- DL manuals

- Quadra-Fire

- Indoor Fireplace

- QV32B-A

- Owner's Manual

Quadra-Fire QV32B-A Owner's Manual

Quadra-Fire • QV32B-A, QV36B-A • 2014-900 Rev. J • 7/08

1

Models:

QV32B-A

QV36B-A

• Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of

this or any other appliance.

• What to do if you smell gas

- Do not try to light any appliance.

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas suppli-

er’s instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency, or the

gas supplier.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury, or death.

Owner’s Manual

Installation and Operation

DO NOT DISCARD THIS MANUAL

CAUTION

This appliance may be installed as an OEM installation in

manufactured home (USA only) or mobile home and must be

installed in accordance with the manufacturer’s instructions and

the manufactured home construction and safety standard, Title

24 CFR, Part 3280 or Standard for Installation in Mobile Homes,

CAN/CSA Z240MH.

This appliance is only for use with the type(s) of gas indicated

on the rating plate.

Installation and service of this appliance should be

performed by qualifi ed personnel. Hearth & Home

Technologies suggests NFI certifi ed or factory trained

professionals, or technicians supervised by an NFI

certifi ed professional.

• Leave this manual with

party responsible for use

and operation.

DO NO

T

DISCARD

• Important operating

a n d m a i n t e n a n c e

instructions included.

• Read, understand and follow

these instructions for safe

installation and operation.

In the Commonwealth of Massachusetts:

• installation must be performed by a licensed plumber

or gas fi tter;

See Table of Contents for location of additional

Commonwealth of Massachusetts requirements.

R

WARNING

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other fl ammable

materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

Summary of QV32B-A

Page 1

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 1 models: qv32b-a qv36b-a • do not store or use gasoline or other fl am- mable vapors and liquids in the vicinity of this or any other appliance. • what to do if you smell gas - do not try to light any appliance. - do not touch any electrical s...

Page 2: Congratulations

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 2 congratulations listing label information/location model name: ___________________________________________ date purchased/installed: __________________ serial number: __________________________________________ location on appliance: _________...

Page 3

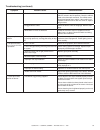

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 3 Î = contains updated information. Table of contents 1 listing and code approvals a. Appliance certifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 b. Glass specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 4 b. Glass specifi cations hearth & home technologies appliances manufactured with tempered glass may be installed in hazardous loca- tions such as bathtub enclosures as defi ned by the con- sumer product safety commission (cpsc). The tempered ...

Page 5

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 5 g. Requirements for the commonwealth of massachusetts for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or op...

Page 6

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 6 a. Design and installation considerations quadra-fire direct vent gas appliances are designed to operate with all combustion air siphoned from outside of the building and all exhaust gases expelled to the outside. No additional outside air so...

Page 7

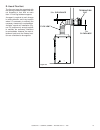

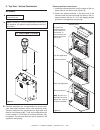

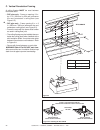

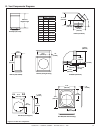

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 7 3 3 framing and clearances note: • illustrations reflect typical installations and are for design purposes only. • illustrations/diagrams are not drawn to scale. • actual installation may vary due to individual design preference. Fire risk pr...

Page 8

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 8 figure 3.2 clearances to combustibles c b d a e h i f g j measure from top of unit opening or from top of hood fire risk. • construct chase to all clearance specifi cations in manual. • locate and install appliance to all clearance specifi ca...

Page 9

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 9 d. Mantel projections 5 6 7 8 9 10 3 4 5 12 11 10 9 8 7 6 top of hood or fireplace opening 4 12 13 11 32 ceiling 3 ft. Maximum 5-3/8 in. Minimum 3 in. Minimum note: clearance from opening to perpendicular wall. Figure 3.5 clearances to mantel...

Page 10

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 10 a. Vent termination minimum clearances fire risk. Explosion risk. Maintain vent clearance to combustibles as specifi ed. • do not pack air space with insulation or other materials. Failure to keep insulation or other materials away from vent...

