- DL manuals

- Radiant

- Boiler

- RSF 20 E

- Installation And Maintenance Manual

Radiant RSF 20 E Installation And Maintenance Manual

Summary of RSF 20 E

Page 1

Ce 0694 ta05a27.A0504 technical specification radiant bruciatori s.P.A. Montelabbate (pu) italy english installation, and maintenance manual for gas fired, wall-hung boilers models rsf 20 e • rsf 24 e • rsf 30 e type c room sealed sedbuk band d.

Page 3

Index product conformity page 1 installation instructions and warnings page 2 technical data page 4 overall dimensions - exhaust flue system page 5 general installation requirements page 8 boiler installation page 10 electrical connections page 12 boiler control panel page 13 starting up the boiler ...

Page 4

Installation manual heat tecnology since 1959 thank you for choosing radiant declaration for purposes of art. 7 of law 46 of 5 april 1990. Radiant bruciatori s.P.A. Hereby declares that all of its products are constructed to industry standards as required by the article in question and by article 5 ...

Page 5

Installation manual installation instructions - warnings this installation, use, and maintenance manual is an essential and integral part of the product, and must always be kept near the device. The warnings contained in this section are addressed both to the user and to installation and maintenance...

Page 6

Installation manual systems with thermostats a by-pass must be installed in heating systems with radiators thermostats. As required by current norms, these devices must be installed by qualified personnel only, who must respect norms uni-cig 7129 and 7131 and revisions, fire department regulations, ...

Page 7

Installation manual technical data type c unit type c devices are devices in which the combustion circuit (air intake, combustion chamber, exchanger, combustion exhaust) is sealed off from the place where they are installed. Coaxial vertical coaxial horizontal c32 c12 c52 double models rsf 20 e rsf ...

Page 8

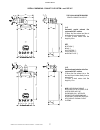

Installation manual overall dimensions - exhaust flue system – mod. Rsf 20 e type c wall-mounted boilers 31 102 80 77 50 70 a f g r c 95 77 0 166 on 40 0.5 70 60 50 80 80 70 60 0.5 50 on 40 80 0 60 10 0 140 410 185 20 370 20 60 10 0 270 80 0 270 105 80 80 20 370 20 185 80 770 31 102 80 77 50 70 c r ...

Page 9

Installation manual overall dimensions - exhaust flue system – mod. Rsf 24 e type c wall-mounted boilers sealed combustion circuit: kit a horizontal coaxial exhaust flue system with 360° rotation. It allows the flue exhaust and the air intake directly to an external wall. To insert a bend, reduce to...

Page 10

Installation manual overall dimensions - exhaust flue system – mod. Rsf 30 e a f g c r 55.5 65.5 70 78 80 102 720 80 85 280 85 82 286 82 190 35 55.5 g 65.5 r 78 70 c 80 f 102 a 80 130 320 800 198 320 130 720 85 82 280 85 286 82 35 137 800 198 s s 80 125 450 = = 80 125 type c wall-mounted boilers sea...

Page 11

Installation manual general installation requirements gas safety it is the law that all gas appliances are installed by a corgi registered installer (you can check this by contacting corgi on 01256.372200) in accordance with the regulations listed below. Failure to install appliances correctly could...

Page 12

Installation manual flue position important: the flue system shall be installed in accordance with the recommendations contained in bs 5440:1. The boiler must be installed so that the terminal is exposed to the external air. It is important that the position of the terminal allows free passage of ai...

Page 13

Installation manual boiler installation minimum distances for fixing to wall minimum distance mm. 45 0 60 450 60 1200 min. 400 m m a minimum distance mm. Section a-a 40 0 m m a balcony s s to allow access in the boiler for maintenance operations, the minimum distances shown below must be respected (...

Page 14

Installation manual gas connections the gas supply must be connected up by qualified person. The following standards must be complied with: unicig 7131/72 and unicig 7129/92 (of 21/04/93) before installing the boiler, make sure of the following: • the pipeline must be of an adequate section and leng...

Page 15

Installation manual electrical connections for qualified personell only: the boiler works with 230 v 50 hz ac current and has maximum input of 170 w. Connection to the electrical mains must be performed with a device having an omnipolar opening of at least 3 mm. Make sure the live and neutral connec...

Page 16

Installation manual control panel 5 4 3 2 1 s 6 7 14 13 8 12 11 9 10 legend (see fig. 1) 1. On / off power button 2. Heating temperature adjustment knob 3. Domestic hot water temperature adjustment knob 4. Outside temperature display pad (only with optional outside temperature sensor fitted) 5. Chim...

