- DL manuals

- Panasonic

- Air Conditioner

- S-106ME1E5

- Service Manual

Panasonic S-106ME1E5 Service Manual

REFERENCE NO

.

85464849304005

SERVICE MANUAL

SM830204-05

2WAY VRF SYSTEM

Order No.SBPAC1307002CE

Outdoor Unit

Model No.

ME1

8HP

U-8ME1E81

10HP

U-10ME1E81

16HP

U-16ME1E81

18HP

U-18ME1E81

20HP

U-20ME1E81

12HP

U-12ME1E81

14HP

U-14ME1E81

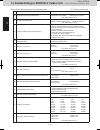

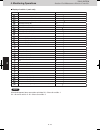

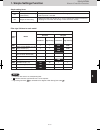

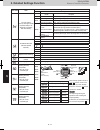

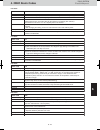

Class

Model Name

Class

73

106

140

224

280

E1

High Static Pressure

Ducted

Indoor Unit

Class

15

22

U1

4-Way Cassette

S-22MU1E5

S-22MU1E51

L1

2-Way Cassette

S-22ML1E5

D1

1-Way Cassette

F1

Low Silhouette Ducted

S-22MF1E5

T1

M1

Ceiling

K1

Wall Mounted

S-22MK1E5

R1

Concealed Floor

Standing

S-22MR1E5

P1

Floor Standing

S-22MP1E5

Y1

4-Way Cassette 60×60

S-22MY1E5

F2

Low Silhouette Ducted

S-22MF2E5

Slim Low Static Ducted

S-22MM1E5

S-15MM1E5

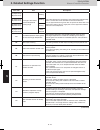

28

S-28MU1E5

S-28MU1E51

S-28ML1E5

S-28MF1E5

S-28MD1E5

S-28MK1E5

S-28MR1E5

S-28MP1E5

S-28MY1E5

S-28MF2E5

S-28MM1E5

36

S-36MU1E5

S-36MU1E51

S-36ML1E5

S-36MF1E5

S-36MD1E5

S-36MK1E5

S-36MR1E5

S-36MP1E5

S-36MY1E5

S-36MF2E5

S-36MM1E5

S-36MT1E5

45

S-45MU1E5

S-45MU1E51

S-45ML1E5

S-45MF1E5

S-45MD1E5

S-45MK1E5

S-45MR1E5

S-45MP1E5

S-45MY1E5

S-45MF2E5

S-45MM1E5

S-45MT1E5

56

S-56MU1E5

S-56MU1E51

S-56ML1E5

S-56MF1E5

S-56MD1E5

S-56MK1E5

S-56MR1E5

S-56MP1E5

S-73ME1E5

S-106ME1E5 S-140ME1E5 S-224ME1E5

S-224ME1E5A S-280ME1E5

S-56MY1E5

S-56MF2E5

S-56MM1E5

S-56MT1E5

60

S-60MU1E51

S-60MF2E5

73

S-73MU1E5

S-73MU1E51

S-73ML1E5

S-73MF1E5

S-73MD1E5

S-73MK1E5

S-71MR1E5

S-71MP1E5

S-73MF2E5

S-73MT1E5

90

S-90MU1E51

S-90MF1E5

S-90MF2E5

106

S-106MU1E5

S-106MU1E51

S-106MF1E5

S-106MK1E5

S-106MF2E5

S-106MT1E5

140

S-140MU1E5

S-140MU1E51

S-140MF1E5

S-140MF2E5

S-140MT1E5

160

S-160MU1E5

S-160MU1E51

S-160MF1E5

K2

Wall Mounted

S-22MK2E5

S-28MK2E5

S-36MK2E5

Y2

4-Way Cassette 60×60

S-22MY2E5

S-28MY2E5

S-36MY2E5

S-45MY2E5

S-56MY2E5

S-160MF2E5

SM830204-05_2WAY SYS_new.indb 1

15/01/05 11:56:42

Summary of S-106ME1E5

Page 1

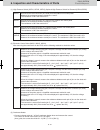

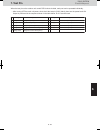

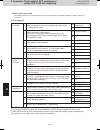

Reference no . 85464849304005 service manual sm830204-05 2way vrf system order no.Sbpac1307002ce outdoor unit model no. Me1 8hp u-8me1e81 10hp u-10me1e81 16hp u-16me1e81 18hp u-18me1e81 20hp u-20me1e81 12hp u-12me1e81 14hp u-14me1e81 class model name class 73 106 140 224 280 e1 high static pressure ...

Page 2

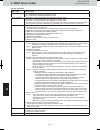

I i important! Please read before starting this air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently. For safe installation and trouble-free ...

Page 3

Ii i important! Please read before starting this air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently. For safe installation and trouble-free...

Page 4

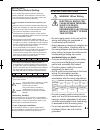

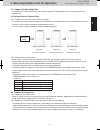

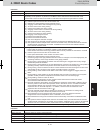

Iii 2. The standards for minimum room volume are as follows. (1) no partition (shaded portion) (2) when there is an effective opening with the adjacent room for ventilation of leaking refrigerant gas (opening without a door, or an opening 0.15% or larger than the respective floor spaces at the top o...

Page 5

Iv 2. The standards for minimum room volume are as follows. (1) no partition (shaded portion) (2) when there is an effective opening with the adjacent room for ventilation of leaking refrigerant gas (opening without a door, or an opening 0.15% or larger than the respective floor spaces at the top or...

Page 6

V precautions for installation using new refrigerant 1. Care regarding tubing 1-1. Process tubing ● material: use c1220 phosphorous deoxidized copper specified in jis h3300 “copper and copper alloy seamless pipes and tubes.” for tubes of ø22.22 or larger, use c1220 t-1/2h material or h material, and...

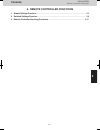

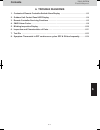

Page 7: Contents —

Precautions for installation using new refrigerant 1. Care regarding tubing 1-1. Process tubing ● material: use c1220 phosphorous deoxidized copper specified in jis h3300 “copper and copper alloy seamless pipes and tubes.” for tubes of ø22.22 or larger, use c1220 t-1/2h material or h material, and d...

Page 8

Vii section 4: outdoor unit maintenance remote controller . . . . . . . . . . . . 4-1 1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 2. Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9: Contents

1 - 1 2way system control functions-outdoor unit 1 1. Control functions-outdoor unit 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 2. Selecting outdoor unit for operation . . . . . . . . . . . . . . . . . . ....

Page 10: 1. Introduction

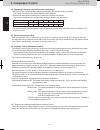

2way system control functions -outdoor unit 1 - 2 1 1. Introduction the 2way system allows multiple outdoor units to be connected. -this system can be expanded to connect a maximum of 3 outdoor units. -the maximum system capacity is 60hp. (at the standard-cop mode) pcb setting of outdoor unit all th...

Page 11

1 - 3 2way system control functions-outdoor unit 1 2. Selecting outdoor unit for operation 2-1. Outdoor unit operating rules all outdoor units in this system contain an inverter compressor. Therefore there is no order of priority for the outdoor units. 2-2. Delayed start of outdoor units 2-2-1. Dela...

