- DL manuals

- Qsonica

- Laboratory Equipment

- Sonicator Q700

- Operation Manual

Qsonica Sonicator Q700 Operation Manual

Summary of Sonicator Q700

Page 1

Rev. 6-12 1 sonicator ultrasonic processor part no. Q700 operation manual 53 church hill road, newtown, ct 06470 u.S.A phone: 203.426.0101 · 1.877.338.9636 fax: 203.426.7026 web: www.Sonicator.Com · e-mail: info@sonicator.Com.

Page 2

Rev. 6-12 2.

Page 3

Rev. 6-12 3 table of contents section page no. 1. Warranty 4 2. Warnings 5 3. Specifications 6-7 4. Principles of operation 8-9 5. Description of components / functions of controls 10-12 6. Preparation for use 13 7. Operating instructions (getting started) 14-23 8. Maintenance 24-26 9. Troubleshooti...

Page 4

Rev. 6-12 4 1. Warranty your ultrasonic processor is w arranted and backed by the manufacturer for a period of tw o years from the date of shipment against defect s in material and w orkmanship under normal use as described in this instruction manual. During the w arranty period, the manufacturer w ...

Page 5

Rev. 6-12 5 2. Warnings please read the manual in its entirety. Necessary instruction and guidance are provided to help ensure the successful operation of this device. Your new ult rasonic liquid processor has been designed, built and t ested t o assure maximum operat or saf et y. How ever, no desig...

Page 6

Rev. 6-12 6 symbols caut ion, risk of elect ric shock, hazardous volt age caut ion, risk of danger. Ref er t o user manual..

Page 7

Rev. 6-12 7 3. Specifications generator input volt age 100 vac – 120 vac @ 50/60 hz 220 vac – 240 vac @ 50/60 hz rat ed current 12 amps max. 6 amps max. Fuse rat ing 15 amps* 8 amps* weight 16 lbs. (7.3 kg) dimensions 8" w x 15.25" l x 8.5" h 203 mm x 387 mm x 216 mm out put volt age 1000 v rms (max...

Page 8

Rev. 6-12 8 environmental pollut ion degree 2 inst allat ion cat egory ii operat ing limit s shipping/storage temperature: 41 - 104ºf (5 - 40ºc) relat ive humidit y 10 - 95% (non condensing) alt it ude: 6,651 f t. (2000 m) temperature: 35 -120 o f (2 - 49 o c) relat ive humidit y 10 - 95% (non conde...

Page 9

Rev. 6-12 9 4. Principles of operation the ult rasonic elect ronic generat or t ransforms ac line pow er to a 20 khz signal t hat drives a piezoelect ric converter/t ransducer. This elect rical signal is converted by the t ransducer t o a mechanical vibrat ion due to t he charact erist ics of the in...

Page 10

Rev. 6-12 10 maint ain amplit ude. For example, a ½ ” probe at 100% amplitude w ill require approximately 5 w atts t o operat e in air. The amplit ude of t his probe is approximately 120um. Insert t he probe in w ater and t he w at t age reading w ill increase to approximat ely 90 w att s. The w at ...

Page 11

Rev. 6-12 11 5. Description of components / functions of controls the model # q700 includes a s tandard 1/2” diameter probe (#4220). 5a. Q700 front panel 5b. Q700 rear panel ½” horn with replaceable tip converter cable generator converter power cord connector converter cable connector on/off switch ...

Page 12

Rev. 6-12 12 functions of keys, controls, indicators, and connectors front panel touch screen display displays prompt s and cont rol parameters including: • amplitude selected • output pow er delivered to the probe in w atts • selected duration of processing • actual processing time • elapsed time •...

Page 13

Rev. 6-12 13 rear panel on / of f sw it ch turns t he pow er supply on and of f . Foot sw it ch connect or connect s to the f oot sw it ch cable. Temperature probe connect or connect s to the temperature monit oring probe or t hermocouple convert er cable connect or (out put ) connect s to the conve...

Page 14

Rev. 6-12 14 6. Preparation for use inspection prior to installing the ultrasonic processor, perform a visual inspection to detect any evidence of damage, w hich might have occurred during shipment. Before disposing of any packaging material, check it carefully for small items. The ultrasonic proces...

