- DL manuals

- Ransomes

- Lawn Mower

- 51 Marquis

- Safety, Operation & Maintenance Manual

Ransomes 51 Marquis Safety, Operation & Maintenance Manual

®

RJL 100 September 2014

GB

United

Kingdom

Safety, Operation & Maintenance Manual

Ransomes - Marquis, Super Certes and Super Bowl

Engine - HONDA GX120

51 Marquis

Product Code: LDAA504

Series: EF4

61 Marquis

Product Code: LDCB604

Series: EG4

51 Super Certes

Product Code: LDFC504

Series: EC4

61 Super Certes

Product Code: LDFC604

Series: JG4

51 Super Bowl

Product Code: LDFD504

Series: JF4

WARNING

WARNING: If incorrectly used this machine can

cause severe injury. Those who use and maintain

this machine must be trained in its proper use,

warned of its dangers and must read the entire

manual before attempting to set up, operate, adjust

or service the machine.

25065G-GB (R1)

Summary of 51 Marquis

Page 1

® rjl 100 september 2014 gb united kingdom safety, operation & maintenance manual ransomes - marquis, super certes and super bowl engine - honda gx120 51 marquis product code: ldaa504 series: ef4 61 marquis product code: ldcb604 series: eg4 51 super certes product code: ldfc504 series: ec4 61 super ...

Page 2

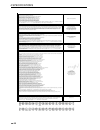

1 contents © ransomes jacobsen limited. All rights reserved section ................................................................................................... Page section ....................................................................................................Page 2 introduction...

Page 3

En-3 introduction 2 2.1 important__________________________________________________________ the ransomes super certes, super bowl & marquis are gasoline powered walk behind reel mowers. Using chain drives for traction drive and cutting reel drives. Important: do the maintenance indicated in this man...

Page 4

En-4 2 introduction 2.2 product identification ___________________________________________ a maximum front axle load in kg (for machines being driven on the highway) b gross weight (mass) in kg c maximum rear axle load in kg (for machines being driven on the highway) d power in kw e date code f mach...

Page 5

En-5 introduction 2 2.3guidelines for the disposal of scrap products _____________________ 2.3.1 during service life _______________________________________________ used oil, oil filters and engine coolant are hazardous materials. Recommended procedures must be followed for their safe removal. If a ...

Page 6

En-6 2 introduction 2.4 parts manual ______________________________________________________ in compliance with the iso14001 standard, ransomes jacobsen limited does not send a paper parts manual with every product. To refer to a parts list for this mower you have four options: 1. Website – www.Ranso...

Page 7

En-7 introduction 2 a b fig 3 2.6 assembly __________________________________________________________ the mower is fitted to a container at the factory and will need assembly before operation. Some tools will be needed for assembly. Discard the container according to the applicable local environment...

Page 8

En-8 2 introduction notes.

Page 9: Warning

En-9 safety 3 3.1 how to operate safely __________________________________________________ 3.1.1 safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operators and te...

Page 10

En-10 3 safety 3.1.3 operation a never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust fumes can increase to dangerous levels. B never carry passengers. Keep other persons or animals away from the mower. C disengage all drives and engage the p...

Page 11

En-11 safety 3 3.1.4 safe handling of fuels a the fuel and the fuel vapors are flammable. Use caution when you add the fuel to the mower. The fuel vapors can cause an explosion. B never use the containers that are not approved to keep or transfer fuel. C never keep the mower or fuel containers near ...

Page 12

En-12 3 safety o keep the mower and the engine clean. P allow the engine to become cool before storage and always remove the ignition key. Q keep all nuts, bolts and screws tight to make sure the equipment is in safe condition. R replace worn or damaged parts for safety. Replace damaged or worn deca...

Page 13

En-13 safety 3 3.1.7 important safety notes this safety alert symbol is used to alert you to possible hazards. Danger: indicates a dangerous condition that will cause death or injury unless it is prevented. Warning: indicates a dangerous condition that can cause death or injury unless it is prevente...