Page 12: 3. Compressor Control

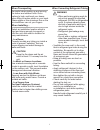

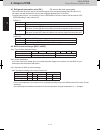

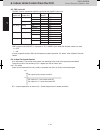

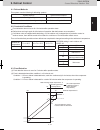

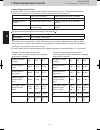

2way system control functions -outdoor unit 1 - 4 1 3. Compressor control 3-1. Compressors mounted in the outdoor units outdoor unit capacity 8 hp 10 hp 12 hp 14 hp 16 hp 18 hp 20 hp installed compressor compressor 1 dc inverter rotary 10 hp 10 hp 6 hp 10 hp 10 hp 10 hp 10 hp compressor 2 constant s...

Page 13: 3. Compressor Control

1 - 5 2way system control functions-outdoor unit 1 3. Compressor control 3-2-5. Operating compressors -cooling operation all the inverter compressors operate when the system starts. The constant speed compressors operate according to those priority orders when the load of air conditioner becomes lar...

Page 14: 3. Compressor Control

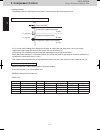

2way system control functions -outdoor unit 1 - 6 1 3. Compressor control 3-4. Operating frequency range of inverter compressor - when one of the constant speed compressor mounted in the outdoor unit do not operate: the inverter compressor can operate between 15hz and 95hz. - when all constant speed...

Page 15: 3. Compressor Control

1 - 7 2way system control functions-outdoor unit 1 3. Compressor control *the evaporation temperature area changes depending on the maximum required level of each indoor unit as shown above. *c area is regarded as b area for 6 minutes after compressor starts. *when the system operates in a minimum c...

Page 16: 3. Compressor Control

2way system control functions -outdoor unit 1 - 8 1 3. Compressor control - heating operation the heating capacity is adjusted with this control. It also prevents abnormal high-pressure. Operation pressure is able to be adjusted for existing old piping. If area shift function is set, values below sh...

Page 17: 3. Compressor Control

1 - 9 2way system control functions-outdoor unit 1 3. Compressor control 1 - 9 2way system control functions-outdoor unit 1 3. Compressor control 3-7. Protection control 3-7-1. Compressor discharge temperature protection discharge temp. The compressor capacity is controlled according to the table be...

Page 18: 3. Compressor Control

2way system control functions -outdoor unit 1 - 10 1 3. Compressor control 1 - 10 1 3-7-4. Primary current protection of hic board the fan motor current is included in primary current. Pcb is protected from the power consumption increase of fan motor when the heat exchanger is blocked by frost, etc....

Page 19: 4. Output of Pcb

1 - 11 2way system control functions-outdoor unit 1 4. Output of pcb indication on pcb remarks item 4-way valve electromagnetic valve save valve refrigerant control valve refrigerant balance valve oil recoverly valve by-pass valve refrigerant interception valve motor operated valve mov for heat exch...

Page 20: 4. Output of Pcb

2way system control functions -outdoor unit 1 - 12 1 4. Output of pcb 4-3. Refrigerant control valve [rcv] the main purpose of this valve is to adjust the flow of refrigerant (refrigerant volume) on the evaporator. When the valve determines that there are signs of a low refrigerant volume, refrigera...

Page 21: 4. Output of Pcb

1 - 13 2way system control functions-outdoor unit 1 4. Output of pcb 4-4. Refrigerant balance valve [rbv] the main purpose of this valve is to adjust the flow of refrigerant (refrigerant volume) in the indoor unit heat exchanger at heating operation. When the valve determines that there are signs of...

Page 22: 4. Output of Pcb

2way system control functions -outdoor unit 1 - 14 1 4. Output of pcb 4-7. Refrigerant interception valve [o2*] *o2 valve is the local supply parts. This valve works when the outdoor unit receives signal of the refrigerant leakage from the indoor unit. The indoor unit that transmits the signal of th...

Page 23: 4. Output of Pcb

1 - 15 2way system control functions-outdoor unit 1 4. Output of pcb 3way system control functions 4. Output of pcb 4-9. Sc circuit electronic control valve [mov4] 4-9-1. Sc control (cooling mode only) during cooling operation, the liquid refrigerant which condenses at the outdoor unit heat exchange...

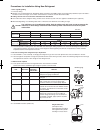

Page 24: 5. Outdoor Fan Control

2way system control functions -outdoor unit 1 - 16 1 5. Outdoor fan control 2way system 5. Outdoor fan control 5-1. No. Of fan motor no. Of fan motor 1 1 1 1 1 1 2 2 outdoor unit capacity 8hp 10hp 12hp 14hp 16hp 18hp 20hp 5-2. Fan mode 5-2-1. High static pressure mode the outdoor unit allows a high ...

Page 25: 5. Outdoor Fan Control

1 - 17 2way system control functions-outdoor unit 1 5. Outdoor fan control 2way system 5. Outdoor fan control 5-1. No. Of fan motor no. Of fan motor 1 1 1 1 1 1 2 2 outdoor unit capacity 8hp 10hp 12hp 14hp 16hp 18hp 20hp 5-2. Fan mode 5-2-1. High static pressure mode the outdoor unit allows a high s...

Page 26: 5. Outdoor Fan Control

2way system control functions -outdoor unit 1 - 18 1 5. Outdoor fan control 5-2-3. Silent mode this unit includes 2 types of silent modes. See the table under the section “5-2. Fan mode” for maximum fan mode in silent mode. Selecting the silent mode results in operation that gives priority to reduci...

Page 27: 5. Outdoor Fan Control

1 - 19 2way system control functions-outdoor unit 1 6. Indoor units control from the ccu some components of indoor unit are under ccu's control. 6-1. Mov of indoor unit 6-1-1. Indoor unit without rap valve kit mode of indoor unit mode of outdoor unit compressor thermostat on/off mov pulse of indoor ...

Page 28

2way system control functions -outdoor unit 1 - 20 1 6. Indoor units control from the ccu 6-2. Rap valve kit the rap valve kit connection might be required on the type e1 indoor unit. Mode of indoor unit mode of outdoor unit compressor thermostat on/off rap valve kit stop cooling stop - off operatio...

Page 29

1 - 21 2way system control functions-outdoor unit 1 6. Indoor units control from the ccu 2way system control functions-outdoor unit 6. Indoor units control from the ccu 6-4. Drain pump control ccu intervenes in drain pump control of the indoor unit according to the setting in eeprom in the outdoor u...

Page 30: 7. Oil Control

2way system control functions -outdoor unit 1 - 22 1 eeprom setting in main outdoor unit code: 2b setting no. Xx 20 20 minutes 30 30 minutes (factory preset mode) 40 40 minutes 50 50 minutes 60 60 minutes * the drain pump always operates when the indoor unit is thermostat on in cooling operation. * ...

Page 31: 7. Oil Control

1 - 23 2way system control functions-outdoor unit 1 7. Oil control 7-2. Oil level detection the compressor oil in the crankcase is sent by bypass via a capillary tube to the low-pressure circuit. The temperature detected by an oil sensor is used to determine whether it is oil (warm) or refrigerant (...

Page 32: 7. Oil Control

2way system control functions -outdoor unit 1 - 24 1 7. Oil control 7-5-2. Simplified flow of system oil recovery control system oil recovery control shall be performed as the flow mentioned below. Normal operation → time before oil recovery 1 minute stop → refrigerant oil recovery control between s...

Page 33: 7. Oil Control

1 - 25 2way system control functions-outdoor unit 1 7. Oil control 7-6. Indoor unit self oil recovery control this control is carried out regularly when the system is in cooling mode. -during stopped, fan or thermostat off condition, indoor unit expansion valve is opened regularly for 1 to 2 min- ut...

Page 34: 9. Defrost Control

2way system control functions -outdoor unit 1 - 26 1 8. 4-way valve adjustment control 8. 4-way valve adjustment control 2way system control functions-outdoor unit this control is to change over the 4-way valve appropriately with big differential pressure. 8-2-1. Whole process 8-2-2. 4-way valve adj...

Page 35: 9. Defrost Control

1 - 27 2way system control functions-outdoor unit 1 9. Defrost control 8. 4-way valve adjustment control 2way system control functions-outdoor unit this control is to change over the 4-way valve appropriately with big differential pressure. 8-2-1. Whole process 8-2-2. 4-way valve adjustment control ...

Page 36: 9. Defrost Control

2way system control functions -outdoor unit 1 - 28 1 9. Defrost control 9. Defrost control 9. Defrost control 2way system control functions-outdoor unit 9-4. Reverse cycle defrost 9-4-1. Start of reverse cycle defrost 9-4-2. Simplified flow of reverse cycle defrost reverse cycle defrost is performed...

Page 37: 9. Defrost Control

1 - 29 2way system control functions-outdoor unit 1 9. Defrost control 9. Defrost control 9. Defrost control 2way system control functions-outdoor unit 9-4. Reverse cycle defrost 9-4-1. Start of reverse cycle defrost 9-4-2. Simplified flow of reverse cycle defrost reverse cycle defrost is performed ...

Page 38: 9. Defrost Control

2way system control functions -outdoor unit 1 - 30 1 9. Defrost control 9. Defrost control 2way system control functions-outdoor unit e c→e e→c s c : evaporator operation *3 only for high static pressure ducted type indoor unit (type e1) : switching from condenser operation to evaporator operation :...

Page 39: 9. Defrost Control

1 - 31 2way system control functions-outdoor unit 1 10. Upper current limitation mode 9. Defrost control 2way system control functions-outdoor unit e c→e e→c s c : evaporator operation *3 only for high static pressure ducted type indoor unit (type e1) : switching from condenser operation to evaporat...

Page 40

2way system control functions -outdoor unit 1 - 32 1 10. Upper current limitation mode 2way system control functions-outdoor unit 10. Upper current limitation mode limit value limited ratio against standard value outdoor unit even if the demand control is not performed, upper current limitation is r...

Page 41: 11. Alarm Information

1 - 33 2way system control functions-outdoor unit 1 11. Alarm information 11-1. Discharge temperature 11-1-1. Discharge temperature protection the upper limit discharge temperature is 106°c for all compressors. When the discharge temperature reaches 106°c, that compressor is stopped and restarted. I...

Page 42: 11. Alarm Information

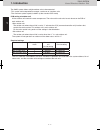

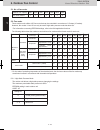

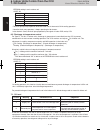

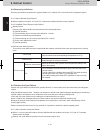

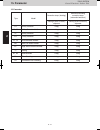

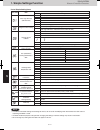

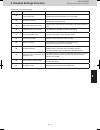

2way system control functions -outdoor unit 1 - 34 1 11. Alarm information 11. Alarm information 2way system control functions-outdoor unit 8 hp 10 hp 12 hp 14 hp 16 hp 18 hp 20 hp 15.1 19.8 18.0 21.0 21.0 21.0 21.0 19.6 21.8 17.6 21.0 22.5 21.0 21.0 primary current outdoor unit description compress...

Page 43: 11. Alarm Information

1 - 35 2way system control functions-outdoor unit 1 11. Alarm information 11. Alarm information 2way system control functions-outdoor unit 8 hp 10 hp 12 hp 14 hp 16 hp 18 hp 20 hp 15.1 19.8 18.0 21.0 21.0 21.0 21.0 19.6 21.8 17.6 21.0 22.5 21.0 21.0 primary current outdoor unit description compresso...

Page 44: 11. Alarm Information

2way system control functions -outdoor unit 1 - 36 1 11. Alarm information 11-5. 4-way valve failure if the maximum heat exchanger temperature of the outdoor unit that operates heating mode is 20°c or higher than the ambient temperature and this condition continues for 15 minutes, it is possible tha...

Page 45: 12. Backup Operation

1 - 37 2way system control functions-outdoor unit 1 12. Backup operation 12. Backup operation this system includes a function for automatic backup operation. An alarm is displayed on the remote controller to inform the user that a failure has occurred. When the following alarm occurs, automatic back...

Page 46: 12. Backup Operation

2way system control functions -outdoor unit 1 - 38 1 12. Backup operation 12. Backup operation 2way system control functions-outdoor unit * backup operation caused by an alarm listed in “alarm list 2” will finish automatically after 24 hours if the same alarm does not occur again for 24 hours. A : w...

Page 47: 12. Backup Operation

1 - 39 2way system control functions-outdoor unit 1 12. Backup operation 12-1-2. Start of automatic backup operation if the above alarms occur, the alarm is displayed on the remote controller, etc. Pressing the remote contoller button again starts automatic backup mode. 12-1-3. Backup operation info...

Page 48: 12. Backup Operation

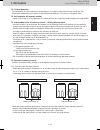

2way system control functions -outdoor unit 1 - 40 1 12. Backup operation all compressors of sub outdoor unit are backed up unit no. 1 main unit ccu function unit no. 2 sub unit unit no. 3 sub unit main outdoor unit sub outdoor unit sub outdoor unit number of setting 2 not necessary not necessary un...

Page 49: 13. Other Functions

1 - 41 2way system control functions-outdoor unit 1 13. Other functions 13. Other functions 13-1. Maintenance function for power supply stop of indoor unit. (e06 ignore) the system can continue operation even if outdoor unit cannot communicate with some indoor units. It is necessary to set to eeprom...

Page 50: 13. Other Functions

2way system control functions -outdoor unit 1 - 42 1 13. Other functions 1 - 40 1 13-2. Auto change over function it is able to select auto mode in each remote controller even in 2way system. The system switches the mode cooling/heating according to number of thermo on mode. The system selects the m...

Page 51: 13. Other Functions

1 - 43 2way system control functions-outdoor unit 1 13. Other functions 1 - 41 1 2way system control functions-outdoor unit 13. Other functions 13-3-3. Outdoor unit pcb led indications in judgment mode when judgment mode is not engaged, the led indicates the normal display (off), or else indicates a...

Page 52

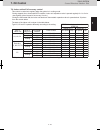

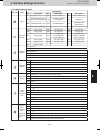

2way system control functions -outdoor unit 1 - 44 1 14. Detailed settings in eeprom of outdoor unit 3way system control functions 14. Detail setting in eeprom of outdoor unit dn item setting no. 04 operation for using snowfall sensor 0=no sensor & control (p) 1=sensor & control 2=no sensor & no con...

Page 53

1 - 45 2way system control functions-outdoor unit 1 14. Detailed settings in eeprom of outdoor unit 3way system control functions 14. Detail setting in eeprom of outdoor unit dn item setting no. 04 operation for using snowfall sensor 0=no sensor & control (p) 1=sensor & control 2=no sensor & no cont...

Page 54: – Memo –

– memo – 1 - 46 sm830204-05_2way sys.Indb 46 2015/01/21 17:00:06.

Page 55: Contents

2 - 1 2way system control functions - indoor unit 2 2. Control functions-indoor unit 1. Room temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 2. Heating standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 56

2way system control functions - indoor unit 2 - 2 2 1. Room temperature control 1. Room temperature control the body sensor or remote controller sensor detects temperature in the room. The detected temperature is called the room temperature. The body sensor is the one contained in the indoor unit. B...

Page 57

2 - 3 2way system control functions - indoor unit 2 1. Room temperature control remote controller sensor is enabled set temp. In remote controller 28℃ 28℃ 28℃ detected temp. By sensor 30.0℃ 27.5℃ 27.0℃ detected temp. By body sensor 30.0℃ 27.5℃ 27.0℃ detected temp. By remote controller sensor 30.0℃ 2...

Page 58: 2. Heating Standby

2way system control functions - indoor unit 2 - 4 2 2. Heating standby 2. Heating standby in heating mode, the indoor fan speed decreases to prevent cold air discharge from the indoor unit. During this time, (heating standby) is displayed on the remote controller. ① this condition occurs in the foll...

Page 59

2 - 5 2way system control functions - indoor unit 2 3. Automatic fan speed control 3. Automatic fan speed control ① the indoor fan mode is controlled as shown below during the automatic fan mode. ② the fan mode does not change for 3 minutes during cooling operation and 1 minute during heating operat...

Page 60: 4. Indoor Unit Mov Control

2way system control functions - indoor unit 2 - 6 2 4. Indoor unit mov control for details, refer to the section 1 "6. Indoor unit control from the ccu". The mov is at 480 pulses in the following cases. ① at the time of factory shipment ② just after the indoor unit power cord is connected. 5. Drain ...

Page 61

2 - 7 2way system control functions - indoor unit 2 6. Automatic heating/cooling control 6. Automatic heating/cooling control ① the operating mode is selected according to the set temperature and room temperature when the operation is started. Room temperature > set temperature in remote controller ...

Page 62: 8. Rap Valve Kit Control

2way system control functions - indoor unit 2 - 8 2 7. Discharge air temperature control discharge air temperature is controlled using the indoor unit discharge air temperature sensor. The discharge air temperature is set in the eeprom on the pcb. The setting is different depending on the model. Dis...

Page 63: 9. Automatic Flap Control

2 - 9 2way system control functions - indoor unit 2 9. Automatic flap control 10. Filter sign 9. Automatic flap control the flap position can be selected from 5 positions. Operating mode flap position cooling/dry f1 ・f2・f3 fan f1 ・f2・f3・f4・f5 heating f1 ・f2・f3・f4・f5 ① the flap moves to the following...

Page 64: 11. Electric Heater Control

2way system control functions - indoor unit 2 - 10 2 11. Electric heater control 12. Fan control during dry mode 11. Electric heater control the electric heater control is performed when an electric heater is installed with the indoor unit. The heater turns on when all of the following conditions (1...

Page 65: 13. Ventilation Fan Output

2 - 11 2way system control functions - indoor unit 2 13. Ventilation fan output 14. T10 terminal 13. Ventilation fan output the out put of ventilation turns on when the indoor unit turns on. Also, when the indoor unit turns off, the output of the ventilation turns off. The ventilation fan can also b...

Page 66: 15. Parameter

2way system control functions - indoor unit 2 - 12 2 15. Parameter 15. Parameter type model correction temp. (heating) heat/cool switching correction temp. (automatic heat/cool) setting at time of factory shipment setting at time of factory shipment u1 4-way cassette 4 deg 2 deg y1, y2 4-way cassett...

Page 67: Contents

3 - 1 2way system outdoor unit repair procedures 3 3. Outdoor unit repair procedures 1. Removing panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 2. Discharging compressor oil . . . . . . . . . . . . . . . . . . . . . . . . . . ...

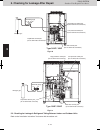

Page 68: 1. Removing Panels

3 - 2 2way system outdoor unit repair procedures 3 1. Removing panels (1) front panel removal (fig. 1) • remove the front panel. Be sure to turn off the power before maintenance. When the power is turned off, wait for 5 minutes without any work. Then start working. Caution power outlet panel tubing ...

Page 69

3 - 3 2way system outdoor unit repair procedures 3 2. Discharging compressor oil discharged oil can be used for checking the condition of the system. Based on the appearance and color of the discharged oil, a judgment can be made on whether the system is operating normally or not. 2-1. Discharging o...

Page 70

3 - 4 2way system outdoor unit repair procedures 3 2. Discharging compressor oil high-pressure outlet port (for ø7.94mm-dia connector) low-pressure outlet port (for ø7.94mm-dia connector) liquid tube service port (for ø7.94mm-dia connector) gas tube service port (for ø7.94mm-dia connector) type 12hp...

Page 71

3 - 5 2way system outdoor unit repair procedures 3 2. Discharging compressor oil 2-2. Discharging oil in compressor recover the refrigerant in the outdoor unit following the procedures in “4. Recovering refrigerant.” remove the compressor and discharge the oil in it. Refer to “9. Compressor” for det...

Page 72: 3. Backup Operation

3 - 6 2way system outdoor unit repair procedures 3 3. Backup operation this system includes an emergency automatic backup function that allows the a/c to operate during the period after trouble occurs until repairs are made. However, during repair and at other times, use manual backup operation. 3-1...

Page 73: 3. Backup Operation

3 - 7 2way system outdoor unit repair procedures 3 3. Backup operation after recovery work is completed, wire the communication lines between indoor and outdoor units again. If it not finished yet, an alarm is emitted immediately. Caution (2) adjusting the refrigerant for backup operation during bac...

Page 74: 4. Recovering Refrigerant

3 - 8 2way system outdoor unit repair procedures 3 4. Recovering refrigerant the following equipment and tools are required: jumper wire with clips, adjustable wrench, set of manifold gauge valves specially designed for refrigerant r410a only, vacuum pump, refrigerant recovery unit, pre-purged refri...

Page 75: 4. Recovering Refrigerant

3 - 9 2way system outdoor unit repair procedures 3 4. Recovering refrigerant high-pressure outlet port (for ø7.94mm-dia connector) liquid tube service port (for ø7.94mm-dia connector) gas tube service port (for ø7.94mm-dia connector) type 14hp / 16hp refrigerant recovery cylinder refrigerant recover...

Page 76: 4. Recovering Refrigerant

3 - 10 2way system outdoor unit repair procedures 3 4. Recovering refrigerant 4-2. Refrigerant recovery procedures (indoor unit) the flowchart below shows the refrigerant recovery procedures you must follow when replacing or repairing the indoor unit due to trouble in the refrigerant circuit. Start ...

Page 77: 4. Recovering Refrigerant

3 - 11 2way system outdoor unit repair procedures 3 4. Recovering refrigerant (2) if the remote controller (cz-rtc2) is not available for maintenance of the outdoor unit 1 determine the outdoor unit where the unit no. Setting (sw5) (3p dip switch) (blue) on the outdoor unit control pcb is set to no....

Page 78: 4. Recovering Refrigerant

3 - 12 2way system outdoor unit repair procedures 3 4. Recovering refrigerant 4-2-3. Refrigerant recovery procedures (2): indoor unit with no ball valve equipped refrigerant in all indoor units and the refrigerant tubing circuit can be pumped into the outdoor unit. The maximum refrigerant storage ca...

Page 79: 4. Recovering Refrigerant

3 - 13 2way system outdoor unit repair procedures 3 4. Recovering refrigerant high-pressure outlet port (for ø7.94mm-dia connector) low-pressure outlet port (for ø7.94mm-dia connector) gas tube service port (for ø7.94mm-dia connector) type 8hp / 10hp / 12hp refrigerant recovery cylinder lo hi manifo...

Page 80: 4. Recovering Refrigerant

3 - 14 2way system outdoor unit repair procedures 3 4. Recovering refrigerant 4-3. Recovery of refrigerant from entire system (1) turn off power to the entire outdoor system. (2) short-circuit the ap (air purge) pins (cn24) on the outdoor control pcb of all outdoor units, then supply power to the ou...

