Summary of QP031

Page 1

1 qp036 qp031.

Page 2

2 model qp036 qp031 motor type 1800w brushless mode model 1500w brushless mode model power input 1800w 1500w voltage see machine nameplate max tip size 0.035 in. 0.031 in. Max flow 5.3 l/min (1.4 gpm) 4.17 l/min (1.1 gpm) max pressure 227 bar (3,300 psi) dimensions (lxwxh) 670mmx580mmx810mm net weig...

Page 3

3 general safety rules warning! Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire and / or serious personal injury. The term “power tool” in all of the warnings listed below refers to your mains-operated (corded) power tool. Save...

Page 4

4 personal safety a) stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury. B) use s...

Page 5

5 f)keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control. G)use the power tool, accessories and tool bits etc., in accordance with these instructions and in the manner intended for the particular type of powe...

Page 6

6 contact with aluminum parts may cause an explosion. Some of the most common of these solvents are: carbontetrachloride, chlorobenzene, dichloroethane, dichloroethyl ether, ethylbromide, ethylchloride, & tethrachloethane. Prevent static sparking fire/explosions vapors created when spraying can be i...

Page 7

7 always inspect spraying area • keep the spraying area free from obstructions. • make sure the spraying area has good ventilation to safely remove vapors and mists. • never keep flammable material in spraying area. • never spray in vicinity of open flame or other sources of ignition. • the spraying...

Page 8

8 allow high pressure spray to be emitted from the coupling and result in an injection injury or serious bodily injury. • only use hoses with a spring guard. The spring guard helps protect the hose from kinks or other damage which could result in hose rupture and cause an injection injury. Do not al...

Page 9

9 • never use cleaning solvents with flash points below 140 degrees f. Some of these are: acetone, benzene, ether, gasoline, naptha. Consult your supplier to be sure. Assembly tools needed: two adjustable wrenches-not included. 1. Attach the hose to the pump and tighten with a wrench. 2. Attach the ...

Page 10

10 grounding instructions this product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. Th...

Page 11

11 lubricate the packings: fill the packing nut/ wet cup with about 2-3 drops of throat seal oil. Prepare at least three buckets the first bucket will hold the material to be sprayed. The second bucket will hold flushing fluid, which will be either mineral spirits (for oil- based materials), lacquer...

Page 12

12 5. Turn the unit on. 6. Turn the pressure control knob clockwise to increase the pressure just enough to let the pump run. 7. Allow the pump to run and watch the fluid discharging from the drain tube. Allow the fluid to discharge until completely clean flushing fluid is coming out. The hose and g...

Page 13

13 unlock the trigger and hold the trigger open. Then close the priming valve. 7. Keep the trigger held open and allow the pump to run and watch the fluid discharging from the gun. Allow the fluid to discharge until pure material is coming out. Turn the machine off. 8. To further bleed out any air, ...

Page 14

14 warning: if the spray tip or hose is clogged, expect material splashing into the bucket while opening the priming valve. So open the valve very slowly and take precautions. Spraying -all models check the quality of the spray pattern on a piece of scrap material, such as cardboard. Turn the pressu...

Page 15

15 bounce-back of the material and a rough finish. All models while spraying, consistently hold the gun perpendicular, about 25-30cm (10-12 inches) away from the surface. Do not swing the gun. Do not tilt the gun. Trigger the gun before moving and release the trigger after each stroke. Overlap each ...

Page 16

16 rate of the spray gun movement, and distance to surface.) the numbers on the tip identify its orifice size and fan width. The first number on the tip identifies the fan width radius in inches. The last two numbers identify the orifice size in thousandths of an inch. So, for example, a 517 tip wou...

Page 17

17 always strain paint before use with a paint strainer bag and regularly clean all filters and strainers. Replace tips before they become excessively worn. Worn tips waste paint, cause overspray, make cutting-in difficult, and decrease sprayer performance. If the tip is the maximum rated size for y...

