Summary of E- ER 700

Page 1

Leading manufacturer of advanced torque systems e-rad user manual electronic battery pneumatic electric.

Page 2

Push-button select torque fast and convenient error-free digital single increment torque settings digital torque console display maximum accuracy by seeing the set torque value and the actual delivered torque value lightweight and ergonomic pistol grip design advanced low-profile handle to reduce op...

Page 3

Table of contents 1. Introduction................................................................. 1 2. Specifications.............................................................. 2 3. System component description ................................. 3 3.1. Controller ....................................

Page 4: Important:

Important: do not operate the tool before reading this user manual. If breakdown, malfunction or damage occurs, do not attempt to repair. Contact new world technologies inc. Or your local distributor immediately. Important: when using a power plug adapter, make sure the earth ground pin is present a...

Page 5: 1. Introduction

1. Introduction rad e series are the world’s most advanced electronic pistol grip torque wrenches. They are designed to provide a high degree of accuracy and repeatability using our patented, legendary gear box design and the precision of an electronic motor. Capable of data collection, angle measur...

Page 6: 2. Specifications

2. Specifications torque ranges: 150 – 700 lb-ft or 200-950 nm 300 – 1200 lb-ft or 400-1600 nm 400 – 2000 lb-ft or 550-2700 nm 500 – 3000 lb-ft or 675-4050 nm 800 – 4000 lb-ft or 1000-5400 nm *custom torque ranges are available up upon request* units supported: Æ lb-ft Æ nm Æ kg.F power source: Æ 11...

Page 7

3. System component description e-rad system (figure 2) includes the following: • controller (weatherproof or steel case) • hand held torque gun • power and control cables (attached to hand held tool) • reaction arm (w. Snap ring) • serial communication cable (calibration / data retrieval) • calibra...

Page 8

3.1. Controller below in figure 3 are all of the input/output ports in the e series . 1. Main input power connector – (115v ac) or (220v ac). 2. Ethernet communication port – ethernet to serial port cable provided to connect your e-rad to a pc for calibration and data retrieval . 3. Connectors for p...

Page 9

3.2. Hand held tool the e-series pistol grip torque gun is trigger activated with a bi-directional forward / reverse switch. On the back of the gun housing is a 3 led light display which notifies when the gun is ready for use, the torque cycle has passed or if the torque cycle has failed. Details ar...

Page 10: 4. System Setup

3.4. Serial communication cable this cable enables serial communication interface between your computer and the controller via standard rs232. This cable is required for calibration and data retrieval. 3.5. Software cd e-rad software cd contains 2 custom made windows based programs for the e- rad sy...

Page 11: Caution

Caution **before powering up the unit perform the following steps** 1. Align control cable notch to the notch in the controller. Push the connector in forward and turn clock wise at least ¼ turn until the plug locks into the connector on the case; 2. Align power cable notch to the notch in the contr...

Page 12: 5. Operation Instructions

5. Operation instructions this section details the operation of the e-rad system. When the tool is in operation, the reaction arm rotates in the opposite direction to the output square drive and must be allowed to rest securely against the adjacent bolt or a near by solid object that is on the same ...

Page 13

• to change units of measurements press on units. The units will cycle between ft.Lb, nm and kg.F. • set the torque to the setting required for your application. • to perform a torque operation: o make sure the torque setting is correct o couple the hand held tool with socket onto the bolt o make su...

Page 14: 6. Calibration Procedure

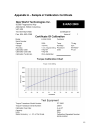

6. Calibration procedure all e-rad systems leaving new world technologies inc are calibrated in the lab prior to shipping. A calibration certificate (see appendix a) is issued for each tool and shipped with each tool. 6.1. Calibration equipment basic requirements: • personal computer with cd-rom and...

Page 15

6.4. Calibration software standard windows based calibration software is required for the calibration and is included with every tool. 6.4.1. Installation to install e-rad cal software: • place the e-rad cal software cd in the cd-rom drive; • if installation does not start automatically, select my c...