Page 81

3 - 15 2way system outdoor unit repair procedures 3 5. Checking for leakage after repair 5-1. Pressure check for leakage of outdoor unit after completing repair of the outdoor unit, carry out the following leakage check. (1) check that all service valves for gas tubes, liquid tube, and balance tube ...

Page 82

3 - 16 2way system outdoor unit repair procedures 3 5. Checking for leakage after repair 5-2. Checking for leakage in refrigerant tubing between indoor and outdoor units refer to the “installation instructions” that came with the outdoor unit. High-pressure outlet port (for ø7.94mm-dia connector) lo...

Page 83: 6. Evacuating System

3 - 17 2way system outdoor unit repair procedures 3 6. Evacuating system this procedure is carried out to ensure there is no remaining refrigerant or other gases (nitrogen, etc.) in the repaired outdoor unit and tubing. 6-1. Evacuating repaired outdoor unit (1) check that each service valve of the g...

Page 84: 6. Evacuating System

3 - 18 2way system outdoor unit repair procedures 3 6. Evacuating system 6-2. Evacuating refrigerant tubing between indoor and outdoor units refer to the “installation instructions” that came with the outdoor unit. Fig. 7-c high-pressure outlet port (for ø7.94mm-dia connector) low-pressure outlet po...

Page 85: 7. Charging Compressor Oil

3 - 19 2way system outdoor unit repair procedures 3 7. Charging compressor oil (dpr : cv6230817937) nipple packless valve (receiver-tank: cv6380152988) fig. 8 7-1. If refrigerant has already been charged to outdoor unit be sure to use an exclusive oil-charging tank for charging compressor oil. Prior...

Page 86: 7. Charging Compressor Oil

3 - 20 2way system outdoor unit repair procedures 3 7. Charging compressor oil when the predetermined amount of oil has been charged into the oil-charging tank, immediately close the lower valve. Next, run the vacuum pump until the system pressure reaches lower than -101kpa {-755mmhg, 5 torr}. Close...

Page 87: 7. Charging Compressor Oil

3 - 21 2way system outdoor unit repair procedures 3 7. Charging compressor oil high-pressure outlet port (for ø7.94mm-dia connector) low-pressure outlet port (for ø7.94mm-dia connector) liquid tube service port (for ø7.94mm-dia connector) gas tube service port (for ø7.94mm-dia connector) type 14hp /...

Page 88: 7. Charging Compressor Oil

3 - 22 2way system outdoor unit repair procedures 3 7. Charging compressor oil next follow the instructions in “4-2-1. Cooling operation (for all units)” at the outdoor unit where oil will be charged, and start cooling operation at all units. When the operating conditions have stabilized, perform st...

Page 89: 7. Charging Compressor Oil

3 - 23 2way system outdoor unit repair procedures 3 7. Charging compressor oil 7-3. Charging additional compressor oil (after replacing compressor) the rated amount of oil is pre-charged in the compressors as given below: when replacing a faulty compressor, be sure to first measure the amount of rem...

Page 90

3 - 24 2way system outdoor unit repair procedures 3 8. Pumping out refrigerant from outdoor unit the hoses may be subject to internal pressure from the refrigerant inside the out- door unit. Check that the manifold gauge valves are fully closed beforehand. A schrader-type push-to-release valve is pr...

Page 91

3 - 25 2way system outdoor unit repair procedures 3 8. Pumping out refrigerant from outdoor unit (8) short-circuit the vacuum application pin on the outdoor unit control pcb of the unit to be repaired. Then turn on the outdoor unit power. When the vacuum application pin is short-circuited and the po...

Page 92

3 - 26 2way system outdoor unit repair procedures 3 8. Pumping out refrigerant from outdoor unit while closing the valves, the rise in discharge temperature or another factor may cause a protective device to activate, stopping the operation of the outdoor unit. If this occurs, immediately fully clos...

Page 93: 9. Compressor

3 - 27 2way system outdoor unit repair procedures 3 9. Compressor 9-1. Compressor trouble diagnosis and check methods generally, compressor failures can be classified into the following categories. (1) mechanical trouble (a) locking (intrusion of foreign objects, galling, etc.) (b) pressure rise fai...

Page 94: 9. Compressor

3 - 28 2way system outdoor unit repair procedures 3 9. Compressor 9-2. Replacing the compressor(s) 9-2-1. Replacing only the failed compressor (1) if backup operation is required, follow the instructions in “3. Backup operation” and engage backup operation. (2) follow the instructions in “9-3. Remov...

Page 95: 9. Compressor

3 - 29 2way system outdoor unit repair procedures 3 9. Compressor 9-2-2. Replacing all compressors in a failed unit (1) follow the instructions in “2. Discharging compressor oil” and drain the oil from the oil separator in the failedunit. Measure the amount of drained oil. (2) if backup operation is...

Page 96: 9. Compressor

3 - 30 2way system outdoor unit repair procedures 3 9. Compressor 9-2-3. Replacing all compressors in a system (1) follow the instructions in “2. Discharging compressor oil” and drain the oil from the oil separators in all out- door units. Measure the amount of drained oil. (2) follow the instructio...

Page 97: 9. Compressor

3 - 31 2way system outdoor unit repair procedures 3 9. Compressor 9-2-4. Dry core cleaning if burning or other failures occur repeatedly at compressors within the same system, in many cases the cause is acid, sludge, carbon, or other substances that remain in the refrigeration cycle as the result of...

Page 98: 9. Compressor

3 - 32 2way system outdoor unit repair procedures 3 9. Compressor (16) after evacuating all nitrogen gas from the tubing, apply vacuum to all outdoor units where dry cores were removed until the pressure is –101kpa {–755 mm hg, 5 torr} or less. (17) installation: refer to the “information for the pe...

Page 99: 9. Compressor

3 - 33 2way system outdoor unit repair procedures 3 9. Compressor 9-3. Removing compressors when removing and installing compressors, use sufficient caution to ensure that moisture or other substances do not enter the refrigerant tubing system. 9-3-1. Removing compressors (for all models) (1) after ...

Page 100: 9. Compressor

3 - 34 2way system outdoor unit repair procedures 3 9. Compressor 9-3-2. Removing constant-speed compressors (for model 12, 14 and 16 horsepower) (1) after retrieving refrigerant from the system, perform nitrogen gas replacement on the service port of the gas side service valve. (2) remove the insul...

Page 101: 9. Compressor

3 - 35 2way system outdoor unit repair procedures 3 9. Compressor 9-3-3. Removing constant-speed compressors (for model 18 and 20 horsepower) (1) after retrieving refrigerant from the system, perform nitrogen gas replacement on the service port of the gas side service valve. (2) remove the insulator...

Page 102: – Memo –

– memo – 3 - 36 sm830204-05_2way sys_new.Indb 36 15/01/05 15:31:42.

Page 103: Contents

4 - 1 2way system outdoor unit maintenance remote controller 4 4. Outdoor unit maintenance remote controller 1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 2. Functions . . . . . . . . . . . . . . . . . . . ...

Page 104: 1. Overview

4 - 2 4 2way system outdoor unit maintenance remote controller 1. Overview outdoor unit maintenance remote controller (cz-rtc2) for 2way system n about the outdoor unit maintenance remote controller the outdoor unit utilizes nonvolatile memory (eeprom) on its pcb. This allows eeprom data to replace ...

