- DL manuals

- Rational

- Grill

- SelfCooking Center

- Operating Manual

Rational SelfCooking Center Operating Manual

Summary of SelfCooking Center

Page 1

Operating instructions selfcooking center ® sign up for your fr ee member ship of club rational now . You will fi nd the details in the middle of the oper ating instructions ..

Page 2: Warning:

- 2 - warning: incorrect installation, adjustment, servicing, maintenance, cleaning, or unauthorized modifi cations to the appliance can result in damage, injury or death. Read the operating manual carefully before starting to use the appliance. For your safety: do not store or use any fl ammable gase...

Page 3

- 3 - dear customer congratulations on your new selfcooking center ® . By purchasing a selfcooking center ® you have entered a new era in cookery. Thanks to a readily understandable visual control concept you and your selfcooking center ® will achieve excellent results in no time at all –with hardly...

Page 4

- 4 - contents general instructions / for your safety 6 daily cleaning and care 12 features 13 general operating instructions 14 selfcooking control ® mode 16 controls 17 operation 18 combi-steamer mode 26 controls 2 moist heat 28 dry heat 29 dry heat and moist heat 30 climaplus control ® 31 time se...

Page 5

- 5 - contents service descaling the steam generator 53 descaling the humidifying nozzle 56 draining the steam generator, unit and software identifi cation, service-info 57 data communications usb data memory (usb stick) 58 haccp logging, software update 59 importing and exporting programs 60 applian...

Page 6

- 6 - • please take the time to read the following safety and operating instructions carefully. • keep this manual carefully so that it can always be consulted by anyone using the appliance. • this appliance must only be used to cook food in catering establishments. Any other use is not intended and...

Page 7

- 7 - warning – if containers are fi lled with liquid or contents which liquefy during cooking, do not use rack levels higher than those where the user can see into the slide-in containers. Warning sticker is enclosed with appliance. Warning! • caution! Hot vapour (risk of scalding)! • caution! Conta...

Page 8

- 8 - loading/removal open appliance door slowly. When it is opened heating and fan wheel shut down automatically. The integral fan wheel brake is activated. The fan wheel keeps running for a brief period only. Do not touch the fan wheel. Do not insert containers or grids until the grid shelf has be...

Page 9

- 9 - working with mobile plate racks please always insert core temperature probe into ceramic tube. Warning! Before the mobile plate rack is removed the core temperature probe must be removed and placed in the holding position on the run-in rail. Warning! • shut the gn container locks on the mobile...

Page 10

- 10 - cool down use the „cool down“ function to cool the cooking cabinet . Warning! • during „cool down“ the fan wheel runs when the door is open! • do not switch on „cool down“ function unless air baffl e is correctly locked. • do not touch the fan wheel. • appliance must not be cooled with cold wa...

Page 11

- 11 - maintenance • inspection, maintenance and repair work must only be carried out by trained technicians. • the unit must be switched off at the mains when cleaning (except cleanjet ® cleaning), carrying out inspection, maintenance or repair work. • if the appliance is installed on casters, free...

Page 12

- 12 - daily cleaning and care warning! • your unit must be cleaned every day to maintain the high quality of the stainless steel, for hygiene reasons and to prevent faults occurring. To do this, follow the instructions in the „cleanjet ® functions“ or „manual cleaning“ sections. • to avoid corrosio...

Page 13

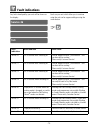

- 13 - features 햲 appliance serial number (visible only when door open) 햳 draft diverter (gas appliances only, optional) 햴 interior lighting 햵 appliance door with double glass panel 햶 door handle table-top units: one-handed operation with slam function floor units: (one-handed operation) 햷 unlocking...

Page 14

- 14 - selfcooking control ® - mode after switching on or operating the selfcooking control ® button you enter selfcooking control ® mode. See chapter on selfcooking control ® mode for description. Combi-steamer-mode by operating the moist heat, dry heat or combination moist heat and dry heat button...

Page 15

- 15 - selecting a function examples: press button short bleep and fl ashing red light confi rms button has been pressed. Active button is surrounded by fl ashing red frame. The central dial can be used to enter data while the button is fl ashing. Confi rmation of data input takes place automatically aft...

Page 16

- 16 - on/off switch selfcooking control ® 9 modes: large roasts pan fries poultry fish side dishes potato products egg dishes/desserts bakery products finishing ® function button programming mode button central dial with push function selfcooking control ® mode.

