- DL manuals

- Rangemaster

- Oven

- 100 Dual Fuel

- User Manual

Rangemaster 100 Dual Fuel User Manual

Summary of 100 Dual Fuel

Page 1

100 dual fuel fsd artno.000-0012 professional + logo professional + user guide & installation & service instructions u110077 - 01.

Page 2: Contents

1. Before you start... 1 important! 1 installation and maintenance 1 peculiar smells 1 if you smell gas 1 ventilation 1 personal safety 1 cooker care 2 cleaning 2 2. Cooker overview 3 hotplate burners 3 wok burner 4 the wok cradle 5 the griddle 5 the glide-out grill 6 the ovens 6 the clock 7 accesso...

Page 3: 1. Before You Start...

1 your cooker should give you many years of trouble-free cooking if installed and operated correctly. It is important that you read this section before you start, particularly if you have not used a dual fuel cooker before. Important! N n this appliance is designed for domestic cooking only. Using i...

Page 4

2 n n do not use harsh abrasive cleaners or sharp metal scrapers to clean the oven door glass since they can scratch the surface, which may result in shattering of the glass. Always keep combustible materials, e.G. Curtains, and flammable liquids a safe distance away from your cooker. N n do not spr...

Page 5: 2. Cooker Overview

3 artno.270-0001 proplus control to high 2. Cooker overview the 100 dual fuel cooker (fig.2-1) has the following features: a. 5 hotplate burners including a wok burner b. A control panel incorporting a timer c. A glide-out grill d. Main fan oven e. Tall fan oven. Hotplate burners the drawing by each...

Page 6

4 artno.311-0002 pan with rim if, when you let go of the control knob, the burner goes out, then the fsd has not been bypassed. Turn the control knob to the off position and wait for one minute before you try again, this time making sure to hold in the control knob for slightly longer. Adjust the fl...

Page 7

5 artno.090-0002 90 griddle position artno.090-0004 incorrect griddle position artno.311-0006 correct wok sizes the wok ring the wok ring is designed to fit a typhoon™ professional 35 cm wok (part code 13840s – available from leading retailers). If you use a different wok, make sure that it fits the...

Page 8

6 the glide-out grill open the door and pull the grill pan carriage forward using the handle (fig.2-15). The grill has two elements that allow either the whole area of the pan to be heated or just the right-hand half. Adjust the heat to suit by turning the knob. To heat the whole grill, turn the kno...

Page 9

7 the clock you can use the timer (fig.2-20) to turn the left-hand oven on and off. The clock must be set to the time of day before the ovens will work. Setting the time of day when the clock is first connected, the display flashes ( 0.00) and ( ) alternately. To set the time, turn and hold the time...

Page 10

8 to start and then stop the left-hand oven automatically before you set the clock, decide on both the ‘cook time’ and the ‘stop time’. Note: you cannot set a start time directly – this is set automatically by a combination of the ‘cook time’ and ‘stop time’. Turn the timer knob to the () position ...

Page 11

9 accessories oven shelves – left-hand (main) oven in addition to the flat shelves (fig.2-33), some models are supplied with a drop shelf (fig.2-34). The drop shelf increases the possibilities for oven shelf spacing. The oven shelves can be easily removed and refitted. Pull the shelf forward until t...

Page 12: 3. Cooking Tips

10 tips on cooking with the timer if you want to cook more than one dish, choose dishes that require approximately the same cooking time. However, dishes can be ‘slowed down’ slightly by using small containers and covering them with aluminium foil, or ‘speeded up’ slightly by cooking smaller quantit...

Page 13: 4. Cooking Table

11 4. Cooking table artno.050-0007 oven shelf positions oven shelf positions top centre base the oven control settings and cooking times given in the table below are intended to be used asaguideonly. Individual tastes may require the temperature to be altered to provide a preferred result. Food is c...

Page 14: 5. Cleaning Your Cooker

12 artno.311-0032 burner layout fsd a b c d e artno.311-0033 wok burner details fsd a b c d e artno.311-0015 burner alignment ‘d’ artno.311-0016 fitting the burner inner head a b fig.5-1 fig.5-2 fig.5-3 fig.5-4 a – cap, b – head, c – notch, d – base , e – electrode a – inner burner cap, b – outer bu...

Page 15

13 artno.331-0001grill pan pulled forwards artno.331-0003 grill frame out, no pan artno.331-0004 removing the grill frame artno.331-0005 removing the grill rail artno.331-0006 grill pan plan fig.5-5 fig.5-6 fig.5-7 fig.5-8 fig.5-9 the griddle always clean the griddle after use. Allow it to cool comp...