Page 15

Rev. 6-12 15 7. Operating instructions (getting started) caution do not operate the pow er supply unless it is connected to the converter. Never allow liquid to spill into the converter. Do not allow a microtip to vibrate in air. Do not allow the vibrating m icrotip to contact anything but the sampl...

Page 16

Rev. 6-12 16 fluctuation in w attage readings. Always use the wrenches supplied with the unit. 6. If you w ill be using a microtip or extender, remove the flat tip on the end of the replaceable tip probe, t hen attached the microtip or extender in its place. 7. Horns and probe tips w ear after norma...

Page 17

Rev. 6-12 17 * if you are not familiar w ith t he microtips and need assistance, please call your representative for help. Warning: improper selection may result in tip damage or poor sonication. Damage caused by not f ollow ing t his step is not covered under the w arranty. After answ ering t he mi...

Page 18

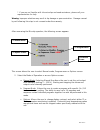

Rev. 6-12 18 the follow ing screen displays the manual mode. A. Microtip mode – indicates that the unit is set for use w ith microtips only. This mode should not be used w ith standard probes or horns (1/2” or larger). See page 15 for information o n selecting yes or no at the “ are you using a micr...

Page 19

Rev. 6-12 19 program menu the unit can be programmed to sonicate at specific, user-selected time intervals including pulse mode. Select/modify a program – create, select or modify up to 10 different programs. Select/modify sequence 1 & 2 – select a sequence of programs for the unit to run in success...

Page 20

Rev. 6-12 20 programming screen how to create a program the ult rasonic processor has t he abilit y to save up to 10 programs. 1. Select a program number f rom t he keypad, the program number w ill appear above t he amplit ude box. For each of the following steps: af t er t ouching a f ield, the bac...

Page 21

Rev. 6-12 21 how to run a saved program from t he program screen (see image at t op of previous page), t ouch t he program number on the right side of the screen and t he selected program set t ings w ill appear. Follow st eps 9 and 10 f rom t he previous page. This run screen is an example of a sam...

Page 22

Rev. 6-12 22 sequencing af t er select ing sequence 1 or 2 f rom t he program menu, t he follow ing screen w ill appear: sequence programming screen af t er creat ing mult iple programs, a sequence of t hose programs may be select ed. Select t he program number and t he amount of t ime desired bet w...

Page 23

Rev. 6-12 23 sequence progress bar – the measure of the total of all programs in the sequence including on, off and delay after times. The follow ing option screen can be accessed from either menu screen. The option menu enables the selection of temperature units and footswitch operational mode. Opt...

Page 24

Rev. 6-12 24 techniques for optimizing results probe depth immerse t he probe tip 1.5 times the tip diameter into t he solution, w ithout touching the bottom. For example, the ½ ” horn should be immersed ¾ ” below the liquid surface. Immersion depth can be less for larger horns and may have to be mo...

Page 25

Rev. 6-12 25 9. Maintenance it is recommended t o periodically inspect t he unit, both visually and physically, to insure optimum and safe performance. This inspection should be scheduled as a routine maintenance procedure, done w ith the unit pow er off and w ith t he unit unplugged from the ac pow...

Page 26

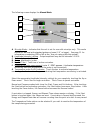

Rev. 6-12 26 follow the steps below for attaching and detaching accessories: 1. Disconnect probe from convertor. Use t he w rench set provided w ith the system. 2. Clean t hreaded stud. Use alcohol and a cotton sw ab to remove any debris on the threading of the connecting stud. Allow the alcohol t o...

Page 27

Rev. 6-12 27 the manufacturer for assistance if the threading is chipped or damaged in anyw ay. Replacement tip removal replacement tip tightening replacement tip removal replacement tip tightening * note: when tightening a microtip the tip must not be in contact w ith the w ork surface. Alw ays hav...

Page 28

Rev. 6-12 28 9. Troubleshooting your ultrasonic processor w as designed to provide you w ith years of safe and dependable service. Nevertheless, because of component f ailure or improper usage, the possibility does exist that it might not perform as it should, shut dow n or stop w orking all togethe...

Page 29

Rev. 6-12 29 10. Return of equipment it is suggested that an ultrasonic processor in need of repair be sent back to the factory. In order t o receive prompt service; alw ays cont act your customer service representative before returning any instrument. Include date of purchase, model number and seri...

Page 30

Rev. 6-12 30 safety certification form it ems being returned: ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ _...