- DL manuals

- Ravelli

- Indoor Fireplace

- Sara

- Owners And Installation Manual

Ravelli Sara Owners And Installation Manual

economical

user

friendly

leading

design

healthy

home

visible

flame

clean air

approved

Sara Wood Pellet Fire Owner’s

Installation

&

Manual

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS WOOD PELLET FIRE.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR

EVEN DEATH.

Contact your local building or fire official about restrictions and installation inspection requirements in your area.

Summary of Sara

Page 1

Economical user friendly leading design healthy home visible flame clean air approved sara wood pellet fire owner’s installation & manual please read this entire manual before installation and use of this wood pellet fire. Failure to follow these instructions could result in property damage, bodily i...

Page 2

Attention if you are a not a registered pellet solutions fire wood pellet re installer, and do not have legitimate access to the necessary passwords to install and program the sara wood pellet re, you must not install or attempt to install this re. The sara wood pellet re requires technical programm...

Page 3: Owners

1 owners table secti n - o of contents 1. Contents introduction......................................................... 2 safety warnings & maintenance recommendations ............................................. 3 pellet quality ........................................................... 3 flamma...

Page 4: 1. Introduction

2 page 1 2.1 pellet quality pellet quality is important - please read the following: your wood pellet fi re has been designed to burn ¼“ (6mm) diameter wood pellets, manufactured to the as/ nzs 4014.6 standard only. The performance of your wood pellet fi re is greatly affected by the type and quality ...

Page 5: 1. Introduction

3 page 1 2.1 pellet quality pellet quality is important - please read the following: your wood pellet fi re has been designed to burn ¼“ (6mm) diameter wood pellets, manufactured to the as/ nzs 4014.6 standard only. The performance of your wood pellet fi re is greatly affected by the type and quality ...

Page 6: 3. What Are Wood Pellets?

4 page 2 3. What are wood pellets? Wood pellets are made from sawdust and wood shavings. The material used cannot contain any foreign substance such as glue, varnish or synthetic substances. Subjecting it to high pressure, the wood is pressed through a plate with holes and due to the high pressure t...

Page 7

5 page 3 5. Operating your pellet fire 4.2 before you begin before carrying out any maintenance take the following pellet precautions: • make sure that the general power supply has been disconnected. • make sure that all parts of the wood pellet fi re are cold. • make sure that the ashes have cooled ...

Page 8

6 page 4 5.1.1 starting the fi re normally 1. Ensure burn pot is clean and the burn pot holes are visible. 2. Ensure the hopper is full of wood pellets. 3. Press button [3] for 3 seconds. The pellet fi re will start its ignition process, going through several ignition phases. • start – loads pellets i...

Page 9

7 page 5 locking mechanism is the locked position before closing the door. 5.3 understanding the remote control 5.4 synchronising the remote control with the pellet fire all insert fi res come with a remote-control (radio-wave) handset and receiver. Sometimes, due to interference in the power supply ...

Page 10: 6. Setting Up Your Pellet

8 page 6 all operations assume the fi re is in the default off mode - press button 3 to achieve this. Some operations can also be performed in fi nal cleaning – use caution if the fi re has been running. If the fi re should come with the wrong language set see “6.4 menu three - select language (setting ...

Page 11

9 page 7 day with [1] or [2] (24 hour clock) example: 4:30p.M would be 16:30 8. Press [7] to confi rm 9. Minutes clock will appear on the display. Change the minutes of the day with buttons [1] or [2] 10. Press [7] to confi rm 11. Press [3] to exit the menu 6.3 menu two - set crono (programmable therm...

Page 12

10 page 8 to set the desired temperature press button [4] then use button [1] & [2] to achieve the desired value. When the set temperature on the display is reached, modulation work will appear on the screen and the fi re will drop to its lowest power setting. 6.4 menu three - select language (settin...

Page 13: 7. Troubleshooting

11 page 9 then press and hold [6] for 3 seconds. The display will show “screw state”. 2. Use button [1] to turn the auger on “screw 1” and button [2] to turn it off. 3. Once started auger will run for a couple of minutes 4. Remember to turn the screw off (screw 0) with button [2] before exiting, but...