Page 11

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 11 v = vent terminal x = air supply inlet = area where terminal is not permitted figure 4.4 minimum clearances for termination a = 12 inches.................Clearances above grade, veranda, porch, deck or balcony b = 12 inches.................C...

Page 12

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 12 fire hazard. Explosion risk. Asphyxiation risk. Do not connect this gas appliance to a chimney fl ue serving a separate solid-fuel or gas burning appliance. • vent this appliance directly outside. • use separate vent system for this applianc...

Page 13

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 13 3 in . C l e a r a n c e t e r m in at io n c a p f l e x -v e n t 1 in . C l e a r a n c e d. Use of flex vent the fl ex vent must be supported with the spacing between support intervals not exceeding 4 feet, with no more than 1/2 inch sag ...

Page 14

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 14 fire risk. Explosion risk. Do not pack insulation or other combustibles between ceiling fi restops. • always maintain specifi ed clearances around venting and fi restop systems. • install wall shield and ceiling fi restops as specifi ed. Fai...

Page 15

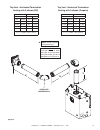

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 15 figure 5.5 top vent - horizontal termination venting with 2 elbows (ng) top vent - horizontal termination venting with 2 elbows (propane) note: there must be a 25% reduction in total h when using fl ex vent except when using the simple up an...

Page 16

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 16 figure 5.6 top vent - horizontal termination venting with 3 elbows (ng) top vent - horizontal termination venting with 3 elbows (propane) note: there must be a 25% reduction in total h when using fl ex vent except when using the simple up an...

Page 17

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 17 2. Top vent - vertical termination no elbow v 1 = 60 ft. Max. (18.3 m) figure 5.8 inner heat shield top vent application rear vent application note: be sure to re- install the inner heat shield after exhaust restrictor installation. Figure 5...

Page 18

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 18 figure 5.9 top vent - vertical termination venting with 2 elbows (ng) top vent - vertical termination venting with 2 elbows (propane) note: there must be a 25% reduction in total h when using fl ex vent except when using the simple up and ou...

Page 19

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 19 figure 5.10 top vent - vertical termination venting with 3 elbows (ng) top vent - vertical termination venting with 3 elbows (propane) note: there must be a 25% reduction in total h when using fl ex vent except when using the simple up and o...

Page 20

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 20 v 1 h 1 v 2 v 3 h 2 2. Top vent - vertical termination - (continued) four 90º elbows v 1 min. H 1 max. V 2 min. H 2 max. V 3 min. 1-1/2 ft. 457 mm 4 ft. 1.2 m 4 ft. 1.2 m 4 ft. 1.2 m 3-1/2 ft. 1.0 m v 1 + v 2 + v 3 + h 1 + h 2 maximum= 40 ft...

Page 21

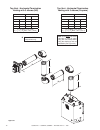

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 21 figure 5.12 h 1 = 24 in. (711 mm) maximum rear vent - horizontal termination no elbows rear vent - horizontal termination venting with 2 elbows h 1 max. V 1 min. H 2 max. H 1 + h 2 max. 1-1/2 ft. 457 mm back to back elbows 1 ft. 305 mm 2-1/2...

Page 22

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 22 ins talle d horizon tal ly rear vent - horizontal termination venting with 3 elbows h 1 max. V 1 min. H 1 + h 2 max. H 1 + h 2 + h 3 max. 1-1/2 ft. 457 mm back to back elbows 1 ft. 305 mm 2-1/2 ft. 762 mm 3-1/2 ft. 1.1 m 1 ft. 305 mm 2 ft. 6...

Page 23

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 23 figure 5.16 v 1 h 2 h 1 in s ta l l e d h o r iz o n ta l ly rear vent - vertical termination venting with 2 elbows v 1 min. H 1 max. H 2 max. H 1 + h 2 max. Back to back elbows 1-1/2 ft. 457 mm 1 ft. 305 mm 2-1/2 ft. 762 mm 1 ft. 305 mm 3-1...

Page 24

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 24 6 6 vent clearances and framing a. Pipe clearances to combustibles fire risk. Explosion risk. Maintain vent clearance to combustibles as specifi ed. • do not pack air space with insulation or other materials. Failure to keep insulation or ot...

Page 25

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 25 figure 6.3 exterior wall hole * shows center of vent framing hole for top or rear venting. The center of the hole is one (1) inch (25.4 mm) above the center of the horizontal vent pipe. C d a* b* 10 in. 10 in. 10 in. 12 in. A* b* c d qv32b-a...

Page 26

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 26 c. Vertical penetration framing figure 6.3 figure 6.4 installing the attic shield attic above a pipe dvp slp a 10 in. (254 mm) 9 in. (229 mm) a a ceiling fi restop must be used between fl oors and attics. • dvp pipe only - frame an opening 1...

Page 27

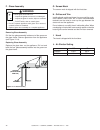

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 27 d. Install attic insulation shield warning! Fire risk. Do not allow loose materials or insulation to touch vent. Hearth & home technologies inc. Requires the use of an attic shield. The national fuel gas code ansi z223.1 and nfpa 54 requires...

Page 28

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 28 a. Top vent figure 7.2 rotate the top heat shield to the vertical position as shown above. The heat shield must remain in the vertical position. Figure 7.4 remove the vent cap. Figure 7.5 remove the insulation basket and white insula- tion f...

Page 29

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 29 figure 7.6 remove the insulation from the outer vent pipe. Figure 7.7 to attach the fi rst section of vent pipe, make sure to use the fi berglass gasket to seal between the fi rst vent component and the outer fi replace wrap. Use 2 self tapp...

Page 30

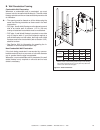

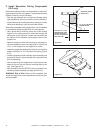

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 30 c. Securing and leveling the appliance the diagram shows how to properly position, level, and secure the appliance (see figure 7.11). Nailing tabs are pro- vided to secure the appliance to the framing members. • venting - refer to vent clear...

Page 31

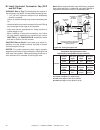

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 31 8 8 installing vent pipe (dvp and slp pipe) a. Assemble vent sections (dvp pipe only) attach vent to the firebox assembly note: the end of the pipe sections with the lanced tabs will face toward the appliance. Attach the fi rst pipe section ...

Page 32

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 32 b. Assemble vent sections (slp pipe only) to attach the fi rst vent component to the starting collars of the appliance: • lock the vent components into place by sliding the pipe section onto the collar. • align the seam of the pipe and seam ...

Page 33

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 33 d. Secure the vent sections • vertical runs of dvp pipe must be supported every 8 ft. (2.44 m) after the 25 ft. (7.62 m) maximum unsupported rise. • vertical runs of slp pipe must be supported every 8 ft. (2.44 m). • horizontal sections must...

Page 34

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 34 f. Install decorative ceiling components (slp only) a decorative ceiling thimble can be installed on a fl at ceil- ing through which the vent passes. The decorative ceiling thimble is used to cover the fi restop. • seal the gap between the v...

Page 35

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 35 g. Install metal roof flashing note: skip this section if using the rf4-8. • see minimum vent heights for various pitched roofs (figure 8.14) to determine the length of pipe to extend through the roof. • slide the roof fl ashing over the pip...

Page 36

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 36 i. Install rf4-8 the rf4-8 may be used in place of the roof fl ashing and storm collar (sections 8.G. And 8.H.) pipe must be supported within 12 inches of the roofline using plumbers strapping or an slp-fs when using the rf4-8 flashing. Refe...

Page 37

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 37 screws caulk storm collar (1 of 3) figure 8.23 figure 8.23 termination cap j. Install vertical termination cap • attach the vertical termination cap by sliding the inner collar of the cap into the inner fl ue of the pipe section while placin...

Page 38

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 38 termination cap specifi cation chart (depth without using additional pipe sections) sl series dvp-trapk1 top vent depth dvp-trap1 rear vent depth dvp-trapk2 top vent depth dvp-trap2 rear vent depth 2-3/4 in. To 4-7/8 in. 3-1/8 in. To 5-1/4 i...

Page 39

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 39 note: have the gas supply line installed in accordance with local building codes, if any. If not, follow ansi 223.1. Installation should be done by a qualifi ed installer approved and/or licensed as required by the locality. (in the commonwe...

