Operators manual notify carrier of damage at once. It is the responsibility of the consignee to inspect the container upon receipt of same and to determine the possibility of any damage, including concealed damage. Randell suggests that if you are suspicious of damage to make a notation on the deliv...

2 table of contents page 2 ...............................................................................................................Congratulations page 2 ................................................................................................Factory correspondence page 3 ................

3 safety procedures · always disconnect power cord before attempting to work on or to clean equipment. Turning the switch off is insufficient as the power remains live to the cabinet and can be a hazard. · route the power cord so that it is not likely to be walked on or pinched by other appliances. ...

4 unit specifications for the bc series blast chillers bc series blast chillers model l d h 12x20x2.5 lbs. H.P. Volt/hz/ph min. Nema btu pans circuit req. Ampacity for remote bc-3 27 30 35 3 30 ½ 120/60/1 20 5-20p 5,400 bc-5 36 34 50 5 50 ¾ 120/60/1 20 5-20p 6,600 bc-5e 56 34 35 5 50 ¾ 120/60/1 20 5...

5 warranty policies parts warranty randell warrants all component parts of manufactured new equipment to be free of defects in material or workmanship, and that the equipment meets or exceeds reasonable industry standards of performance for a period of one year from the date of shipment from any ran...

6 responsibility of the customer. Adherence to recommended equipment maintenance procedures, according to the owners manual provided with each unit, is required for this warranty to remain in effect, and can have a substantial effect on extending the service life of your equipment. Equipment abuse v...

7 d. Installation checklist after the final location of the unit has been determined refer to the following checklist prior to start up: 1. Check all exposed refrigeration lines to ensure that they are not kinked, dented or rubbing together. 2. Check that condenser and evaporator fans rotate freely ...

8 operation for control there are three modes of operation for the blast chiller. Idle, automatic, and manual. When a cycle is running (start has been pushed), the selected modes’ led will flash. The following explains how to use each mode: idle mode - when the control is first turned on, it will pr...

9 3. If you think there’s a pattern to the freezing, try putting the last pan into the coldest location; this gives the first pans in a head start and this may be just enough to solve the problem. 4. The product temperature set point can be adjusted from 0 to +40 °f. The recommended setting is 38°f,...

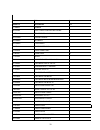

10 7. The up and down arrows will increment the value of the parameter, the sel button will toggle to the next parameter. 8. Once the last parameter is reached, the control will advance to the idle mode. R e t e m a r a p r o t a c i d n i l a m r o n g n i t t e s t n e m t s u j d a e g n a r t n ...

11 calibrating the probes: 1. With the unit on and the unit in idle mode, immerse probes in an ice bath for at least 5 minutes. 2. Press the sel button to index the led to illuminate next to the probe to be calibrated. 3. If the display reads 32° f, move on to the next probe (if applicable). If the ...

12 preventative maintenance randell strongly suggests a preventive maintenance program which would include the following monthly procedures: 1. Cleaning of all condenser coils. Condenser coils are a critical component in the life of the compressor and must remain clean to assure proper air flow and ...

13 troubleshooting guide m o t p m y s e s u a c e l b i s s o p e r u d e c o r p n u r t ’ n s e o d t i n u t i n u o t r e w o p o n t i n u n i g u l p d e t a e h r e v o r o s s e r p m o c l i o c r e s n e d n o c n a e l c y t l u a f n a f r e s n e d n o c r o t o m n a f r e s n e d n o...

14 1. Cleaning condenser coil. An accumulation of dirt and dust prevents the condenser coil from removing heat, making your unit cool poorly, run constantly, or even stop completely if the compressor overheats. Clean coil using a vacuum cleaner with a wand attachment. If the coil is greasy, wash it ...

15 next set the meter at rx1000 and touch one probe to the motor terminals and the other one to any unpainted metal part of the unit. If the meter needle moves, the motor is grounded and should be replaced. To remove the motor unscrew the bracket that holds the fan motor to its housing, slide the mo...

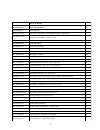

16 3 c b # l l e d n a r n o i t p i r c s e d y t q 1 0 0 0 b n s l e r e b b u n s 2 1 0 9 9 t n c d h l o r t n o c e r u t a r e p m e t r e l l i h c t s a l b 1 5 0 9 9 n r t l e a v 6 c a v 2 1 , r e m r o f s n a r t 1 2 0 9 9 r v o d h y a l r e v o l o r t n o c 1 2 0 9 9 b r p d h s e b o...

17 e 5 c b & 5 c b # l l e d n a r n o i t p i r c s e d - t q y 1 0 0 0 b n s l e r e b b u n s 2 1 0 9 9 t n c d h l o r t n o c e r u t a r e p m e t r e l l i h c t s a l b 1 5 0 9 9 n r t l e a v 6 c a v 2 1 , r e m r o f s n a r t 1 2 0 9 9 r v o d h y a l r e v o l o r t n o c 1 2 0 9 9 b r p...

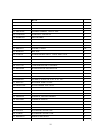

18 0 1 c b r e b m u n t r a p n o i t p i r c s e d y t q 1 0 0 0 b n s l e r e b b u n s 2 1 0 9 9 t n c d h l o r t n o c e r u t a r e p m e t r e l l i h c t s a l b 1 5 0 9 9 n r t l e a v 6 c a v 2 1 , r e m r o f s n a r t 1 2 0 9 9 r v o d h y a l r e v o l o r t n o c 1 2 0 9 9 b r p d h s...

19 e 0 1 c b # l l e d n a r n o i t p i r c s e d y t q 1 0 0 0 b n s l e r e b b u n s 3 1 0 9 9 t n c d h l o r t n o c e r u t a r e p m e t r e l l i h c t s a l b 1 5 0 9 9 n r t l e a v 6 c a v 2 1 , r e m r o f s n a r t 1 2 0 9 9 r v o d h y a l r e v o l o r t n o c 1 2 0 9 9 b r p d h s e...

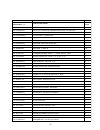

20 0 2 c b # l l e d n a r n o i t p i r c s e d y t q 1 0 0 0 b n s l e r e b b u n s 2 1 0 9 9 t n c d h l o r t n o c e r u t a r e p m e t r e l l i h c t s a l b 1 5 0 9 9 n r t l e a v 6 c a v 2 1 , r e m r o f s n a r t 1 2 0 9 9 r v o d h y a l r e v o l o r t n o c 1 2 0 9 9 b r p d h s e b...