.2 41±1 ul-1015 awg16 28±1 5.5 ±1 11 ±1 28.5±1 4.5 ±0.5 200 +30 −0 1 2 [unit: mm] ① ② ③ ① ② ...

Page 49: Specifications

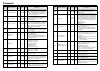

- 97 - - 96 - • brushless amplifier gp series specifications item specifications basic specifications amplifier model no. Mbeg5a1bcp mbeg5a5bcp mbeg9a1bcp mbeg9a5bcp mbeg1e1bcp mbeg1e5bcp applicable motor model no. Mbmu5azab mbmu9a1ab mbmu9a2ab mbmu1e1ab mbmu1e2ab motor rated output (w) 50 90 130 in...

Page 50: Specifications

- 99 - - 98 - mbeg9a1bcp / mbmu9a1 * * mbeg9a5bcp / mbmu9a2 * * mbeg5a1bcp / mbmu5az * * mbeg5a5bcp / mbmu5az * * mbeg1e1bcp / mbmu1e1 * * mbeg1e5bcp / mbmu1e2 * * • speed-torque characteristic torque [n·m] rotation speed [r/min] 4000 3000 2000 1000 0.3 0.2 0.24 0.16 0.24 0.16 (0.12) 0.1 0 torque [n...

Page 51: • Gear Head

- 101 - - 100 - • gear head mb8g□bv dimension in ( ) marked with * indicates dimension with reduction gear ratio 30 or above. • reduction gear ratio in □ • reduction gear ratio is available in 6 types: 5, 10, 15, 20, 30, and 50. • backlash less than 2 ° (design value) key dimension 5 25 0 -0.030 5 0...

Page 52: Options

- 103 - - 102 - options • digital key pad 20 65 55 60 70 2-ø3.5 [unit: mm] dv0p3500 • digital key pad connection cable optional parts number dv0p38310 dv0p38330 dv0p38350 length (l) 1 m 3 m 5 m optional parts number dv0p38310 dv0p38330 dv0p38350 length (l) 1 m 3 m 5 m mounting hole side 65 55 14 ø30...

Page 53: Options

- 105 - - 104 - options optional parts number dv0pm20077 length (l) 2 m [unit: mm] • power cable (single phase 100 v, 200 v) with connector • when supplying 3-phase power source to a 200 v brushless amplifier, use the supplied power cable and connect 2 conductors to l1 and l2. • when supplying 3-pha...

Page 54: Options

- 107 - - 106 - options • reactor fig.1( for 3-phase power supply) fig.2 (for single phase power supply) f: center-to-center distance on slotted hole e f g f a 4-h a b c d 4-h g 4-h e f (mounting pitch) a h f f: center-to-center distance on outer circular arc b a (mounting pitch) 6-i c d optional pa...

Page 55: Options

- 109 - - 108 - options list of peripheral equipments manufacturer tel no. / home page peripheral components tdk corporation +81-3-5201-7229 http://www.Tdk.Co.Jp/ noise filter for signal lines okaya electric industries co. Ltd. +81-3-4544-7040 http://www.Okayatec.Co.Jp/ surge absorber noise filter s...

Page 56: After-Sale Service (Repair)

Ime49 p1212-0 「 © panasonic corporation 2012 」 after-sale service (repair) repair consult to a dealer from whom you have purchased the product for details of repair. When the product is incorporated to the machine or equipment you have purchased, consult to the manufacuter or the dealer of the machi...