Page 40

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 40 fire hazard. Do not change the valve settings. • this valve has been preset at the factory. • changing valve settings may result in fi re hazard or bodily injury. High altitude installations u.L. Listed gas appliances are tested and approved...

Page 41

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 41 a. Recommendation for wire this appliance requires 110-120 vac be wired to the junction box either for use of optional accessories (stand- ing pilot ignition) or for proper operation of the appliance (intellifi re ignition). Refer to figure ...

Page 42

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 42 wht wht blk blk grn wire inside box copper ground attached to grn screw with grn wire 14/2wg cover plate outside firebox romex connector d. Junction box installation e. Wall switch installation for fan (optional) if the box is being wired fr...

Page 43

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 43 a. Mantel projections figure 11.1 shows the minimum vertical and corresponding maximum horizontal dimensions of appliance mantels or other combustible projections above the top front edge of the appliance. Figure 11.3 mantel leg (acceptable ...

Page 44

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 44 b. Facing material fire risk. Do not obstruct air inlet or outlet grilles. Do not modify grilles. • modifying or covering grilles could cause temperature rise and fi re hazard. Finishing materials must not interfere with: • air fl ow through...

Page 45

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 45 12 12 appliance setup a. Remove shipping materials remove shipping materials from inside or underneath the fi rebox. B. Clean the appliance clean/vacuum any sawdust that may have accumulated inside the fi rebox or underneath in the control c...

Page 46: Log Set Assembly: Logs-2014

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 46 e. Positioning the logs if the gas logs have been factory installed they should not need to be positioned. If the logs have been packaged separately, refer to the following instructions. 2014-925b 6/03 log set assembly: logs-2014 models: qv3...

Page 47: Log Set Assembly: Logs-2016

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 47 step 1: carefully remove the logs from the packaging. Caution: logs are fragile! 2016-925b 6/03 step 2: log #1 (srv2016-701): place notches of log #1 on outer two grate tines, and push against back of fi rebox. Log set assembly: logs-2016 mo...

Page 48

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 48 figure 12.14 glass assembly f. Glass assembly removing glass assembly pull the four glass assembly latches out of the groove on the glass frame. Remove glass door from the appliance (see figure 12.14). Replacing glass assembly replace the gl...

Page 49

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 49 a. Before lighting appliance before lighting this appliance determine if it has a stand- ing pilot or intellifi re ignition system by opening the con- trol access panel to view wiring system and gas valve. If this appliance has a red or blac...

Page 50: Lighting

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 50 b. Lighting appliance 1. Turn off all electric power to the appliance if service is to be performed. 2. Open control access panel. 3. Move switch to “off” position. 4. Push in gas control knob slightly and turn clock- wise to off”. Do not fo...

Page 51

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 51 initial break-in procedure when you light the appliance, you may notice that it pro- duces heat which does have an associated odor or smell. If you feel this odor is excessive it may require the initial three to four hour continuous burn on ...

Page 52

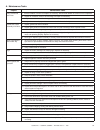

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 52 a. Standing pilot ignition system 14 14 troubleshooting with proper installation, operation, and maintenance your gas appliance will provide years of trouble-free service. If you do experience a problem, this troubleshooting guide will assis...

Page 53

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 53 troubleshooting (continued) symptom possible cause corrective action 3. Continued c. Defective valve. Turn the valve knob to the on position. Place the on/off switch in the on position. Check the millivolt meter a the thermopile terminals. T...

Page 54

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 54 15 15 maintaining and servicing appliance although the frequency of appliance servicing and maintenance will depend on use and the type of installation, a qualifi ed service technician should perform an appliance checkup at the beginning of ...

Page 55

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 55 inspect maintenance tasks doors, surrounds and fronts 1. Assess condition of screen and replace as necessary. Recommend addition of screen if one is not present. 2. Inspect for scratches, dents or other damage and repair as necessary. 3. Ver...

Page 56

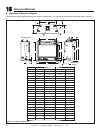

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 56 16 16 reference materials a. Appliance dimension diagram dimensions are actual appliance dimensions. Use for reference only. For framing dimensions and clearances refer to section 3. Figure 16.1 appliance dimensions a b t e electrical access...

