- DL manuals

- Quiko

- Garage Door Opener

- QK-B220

- Use And Maintenance Manual

Quiko QK-B220 Use And Maintenance Manual

Summary of QK-B220

Page 1

Boxter automation for overhead garage doors use and maintenance manual v01_2011 e n g l i s h qk-b24 qk-b220

Page 2

1 c o n t e n t s technical features 2 dimension of gearmotor 2 pre-installation control 2 materials for installation 3 fixing the longitudinal frame member 3 measures to be respected 4 installing the gearmotor 5 installation of transmission axes for central single motor 5 installing the telescopic ...

Page 3

2 technical features pre-installation control before installing the automation, you must check that: - all structural changes must be implemented to realize safety freeboards; - the existing structure must comply with the necessary sturdiness and stability criteria; quiko italy sas is liable only fo...

Page 4

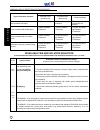

3 materials for installation central single motor lateral double motor 1. 1600 mm longitudinal frame member; 2. Bossed driving shaft; 3. Straight,telescopic arm,complete with: upper fitting; fitting.Axis; 4. M8 x 25 galvanized screw; 5. M8 self-locking nut; 6. M6 x 120 galvanized screws; 7. Flat was...

Page 5

4 measures to be respected installation of central single motor installation of lateral double motor in both central single motor and lateral double motor, the condition described in the figure is equally defined. Supporting frame up & over door e n g l i s h.

Page 6

5 installing the gearmotor 1. Valuate the anchoring position of the gear motor based on the dimensions shown in the figure; 2. Fasten the stud-bolt with the relative washer and tighten the nuts. Installation of transmission axes for central single motor 1. After having cut the transmission axes to t...

Page 7

6 installing the telescopic arms central single motor lateral double motor 1. Cut the components of the telescopic arms and anchor them to the transmission axis. 1. Cut the components of the telescopic arms and anchor them. Adjusting the end-limit switches in case the installed automation is made up...

Page 8

7 manual unlock integrate the safety device relative to the tilting gate in compliance with the local norm. Choose short routes for cables and keep power cables separate from control ones. Install the control card in a waterproof box. For the precision adjustment of the gear motor’s maximum torque, ...

Page 9

8 typical system main components 1 – gearmotor 2 – key selector 3 – switch 4 – flashing light 5 – pneumatic edge e n g l i s h.

Page 10

9 use t he gear motors located in the automation have a long life; nonetheless, their regular functioning can be jeopardized by the state of the tilting gate. Therefore we describe a few operations to maintain the tilting gate efficient. Warning: non-specialized staff cannot operate the gate during ...

Page 11

10 in accordance with the regulation on machinery, the following definitions are applicable: − “danger zones:” any area inside and/or near a machine where the presence of a person is a risk to his/her health and safety. − “exposed person:” any person located entirely or partially in a danger zone. A...

Page 12

11 minimum level of protection for the main edge mode of use type of activation controls informed users (private area) informed users (public area) uninformed users man-operated command □ button command □ turnkey button command the man-operated command is not allowed pulse command with visible doors...

Page 13

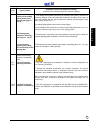

12 [3] impact and crashing on the lower retaining edge (figure 1, risk a) □ measure the closing stress (with the proper tool required by regulation en 12445) as indicated in the figure. Check that the values measured by the instrument are less than the ones indicated in the graphic. Take measurement...

Page 14

13 [5] impact and crashing on the lower retaining edge (figure 1, risk a) install two photo-cells (recommended height: 200 mm) to detect the presence of the test parallelepiped (height 300 mm) positioned as indicated in the figure. In case of a tilting gate installed in a private residence, which do...

Page 15

14 md annex 1 types of risks evaluation criteria and solutions to adopt (check the box corresponding to the solution adopted) [9] impact, crashing, cutting on the sliding lateral guides of the moving gate (figure 1, risk e) □ the sliding lateral guides (necessary for operating the system) must have ...

Page 16

15 md annex 1 types of risks evaluation criteria and solutions to adopt (check the box corresponding to the solution adopted) 1.2 [14] safety conditions in case of power failure □ use activation groups in accordance with regulation en 12453 and safety devices in accordance with regulation en 12978. ...

Page 17

16 md annex 1 types of risks evaluation criteria and solutions to adopt (check the box corresponding to the solution adopted) safety and information integration principles 1.7.1 [21] notification means □ install the blinker in a visible position to signal the movement of the door. □ to regulate traf...

Page 18

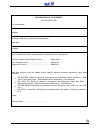

17 maintenance record book this maintenance record book contains technical information as well as a list of installations, maintenance and repairs performed and must be available for possible inspections by authorized bodies. Technical data and installation of the motorized door/gate customer: _____...

Page 19

List of residual risks and improper, foreseeable use notification through signs posted on the product’s danger points and/or through written notices to deliver to and explain to the user or the person in charge about the existing risks and the improper, foreseeable use. _____________________________...

Page 20: Declaration Of Conformity

Declaration of conformity (of the manufacturer) manufacturer: quiko italy sas hereby declares, under his liability, that the products: qk-b220, qk-b24 are in compliance with the essential safety requirements of the regulations: electromagnetic compatibility directive .........................2004/10...

Page 21

Declaration of conformity (of the installer) the undersigned: address: in charge of the set-up, declares that the product: gate type: location: are in compliance with the essential safety requirements of the regulations: electro magnetic compatibility directive .........................2004/108/ec l...

Page 24

The manufacturer can technically improve the quality of its products without any prior notice. Quiko italy via seccalegno, 19 36040 sossano (vi) - italy tel. +39 0444 785513 fax +39 0444 782371 info@quiko.Biz www.Quikoitaly.Com.