Page 14

En-14 3 safety warning california proposition 65 engine exhaust, some of its constituents, and some vehicle components contain or release chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Warning to prevent injury from the hot oil at high pressu...

Page 15

En-15 safety 3 warning vibration exposure limits exposure limits are calculated as a combination of the vibration level (magnitude) of the tool and the daily exposure time (trigger time). E.G. A product with 5m/s² vibration can be used up to 2 hours/day to reach the eav and up to 8 hours/day to reac...

Page 16

En-16 3 safety notes.

Page 17

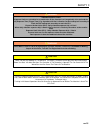

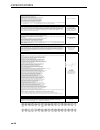

En-17 specifications 4 4.1 engine specification ______________________________________________ all 51 and 61 machines 4.2 dimensions & weights _____________________________________________ type honda 2.1kw (2.8hp) @ 2700 rpm, single cylinder, air cooled, 4 stroke ohv petrol engine, 25° inclined cyli...

Page 18

En-18 4 specifications 4.3 machine specification _____________________________________________ frame construction pressed steel welded transmission by heavy duty roller chains clutches transmission clutch. Separate cylinder clutch. Separate landroll clutch handles tubular steel adjustable at the low...

Page 19

En-19 specifications 4 the machine was tested for whole body vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The cutting device was in rotation with the machine driven in a straight line at 6 km/hr on a level and cut lawn. The...

Page 20

En-20 4 specifications 4.7 cutting unit specification_________________________________________ note these cutting units are made to cut grass of maximum height 100 mm down to the available height of cut range. 4.8 cutting performance _____________________________________________ 51cm (20in) width of...

Page 21

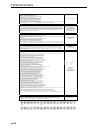

En-21 specifications 4 %xvlqhvvqdphdqgixoodgguhvvriwkhpdqxidfwxuhuƒɌɴɪɝɨɜɫɤɨɢɦɟɢɩɴɥɟɧɚɞɪɟɫɧɚɩɪɨɢɡɜɨɞɢɬɟɥɹƒ 2efkrgqtmppqrdsoqidguhvdyêurefhƒ3urgxfhqwhqvilupdqdyqrjixoghdguhvvhƒ%hgulmivqddphqyroohgljdguhvydqghideulndqwƒ7rrwmdlulqlplmdwllholnddguhvvƒ 9doplvwdmdqwrlplqlplmdwl\ghoolqhqrvrlwhƒ1rpfrpphufld...

Page 22

En-22 4 specifications 2shudwru(du1rlvh/hyhoƒɈɩɟɪɚɬɨɪɧɚɧɢɜɨɬɨɧɚɞɨɥɨɜɢɦɨɬɭɯɨɬɨɲɭɦƒ +odglqdkoxnxyreodvwlxãtrshuiwrudƒ6w¡mqlyhdxli¡uhuv¡uhk¡mghƒ *hoxlgvqlyhdxrruehvwxxughuƒ0udwdvhrshuddwruln}uydvƒ 0hoxwdvrnl\wwlmlqnruydqnrkgdoodƒ1lyhdxgheuxlwjkdxwhxughvruhloohvgho¶rspudwhxuƒ 6fkdooshjhodp%hglhqhurkuƒǼ...

Page 23

En-23 specifications 4 %xvlqhvvqdphdqgixoodgguhvvriwkhpdqxidfwxuhuƒɌɴɪɝɨɜɫɤɨɢɦɟɢɩɴɥɟɧɚɞɪɟɫɧɚɩɪɨɢɡɜɨɞɢɬɟɥɹƒ 2efkrgqtmppqrdsoqidguhvdyêurefhƒ3urgxfhqwhqvilupdqdyqrjixoghdguhvvhƒ%hgulmivqddphqyroohgljdguhvydqghideulndqwƒ7rrwmdlulqlplmdwllholnddguhvvƒ 9doplvwdmdqwrlplqlplmdwl\ghoolqhqrvrlwhƒ1rpfrpphufld...