Page 16

3. Once there is a controller listed under “list of e-rad’s found on this computer”, click “ok”. Figure 7: communication port setup 4. Once the software has opened (figure 8) click the “connect” button on the lower task bar of the screen. Figure 8: main calibration screen 5. Once connected the “conn...

Page 17: Attention:

Figure 9: start calibration screen 8. Select 7%, motor load to limit motor power output to 7%. 9. Make sure direction switch on the tool is in forward position. (reverse does not appear on the controller display verify this ) depress the trigger on the tool. Do not let the trigger go until the tool ...

Page 18: Important Note:

6.6. Calibration testing if you choose to optimize your individual torque requirement on your e-rad, perform the following procedures. 1. Turn on/off switch on the controller to on position; 2. Set the display to which ever torque value(s) you wish to optimize. 3. Set the tool in forward direction a...

Page 19: 7. Data Retrieval

6.7. Calibration adjustment example 1. Example: e-rad set to 1800 ftlbs = transducer reads out 1750 ftlbs. 2. All though this value is within +/- 3%, we can narrow this difference. 3. By following steps 1 through 7 in section (6.5) re-connect to the e- rad calibration software. 4. Once connected, in...

Page 20

Minimum requirements: 1. Personal computer with cd-rom and a serial port or usb port. 3. Windows nt, windows 2000 windows xp or newer 4. E-rad calibration software already installed on the same pc; 5. Microsoft excel installed on the same pc. The software does not require installation but the follow...

Page 21

Figure 10: data retrieval main screen 1.) once the data retrieval main screen appears, fill out your desired information into the screen (operator id, job number, job location, completion date, completion time). 2.) click “connect to e-rad” on the interface and the “red” disconnected will turn “gree...

Page 22

4.) the data retrieval software will automatically open up an excel spreadsheet and download all of the stored data. This will take approx 30 seconds. ( figure 11 ) ( figure 11 ) 5.) save this file under any file name and in your desired location in your computer and your bolting specs are now recor...

Page 23

Appendix a – sample of calibration certificate 19.

Page 24

Appendix b – option 1 operation selector switch provides the ability to program up to 8 torque settings, 1 per switch position. These settings are usually the most common settings used and allow a fast switch between torque settings instead of dialing up/down the torque each time a different torque ...

Page 25: Standard Features:

Appendix c – option 2 operation standard features: 9 all e-rad torque/angle pre-sets will come pre-set to zero from the manufacturer and are to be adjusted to the desired settings by the user. This is outlined below. 9 if the angle is set to zero than no angle movement will take place. 9 if the torq...

Page 26

Figure 1.1 = user interface (above) • (1) this indicates the initial torque value that the e-rad will achieve before initializing into the angle movement. • (2) this will indicate the actual torque applied by the e-rad in your initial torque cycle. • (3) this will indicate which unit of measurement ...

Page 27: Standard Features:

Appendix d – option 3 operation standard features: 9 all e-rad torque/angle pre-sets will come pre-set to zero from the manufacturer and are to be adjusted to the desired settings by the user. This is outlined below. 9 positions (1 through 8) will have the option of torque and angle. 9 if the angle ...

Page 28

24 • (3) this will indicate which unit of measurement your e-rad is operating in. This system can operate in ft.Lbs / nm / or kgf. • (4) this arrow will indicate which value or setting you would like to adjust. In figure 1.1 this arrow is positioned to the right of the fp (ft.Lbs) which means that b...

Page 29

Appendix d – contact information new world technologies inc. 30580 progressive way abbotsford b.C. Canada v2t 6z2 tel: (604) – 852 – 0405 toll free: 1-800-983-0044 fax: (604) – 852 – 0269 email: info@radtorque.Com www.Radtorque.Com 25.

Page 30

E-rad limited warranty new tool warranty any new tool branded with the rad name and purchased from new world technologies inc., or through one of its authorized distributors or agents, is warranted to the original purchaser against defects in materials and workmanship for a period of one (1) year fr...

Page 31

Lighter • faster • stronger www.Radtorque.Com about new world technologies inc. New world technologies is a leading canadian manufacturer of pneumatic, battery powered, and electronic pistol grip torque wrenches. Our advanced products have proven to be successful all over the world in such industrie...