Page 105: 2. Functions

4 - 3 2way system outdoor unit maintenance remote controller 4 2. Functions n functions on the ordinary display (1) functions: button operations can be used to perform the following functions. • start/stop of all indoor units • switching between cooling and heating • test run of all indoor units • d...

Page 106

2way system outdoor unit maintenance remote controller 4 - 4 4 3. Ordinary display controls and functions n functions on the ordinary display • connect the special service checker wiring to the outdoor unit pcb. The connection is shown in the figure below. L if the communications line in the inter-u...

Page 107

4 - 5 2way system outdoor unit maintenance remote controller 4 3. Ordinary display controls and functions fig. 1 l all units start/stop (fig. 1) the (on/off operation) button can be used to start and stop all the indoor units. • the led illuminates if any indoor units is operating. • the led blinks ...

Page 108

2way system outdoor unit maintenance remote controller 4 - 6 4 3. Ordinary display controls and functions n display (functions) • use the temperature setting and buttons to change the item code. À item code Á item remarks outdoor unit alarm alarm code display no. Of connected indoor units quantity u...

Page 109

4 - 7 2way system outdoor unit maintenance remote controller 4 3. Ordinary display controls and functions xx-yy r.C. Displays the outdoor unit sub-bus address which is currently selected. Xx = outdoor system address on main bus line (1 – 30) yy = outdoor unit sub-bus address (1 – 8) “1” appears when...

Page 110

2way system outdoor unit maintenance remote controller 4 - 8 4 3. Ordinary display controls and functions n concerning the 7-segment, 4-digit display remote controller timer display the unit nos. Of connected units are indicated by four 7-segment digits ( ) and a colon. 1 2 7 12 17 3 13 18 8 4 14 19...

Page 111

4 - 9 2way system outdoor unit maintenance remote controller 4 4. Monitoring operations display the indoor unit and outdoor unit sensor temperatures. À press and hold the (check) button and buttons simultaneously for 4 seconds or longer to engage temperature monitor mode. During temperature monitori...

Page 112

2way system outdoor unit maintenance remote controller 4 - 10 4 4. Monitoring operations display of unit no. 1 (main unit) remarks description dn °c °c °c °c °c °c °c °c °c °c °c °c °c °c °c °c °c °c °c °c indoor unit intake temp. (ta) indoor unit heat exchanger temp. E1 (e1) — indoor unit heat exch...

Page 113

4 - 11 2way system outdoor unit maintenance remote controller 4 5. Outdoor unit alarm history monitor • displays outdoor unit alarms only. • check the indoor unit alarm histories separately using the indoor unit remote controllers or other control device. À press and hold the (check) button and butt...

Page 114: 6. Mode Settings

2way system outdoor unit maintenance remote controller 4 - 12 4 6. Mode settings 2way system outdoor unit maintenance remote controller 6. Mode settings setting mode 1 press and hold the 1 2 (check) button and (ventilation) button simultaneously for 4 seconds or longer. Press the temperature setting...

Page 115: 6. Mode Settings

4 - 13 2way system outdoor unit maintenance remote controller 4 6. Mode settings n setting mode 2 À press and hold the (check) button, button, and button simultaneously for 4 seconds or longer. Á press the temperature setting and buttons to change the item code. The item codes and setting data are s...

Page 116: – Memo –

– memo – 4 - 14 sm830204-05_2way sys.Indb 14 2015/01/23 11:57:01.

Page 117: Contents

2way system remote controller functions 5 - 1 5 5. Remote controller functions 1. Simple settings function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 2. Detailed settings function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 118: 1. Simple Settings Function

2way system remote controller functions 5 - 2 1. Simple settings function 5 • this allows the filter lifetime, operating mode priority change, central control address, and other settings to be made for an individual or group- control indoor unit to which the remote controller used for simple setting...

Page 119: 1. Simple Settings Function

2way system remote controller functions 5 - 3 1. Simple settings function 5 cz-rtc3 fig. 2 1 keep pressing the , and buttons simultaneously for 4 or more seconds. The “maintenance func” screen appears on the lcd display. 2 press the or button to see each menu. If you wish to see the next screen inst...

Page 120: 1. Simple Settings Function

2way system remote controller functions 5 - 4 1. Simple settings function 5 list of simple setting items item code item setting data no. Description filter sign on time (filter life time) 0000 not displayed 0001 150 hours 0002 2,500 hours 0003 5,000 hours 0004 10,000 hours 0005 use the filter cloggi...

Page 121: 1. Simple Settings Function

2way system remote controller functions 5 - 5 1. Simple settings function 5 simple setting items item code item description 01 filter sign on time setting (filter lifetime) changes the indoor unit filter lifetime when a high-performance filter or other optional product is installed. 02 degree of fil...

Page 122: 1. Simple Settings Function

2way system remote controller functions 5 - 6 1. Simple settings function 5 item code item description 03 central control address set when using a central control device. Used when setting the central control address manually from the remote controller. 04 operating mode priority change note (1) not...

Page 123: 1. Simple Settings Function

2way system remote controller functions 5 - 7 1. Simple settings function 5 when the operating mode at the priority remote controller is changed, the operating modes of other remote controllers change as shown below. Mode change at priority remote controller operating modes at other remote controlle...

Page 124

2way system remote controller functions 5 - 8 2. Detailed settings function 5 • this allows the system address, indoor unit address, and other settings to be made for the individual or group-control indoor unit to which the remote controller used for detailed settings is connected. When detailed set...

Page 125

2way system remote controller functions 5 - 9 2. Detailed settings function 5 the flap swings during the operation under "setting the flap separately". At this time, the unselected flaps are moved to the position 1 . (refer to fig.4) * setting data “ ” (refer to fig.4) flap position 1 5 7 press the ...

Page 126

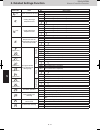

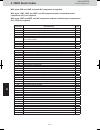

2way system remote controller functions 5 - 10 2. Detailed settings function 5 2. Detailed settings function list of detailed setting items item code item . O n . O n . O n setting data description description description 0001 2-way cassette (l1) type indoor unit capacity 0003 0009 0012 0017 0021 00...

Page 127

2way system remote controller functions 5 - 11 2. Detailed settings function 5 2. Detailed settings function list of detailed setting items item code item . O n . O n . O n setting data description description description 0001 2-way cassette (l1) type indoor unit capacity 0003 0009 0012 0017 0021 00...

Page 128

2way system remote controller functions 5 - 12 2. Detailed settings function 5 item code item setting data no. Description (1b) forced thermostat on time 0000 5 minutes 0001 4 minutes cooling discharge temperature shift –010 shifts discharge temperature setting 10°c down –009 shifts discharge temper...

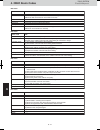

Page 129

2way system remote controller functions 5 - 13 2. Detailed settings function 5 item code item setting data no. Description automatic drain pump operation 0000 no forced operation 0001 forced operation for 1 minute 0060 continuous operation ventilation fan operation 0000 none 0001 ventilation fan ope...

Page 130

2way system remote controller functions 5 - 14 2. Detailed settings function 5 item code item setting data no. Description fan tap setting (fan tap change in order to prevent drop in air discharge caused by filter installation) dc fan tap operating mode purpose 0000 standard standard (setting at shi...

Page 131

2way system remote controller functions 5 - 15 2. Detailed settings function 5 item code item description 10 unit type set when the indoor unit eeprom memory is replaced during servicing. 11 indoor unit capacity 12 system (outdoor unit) address these are not set at the time of shipping from the fact...