Page 24

En-24 4 specifications 2shudwru(du1rlvh/hyhoƒɈɩɟɪɚɬɨɪɧɚɧɢɜɨɬɨɧɚɞɨɥɨɜɢɦɨɬɭɯɨɬɨɲɭɦƒ +odglqdkoxnxyreodvwlxãtrshuiwrudƒ6w¡mqlyhdxli¡uhuv¡uhk¡mghƒ *hoxlgvqlyhdxrruehvwxxughuƒ0udwdvhrshuddwruln}uydvƒ 0hoxwdvrnl\wwlmlqnruydqnrkgdoodƒ1lyhdxgheuxlwjkdxwhxughvruhloohvgho¶rspudwhxuƒ 6fkdooshjhodp%hglhqhurkuƒǼ...

Page 25

En-25 specifications 4 %xvlqhvvqdphdqgixoodgguhvvriwkhpdqxidfwxuhuƒɌɴɪɝɨɜɫɤɨɢɦɟɢɩɴɥɟɧɚɞɪɟɫɧɚɩɪɨɢɡɜɨɞɢɬɟɥɹƒ 2efkrgqtmppqrdsoqidguhvdyêurefhƒ3urgxfhqwhqvilupdqdyqrjixoghdguhvvhƒ%hgulmivqddphqyroohgljdguhvydqghideulndqwƒ7rrwmdlulqlplmdwllholnddguhvvƒ 9doplvwdmdqwrlplqlplmdwl\ghoolqhqrvrlwhƒ1rpfrpphufld...

Page 26

En-26 4 specifications 2shudwru(du1rlvh/hyhoƒɈɩɟɪɚɬɨɪɧɚɧɢɜɨɬɨɧɚɞɨɥɨɜɢɦɨɬɭɯɨɬɨɲɭɦƒ +odglqdkoxnxyreodvwlxãtrshuiwrudƒ6w¡mqlyhdxli¡uhuv¡uhk¡mghƒ *hoxlgvqlyhdxrruehvwxxughuƒ0udwdvhrshuddwruln}uydvƒ 0hoxwdvrnl\wwlmlqnruydqnrkgdoodƒ1lyhdxgheuxlwjkdxwhxughvruhloohvgho¶rspudwhxuƒ 6fkdooshjhodp%hglhqhurkuƒǼ...

Page 27

En-27 specifications 4 ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt product code serial number lmaa628 qr000301 - qr999999 vi vil, på anmodning fra nasjonale myndigheter, formidle all relevant informasjon om det delvis ferdigstilte maskineriet. Informasjonen vil ...

Page 28

En-28 4 specifications ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt 1st september 2014 mbg5209 (rev.6) these accessories have been designed to be fitted to the ransomes marquis 51 & 61 ldaa500, ldaa510, ldcb600 & ldcb610 ransomes matador 71 lddd081, lddd181, lbdd...

Page 29

En-29 specifications 4 notes.

Page 30: 100

En-30 5 decals 5.1 safety decals ____________________________________________________ a903491 read operator's manual. A903489 keep a safe distance from the machine. A903492 stay clear of hot surfaces. A903490 do not remove safety shields while engine is running. A911424 unleaded petrol, safety alert...

Page 31

En-31 6 controls 6.1 operator presence control - mechanical (opc)__________________ the opc control is on the right-side handle bar. To operate, press the button [b) and pull the lever [a] to engage the drive. To disengage the opc, release lever [a]. Button [b] will spring into position and prevent ...

Page 32

En-32 6 controls 6.4 brake release lever _____________________________________________ to apply the landroll brake, move the hand lever [f] to the top position. To release the landroll brake, move the hand lever [f] to the lowest position. 6.5 cylinder clutch lever __________________________________...