Page 17

- 17 - the 9 selfcooking control ® modes (roasts, pan fries, poultry, fi sh, side dishes, potato products, egg dishes/desserts, baked products, finishing ® ) automatically detect product-specifi c requirements, the size of the food to be cooked and the load size. Cooking time, temperature and the idea...

Page 18

- 18 - example 1: veal roast select large joint select preparation e.G. Roast – that’s it! The unit right away works with preset, factory- tested settings. . Or you have the option of making individual changes to the level of browning and cooking. After preheating you can change the default settings...

Page 19

- 19 - note: the required total cooking time is displayed when the cooking time has elapsed and the cooking cabinet door is opened. You can cook different-sized roasts at the same time. To do this, fi rst insert the core temperature probe into the smallest joint. The buzzer will sound when the smalle...

Page 20

- 20 - example 2: muffi ns select „bakery products“ mode select „baking“ – that’s it! The unit right away works with preset, factory- tested settings. Alternatively, you have the option of making individual changes to the degree of browning. After preheating you can change the default settings as des...

Page 21

- 21 - note: the requisite cooking time is displayed once the cooking time is up and the cooking cabinet doors have been opened. Discontinuing an operation in selfcooking control ® mode an operation in selfcooking control ® mode may be discontinued while the display shows the „back“ symbol. As soon ...

Page 22: Levelcontrol

- 22 - selfcooking control ® mode – operation example 3: „finishing ® – à la carte” select „finishing ® “ mode select „plates à la carte“ – that’s it! The unit right away works with preset, factory- tested settings. Or you can change the desired cabinet climate, e.G. „dry“ or „moist“. Unit preheats ...

Page 23

- 23 - selfcooking control ® mode – operation „levelcontrol ® “ with level control ® you can enter an individual time for each of your appliance racks and have it displayed. That way you can always see exactly when each rack is ready. A buzzer sounds and the indicated level fl ashes as soon as the pr...

Page 24

- 24 - selfcooking control ® mode – operation example 4: „finishing ® – banquet” select „finishing ® “ mode select „plated banquet „ – that’s it! The unit right away works with preset, factory- tested settings. Or you can change the desired finishing climate e.G. „dry“ or „moist“. The preset time ma...

Page 25

- 25 - selfcooking control ® mode – operation example 5: rice select side dishes select „steamed rice“ – that’s it! The unit right away works with preset, factory- tested settings. Or you have the option of making individual changes to the time. If desired the default settings can be changed within ...

Page 26

- 26 - combi-steamer-mode all combi-steamer functions are available in combi-steamer mode. You enter combi-steamer mode by operating the moist heat, dry heat or combination moist heat and dry heat button..

Page 27

- 27 - combi-steamer mode – controls on/off switch 3 operating modes: „moist heat“ button „dry heat“ button combination of dry and moist heat clima window cooking cabinet temperature time core temperature humidifi cation air speed cool down function button programming mode button central dial with pu...

Page 28: Or Work With

- 28 - the fresh steam generator generates hygienic fresh steam. Cooking cabinet temperature can be set to between 30 °c and 130 °c. Cooking methods: steaming, stewing, blanching, simmering, soaking, vacuum cooking, thawing, preserving example setting range between 30 °c and 130 °c or work with core...

Page 29: Or Work With

- 29 - powerful heating elements heat the dry air. Cooking cabinet temperature can be set to between 30 °c and 300 °c cooking cabinet humidity can be defi ned (see chapter on climaplus control ® ). Cooking methods: baking, roasting, grilling, deep-frying, gratinating, glazing or work with core temper...

Page 30: Or Work With

- 30 - „moist heat“ and „dry heat“ cooking modes are combined. This combination creates a hot humid cabinet climate for especially intensive cooking. Cooking cabinet humidity can be defi ned (see chapter on climaplus control ® ). Cabinet temperature can be set to between 30 °c and 300 °c . Garungsart...

Page 31: Moist Heat

- 31 - climaplus control ® measures and regulates the humidity in the cooking cabinet to within one percent. You can set the exact product-specifi c climate for each food in the clima window. Moist heat climaplus control ® is factory-set to 100 % humidity. Dry heat climaplus control ® allows cooking ...

Page 32

- 32 - timer continuous operation press clock symbol and hold button down until „continuous“ appears on the display. Or rotate central dial to the left until „continuous“ appears. Manual preheat # rotate central dial to the left. First „continuous“ appears, then „preheat“. Real-time setting (see cha...

