- DL manuals

- R.P.S. Corporation

- Floor Machine

- GTX Series

- Operator's Manual

R.P.S. Corporation GTX Series Operator's Manual

Summary of GTX Series

Page 1

Operator manual sei re s model r.P.S. Corporation phone: 1-800-634-4060 mailing: p.O. Box 368 fax: 1-866-901-3335 racine, wi. 53401 shipping: 1711 south st. Racine, wi. 53404 2010 version 3.0 factory cleaning equipment, inc. 800.793.3790 www.Thesweeper.Com.

Page 2: How To Use This Manual

How to use this manual this manual contains the following sections: - how to use this manual - safety - operations - maintenance - parts list the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized tom...

Page 3: Table Of Contents

Table of contents machine information machine delivery form machine specifications common wear parts/scrub brushes safety messages !!Safety precautions!! Machine controls and features lcd screen menu displays machine setup attaching squeegee adjusting squeegee leveling scrub deck attaching brushes a...

Page 4

Standard warranty policy (rps corporation) rps corporation warrants its machines, parts and accessories to be free of manufacturer’s defects for the periods specified below. Warranty will be granted at the sole discretion of rps corporation and is subject to final claim and parts review by r.P.S. Co...

Page 5: Page 1

Page 1 machine information model number_____________________________________________________________ serial number:______________________________________________________________ installation date:___________________________________________________________ installing dealer:__________________________...

Page 6

1-800-634-4060 machine install / warranty registration www.Factorycat.Com installing dealer: installed by: location: (city, state): install date: end-user company name end-user contact: address: city/state: zip phone: fax: email: model: serial #: hour meter: buyer’s representative has received instr...

Page 7: Page 3

Page 3 specs disk cylindrical body construction tank material: (3/8”) roto-poly (3/8”) roto-poly frame construction: 3/16” coated steel 3/16” coated steel front wheel: 10” x 3” 10” x 3” rear wheel: (2) 12” x 5” (2) 12” x 5” body dimensions ( l x w x h ): 54” x 26” x 55” 54” x 26” x 55” width (squeeg...

Page 8: Page 4

Page 4 common wear parts note: squeegee blade kits include (1) rear blade, (1) front blade, and (2) backup wheels with harware. Note: squeegee assemblies (complete) listed above all come with linatex blades. Note: size is stamped into the top of the painted steel squeegee body on all squeegee's. Not...

Page 9: Page 5

Page 5 your safety, and the safety of others, is very important, and operating this unit safely is an important responsibility. To help you make informed decisions about safety, we have provided operating procedures and other safety information in the manual. This information informs you of potentia...

Page 10: Page 6

Page 6 !! Safety precautions!! Warning: hazardous voltage. Shock, burns or electrocution can result. Always disconnect the batteries before servicing machine. Warning: batteries emit hydrogen gases, explosion or fire can result. Keep sparks and open flames away. Warning: charge unit in a well ventil...

Page 11: Page 7

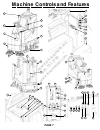

Page 7 4 8 2 1 7 6 8 3 19 18 21 22 20 5 25 24 24 23 26 27 31 30 28 29 32 34 41 39 37 33 38 40 48 44 47 46 42 43 45 49 50 51 52 35 36 14 15 11 10 13 12 16 17 machine controls and features factory cleaning equipment, inc. 800.793.3790 www.Thesweeper.Com.

Page 12: Page 8

Page 8 1. Recovery tank lid: latch must be secured for recovery tank to seal properly. 2. Steering wheel: steers the machine. 3. Headlight: helps you see in low light areas and to warn oncoming traffic. 4. Polyurethane rollers: helps prevent damage to machine and objects you may drive close to. 5. F...

Page 13: Page 9

Page 9 1. Battery level indicator - indicates the energy level remaining in the batteries. (shown on all menu displays) 2. Scrubdeck down pressure gauge - sets the down pressure on the brushes. 3. Vacuum on - indicates the vacuum is "on". 4. Scrub motors on - indicates the brush motors are "running"...

Page 14: Page 10

Page 10 uncrating machine and connecting batteries 1. Carefully check the crate for any signs of damage. Batteries are in the unit. 2. To uncrate the machine, remove banding from around the crate. Take off the top and sides and dispose of properly. 3. Remove banding from machine. Remove the chocks a...

Page 15: Page 11

Page 11 attaching squeegee 1. Lower the squeegee mounting plate by depressing the squeegee switch (a) to the down positio n. (see picture below) 2. Loosen the two knobs (b) on the squeegee and slide them into the slots in the squeegee mounting plate. (see picture below) 3. Tighten the two knobs (b) ...

Page 16: Page 12

1. Turning adjustment knob clock-wise (tightening) will raise tips & lower the center of the squeegee. (see picture to the left) 2. This squeegee is adjusted too far back and will not pick up on the outer tips of the squeegee. Note: the tips of the squeegee are off the floor. (see picture to the lef...