Page 14

12 page 10 warning reason solution pellets finished alarm • the pellet hopper is empty • check whether there are pellets in the hopper and refi ll if necessary. • the raio-motor does not load pellets. • empty the hopper to check that no foreign objects have fallen inside which could prevent the corre...

Page 15

13 page 11 8. Maintenance and cleaning before carrying out any maintenance take the following precautions: • make sure that the general power supply has been disconnected. • make sure that all parts of the wood pellet fi re are cold. • make sure that the ashes have cooled completely. • make sure that...

Page 16

14 page 12 to remove the burn pot liner, open the door and lift the burn pot liner from the burn pot holder. Using the metal scrapper or suitable tool (wire brush) remove material that has accumulated in the burn pot liner or is clogging the holes, then dispose of the scrapped ashes . Place the burn...

Page 17

15 page 13 the combustion and performance of the fi re. During combustion, firex 600 turns white, due to an effect called pyrolysis, making the fl ame clear and shining. If the combustion is regulated correctly, the firex 600 interior always remains clean and white. The condition of firex 600 is there...

Page 18

16 page 14 venting system should be inspected and cleaned at least once every year or after every ton of pellets burnt. We recommend contacting your dealer for professional cleaning. To remove dust from the vent pipe, tap lightly on the pipe to dislodge any loose ash. Open the bottom of the fl ue ada...

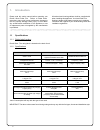

Page 19: 9. Maintenance Record

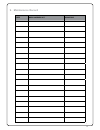

17 page 16 9. Maintenance record e r u t a n g i s t u o d e i r r a c k r o w e t a d.

Page 20: 10. Warranty Information

18 page 17 10. Warranty information pellet solutions fire and its partner ravelli , manufacturers of the ravelli range of pellet fires extends the following warranty for their wood pellet fires when purchased from an authorised pellet solutions fire dealer. 10.1 warranty coverage pellet solutions fire...

Page 21

19 page 18 10.3 warranty exclusions this warranty does not cover the following: • changes in surface finishes as a result of normal use. As a heating appliance, some changes in colour of interior and exterior surfaces may occur. This is not a flaw and is not covered under warranty. • damage to printed...

Page 22

20 page 19 11. Proof of purchase/warranty use this page to note down the details of your wood pellet fi re purchase, and attach the receipt and any other documents/ business cards from the retailer that sold you the fi re. Name of store where pellet fi re was purchased: ...................................

Page 23: Installation

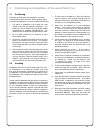

21 installation table - section of contents introduction...................................................22 positioning and installation of the wood pellet fire ..................................23 positioning ....................................................... 23 installing.......................

Page 24: 1. Introduction

Page 1 2.1 positioning generally the sara should be installed in a centrally located position within the home. When deciding where to position the appliance, you must consider the following: 1. The place of installation of the pellet fi re must comply with local and national regulations. The pellet fi...

Page 25: 1. Introduction

Page 1 2.1 positioning generally the sara should be installed in a centrally located position within the home. When deciding where to position the appliance, you must consider the following: 1. The place of installation of the pellet fi re must comply with local and national regulations. The pellet fi...

Page 26

24 page 2 10. Before connecting the pellet fi re electrically, the connection of the exhaust spigot must be completed (specifi cally for non-aluminium pellet fi res) with the fl ue. (all fl ue joins must be sealed with maniseal exhaust cement). 11. Seismic restraint - please see “9. Seismic restraint” on...

Page 27

25 page 3 ravelli and pellet solutions fire declines all responsibility deriving from the improper use of the pellet fi re, from its incorrect use by the user, by unauthorised modifi cations and/or repairs or from the use of spare parts which are not original. Ravelli and pellet solutions fire decline...

Page 28: Creating The Cavity

26 as the sara insert wood pellet fire is typically installed in new homes, it is necessary to build a compliant cavity that will house the fi re and the frame. The front facia of the enclosure must be made of a fi reproof rated board (above 80°c) such as (but not limited to) micore, supalux or eterpa...

