Protherm Lion 24 KKV Operation And Installation Manual - Protective Functions

9

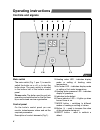

Using the boiler with equithermal

control

The boiler changes the heating water

temperature as the outdoor temperature

changes.

When this type of control is used, it is

necessary to install a control unit which

has the equithermal control function,

Protherm Thermolink B or Thermolink P.

In addition, it is necessary to install an

outdoor temperature sensor.

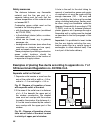

Protection against freezing

The boiler has an antifreeze protection

system which protects the boiler (but not

the heating and the hot water distribution

systems) against freezing.

When the heating water temperature

inside the boiler drops to 8°C, the pump

is switched on, regardless of signal

from room control unit and summer-

mode setting. When the heating water

temperature inside the boiler reaches

10°C, the pump is automatically switched

off. If the heating water temperature inside

the boiler continues to drop, at 5°C the

boiler lights itself up and heats the heating

water to 35°C.

Important:

When the frost protection

function is enabled, the three-way valve

switches to the middle position and both

heating water and hot water start to be

heated.

Protection of hot water tank against

freezing

When the temperature in hot water tank

drops to 10°C, the boiler heats the tank to

15°C. The function is enabled only when

the external hot water tank with an NTC

sensor is connected.

Protective functions

Pump protection

When the pump has been continuously

idle for 23 hours, it is automatically

switched on for about 20 seconds, to

prevent it from ceasing or clogging due to

protracted inactivity.

The boiler is also equipped with a clogging

protection system.

Important:

This boiler function cannot be

disabled.

Two-speed pump

Two-speed pump with automatical

switching of the speed is mouted in the

boiler. When boiler warm heating water,

pump is runing according to setup of the

parameter on control board. When boiler

warm hot water, pump is runing for higher

speed.

Please note:

Pump runing parameter

may be seting up only by an authorised

technician.

Pump run-down

Pump run-down is factory set to 30

seconds for heating of hot water. When

heating a heating water, the run-down is

set to 3 minutes. The maximum run-down

can be set to 60 minutes.

Important:

Room control unit and outdoor

sensor must be installed by an authorised

service only.

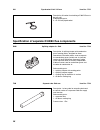

Setting the boiler output

The boiler is factory-set to its maximum

output. If necessary, the boiler heating

water output can be adjusted as required

(in view of the boiler’s features).

Important:

Output setting may be chan-

ged only by an authorised technician.