Page 33

- 33 - the cooking process is regulated by a 6-point core temperature measurement in the food. Clean core temperature probe prior to use and cool with hand shower. Insert the core temperature probe into the thickest part at an angle of 30-45 degrees, so that the tip of the probe is in the centre of ...

Page 34

- 34 - humidifi cation a powerful jet atomises bursts of water and distributes it throughout the cooking cabinet. Humidifi cation creates ideal rising conditions and gives bakery products an attractive glossy fi nish. Can be selected with dry heat or combination moist heat and dry heat. Humidifi cation ...

Page 35

- 35 - you have been operating your appliance at high cooking cabinet temperature and now want to continue working at low cabinet temperature. „cool down“ function lets you cool the cabinet quickly and gently. Deselect mode close door open door display shows current cooking cabinet temperature. You ...

Page 36

- 36 - it takes no time at all to create your own cooking programs in programming mode using the easy-to-understand control concept. Select program program name new program new levelcontrol ® program copy program change program delete program function button cooking programs display: selfcooking coo...

Page 37

- 37 - programming selfcooking mode you can copy or adapt the 9 operating modes (roasts, grills, poultry, fish, side dishes, potato products, egg dishes/desserts, baked products, finishing ® ) to meet your individual requirements and store them under a new name. Examples: you could rename “roasts” a...

Page 38: Or Preheat

- 38 - programming mode – “programming - combi-steamer mode“ programming manual-mode enter desired program name. Dial letter with central dial and press central dial to select. Or preheat or work with core temperature probe all optional functions, e.G. Fan wheel (excepting cleanjet ® , descale and c...

Page 39

- 39 - start program e.G. „test“ program during program execution the program name and program step appear on the display. Note: you can adjust the settings (climaplus control ® temperature, time, etc.) as required while a program is running. Test program steps e.G. „test“ program program step 1 pro...

Page 40

- 40 - delete individual programs e.G. „test“ program delete all programs briefl y press key 1x, a red frame fl ashes. Hold key down until the background changes from red to blue. The deletion process is represented by a moving arrow. Note: after deletion the unit starts automatically. Copy program e....

Page 41: Welcome to

Welcome to new.

Page 42: Rational Master Chefs.

We are at the start of a new era in cooperation. You can now become a member of club rational – the rational owners’ club – free of charge. As a club member we will offer you many options to extend your knowledge about cooking with rational cooking technology. For example, owner seminars and a new i...

Page 43

The serial and software numbers can be displayed using the “type” function. Application to join club rational please fax us your application or register directly on the website: rational uk fax: 01582 485001 internet: www.Rational-uk.Com rational international ag fax: +41 71 727 9080 internet: www.R...

Page 45

- 41 - with level control ® you can enter an individual time for each of your appliance racks and have it displayed. That way you can always see exactly when each rack is ready. The buzzer sounds and the indicated level fl ashes as soon as the preset time for the relevant rack is up. Once the cabinet...

Page 46

- 42 - „start“ level control ® program e.G. „test“ program the unit preheats automatically – the display shows: note: levelcontrol ® is automatically activated for “finishing ® plated à la carte”, “finishing ® container” and “steam vegetables”. Select level loaded (e.G. Level 3) you can repeat this ...

Page 47

- 43 - setting program lock: new programs cannot be created when „program lock“ is set. You can use existing programs, but not change, copy or delete them. Or only cooking programs can be used. Manual operation is not possible. Enter password use central dial to dial desired letter or number and pre...

Page 48

- 44 - cleanjet ® is the automatic cleaning system for cleaning the cooking cabinet. Attention: for hygiene reasons and to prevent malfunctions it is essential to clean the unit every day. Please note that your unit must be cleaned every day at the close of work, even if it is only operated in moist...

Page 49

- 45 - you are asked to open the door and remove the container. Stainless steel grids, combifry ® and super-spike poultry grids can stay in the cabinet during cleaning. Rinse aid (blue) cleaner (red) note: when using softened water the recommended amount of cleaner tablets can be reduced by up to 50...

Page 50: 0:00

- 46 - cleanjet ® place cleaner tablet (white) on top of rinse aid tablet (blue). Caution! • do not place cleaner and rinse aid tablets in the cooking cabinet! • before the start of cleanjet ® cleaning the hinging racks or mobile plate rack must be inserted in the cooking cabinet as instructed. Clos...