Page 16

14 artno.320-0008 removing the oven lining artno.320-0022 tall oven side support glass fronted door panels the oven door front panels can be taken off so that the glass panels can be cleaned. Move the cooker forward to gain access to the sides (see the ‘moving the cooker’ section under ‘installation...

Page 17

15 cleaning table cleaners listed are available from supermarkets or electrical retailers as stated. For enamelled surfaces use a cleaner that is approved for use on vitreous enamel. The vitreous enamel association has a list of approved cleaners. Contact them via their website http://www.Ive.Org. U...

Page 18: 6. Troubleshooting

16 hotplate ignition or hotplate burners faulty is the power on? Is the clock illuminated? If not, there maybe something wrong with the power supply. Are the sparker (ignition electrode) or burner slots blocked by debris? Are the burner trim and caps correctly located : see the section on ‘cleaning’...

Page 19

17 oven temperature getting hotter as the cooker gets older if turning the temperature down using the oven control knob has not worked, or has only worked for a short time, then you may need a new thermostat. This should be fitted by a service person. An oven light is not working the bulb has probab...

Page 20: 7. Installation

Installation check the appliance is electrically safe and gas sound when you have finished. 18 dear installer before you start your installation, please complete the details below, so that, if your customer has a problem relating to your installation, they will be able to contact you easily. Safety ...

Page 21

Installation check the appliance is electrically safe and gas sound when you have finished. 19 checking the parts: location of cooker the cooker may be installed in a kitchen/kitchen diner but not in a room containing a bath or shower. This appliance is designed for domestic cooking only. Use for an...

Page 22

Installation check the appliance is electrically safe and gas sound when you have finished. 20 artno.105-0008 - 100df 2bc cooker min spacings professional + 905 mm min 930 mm max 75 mm min 75 mm min 650 mm min 130 mm min fig.7-3 positioning the cooker fig.7-1 shows the minimum recommended distance f...

Page 23

Installation check the appliance is electrically safe and gas sound when you have finished. 21 artno.010-0004 moving the cooker artno.105-0010 - 100 fitting the stability bracket a 70 mm c d 500 mm b b 600 mm artno.010-0010 lowering the rear rollers (90) x10 fig.7-6 fig.7-7 fig.7-8 a – wall face, b ...

Page 24

Installation check the appliance is electrically safe and gas sound when you have finished. 22 as you progress, make sure that both the electricity cable and gas hose always have sufficient slack to allow the cooker to move. With a stability chain fitted, release it as you ease the cooker out. Do no...

Page 25

Installation check the appliance is electrically safe and gas sound when you have finished. 23 screw connect the threaded end of the hose into the gas inlet. After completing the gas connection, ensure that the cooker is gas sound with a pressure test. Pressure testing the gas pressure can be measur...

Page 26

Installation check the appliance is electrically safe and gas sound when you have finished. 24 artno.000-0012 - securing the plinth fig.7-11 oven check set the clock as described earlier in the instructions, and then turn on the ovens. Check that the oven fans start to turn and that the ovens start ...

Page 27: 8. Conversion to Lp Gas

Warning – servicing to be carried out only by an authorised person disconnect from electricity and gas before servicing. Check appliance is safe when you have finished. 25 a b c artno.311-0010 injectors fig.8-1 a – jet, b – internal injector, c – external injector artno.0102-0001 - unscrewing the co...

Page 28: 9. Circuit Diagram

26 9. Circuit diagram a b e f c d 1 2 p095199 1 2 p2 p1 e 1 2 1 2 p095199 1 2 p2 p1 b b b or or bk v v bk bk r r r br br r y y y w w w b b y br br br b b b b y y y or or w w b bk bk br br br br y y y y b b gy b b b b b br br br gy br br a1 a2 b1 c d1 d2 d3 d4 f1 f2 g1 h i b2 b3 b4 g2 h h i a3 j key ...

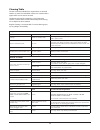

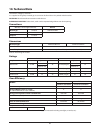

Page 29: 10. Technical Data

27 10. Technical data the cooker is category: cat ii2h3+. It is supplied set for group h natural gas. A conversion kit from ng to lp is packed with the cooker. Installer: please leave these instructions with the user. Data badge location: cooker back, serial number repeater badge below oven door ope...

Page 30

28.

Page 31

29.

Page 32

Www.Rangemaster.Co.Uk clarence street, royal leamington spa, warwickshire, cv31 2ad, england. Tel: +44 (0) 1926 457000 fax: +44 (0) 1926 450526 e-mail: consumers@rangemaster.Co.Uk artno.000-0003 ce logo docno.000-0001 - back cover rangemaster.