Page 57

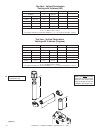

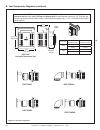

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 57 b. Vent components diagrams figure 16.2 dvp vent components 10-1/2 in. (267 mm) 10-7/8 in. (276 mm) 45 ° 7-3/8 in. (187 mm) 11-3/8 in. (289 mm) 1-1/4 in. (32 mm) 9-1/4 in. (235 mm) 13-1/4 in. (337 mm) 1/2 in. Typ dvp90st (90° elbow) 10 in. (...

Page 58

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 58 dvp-trap1 dvp-trap2 dvp-trapk1 dvp-trapk2 dvp-trap horizontal termination cap 15-1/8 in. (384 mm) 12 in. (305 mm) 8 in. (203 mm) max effective length note: heat shields must overlap by a minimum of 1-1/2 in. (38 mm). The heat shield is desig...

Page 59

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 59 b. Vent components diagrams (continued) figure 16.4 dvp vent components 13-1/4 in. (367 mm) 24-5/8 in. (625 mm) 27-1/2 in. (127 mm) rf6m roof flashing multi-pak 31 in. (787 mm) 24-5/8 in. (625 mm) 13-1/4 in. (367 mm) rf12m roof flashing mult...

Page 60

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 60 effective height/ length 8-3/4 in. 222 mm 6-1/2 in. 165 mm 6-5/8 in. 168 mm 6 in. 152 mm 6-1/2 in. 165 mm 6-5/8 in. 168 mm 9-7/8 in. 251 mm 6-1/2 in. 165 mm 9-1/4 in. 235 mm effective height/ length effective height/length pipe inches mm slp...

Page 61

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 61 slk-snkd snorkel termination cap slp-tvhw vertical termination cap slp-flex-trap horizontal termination kit slp-ccs-bk cathedral ceiling support box-black slp-dcf-bk ceiling firestop black slp-wt-bk wall thimble-black b. Vent components diag...

Page 62: Qv32B-A

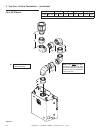

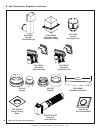

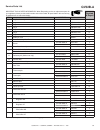

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 62 service parts diagram qv32b-a beginning manufacturing date: june 2003 ending manufacturing date: ______ r 6 8 9 10 11 12 13 7 part number list on following page. Log set assembly 1 2 3 4 5 c. Service parts list.

Page 63: Qv32B-A

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 63 important this is dated information: when requesting service or replacement parts for your appliance please provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer. Stocked at depot it...

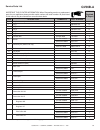

Page 64: Qv36B-A

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 64 qv36b-a service parts diagram beginning manufacturing date: june 2003 ending manufacturing date:______ r 7 12 11 10 9 8 6 part number list on following page. Log set assembly 1 2 3 4 5 service parts list.

Page 65: Qv36B-A

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 65 important this is dated information: when requesting service or replacement parts for your appliance please provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer. Stocked at depot it...

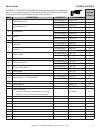

Page 66: Qv32B-A, Qv36B-A

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 66 valve assembly parts list qv32b-a, qv36b-a beginning manufacturing date: june 2003 ending manufacturing date: ______ service parts r standing pilot valve assembly part number list on following page. 1 8 7 6 5 4 3 2 13 12 11 10 9.

Page 67

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 67 important this is dated information: when requesting service or replacement parts for your appliance please provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer. Stocked at depot it...

Page 68: Lifetime Warranty

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 68 d. Limited lifetime warranty limited lifetime warranty the hearth & home technologies limited lifetime warranty guarantees that the following components will work as designed for the lifetime of the stove or hearth & home technologies will r...

Page 69

Quadra-fire • qv32b-a, qv36b-a • 2014-900 rev. J • 7/08 69 quadra-fire, a brand of hearth & home technologies inc. 20802 kensington boulevard, lakeville, mn 55044 www.Quadrafi re.Com e. Contact information please contact your quadra-fire dealer with any questions or concerns. For the location of you...