Page 51

- 47 - cleanjet ® examples of cleaning step selections: cleaning step description/application cleaner/rinse aid rinse without tablets rinse cabinet with warm water. No rinse for non-greasy limescale deposits rinse aid e.G. After baking, working in moist heat. Interim cleaning for all deposits – with...

Page 52

- 48 - cleanjet ® /interrupt cleanjet ® interrupting the cleanjet ® - program: if there is a power cut of more than 10 minutes or after the unit is switched off the display shows. If interrupt cleanjet ® is not confi rmed within 20 seconds by pressing the display or the central dial, the program cont...

Page 53

- 49 - cleanjet ® – request cleanjet ® request this function allows a fi xed operating hours time to be set for cleanjet ® cleaning. You can set the desired operating hours for the cleaning request using the central dial. Note: „red” cleanjet ® request active. „blue” cleanjet ® request inactive. The ...

Page 54: 0:30

- 50 - delta t cooking, 1/2 power, power optimisation connection by gradually raising the temperature in the cabinet until the cooking process ends and maintaining a constant differential to the current core temperature, the meat is cooked more slowly. Delta = difference between core temperature and...

Page 55: Start Time

- 51 - automatic start time if your kitchen setup so requires, you can set your unit to start automatically. Enter automatic start time: most recently set start time is automatically displayed. Set the desired start time using the central dial and press the central dial to confi rm. Set the desired d...

Page 56

- 52 - chefline ® , calcdiagnosis system ® (cds) chefline ® you are given the opportunity of having the chefline ® telephone number displayed. The display shows: calcdiagnosis system ® (cds) the calcdiagnosis system ® rinses and drains the steam generator as required by the amount of use. The calcdi...

Page 57

- 53 - descaling warning! • the process described involves working with an aggressive chemical fl uid – danger of corrosive burns! • to prevent damage to materials and health it is vital that you use: protective clothing safety goggles protective gloves face mask the manufacturer’s descaler hand pump...

Page 58

- 54 - guide the hose into the steam inlet up to the mark shown on the hose. Fasten the hose to the left grid shelf with the wire hook. Note: the allocation of marking to unit size is described in the descaler pump instructions. Replace left grid shelf to secure the descaler hose. Introduce the hose...

Page 59: 1:30

- 55 - descaling processes and descaling time are shown on the display. When the descaling process has fi nished the descaling status of the steam generator is indicated. If more than 3 bars are displayed after the descaling process, the descaling process can be repeated. Aborting the descaling proce...

Page 60

- 56 - descaling the humidifying nozzle please check the humidifying nozzle for limescale deposits once a month. Warning! • the process described involves working with an aggressive chemical fl uid – danger of corrosive burns! • to prevent damage to health it is vital that you use: protective clothin...

Page 61

- 57 - draining the steam generator you can drain the steam generator before moving it or to stop it freezing. Deselect cooking process. Open cabinet door. The steam generator is drained automatically. Unit and software identifi cation the unit and software identifi cation can be read out using the „m...

Page 62

- 58 - usb data memory (usb stick) usb data storage (usb stick) you can read out cooking programs and haccp data from the unit with the usb stick. The status of the usb data memory is shown on the display: insert usb memory stick into the usb interface below the control panel. Usb data storage (usb ...

Page 63

- 59 - there is a continuous output of haccp process data via the unit interface. Haccp process data is also stored for a period of 10 days and can be outputted via the unit interface as required. You will need a pc/laptop and combilink ® software. You will fi nd more detailed explanations in the com...

Page 64

- 60 - importing and exporting programs importing and exporting programs you can copy your cooking programs to an original usb memory stick made by the appliance manu- facturer. The cooking programs can subsequently be copied to a computer or another unit. Program export: plug usb memory stick into ...

Page 65

- 61 - real-time, time format, time format for cooking sequences basic appliance settings can be displayed and changed. Real-time time format press the display to change between the 24 hour and 12 hour indication. Set time format glows red (date format changes automatically). Time format for cooking...

Page 66

- 62 - modifying the basic settings temperature unit setting your appliance gives you the choice of two temperature units. Press the display to change between the temperature units °c and °f. The set temperature unit glows red. Date setting date format is linked to time format. Selection: 24h appear...

Page 67

- 63 - modifying the basic settings factory defaults briefl y press key 1x, a red frame fl ashes. Hold key down until the background changes from red to blue. Press the button to reset the basic settings (language, temperature unit, buzzer tone, time unit, display settings, forced clean) to their fact...

