© panasonic corporation 2010 unauthorized copy- ing and distribution is a violation of law. Orderno.Ptw1003508ce automatic bread maker model no. Sd-257wst chassis product color white destination australia table of contents page page 1 safety precautions-----------------------------------------------...

2 1 safety precautions.

3 2 specifications power supply 230-240v -50 hz power consumed 505-550 w capacity (strong flour for a loaf) max.550g min.400g (strong flour for a dough) max.600g min.250g (yeast) max.8g min.0.75g capacity of raisin nut dispenser max.150g dried fruit/nuts timer digital timer (up to 13 hours) dimensio...

4 3 location of controls and components.

5.

6 4 operating instructions.

7.

8.

9.

10

11.

12.

13 5 test mode 5.1. Key operation and check mode before trobleshooting, operate the checkmode in the following procedure. 5.1.1. Check mode 5.1.1.1. Electric power breakdown mode when an electric power breakdown is detected, all load of the device goes off in this mode. Behavior of device after rest...

14 5.1.1.2. Sensor disconnection mode when the disconnection of a sensor is detected, all load of the device goes off in this mode. Indication on lcd • "h01" is displayed on the lcd during the sensor disconnec- tion. ("h01" is brinking) 5.1.1.3. High temperature alarm mode when the "start" key is pr...

15 6 troubleshooting guide before troubleshooting, operate the main body test mode in the following procedure in order to check the p.C.Boards. 6.1. Main body test mode 6.1.1. Setting the main body initial test mode operation procedure 1. Insert the power cord plug into an electrical outlet. 2. Pres...

16 6.1.3. Solenoid/motor operation test (volume.2) mode operation procedure 1. Press the "timer" key. Phenomena • lcd indication: it light up like the right figure. • behaviour of device: the solenoid runs for 1 second and stops for 1 second. Then the motor runs and stops in the manner of 0.5 sec on...

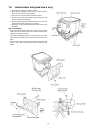

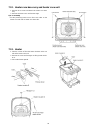

17 7 disassembly and assembly instructions important: • refer to the tips on assembly, and carry out the disassembly procedure backward to assembly. • remove the bread pan assy and kneading blade b unit before disassembling. 7.1. Dispenser cover assy 1. Remove the dispenser cover from the hinge part...

18 7.2. Top lid assy 1. Detach the hinge screw. 2. Slide the top lid assy and remove it from its hinge part..

19 3. Remove 3 screws from the inner lid. 4. Remove the inner lid with the ( - ) top screw driver wrenching into the chink between the top lid assy and the inner lid. * the inner lid is held with the top lid assy by 8 locks. 5. Remove dispenser b assy. 6. Remove the screw and detach the lid lever b,...

20 7.3. Control panel unit 1. Remove 2 screws. 2. Unlock the control panel inner lid from the upper frame lock part while lifting the control panel unit, and while pushing 2 square holes with ( - ) top screw driver. 3. Remove the control panel unit from the locks on the body while pulling and pushin...

21 7.4. Solenoid assy b 1. Remove the screw and detach the solenoid assy b, sole- noid fixing plate and spring a..

22 7.5. P.C.Board a 1. Remove 2 screws and detach p.C.B cover. 2. Disconnect the flat cable and lead wire from p.C.Board a. 3. Remove the p.C.Board a from the p.C.B cover..

23 7.6. Body and others 1. Remove 4 screws for rubber leg fixing, and detach the rubber legs. 2. Remove 2 screws and detach the cord support. 3. Remove the glass tape and disconnect the connector for the power cord assy. 4. Disconnect the connector for grand wire a assy. 5. Pull the power cord assy ...

24 7.7. Upper frame 1. Remove 3 screws. 2. Remove the upper frame and the device body in order to disconnect the locks..

25 7.8. P.C.Board b 1. Remove the screw and detach the p.C.B holder lid. 2. Disconnect 3 faston terminals and 2 connectors from p.C.Board b assy. 3. Remove 2 screws and detach p.C.B holder. 4. Remove the p.C.Board b assy from the p.C.B holder. * the p.C.Board b assy is held to the p.C.B holder with ...

26 7.9. Heat insulator and grand wire a assy 1. Remove the bind wires a of the lead wires. 2. Move the non-flammable tubes a and c and disconnect the 2 faston terminals from the heater. 3. Remove the screw and detach the heat insurator. 4. Remove the screw, spring washer and hexagon nut and detach t...

27 7.10. Sensor assy 1. Remove the screw and hexagon nut and detach the sen- sor assy from the heater case unit. Tips on assembly • insert the notched part of the sensor assy into the fixing square hole of heater case unit and screw the sensor assy to the heater case unit. 7.11. Pulley b, connector ...

28 7.12. Heater case base assy and heater case unit 1. Remove the 4 screws and detach the heater case base assy. 2. Remove the heater case unit from the angle. Tips on assembly • set the positioning marks across from each other on the heater case side and on heater case base side. 7.13. Heater 1. Ta...

29 7.14. Motor assy 1. Remove 4 screws and detach the motor assy. 7.15. Bread pan 1. Turn the bread pan upside down and remove 3 screws. 2. Remove the packing. Tips on assembly • set the positioning marks across from each other when assembling the mounting shaft assy and the bread pan. 7.16. Post-as...

30 8 wiring connection diagram 8.1. Schematic diagram.

31 8.2. Basic wiring diagram.

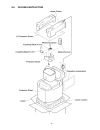

32 9 exploded view and replacement parts list 9.1. Parts location.

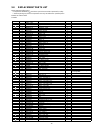

33 9.2. Replacement parts list notes:important safety notice • components identified by mark have special characteristics important for safety. • " when replacing any of these components use only manufacturer's specified parts." model no.Sd-257-wst australia safety ref. No. Part no. Part name & desc...

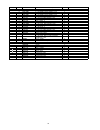

34 a xtb4+14bfc 4 x 14 binding head tapping screw 5 b xtt4+10bfc 4 x 10 truss head tapping screw 7 c xtb4+14bfj 4 x 14 binding head tapping screw 5 d xtb4+22bfj 4 x 22 binding head taptite screw 1 e xss4+8uw 4 x 8 flush head machine screw 3 f xsn4+8ffj 4 x 8 pan head machine screw 1 g x0227-031 moto...

35 9.3. Packing instruction.