Page 17

Installation manual domestic hot water with storage cylinder – ta05a027.A0504 14 • check the pressure in the system: if this has gone down, comes on restore pressure; air vent valve cap circulating pump rs air vent valve pump cap • close the tap on the filling loop once this operation is completed; ...

Page 18

Installation manual 6 1 5 4 3 3 9 6 8 10 7 9 8 11 7 6 11 9 7 8 10 5 3 8 1 4 3 5 5 1 5 4 3 6 10 8 11 9 7 7 9 8 3 9 7 2 2 2 mod. Rsf 30 e fig. 1 fig. 3 conversion of gas type conversion of the boiler from natural gas to lpg and viceversa must be performed by qualified personnel only. Conversion is per...

Page 19

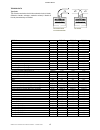

Installation manual gas data table models: rsf 20 e natural gas g 20 liquid butan gas g 30 liquid propane gas g 31 lower wobbe index (15°c; 1013 mbar) mj/nm 3 45.67 80.58 70.69 rated feed pressure mbar 20 30 37 minimum feed pressure mbar 17 20 25 main burner: 11 jets - Ø jet mm 1.30 0.78 0.78 consup...

Page 20

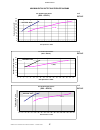

Installation manual maximum heating output gas pressure diagrams for 22 kw output boiler (g20 - g30/31) l.P.G. Natural gas 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 gas pressure in mbar output capaci ty i n kw ...

Page 21

Installation manual 14 17 19 9 10 16 15 25 12 21 13 4 7 2 5 1 22 20 6 18 8 11 3 24 23 21 main components key 1. Flue hood 2. Combustion chamber 3. Room sealed chamber cover 4. Room sealed chamber back 5. Heat exchanger 6. Flat plate type exchanger 7. Multigas burner 8. Heating safety thermostat 9. E...

Page 22

Installation manual wiring diagrams printed circuit board cvi-m sm20015 (cod. 76655la) r 22 m4 m4 19 18 21 20 c br o w n lig ht -b lu e ligh t- bl ue bl ac k s c br o w n vd red electric connection with mater xp300 water pressure switch 50 bl ac k bl ac k bl ac k bl ac k wh ite 46 45 47 49 48 sr ss ...

Page 23

Installation manual wiring diagram for remote control installation (no zone valves) fit the interface (fig. 2) on the circuit board (fig. 1) into the holes a and b provided (see fig. 1). Connect plug m1 on the interface circuit board (fig. 2) to plug m11 on the modulation circuit board (fig. 1). Con...

Page 24

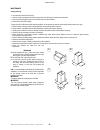

Installation manual maintenance casing removing • pull and remove the boiler front casing; • undo the 4 bottom screws that fix the side casing to the lower boiler grid (2 screws each side panel); • undo the casing fixing plate screw on the left side of the room seal chamber; • lift and remove the 2 ...

Page 25

Installation manual fault description possible cause solution code 01 flame lock-out boiler fails to fire a. No gas / gas turned off b. Ignition electrode damaged or earthed c. Electronic ignition board s4565qm faulty d. Gas valve faulty e. Minimum mechanical gas setting too low (onto the gas valve)...

Page 26

Installation manual spare parts short list code description rsf 20 e rsf 24 e rsf 30 e 20040la plate exchanger 16 p 561222 √ 20046la plate exchanger 24 p 3017b1902406 √ 20047la plate exchanger 20 p 17b1902006 √ 21001la gas burner 13 ramp 1.25 natural gas 401.1207.02 √ 21004la gas burner 13 ramp 0,77...

Page 27

Installation manual multiplex - spare parts short list 20046la 43139la 64103la 43150la 64072la 64067la 54024la 54023la 64075la 96032la 43145la 64068la 43135la 64066la 64065la 43139la 64093la 43150la 43150la 43151la 54022la 43151la 43150la 43139la 43150la 43139la 64060la 43150la 54022la 43150la 89134...

Page 28

Radiant bruciatori s.P.A. Via pantanelli, 164/166 - 61025 loc. Montelabbate (pu) tel. +39 0721 9079.1 • fax. +39 0721 9079279 e-mail: info@radiant • internet: http: www.Radiant.It uk – radiant helpline – 01329.828555 all descriptions and illustrations contained in this leaflet have been carefully pr...