Page 18

18 minimum position and turn the unit on. 9. With the trigger held open, slowly turn the pressure knob clockwise to increase the pressure just enough to let the pump run. 10. Allow the pump to run and watch the material discharging from the gun. Allow the material to discharge until the material beg...

Page 19

19 20. If flushing was with water, flush again with mineral spirits to prevent corrosion inside the pump. Caution: never leave water in the pump for any length of time. Water will corrode the pump. Long term storage for long- term storage, fill the pump with a storage solution made of a 50/50 mix of...

Page 20

20 and tighten the packing nut. Replace fence. Caution: the packing nut should be tightened just enough to stop leakage only, but not any tighter. Overtightening will damage the packings and reduce packing life. 3. Clean the intake check ball and seat. To clean: a. Using the supplied dual purpose wr...

Page 21

21 7. Loosen the packing nut (24) from pump housing(19). 8. Pull the displacement piston (17) out from pump housing (19). 9. Remove the packing set seat (22), release intake disc seat (08) and remove and discard all old packings. 10. Soak the new leather packings in w30 oil for at least one hour bef...

Page 22: Troubleshooting

22 problem: motor will not run check solution electrical supply- must match voltage use correct outlet on machine nameplate extension cord-check continuity replace extension power supply cable-check continuity replace cable carbon brushes replace brushes bad switch replace switch motor damage replac...

Page 23: Lcd Screen Error Codes:

23 lcd screen error codes: check solution e05 disconnected check if pressure transducer and lcd display are disconnected e06 material shortage fill material again e07 overload (must be replaced by the service organization.) check motor or pressure transducer e09 maximum pressure exceeded check press...

Page 24: Wiring

24 wiring w v u ac mot or pressure transducer control box electronics unit ear th.

Page 25

25.

Page 26

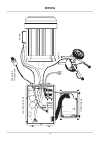

26 exploded view (qp031,qp036) 13 14 15 16 08 02 03 04 06 07 18 22 13 24 36 39 40 41 44 42 43 45 49 50 51 52 54 55 57 56 55 58 59 55 46 47 60 69 70 61 46 74 75 77 75 79 80 81 78 98 98 99 99 95 96 97 96 95 90 91 75 75 91 90 92 84 85 85 88 87 82 68 64 65 20 66 46 72a 72b 72c 73 83 37 38 108 107 107 10...

Page 27: Parts List (Qp031,qp036)

27 parts list (qp031,qp036) item q-tech part no. Description q'ty qp031 qp036 1a qp031-1a suction tube 4 -160l 1 - 1b qp036-1a suction tube 4 -105l - 1 1c qp031-1b suction tube 10 -160l 1 - 1d qp036-1b suction tube 10 -105l - 1 2 qp036-02 gland nut 1 1 3 qp036-03 o-ring Ø39.3xØ45.1x2.8 1 1 4 qp036-0...

Page 28

28 item q-tech part no. Description q'ty qp031 qp036 39 qp036-39 screw m5 x 15 4 4 40 qp036-40 retaining ring Ø1.5 x Ø44 x Ø47 1 1 41 qp036-41 drive piston 1 1 42 qp036-42 pump wrist pin Ø12 x 52 1 1 43 qp036-43 drive wrist pin Ø20 x 42 1 1 44 qp036-44 connecting rod 1 1 45 qp036-45 needle bearing t...

Page 29

Item q-tech part no. Description q'ty qp031 qp036 82 qp036-82 dual purpose wrench 1 1 83 q400-005 lubricating oil tank 100 cc 1 1 84 qp036-84 nut m10 4 4 85 qp036-85 spring washer m10 8 8 86a qp031-86 motor unit 2hp 1 - 86b qp036-86 motor unit 2.5hp - 1 87 qp036-87 screw m10 x 20 4 4 88 qp036-88 scr...

Page 30: Dublin

Dublin aristospray 2b stephenstown industrial park, balbriggan, co. Dublin tel: 00353 1690 3162 fax: 00353 1690 3480 www.Edx-tools.Co.Uk e:sales@aristospray.Com london aristospray uk, granville house wallingford road, uxbridge middlesex ub8 2rw.