- DL manuals

- Rancilio

- Coffee Maker

- epoca CD

- Use And Maintenance Manual

Rancilio epoca CD Use And Maintenance Manual

Summary of epoca CD

Page 1

Epoca use and maintenance · s · cd · de version 2.0

Page 2: Epoca

1 epoca use & maintenance the operations marked by this symbol are to be undertaken exclusively by an authorized technician. The operations marked by this symbol are to be undertaken by the user. Contents machine identification data................................. 2 1. General safety rules............

Page 3

2 name: epoca series espresso machine model: de - s - cd versions: 2 groups the label illustrated below corresponds to the identification label placed on the machine(fig. 2 - pos. A). Label identification: fig. 1 fig. 2 1 manufacturer 2 model and version 3 voltage 4 ec conformity mark(if required) 5...

Page 4

3 1. General safety rules do not leave the packing materials(plastic bags, expanded polystyrene, nails, cardboard, etc.) within reach of children, as these items are potential sources of danger. Verify that the data on the machine corresponds to that of the electrical supply network before connectin...

Page 5

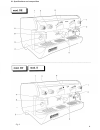

2.1 specifications and composition fig. 3 4.

Page 6

5 a b c d e de no yes 2 2 1 cd/s yes no 2 2 1 legend: a semiautomatic system; manual dispensing start and stop. B automatic system; electronic control of coffee and hot water doses dispensed. C number of coffee dispensing units(groups). D number of steam spouts. E number of hot water spouts. Cup war...

Page 7

6 2.2. Machine equipment 2 group 1 dose filter holder 1 2 dose filter holder 2 filters 3 blind filter for backflushing 1 1 mt. Supply pipe 1 1,5 mt. Supply pipe 1 1,5 mt. Drainage pipe 1 supply pipe adapters 1 blind disks for cleaning 2 doser and tamper 1 instruction manual 1 wiring diagram 1 2.3. M...

Page 8

7 the user must not: · touch the hot surfaces and dispensing areas; · pour or spill liquids on the cup warmer shelf; · put his hands under the spouts during use; · transport the machine or perform maintainence operations while the plug is connected or while the machine is hot; · wash the machine wit...

Page 9

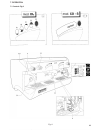

8 6. Installation 5. Transport 5.1 packaging the machine is delivered in a strong cardboard box with internal protection. The packaging bears symbols which must be observed during handling and stocking of the item. Always keep the package in a vertical position during transport. Do not turn it over ...

Page 10

9 6.2. Preliminary operations anti-siphon valve clip removal warning: if the supply cable is damaged, it must be replaced by the manufacturer or by an authorized technician /electrician to prevent any risks to the user. 6.3. Connections ·place the machine on the horizontal surface previously prepare...

Page 11

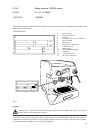

7. Operation 7.1 controls fig.8 fig. 8 10

Page 12

11 7.2. Control instruments (fig. 8) 9 gauge with mobile needle on a fixed dial with a scale and color indicators. Visual control of the boiler pressure. 10 minimum and maximum water level indicator. Visual control of water level in boiler(green led). 12 cup warmer switch (optional). 7.3. Starting u...

Page 13

12 8. Use if ground coffee is left on the rim of the filter, a leak tight seal is not ensured, and water or coffee grounds may leak out of the filter. Lock the filter-holder into the dispensing group firmly to obtain a leak tight seal. Place the cups under the spouts; begin dispensing using control ...

Page 14

13 8.4 preparing tea, camomile, etc. Place the receptacle under the hot water spout and use the dispensing control according to the model (fig.9). When the desired quantity has been obtained turn off the switch. Add the beverage desired. When purified water is used, these beverages often assume a da...

Page 15

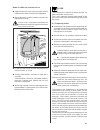

14 fig. 12 stop and start dispensing several times until clean water comes out of the discharge unit tube. Remove the filter-holder, take out the blind filter, and insert a normal filter. Replace the filter-holder on the group and rinse by dispensing water several times. Make a coffee to eliminate a...

Page 16

15 11. Storage of the machine a - temporary storage · perform cleaning and maintenance operations. · wind up the cable and fasten it to the machine with duct tape. · cover the machine and place it in a dry room. Do not leave it exposed to harmful atmospheric agents. Do not allow it to be touched by ...

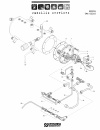

Page 17: Epoca

Epoca parts breakdown · cd · de version 1.01.

Page 32: Epoca

Epoca diagrams · s · cd · de version 1.01.

Page 44

● ● ● ● ● e1 ● ● ● ● ● s1 ● ● ● ● ● s1 tank macchina per caffè machine à café kaffeemaschinen coffee machine máquina para café uso e manutenzione emploi et entretien gebrauch und instandhaltung use and maintenance uso y manutención.

Page 45

2 gentile cliente, grazie per averci accordato la sua fiducia. Siamo sicuri che il prodotto che lei ha acquistato risponderà in pieno alle sue aspettative, come tutti gli altri articoli della produzione rancilio. Il prodotto che lei si accinge ad usare è il risultato di approfonditi studi e meticolo...

Page 46

3 il presidente - the president la presente dichiarazione perde la sua validità se la macchina viene modificata senza la nostra espressa autorizzazione. La présente déclaration perd sa validité dès lors que la machine est modifiée sans notre expresse autorisation. Die vorliegende erklärung verliert ...

Page 47

56 i italiano 5-21 f francais 22-38 d deutsch 39-55 gb english 56-72 e espaÑol 73-89 gb english contents machine identification data ......................... 57 1. General safety rules ................................... 58 2. Description ................................................. 58 2.1. Sp...