Page 33

En-33 6 controls notes.

Page 34

En-34 7 operation 7.1 daily inspection ___________________________________________________ 1. Check the complete unit. Look for worn or loose hardware, missing or damaged components, fuel or oil leaks. Make sure the hose connections are tight and all lines are in good condition. 2. Check the fuel su...

Page 35

En-35 7 operation 7.2 operator presence and safety interlock system _________________ 1. The opc system controls the primary drive clutch. You can start the engine, but the drive will not engage until the opc system is in operation (see 6.1). The machine will not drive until the opc is engaged. To e...

Page 36

En-36 7 operation 7.3 operating procedure _____________________________________________ 1. Do not start the engine with the opc system engaged. 2. Do not operate the machine or attachments with loose, damaged or missing components. Mow when the grass is dry 3. Mow a test area to understand the opera...

Page 37

En-37 7 operation 9. When you operate on a gradient, or near a drop off point, decrease the speed and be careful. Read the section 3.7. 10. To clean the cutting units, use a brush to remove grass from the cutting cylinder. The cutting cylinder blades are sharp and can cause injuries. Never use the h...

Page 38

En-38 7 operation 7.4 operation of the machine _________________________________________ read the safety instructions. How to start the engine for the first time • remove the sump filler cap and with the machine on level ground. Make sure that the sump is filled with oil. If necessary, fill the sump...

Page 39

En-39 7 operation notes.

Page 40

En-40 8 adjustments e d 8.1 marquis: aligning the front rolls _______________________________ adjust the front roll as follows. 1. Loosen the nut on the front roll carriage. Left side for the 61 cm (24 inch) machine.Right side for the 51cm (20in) machine. 2. Put a straight edge between the front and...

Page 41

En-41 8 adjustments 8.3 61 marquis: height of cut adjustment__________________________ to set the height of cut, set the position of the front roll. Adjust the front roll with handwheel [c]. To increase the height of cut, lower the front roll, turn [c] to the right side. To decrease the height of cu...

Page 42

En-42 8 adjustments 8.5 marquis: side rolls ______________________________________________ to allow long grass to the cut, remove the centre sections of the front roll. 1. Remove the front-roll bolts, spindle and rolls. 2. Install the split pins into the spindle, position the washers and outer rolls...

Page 43

En-43 8 adjustments 8.8 concave adjustment ____________________________________________ if the grass clippings do not enter the grass box, the concave needs adjustment. 1. Make sure that the concave aligns correctly with the edge of the bottom block. 2. Loosen the screws [a] which fasten the concave...

Page 44

En-44 8 adjustments 8.10 landroll clutch adjustments __________________________________ loosen the locknut (a) and rotate the adjuster (b) until the lever (c) touches the pin (d). Loosen the adjuster (b) one complete turn so that the lever does not make contact with the pin. Tighten the locknuts to ...

Page 45

En-45 8 adjustments 8.12 backlapping _____________________________________________________ there is no need to remove the cutting cylinder to backlap. • backlapping grinds the cutting cylinder blades the bottom blade. •if the cutting cylinder needs frequent backlapping, remove the cutting cylinder a...

Page 46

En-46 8 adjustments 8.13 handle adjustment _______________________________________________ the handle is adjustable for height and angle. To adjust the angle. 1. Loosen the clamp bolts [a] to adjust the angle on the handle bars tighten the bolts[a]. To adjust the height. 2. Remove the bolt [c] from ...

Page 47

En-47 8 adjustments notes.

Page 48

En-48 9 accessories 9.1 brush and comb set______________________________________________ a brush and comb set are available for this range of machines. Do not use the brush in wet conditions. 1. Remove the bolt [a] on both sides of the front roll. 2. Fit the bracket [b] and tighten the bolt [a]. 3. ...