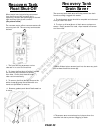

Page 17: Page 13

Page 13 leveling scrubdecks leveling disk scrubdeck 1. Drive machine to a flat level surface and turn machine off. (see picture to the left) 2. Deck should be raised off the floor. 3. With the shrouds off, measure from the ground to a parallel surface on all four corners of the scrubdeck. (see pictu...

Page 18: Page 14

Page 14 *** for correct pad application , call your local dealer*** 1. Turn "on" machine power. 2. Raise the scrub deck by depressing the brush switch (a) to the ("0") position and turn machine power "off". Disconnect batteries. (see picture to the left) 3. Loosen knobs (b) and remove shrouds to acc...

Page 19: Page 15

Page 15 1. The shroud must be adjusted correctly in order to have proper water control during turns. The front of the shroud should be slightly higher than the rear. (see picture to the left) 2. To adjust shrouds loosen knobs (a) and remove shroud. (see picture to the left) 3. Spin the red shroud su...

Page 20: Page 16

Page 16 adjusting cylindrical side wipers 1. The cylindrical deck comes euipped with side wipers for increased water control when turning. (see picture to the left) 2. To adjust the side wipers, first loosen the locking nut (a) , then turn the adjusting screw (b) in to raise or out to lower the heig...

Page 21: Page 17

Page 17 solution system 1. To access the items listed below, completely drain solution and recovery tanks (see picture to the left) i. Carefully tip the tank back until it is supported by the strap. Ii. Gate valve iii. Stainless steel inline filter iv. Solution flow valve 2. To clean filter (a) clos...

Page 22: Page 18

Page 18 1. The "high recovery" light (a) ( red) will illuminate and the horn will sound when the recovery tank is full. Stop immediately and drain the recovery tank. (see picture to the left) 2. If the red light is ignored the vac motor will overheat. 3. If the vac motor is pulling excessive current...

Page 23: Page 19

Page 19 one pass scrubbing steps: (see picture below) 1. Turn machine on with the key switch. 2. Lower squeegee by pressing the switch. 3. Lower scrub head to the floor, use the top half of the brush switch. 4. Adjust the solution +/- to the desired setting. (start at half way). 5. Begin scrubbing b...

Page 24: Page 20

Page 20 double scrubbing steps: (see picture below) 1. Turn machine on with the key switch. 2. Lower scrub head to the floor, use the top half of the brush switch. 3. Adjust the solution to the desired setting. (set half way) 4. Begin scrubbing by depressing the foot pedal slowly and then to the spe...

Page 25: Page 21

Page 21 1. Observe the amount of solution the machine is dispensing on the floor and adjust to the desired flow. To increase the solution flow rate, push solution switch (a) + , to decrease push solution switch (a) - . (see picture to the left) 2. Keep an eye on the "red" recovery full light (b) to ...

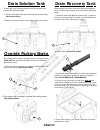

Page 26: Drain Solution Tank

2. Remove cap and begin draining, squeeze "c" to control flow. (see picture below) 3. Open the top "recovery tank lid" and flush out with fresh water to keep tank clean. Rinse the recovery tank after every use. This will prevent heavy build up on the bottom of the tank, foul odors and clogging of th...

Page 27: Page 23

Page 23 recovery tank drain saver recovery tank float shut-off when water is no longer being vacuumed from the floor and the vacuum fan is operating, the ball float has engaged the red high recovery light (1) will come on. (see picture below) the vacuum motor will not vacuum water with recovery tank...

Page 28: Page 24

Page 24 standard charger caution: the following instructions are intended for the 36v charger supplied with the machine. Do not use any non oem charger with this machine. 1. Transport machine to a well ventilated area for charging. 2. Turn the machine off. 3. Hinge opens the tank to expose the batte...

Page 29: Page 25

Page 25 optional battery charging description of led red led battery level low. Yellow led battery at 1/2 charge. Green led battery fully charged. Charger specifications output voltage of 36 volts. (optional) output current of 25 amps max. Input voltage of 110 volts/60 hz. Automatic shut off circuit...

Page 30: Page 26

Page 26 operating manual general information and warning • electronic automatic battery charger with microprocessor suitable for any battery type. • fully automatic charging cycle with electronic setting; protected against overload, short‐circuit at clamps and reversed polarity. • never disconnect t...

Page 31: Page 27

Page 27 power cat 36 volt 25 amp sealed battery charger *continued on next page* the power cat 3625s is a sealed high frequency electronic battery charger with an on board microprocessor that can be programmed for different types of batteries. The charger features a fully automatic charging cycle an...