Page 132

2way system remote controller functions 5 - 16 2. Detailed settings function 5 item code item description 1f (upper limit) 20 (lower limit) change to the remote control temperature setting range cooling this setting changes the temperature range (upper limit and lower limit) which is set from the re...

Page 133

2way system remote controller functions 5 - 17 2. Detailed settings function 5 (continued from previous page) item code item description 3c heat exchanger temperature for cold air discharge the heat exchanger temperature control point for prevention of cold air discharge during heating operation can...

Page 134

2way system remote controller functions 5 - 18 2. Detailed settings function 5 selecting the dc fan motor tap (when setting with the remote controller) stop the system before performing these steps. Press and hold the , and buttons simultaneously for 4 seconds or longer. If group control is in effec...

Page 135

2way system remote controller functions 5 - 19 2. Detailed settings function 5 3. Detailed settings function 1 keep pressing the , and buttons simultaneously for 4 or more seconds. The “maintenance func” screen appears on the lcd display. 2 3 press the or button to see each menu. If you wish to see ...

Page 136

2way system remote controller functions 5 - 20 2. Detailed settings function 5 2way system remote controller functions 2. Detailed settings function selecting the dc fan motor tap (when setting from the pcb) 4-way cassette type stop the system before performing these steps. Open the electrical compo...

Page 137

2way system remote controller functions 5 - 21 3. Remote controller servicing functions 5 2way system remote controller functions 3. Remote controller servicing functions the remote controller includes a number of servicing functions. Use these as needed for test runs and inspections. List of servic...

Page 138

2way system remote controller functions 5 - 22 3. Remote controller servicing functions 5 display of "maintenance function" screen 1 keep pressing the , and buttons simultaneously for 4 or more seconds. The “maintenance func” screen appears on the lcd display. 2 press the or button to see each menu....

Page 139

2way system remote controller functions 5 - 23 3. Remote controller servicing functions 5 display of "maintenance function" screen 1 keep pressing the , and buttons simultaneously for 4 or more seconds. The “maintenance func” screen appears on the lcd display. 2 press the or button to see each menu....

Page 140

2way system remote controller functions 5 - 24 3. Remote controller servicing functions 5 n sensor temperature display function (displayed regardless of whether unit is operating or stopped) the procedure below displays the sensor temperatures from the remote controller, indoor unit, and outdoor uni...

Page 141

2way system remote controller functions 5 - 25 3. Remote controller servicing functions 5 1 keep pressing the , and buttons simultaneously for 4 or more seconds. The “maintenance func” screen appears on the lcd display. 2 press the or button to see each menu. If you wish to see the next screen insta...

Page 142

2way system remote controller functions 5 - 26 3. Remote controller servicing functions 5 2way system remote controller functions 3. Remote controller servicing functions indoor unit sensors remote controller temp. Indoor unit intake temp. (ta) indoor unit heat exchanger temp. E1 (e1) — indoor unit ...

Page 143: 6. Trouble Diagnosis

6 - 1 2way system trouble diagnosis 6 6. Trouble diagnosis 6. Trouble diagnosis 1. Contents of remote controller switch alarm display . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 2. Outdoor unit control panel led display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 144: Switch Alarm Display

6 - 2 1. Contents of remote controller switch alarm display 2way system trouble diagnosis 6 1.Contents of remote controller switch alarm display 2way system trouble diagnosis on: blinking: off: possible cause of malfunction wired remote control display wireless remote controller receiver display ope...

Page 145: Switch Alarm Display

6 - 3 1. Contents of remote controller switch alarm display 2way system trouble diagnosis 6 1.Contents of remote controller switch alarm display 2way system trouble diagnosis on: blinking: off: possible cause of malfunction wired remote control display wireless remote controller receiver display ope...

Page 146

6 - 4 2. Outdoor unit control panel led display 2way system trouble diagnosis 6 ( : on : blinking : off) led (red) display meaning 1 2 after the power is turned on (and automatic address setting is not in progress), no communication with the indoor units in that system is possible. (both on) after p...

Page 147

6 - 5 3. Remote controller servicing functions 2way system trouble diagnosis 6 sensor temperature display function (displayed both when unit is running and stopped) • use the following check procedure to display the sensor temperatures from the remote controller, indoor unit, and outdoor unit sensor...

Page 148

6 - 6 3. Remote controller servicing functions 2way system trouble diagnosis 6 3. Remote controller servicing functions 2way system trouble diagnosis sensor temperature relationship table *room temp. Controlled: = controlled room temperature •when body thermostat controlled: controlled room temperat...

Page 149

6 - 7 3. Remote controller servicing functions 2way system trouble diagnosis 6 3. Remote controller servicing functions 2way system trouble diagnosis sensor temperature relationship table *room temp. Controlled: = controlled room temperature •when body thermostat controlled: controlled room temperat...

Page 150: 4. 2Way Alarm Codes

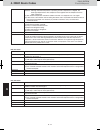

6 - 8 2way system trouble diagnosis 6 4. 2way alarm codes 2way system trouble diagnosis 4. 2way alarm codes alarm meaning 6-10 6-10 6-10 6-11 6-11 outdoor unit failed to receive serial communication signals from indoor unit. Automatic address setting start is prohibited. Automatic address setting al...

Page 151: 4. 2Way Alarm Codes

6 - 9 2way system trouble diagnosis 6 4. 2way alarm codes 2way system trouble diagnosis 4. 2way alarm codes alarm meaning 6-10 6-10 6-10 6-11 6-11 outdoor unit failed to receive serial communication signals from indoor unit. Automatic address setting start is prohibited. Automatic address setting al...

Page 152: 4. 2Way Alarm Codes

6 - 10 2way system trouble diagnosis 6 4. 2way alarm codes e06 alarm alarm code alarm meaning alarm conditions probable cause (2) an open circuit or short-circuit occurred in the inter-unit control wiring after initial communications were completed. Check correction example notes e06 outdoor unit fa...

Page 153: 4. 2Way Alarm Codes

6 - 11 2way system trouble diagnosis 6 4. 2way alarm codes e16 alarm alarm code alarm meaning alarm conditions after initial communications were completed, an unrecognized unit was detected. • • probable cause (1) the number of indoor units set at the indoor unit quantity setting sw (sw3, sw4) on th...

Page 154: 4. 2Way Alarm Codes

6 - 12 2way system trouble diagnosis 6 4. 2way alarm codes e25 alarm alarm code alarm meaning alarm conditions address as that unit 5 times or more within 3 minutes. Probable cause check correction example notes e25 outdoor unit address setting failure (duplication) communication by outdoor unit mai...

Page 155: 4. 2Way Alarm Codes

6 - 13 2way system trouble diagnosis 6 4. 2way alarm codes f04, f05, f22 alarm alarm code f04, f05, f22 alarm meaning compressor 1 discharge temperature sensor trouble, compressor 2 discharge temperature sensor trouble, compressor 3 discharge temperature sensor trouble. Alarm conditions (1) discharg...

Page 156: 4. 2Way Alarm Codes

6 - 14 2way system trouble diagnosis 6 4. 2way alarm codes check (3) leakage from the discharge tube check valve trouble: although the other compressor is operating and this compressor is stopped, the discharge temperature of this compressor rises together with the temperature of the other compresso...

Page 157: 4. 2Way Alarm Codes

6 - 15 2way system trouble diagnosis 6 4. 2way alarm codes f08 alarm alarm code f08 alarm meaning outdoor air temperature sensor trouble alarm conditions (1) a/d step is 10 steps or less (short circuit). (2) a/d step is 1014 steps or more (open circuit) probable cause (1) sensor malfunction (includi...