Page 49

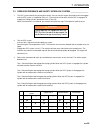

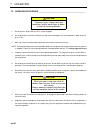

En-49 9 accessories 9.3 trailing seat _____________________________________________________ a trailing seat is available for the marquis 61.It is attached by a one pin hitch. Only use a ransomes trailing seat (lmaa628) and towbar(lmaa747) with this machines. Installation 1. Position trailing seat be...

Page 50

En-50 9 accessories 9.4 verti-groom attachment ________________________________________ adjustments: machine set up.. Verti-groom settings the verti-groom reel must be parallel to the bottom blade. 1. Make sure that the verti-groom handwheels are in the down position. 2. Use the height of cut bar to...

Page 51

En-51 9 accessories 9.5 verti-groom drive belt __________________________________________ the drive belt is found on the right side of the machine. To access, remove the lid from the drive belt housing. Adjust the verti-groom drive belt: loosen the belt tensioner. Apply a force of 2.2kgs (5lbs) in t...

Page 52

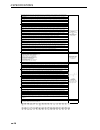

En-52 10 maintenance maintenance and lubrication chart interval item section first month or 20 hours change engine oil 11.3 each day 10 hours check engine oil level 11.1 check air filter element 10.2 check engine for dirt 11.1 first 50 hours clean or replace air filter element * 11.2 check and adjus...

Page 53

En-53 10 maintenance these figures are for instruction only. If the hours of use in any calendar period, are more than those given, use the work hours as your maintenance schedule. 10.1 engine daily (every 8 working hours) ____________________________ make sure the engine and controls are kept clean...

Page 54

En-54 10 maintenance 10.2 engine weekly: (every 50 working hours) ________________________ air cleaner two element type): remove the wing nut and the air cleaner cover. Check both elements for damage. Replace if dirty or damaged. Wash the foam element in a solution of detergent and warm water. Allow...

Page 55

En-55 11 lubrication the recommended lubricants are recorded on section 4.5 these figures are for instruction only. If the hours of use in any calendar period, are more than those given, use the work hours as your lubrication schedule. 11.1 engine daily: (every 8 working hours) _____________________...

Page 56

En-56 11 lubrication 11.4 machine ___________________________________________________________ before you use the machine for the first time, lubricate a,b and c. Use the recommended grease: cutting cylinder bearings (a) landroll clutch (b) landroll (c) - marquis and super bowl only lubricate the fro...

Page 57

En-57 11 lubrication notes.

Page 58

En-58 12 quality of cut it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area should provide known and consistent turf conditions to allow accurate evaluation of the mower’s ...

Page 59

En-59 12 quality of cut 12.2 marcelling______________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-tip dis- t...

Page 60

En-60 12 quality of cut 12.3 step cutting _____________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to an- other. This is usually caused by mechanical wear or ...

Page 61

En-61 12 quality of cut 12.4 scalping ________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is usu...

Page 62

En-62 12 quality of cut 12.5 stragglers ______________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull reel or be...

Page 63

En-63 12 quality of cut 12.6 streaks _________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged or uneve...

Page 64

En-64 12 quality of cut 12.7 windrowing ______________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Probabl...

Page 65

En-65 12 quality of cut 12.8 rifling or tramlining ___________________________________________ 12.9 mismatched cutting units _______________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in a wave-like cut ...

Page 66

En-66 12 quality of cut notes.

Page 67

En-88 13 fuses and relays.

Page 68

En-89 13 fuses and relays 13.1 fuse and relay identification____________________________________ fuse number function 1 left hand side lamps 2 right hand side lamps 3 left hand head lamps 4 right hand head lamps 5 beacon 6 plus one supply 7 ignition on circuits 8 direction indicators 9 hazard lamps ...

Page 69

En-97 14 guarantee warranty warranty is subject to specific terms and conditions, e.G. Wearing parts, unapproved modifications, etc. Are not included. For a full set of warranty conditions, contact your local dealer or distributor. Service a network of authorised sales and service dealers has been e...

Page 70

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...