Page 48

57 m name: coffee machine, epoca series model: e1 - s1 - s1 tank versions: 1 group the label illustrated on the ec declaration of conformity of this instruction manual corresponds to the identification label placed on the machine. Label identification: symbols warning signal. The instructions which ...

Page 49

58 1. General safety rules ● don’t leave the packing elements (plastic bags, expanded polystyrene, nails, cardboard, etc.) within the reach of children, as these elements are potential sources or danger. ● check that the data on the machine corresponds to that of the electrical supply network, befor...

Page 50

59 2.1. Specifications and composition mod. S1 mod. E1 fig. 3 fig. 2 1 2 3 4 5 6 7 9 10 8 1 2 3 4 5 6 7 9 10 8.

Page 51

60 legend: a semiautomatic system; manual dispensing start and stop. B automatic system; electronic control of coffee doses dispensed. C n. Of coffee dispensing units. D n. Of steam spouts. E n. Of hot water spouts. 1 steam tap 2 steam spout 3 hot water tap 4 hot water spout 5 coffee dispensing unit...

Page 52

61 3. Technical data 3.1. Dimensions and weights 2.2. Machine equipment 2.3. Mechanical protective devices the machine is equipped with the following protective devices: ● complete panelling protection of all the parts subject to heat and of the steam and hot water supplier; ● work surface provided ...

Page 53

62 the user must not: ● touch the hot surfaces and dispensing areas; ● place liquids containers on the machine; ● put his hands under the spouts during use; ● transport the machine or carry out maintenance operations when the plug is connected or when the machine is hot; ● wash the machine with wate...

Page 54

63 4.1. Precautionary measures this machine may only be used with foodstuffs. It cannot be used for heating liquids or grinding any other kind of product that could damage and pollute it. The manufacturer cannot be held responsible for damage to people or things caused by unsuitable, erroneous or ir...

Page 55

64 6.1.2. Electric supply the machine is supplied ready for connection according to the required electrical specifications. Before connecting the machine ensure that the plate details ( fig. 1) comply with those of the electric distribution network. The electrical connection cable must be directly c...

Page 56

65 7. Operation 7.1. Controls fig.8 fig. 8 a b c d e 4 mod. E1 - s1 mod. S1 tank mod. S1 tank 1 2 2 3 5 6 7 8 8 9 1.

Page 57

66 7.3. Starting up model s1 ● turn on the water supply tap 2 fig.6. ● turn on main switch 1. The pump for boiler filling will activate . Orange led (8) on ● when the level is reached, the pump stops, the led switches off, turn the esistance switch 2; water is heated in the boiler; then, operate the...

Page 58

67 model s1 tank with autonomous tan ● open the lid on the water-tank and check that the softener a has been inserted in the dip pipe b; ● ensure that the air trap c has been inserted in the appropriate housing; if the air trap is not properly positioned, the machine may not heat or properly indicat...

Page 59

68 8.4. Preparing tea, camomile, etc. ● place the jug under the hot water spout and turn the water tap 5. When the desired quantity has been obtained, turn off the tap. ● add the beverage desired. When purified water is used, these beverages often assume a darker colour. Should the user prefer a lig...

Page 60

69 9. Adjustment and setting of the dose (where available) 9.1. Models e1 it is possible to adjust the dose of coffee dispensed e1 models. 9.1.1. Adjusting the dose the coffee dose adjustments are made by acting on the group keyboads with machine at rated pressure. 1 press the button e on the panel ...

Page 61

70 10.3. Periodical maintenance operation to be carried out with the machine under pressure. ● discharge the water from the boiler (about four litres) with hot water delivery switch 5 ● wait until the machine has returned to heat equilibrium before reuse. ● check and clean the drainage sump (fig.13)...

Page 62

71 10.3.1. Renewal of water in the boiler to be carried out only by qualified personnel. ● turn off the machine and wait for the pressure in the boiler to diminish (gauge needl on “0”). ● insert a rubber hose (1) into the hose-end fitting (2) (fig.14) ● loosen the hose-end fitting (2). ● allow the w...

Page 63

72 11. Stopping the machine a - temporary stop ● carry out cleaning and maintenance operations. ● wind up the cable and fasten it to the machine with sticky tape. ● cover the machine and place it in a dry room. Do not leave it exposed to atmospheric agents and do not allow it to be touched by childr...

Page 64

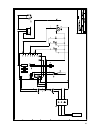

90 i f d gb e ca = centralina autolivello controle de niveau de l’eau wasserniveaukontrolle water level control transductor autonivel cem = centralina microprocessore boite electr. Du elektronische schactel microprocessor card cedula electronica microprocessor microprocesseur des mikroprozessor cv =...

Page 65

91 rev 00 j5 j6 j4 gr.

Page 66

92.

Page 67

93.

Page 68

94 w8 gr r ro f1 r23 scheda elettronica - carte Électronique - elektronikkarte - electric board - tarjeta electrÓnica (e 1) r23= regolazione pressione - pressure setting - réglage pression - duck einstellung - regulación presión w8= abilitazione programmazione dosi dose setting mode habilitation rég...

Page 69

95 i f d gb e ac = acqua calda eau chaude heißes wasser hot water agua caliente af = acqua fredda eau froide kaltes wasser cold water agua fría ca = caldaia chaudière kessel boiler caldera ec = elettrovalvola carico électrovanne d’arrivée elektroventil aufladen inlet water valve electroválvula de ca...

Page 70

96 epoca e1.

Page 71

97 pv epoca s1.

Page 72

98 epoca s1 tank.