Page 158: 4. 2Way Alarm Codes

6 - 16 2way system trouble diagnosis 6 4. 2way alarm codes 3way system trouble diagnosis 4. 3way alarm codes f16 alarm alarm code f16 alarm meaning high-pressure sensor malfunction alarm conditions high-pressure sensor disconnected or open circuit high-pressure sensor detected over 3.6mpa continuous...

Page 159: 4. 2Way Alarm Codes

6 - 17 2way system trouble diagnosis 6 4. 2way alarm codes 3way system trouble diagnosis 4. 3way alarm codes f16 alarm alarm code f16 alarm meaning high-pressure sensor malfunction alarm conditions high-pressure sensor disconnected or open circuit high-pressure sensor detected over 3.6mpa continuous...

Page 160: 4. 2Way Alarm Codes

6 - 18 2way system trouble diagnosis 6 4. 2way alarm codes 2way system trouble diagnosis 4. 2way alarm codes h11, h12, h21, h22 alarm alarm code h11, h12, h21, h22 alarm meaning h11: h12: h21: h22: constant speed compressor 2 overcurrent alarm constant speed compressor 2 lock current alarm constant ...

Page 161: 4. 2Way Alarm Codes

6 - 19 2way system trouble diagnosis 6 4. 2way alarm codes 2way system trouble diagnosis 4. 2way alarm codes h11, h12, h21, h22 alarm alarm code h11, h12, h21, h22 alarm meaning h11: h12: h21: h22: constant speed compressor 2 overcurrent alarm constant speed compressor 2 lock current alarm constant ...

Page 162: 4. 2Way Alarm Codes

6 - 20 2way system trouble diagnosis 6 4. 2way alarm codes 3way system trouble diagnosis 4. 3way alarm codes h06 alarm alarm code h06 alarm meaning abnormal decrease of low-pressure alarm conditions probable cause (1) low-pressure sensor failure (1) low-pressure sensor failure (1) replacement of low...

Page 163: 4. 2Way Alarm Codes

6 - 21 2way system trouble diagnosis 6 4. 2way alarm codes 3way system trouble diagnosis 4. 3way alarm codes h06 alarm alarm code h06 alarm meaning abnormal decrease of low-pressure alarm conditions probable cause (1) low-pressure sensor failure (1) low-pressure sensor failure (1) replacement of low...

Page 164: 4. 2Way Alarm Codes

6 - 22 2way system trouble diagnosis 6 4. 2way alarm codes h31 alarm alarm code alarm meaning alarm conditions temperature or other trouble) from the hic. The hic judges the current and temperature, and outputs the trouble signal. In general this indicates trouble with the hic itself. Probable cause...

Page 165: 4. 2Way Alarm Codes

6 - 23 2way system trouble diagnosis 6 4. 2way alarm codes l10 alarm alarm code alarm meaning alarm conditions probable cause check setting mode screen, check the value for the outdoor unit capacity (item code 81). Check that it is not set to “0” or to a capacity that is not allowed. Correction corr...

Page 166: 4. 2Way Alarm Codes

6 - 24 2way system trouble diagnosis 6 4. 2way alarm codes p03, p17, p18 alarm 2way system trouble diagnosis 4. 2way alarm codes alarm code p03, p17, p18 alarm meaning p03 : compressor 1 discharge temperature trouble p18 : compressor 3 discharge temperature trouble alarm conditions compressor 1 : pr...

Page 167: 4. 2Way Alarm Codes

6 - 25 2way system trouble diagnosis 6 4. 2way alarm codes p03, p17, p18 alarm 2way system trouble diagnosis 4. 2way alarm codes alarm code p03, p17, p18 alarm meaning p03 : compressor 1 discharge temperature trouble p18 : compressor 3 discharge temperature trouble alarm conditions compressor 1 : pr...

Page 168: 4. 2Way Alarm Codes

6 - 26 2way system trouble diagnosis 6 4. 2way alarm codes p14 alarm alarm code alarm meaning alarm conditions probable cause check and correction example notes p14 o 2 sensor operation (1) 1-1 system configuration is an o 2 sensor being used? If “yes”, see “3-1”. If “no”, see “2-1”. If “yes”, chang...

Page 169: 4. 2Way Alarm Codes

6 - 27 2way system trouble diagnosis 6 4. 2way alarm codes p14 alarm alarm code alarm meaning alarm conditions probable cause check and correction example notes p14 o 2 sensor operation (1) 1-1 system configuration is an o 2 sensor being used? If “yes”, see “3-1”. If “no”, see “2-1”. If “yes”, chang...

Page 170: 4. 2Way Alarm Codes

6 - 28 2way system trouble diagnosis 6 4. 2way alarm codes p29 alarm alarm code p29 alarm meaning inverter compressor missing phase or lock alarm alarm conditions this alarm may occur at start, and occurs when missing phase or lock is detected, and when a dcct failure occurs. Probable cause generall...

Page 171

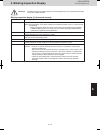

6 - 29 5. Blinking inspection display 2way system trouble diagnosis 6 currently the blinking inspection display can be displayed only on the wired remote controller and system remote controller. Blinking inspection display (1) (automatic backup) alarm code (blinking inspection display) alarm meaning...

Page 172

6 - 30 5. Blinking inspection display 2way system trouble diagnosis 6 blinking inspection display (2) (compressor magnet sw seizing detection) alarm code (blinking inspection display) alarm meaning compressor magnet sw seizing detected status: although an outdoor unit exists where the outdoor unit f...

Page 173

6 - 31 6. Inspection and characteristics of parts 2way system trouble diagnosis 6 (1) high-pressure switch (63ph1, 63ph2, 63ph3), optional high-pressure switch for renewal (63ph4,63ph5) 63ph1 measure the resistance between socket pins 1 and 3. The resistance is ok if the result is 0 Ω. (2) electroni...

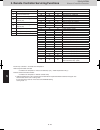

Page 174: 7. Test Pin

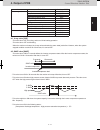

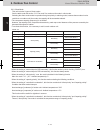

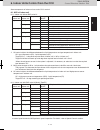

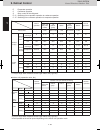

6 - 32 6. Inspection and characteristics of parts 2way system trouble diagnosis 6 6. Inspection and characteristics of parts 2way system trouble diagnosis u - v 8.8 8hp 10hp 12hp 14hp 16hp 18hp 20hp u - w resistance (at 20°c) dmsbg75sy unit : ohm 8.8 v - w 8.8 u - v u - w outdoor unit inverter compr...

Page 175: 7. Test Pin

6 - 33 7. Test pin 2way system trouble diagnosis 6 6. Inspection and characteristics of parts 2way system trouble diagnosis u - v 8.8 8hp 10hp 12hp 14hp 16hp 18hp 20hp u - w resistance (at 20°c) dmsbg75sy unit : ohm 8.8 v - w 8.8 u - v u - w outdoor unit inverter compressor (at 20°c) constant speed ...

Page 176

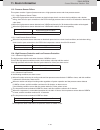

6 - 34 2way system trouble diagnosis 6 8. Symptom: thermostat in off continues or cycles off & on too frequently 5 - 53 5 mini vrf system trouble diagnosis 6. Symptom: thermostat in off continues or cycles off & on too frequently 1-1 adjust setting temperature 1-2 yes no connect correctly 1-3 yes no...

Page 177

201502 sm830204-05_2way sys.Indb 1 15/02/13 17:00:51.