Page 68

- 64 - manual cleaning or, instead of cleaning with cleanjet ® , you can clean your unit manually. For hygiene reasons and to prevent malfunctions it is essential to clean the unit every day. Warning! • the process described involves working with an aggressive chemical fl uid – danger of corrosive bu...

Page 69: 0:50

- 65 - manual cleaning close unit door, cleaning starts automatically. Follow the appliance menu prompt. The cleaning time is shown on the display. When „rinse“ request appears, please thoroughly rinse grid rack, mobile oven rack, cooking cabinet and the area behind the air baffl e with the hand show...

Page 70

- 66 - inspections which shoud only be carried out by experienced staff technicians. Danger! • high voltage! • switch off the unit at the mains before opening the service doors and working on live components. • use only genuine spare parts made by the appliance manufacturer. Cleaning the air fi lter ...

Page 71

- 67 - replacing the door gasket the door gasket comprises a vulcanised frame which slots into a guide on the cooking cabinet. If a gasket needs changing, pull the old gasket out of the guide. Clean any dirt from the guide rails. When fi tting the gasket make sure the rectangular part of the gasket i...

Page 72

- 68 - draft diverter (gas appliances only) exhaust gas pipe diameter: 180 mm ultravent ® condensation hood the patented condensation technology used in the ultravent ® condensation hood totally absorbs steam in enclosed areas and discharges it through the integral exhaust system. Vapour is automati...

Page 73

- 69 - combi duo model 6 x 1/1 on 6x1/1 or 10 x 1/1 gn (electric) model 6 x 2/1 on 6 x 2/1 or 10 x 2/1 gn (electric) model 6 x 1/1 on 6x1/1 gn (gas) model 6 x 2/1 on 6x2/1 gn (gas) standard top rack 1.60 m mobile top rack 1.72 m with 150 mm height-adjustable feet top rack 1.68 m article numbers on r...

Page 74

- 70 - fault indications any faults developed by your unit will be shown on the display: faults on your unit which allow you to continue using the unit can be suppressed by pressing the arrow button. Fault when and how what to do indication service 10 for 30 seconds after switching on can be suppres...

Page 75

- 71 - fault indications service 25 indicated for 30 seconds during cleanjet ® not functioning! Cleanjet ® cleaning • turn water tap on full • check supply fi lter • remove containers from cooking cabinet • if you cannot identify the fault please notify customer service. • if service 25 appears when ...

Page 76

- 72 - before you call customer service error possible cause to eliminate water dripping out of the unit’s door door is not closed correctly. Door seal is worn or damaged. If the door is closed correctly, the door handle will point down on fl oor units. Replace the door seal (see the „maintenance” se...

Page 77

- 73 - before you call customer service error possible cause to eliminate the unit does not indicate a function after it is switched on. External main switch is switched off. Fuse on the premises’ distribution board has tripped. The ambient temperature after switching the unit off remained below 5 °...

Page 78

- 74 - eu declaration of conformity for electrical units manufacturer: rational ag address: iglinger straße 62 d-86899 landsberg, germany product: circulating hot-air oven with steaming unit for commercial kitchens type designation: scc 61, scc 62, scc 101, scc 102, scc 201, scc 202 the designated p...

Page 79

- 75 - eu declaration of conformity for electrical units manufacturer: rational ag address: iglinger straße 62 d-86899 landsberg, germany product : circulating hot-air oven with steaming unit for commercial kitchens type designation: cm 61, cm 62, cm 101, cm 102, cm 201, cm 202 scc 61, scc 62, scc 1...

Page 80

- 76 - eu declaration of conformity for gas units manufacturer: rational ag address: iglinger straße 62 d-86899 landsberg, germany product: circulating hot-air oven with steaming unit for commercial kitchens type designation: cm 61 g, cm 62 g, cm 101 g, cm 102 g, cm 201 g, cm 202 g scc 61 g, scc 62 ...

Page 81

- 77 - eu declaration of conformity for gas units manufacturer: rational ag address: iglinger straße 62 d-86899 landsberg, germany product: circulating hot-air oven with steaming unit for commercial kitchens type designation: cm 61 g, cm 62 g, cm 101 g, cm 102 g, cm 201 g, cm 202 g scc 61 g, scc 62 ...

Page 82

- 78 - notes.

Page 84

80.01.001 · v-09 · mediadesign and services · ad · 09/06 englisch uk rational international.