- DL manuals

- Qsonica

- Laboratory Equipment

- Sonicator Q700

- Operation Manual

Qsonica Sonicator Q700 Operation Manual

Summary of Sonicator Q700

Page 1

Rev. 9-16 1 sonicator ultrasonic processor part no. Q700 operation manual qsonica, llc. 53 church hill rd. Newtown, ct 06470 usa phone: 203.426.0101 fax: 203.426.7026 info@sonicator.Com www.Sonicator.Com.

Page 2

Rev. 9-16 2 table of contents section page no. 1. Warranty 3 2. Warnings 4 3. Specifications 5-6 4. Principles of operation 7-8 5. Description of components / functions of controls 9-12 6. Preparation for use 13 7. Operating instructions (getting started) 14-23 8. Maintenance 24-26 9. Troubleshootin...

Page 3

Rev. 9-16 3 1. Warranty your ultrasonic processor is warranted and backed by the manufacturer for a period of two years from the date of shipment against defects in material and workmanship under normal use as described in this instruction manual. During the warranty period, the manufacturer will, a...

Page 4

Rev. 9-16 4 2. Warnings please read the manual in its entirety. Necessary instruction and guidance are provided to help ensure the successful operation of this device. Your new ultrasonic liquid processor has been designed, built and tested to assure maximum operator safety. However, no design can c...

Page 5

Rev. 9-16 5 3. Specifications generator input voltage 100 vac – 120 vac @ 50/60 hz 220 vac – 240 vac @ 50/60 hz rated current 12 amps max. 6 amps max. Fuse rating 15 amps* 8 amps* weight 16 lbs. (7.3 kg) dimensions 8"w x 15.25"l x 8.5"h 203 mm x 387 mm x 216 mm output voltage 1000 v rms (max.) outpu...

Page 6

Rev. 9-16 6 environmental pollution degree 2 installation category ii operating limits shipping/storage temperature: 41 - 104ºf (5 - 40ºc) relative humidity 10 - 95% (non condensing) altitude: 6,651 ft. (2000 m) temperature: 35 -120 o f (2 - 49 o c) relative humidity 10 - 95% (non condensing) ambien...

Page 7

Rev. 9-16 7 4. Principles of operation the ultrasonic electronic generator transforms ac line power to a 20 khz signal that drives a piezoelectric converter/transducer. This electrical signal is converted by the transducer to a mechanical vibration due to the characteristics of the internal piezoele...

Page 8

Rev. 9-16 8 the amplitude control allows the ultrasonic vibrations at the probe tip to be set to any desired level. Although the degree of cavitation/ultrasonic energy required to process the sample can readily be determined by visual observation, the amount of power required cannot be predetermined...

Page 9

Rev. 9-16 9 note: improper clamping can damage the system and void the warranty. Correct way to clamp not correct note: using a qsonica sound enclosure or stand will ensure a proper fit..

Page 10

Rev. 9-16 10 5. Description of components / functions of controls the model # q700 includes a standard 1/2” diameter probe (#4220). 5a. Q700 front panel 5b. Q700 rear panel ½” horn/probe with replaceable tip converter cable generator converter power cord connector converter cable connector on/off sw...

Page 11

Rev. 9-16 11 functions of keys, controls, indicators, and connectors front panel touch screen display displays prompts and control parameters including: • amplitude selected • output power delivered to the probe in watts • selected duration of processing • actual processing time • elapsed time • set...

Page 12

Rev. 9-16 12 rear panel on / off switch turns the power supply on and off. Footswitch connector connects to the footswitch cable. Temperature probe connector connects to the temperature monitoring probe or thermocouple converter cable connector (output) connects to the converter. Power supply connec...

Page 13

Rev. 9-16 13 6. Preparation for use inspection prior to installing the ultrasonic processor, perform a visual inspection to detect any evidence of damage, which might have occurred during shipment. Before disposing of any packaging material, check it carefully for small items. The ultrasonic process...

Page 14

Rev. 9-16 14 7. Operating instructions (getting started) caution • do not operate the power supply unless it is connected to the converter. • never allow liquid to spill into the converter. • do not allow a microtip to vibrate in air. • do not allow the vibrating microtip to contact anything but the...

Page 15

Rev. 9-16 15 10. If using a laboratory stand, mount the convertor /probe assembly using a clamp. Be sure to secure the clamp to the upper section of the convertor housing only. Never secure the clamp to any other portion of the convertor/probe assembly. If you are using an acoustic enclosure mount t...

