Danger tool for use by licensed operators only. Operator's license can be obtained at www.Ramset.Com. Read and obey all safety and operating instructions before operating tool. Cobra tool operator’s safety & operating instruction manual semi-automatic, low velocity, piston-type fastening tool part #...

2 safety introduction danger danger safety introduction this tool is to be used only by properly trained and licensed operators. You must successfully complete the ramset training program for the tool and obtain a certified operator's license before handling, loading, or operating this tool. Safety ...

Safety instructions safety instructions 3 preparation acceptable base materials powder-actuated fastening is suitable for use in the following base materials only: • poured concrete • structural steel • masonry joints (see page 8) never attempt to fasten into any other type of material. Fastening in...

Safety instructions safety instructions 4 loads and load selection safety 1. Always make a test fastening after being sure that the base material is suitable for powder actuated fastening. Failure to determine the correct power level to be used may result in the use of excessive power, allowing the ...

5 safety instructions safety instructions tool handling safety 1. Always be sure tool is operating properly before attempting to use it. Follow the “daily function check” shown to the right and described on page 9. 2. Always load tool using a strip load selected directly from a box indicating the po...

6 el no seguir las instrucciones puede ocasionar lesiones al operador de la herramienta o a terceras personas seguridad en la aplicación de elementos de fijación 1. U tili ce úni cam ent e la he rra mie nta par a fi jar so bre un m ate ria l b ase ade cua do. 2. N unc a d isp are la he rra mie nta s...

Fasteners / loads fasteners / loads 7 your ramset cobra tool uses only the ramset fasteners and loads shown below or listed for the tool in the product catalog. Danger never use any other types of fasteners or strip loads in the ramset cobra tool. Use of other types of fasteners or loads may cause u...

Fastening applications fastening applications 8 fastening applications your ramset tool can be used for a wide range of fastening needs in a variety of base materials. Reading and following these important fastening guidelines will help you get the best results from your tool, fasteners, and powder ...

Tool operating instructions tool operating instructions 9 tool operation daily function test always check the tool first to make sure it does not contain a strip load or fastener. Test the tool several times by depressing the muzzle bushing fully on a hard surface and pulling the trigger. You should...

4. Hold the tool perpendicular (90˚) to the work surface with both hands, and press down firmly to fully depress the tool. Maintain firm downward pressure on the tool with both hands and pull the trigger to drive the fastener. Do not depress the tool against anything other than the intended work sur...

11 troubleshooting troubleshooting refer to parts schematic for proper assembly of parts – overdriving of fasteners – excessive power – change to next lower power level load strip color and number – tool fails to fire – failure to index strip – strip not inserted in tool correctly or is damaged – da...

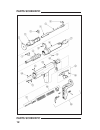

Parts schematic parts schematic 12 diagrama de piezas diagrama de piezas 12.

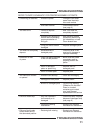

Parts list / maintenance parts list / maintenance 13 cobra tool parts list key part no. Description 1 sc301500 spall guard 2 sc301009 front barrel (baseplate) 3 sc301011a shear clip (pkg. Of 3) 4 sc301010 fastener guide 5 sc301200a piston assembly 6 sc301208 piston ring 7 sc301012 pawl (stop) 8 sc30...

14 disassembly disassembly 1. Rotate the barrel retention clip off of the pawl using a flat blade screwdriver or the point of a long fastener. Rotate the barrel retention clip away from pawl remove the pawl 2. Remove the pawl by lifting it up and away from the tool body. Remove the barrel assembly 3...

15 disassembly disassembly 6. Slide the piston out of the rear barrel assembly and slide the guide out of the front barrel. The tool is now disassembled for normal cleaning. Inspect all parts for wear or damage and clean or replace as required. Use detergent oil and cleaning brushes to remove dirt a...

Warranty all warranties of the products described herein, expressed or implied, including the warranty of merchantability and fitness for particular purposes, are specifically excluded, except for the following: ramset will repair or replace, at its sole option, any tool, part, or fastener which, wi...