Page 32: Page 28

Page 28 power cat 36 volt 25 amp sealed battery charger ezlamp code charger phase flashing red internal charger check – “flooded lead settings” flashing red & green internal charger check – “agm settings” steady red indicates first and second phase of charge steady yellow indicates finish charge in ...

Page 33: Page 29

Page 29 - - - - - - + + + + + + 36 volts ! Fron t of m a ch in e > @ changing batteries stop machine in a clean area next to the charger. Turn off machine. For safety: before leaving or servicing the machine; stop on level surface, turn off machine and remove key. Use eye protection. 1. Tip back tan...

Page 34: Side Broom System

1. Flip side broom switch (a) up to lower and engage broom. (see picture below) 2. To adjust side broom height, loosen locking nut located behind screwhead (b) of screw that is in front of scrubdeck just inside the side wall of frame on each side of the machine. Use 1/2" wrench to loosen locking nut...

Page 35: Page 31

Page 31 overhead guard 1. Your machine may be equipped with an "optional" "overhead guard" (a) that helps protect the operator from falling objects that are above the operators head . (see picture below) non-marking tires 1. Your machine may be equipped with non marking (d) tires, which may have red...

Page 36: Page 32

Page 32 water control lock out your machine may be equipped with a "optional" water control lock out switch (a) , which prevents people from changing the water levels on the machine. (see picture above) machine options down pressure lock-out your machine may be equipped with a "optional" down pressu...

Page 37: Page 33

Page 33 on-board soap 1. Switch toggel switch up once for normal soap distribution and up twice for heavy duty soap distribution. (see picture at top of the page item "a") . Vac wand 1. Turn on spray jet pump using the togle switch on the central command. (see picture at top of page item "b" ) 2. De...

Page 38: Page 34

Page 34 yearly maintenance 1. Call your local dealer for yearly maintenance storing machine 1. Be sure to flush the tanks out completely. To thoroughly flush out any solution chemicals in solution line and valves, refill solution tank with a few gallons of warm clean water and run machine until tank...

Page 39: Page 35

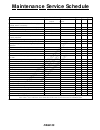

Page 35 maintenance service schedule maintenance sevice schedule maintenance before each work period after each work period 50 hrs 100 hrs 200 hrs check water level of batteries after charging add distilled water if necessary x check that recovery tank cover seals tightly x visualy check for damaged...

Page 40: Page 36

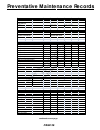

Preventative maintenance records page 36 continued on next page customer information customer address city state zip code machine information model # serial # work order# hour meter: battery condition cell #1 cell #2 cell #3 battery # 1 hydrometer reading battery # 1 water condition battery # 2 hydr...

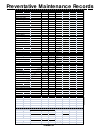

Page 41: Page 37

Preventative maintenance records page 37 continued from previous page check operation and condition of: in spec repair problem brush switch solution potentiometer solution solenoid solution drain valve low solution light brush deck lift system brush motors & motor brushes vacuum switch vacuum motor ...

Page 42: Page 38

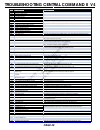

Troubleshooting central command note: this machine is operated by a sophisticated electronic "controller" that has many fail-safes within it. It self-analyzes problems and flashes a four-digit alpha-numeric code of what is wrong in the lcd window. Most of these codes require a technician attention. ...

Page 43: Page 39

9. All other error codes. Turn off the key, and disconnect the positive battery cable from the batteries for more than one minute (the time is needed to drain the controler on-board capacitor). Reconnect cables, being sure that it is tight. Too loose and you will burn battery. If you over tighten th...

Page 44: Page 40

Page 40 code fault description course of correction 0700 bias voltage error high reference signal is grounded 0701 mid rail voltage high 0702 mid rail bias voltage high 0704 12v supply failure 0705 2.5 v reference error 0706 high reference ground fault 5 volt reference is contacting 0 volt reference...

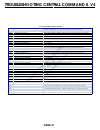

Page 45: Page 41

Page 41 7001 push activated in drive mode freewheel input signal activated while driving. Disconnect freewheel switch. Note: as of this reading, we do not use freewheel. This permits pushing machine more easily b y disconnecting traction motor from control. 7500 throttle comms time out problem with ...

Page 46: Troubleshooting

Problem no power, nothing operates brush motor(s) do not operate drive motor does not operate vacuum motor does not operate drive motor runs incorrectly insufficient solution flow cause faulty key switch batteries need charging faulty battery loose battery cable main circuit breaker tripped brush de...

Page 47: Troubleshooting

Problem no solution flow poor water recovery poor water recovery on turns rear tires noisy poor traction short run time cause no solution in tank solution valve off solution switch off solution screen clogged faulty solution solenoid faulty solution switch recovery tank is full ball/screen in recove...

Page 48

Factory cleaning equipment, inc. 800.793.3790 www.Thesweeper.Com.