Page 16

Rev. 9-16 16 this screen allows the user to select manual mode, program menu or options screen. 2. Select the mode of operation or access options screen. A. Manual mode: selecting manual run allows the user to set the unit output level manually (setting 1 – 100%). Starting and stopping the ultrasoun...

Page 17

Rev. 9-16 17 the following screen displays the manual mode . A . Microtip mode – indicates that the unit is set for use with microtips only. This mode should not be used with standard probes or horns (1/2” or larger). See page 15 for information on selecting yes or no at the “are you using a microti...

Page 18

Rev. 9-16 18 program menu the unit can be programmed to sonicate at specific, user-selected time intervals including pulse mode. Select/modify a program – create, select or modify up to 10 different programs. Select/modify sequence 1 & 2 – select a sequence of programs for the unit to run in success...

Page 19

Rev. 9-16 19 programming screen how to create a program the ultrasonic processor has the ability to save up to 10 programs. 1. Select a program number from the keypad, the program number will appear above the amplitude box. For each of the following steps : after touching a field, the background wil...

Page 20

Rev. 9-16 20 how to run a saved program from the program screen (see image at top of previous page), touch the program number on the right side of the screen and the selected program settings will appear. Follow steps 9 and 10 from the previous page. This run screen is an example of a sample program...

Page 21

Rev. 9-16 21 how to create a sequence 1. Touch the program (pgm) field, select the appropriate program number and touch ent. 2. Enter each desired program number in order, in the pgm fields. 3. If a delay or rest time between programs is desired, touch the delay after field. Enter the appropriate ti...

Page 22

Rev. 9-16 22 temperature units – a temperature probe (part# 4102 or 4103) is required for use of this option. The temperature probe option can be selected if you wish to monitor the temperature of the sample being processed. The temperature probe must be plugged into the back of the ultrasonic proce...

Page 23

Rev. 9-16 23 techniques for optimizing results probe depth immerse the probe tip 1.5 times the tip diameter into the solution, without touching the bottom. For example, the ½” horn should be immersed at least ¾” below the liquid surface. Immersion depth must be sufficient to prevent foaming and allo...

Page 24

Rev. 9-16 24 9. Maintenance it is recommended to periodically inspect the unit, both visually and physically, to insure optimum and safe performance. This inspection should be scheduled as a routine maintenance procedure, done with the unit power off and with the unit unplugged from the ac power sou...

Page 25

Rev. 9-16 25 follow the steps below for attaching and detaching accessories: 1. Disconnect probe from convertor. Use the wrench set provided with the system. 2. Clean threaded stud. Use alcohol and a cotton swab to remove any debris on the threading of the connecting stud. Allow the alcohol to dry c...

Page 26

Rev. 9-16 26 replacement tip removal replacement tip tightening replacement tip removal replacement tip tightening *note: when tightening a microtip the tip must not be in contact with the work surface. Always have the tip extending off of the table or work surface to minimize stress to the tip. Sys...

Page 27

Rev. 9-16 27 9. Troubleshooting your ultrasonic processor was designed to provide you with years of safe and dependable service. Nevertheless, because of component failure or improper usage, the possibility does exist that it might not perform as it should, shut down or stop working all together. Th...

Page 28

Rev. 9-16 28 10. Return of equipment it is suggested that an ultrasonic processor in need of repair be sent back to the factory. In order to receive prompt service; always contact your customer service representative before returning any instrument. Include date of purchase, model number and serial ...

Page 29

Rev. 9-16 29 safety certification form items being returned: ________________________________________________________________________ ________________________________________________________________________ ________________________________________________________________________ ____________________...

Page 30

Rev. 9-16 30 addendum converter cooling continuous sonication will cause both the probe and sample temperature to increase. The heat will transfer up to the converter. If the converter overheats the internal crystals can crack and the entire converter will require replacement. Converter damage due t...

Page 31

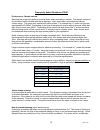

Rev. 9-16 31 frequently asked questions (faq) probe size vs. Sample volume selecting the proper size probe is a critical factor when sonicating a sample. The sample volume to be processed must correlate with the tip diameter. Each probe has a recommended sample volume range. This range may overlap w...

Page 32

Rev. 9-16 32 tip depth the depth of the probe inside the sample vessel is another important issue. If the probe is too close to the surface of the liquid it can create foam. If the probe is too deep it may sonicate against the bottom of the vessel and not effectively processing the sample. The sampl...