Page 29: New

27 page 5 6. Installing into an existing cavity - new d li u b r o y r n o s a m as the sara insert wood pellet fire is typically installed to in masonry a y ti v a c , it can installed ll it s e b o t n i a compliant cavity that will house the fi re and the frame. The front facia of the enclosure mu...

Page 30: 7. Architectural Drawings

28 page 6 7. Architectural drawings 7.1 example of cavity design - section view 1. Angle section for support fi xed to timber frame/fl oor using coach screws or ‘dynabolts’ when fi xing to concrete. 2. The joint for fi re rated board* and plasterboard located over frame member must be stopped to manufac...

Page 31

29 page 7 7.2 example of cavity design - top v iew 1. Angle section for support fi xed to timber frame/ fl oor using coach screws or ‘dynabolts ’ when fi xing to concrete. 2. The joint for fi re rated board* and plasterboard located over frame member must be stopped to manufacture r’s instructions. Note...

Page 32: Seismic Restraint

30 page 8 8. Adjusting the support frame the sara wood pellet fire must be installed on the supplied, adjustable support frame. The height of this frame can be set at the home-owner’s desired height, up to a maximum of 530mm. The frame is adjusted by manipulating the bolts, which are located on each...

Page 33: 14. Television Clearances

31 page 9 14. Television clearances if electrical equipment (eg plasma tv, lcd tv or home theatre) is to be installed above the wood pellet fi re, we recommend installing a non combustible mantle below the tv screen, or recessing the tv screen into the wall, for heat protection. The clearances shown ...

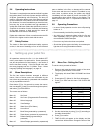

Page 34: 16. Flueing

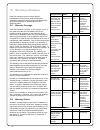

Each 55 built-in-heater flue kit (non-chimney installation) contains:- y t i t n a u q n o i t p i r c s e d o n t r a p 1 galvanised outer liner ø100mm x 900mm long 4 2 stainless steel inner liner ø75mm x 900mm long 4 5 inner/outer flue liner spacer 2 8 rain cap 75mm 1 9 rain cap 100mm 1 this flue ...

Page 35: 17. Controls and Menus

33 page 11 17. Controls and menus 17.1 description of controls • p1 : button to decrease general values • p2 : button to increase general values • p3 : turns re on-off • p4 : button to change ambient temperature • p5 : button to change operating power • p6 : multifunction button • p7 : multifunction...

Page 36

34 page 12 5. Set the desired day by using [1] or [2] according to the table shown below. 6. Press [7] to confi rm 7. Time clock will appear on the display and the current time will be shown. Change the hours of the day with [1] or [2] (24 hour clock) example: 4:30p.M would be 16:30 8. Press [7] to c...

Page 37

35 page 13 17.3.6 loading the screw (auger) insert models - loading the auger should only be carried out in off mode when the stove is new or the fi re has run out of fuel, the auger will be empty. In this case it may be necessary to ‘load’ the auger so the fi re will start. To load the screw/auger, p...

Page 38

36 page 14 18. Programming & commissioning fi this pellet approved solutions fire pellet only menues. Fire pellet the of sections protected password to refers section re installers and technicians will have access to these passwords. If you are not a pellet solutions. Fire pellet from fire pellet an...

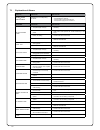

Page 39

Page 15 degrees pr37 °c / °f °c blackout pr38 sec 10 re-ignition block pr39 min 4 t-extinction min pr40 min 5 fan 2 threshold pr41 °c 120 comfort climate pr42 on / off off fan 2 speed - 1 pr43 v fan 2 speed - 2 pr44 v 140 fan 2 speed - 3 pr45 v 160 fan 2 speed - 4 pr46 v 180 fan 2 speed - 5 pr47 v 2...

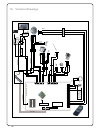

Page 40: 19. Technical Drawings

Page 16 19. Technical drawings microprocessor f n fumi scamb. Coc. Acc. Al2 al1 n -tc1+ term. N.Amb. N.H2o n.Pel. Enc +5v gnd blue capacitor red blue black black yellow/green yellow/green yellow/green 7 8 11 12 9 10 3 4 brown brown yellow/green brown 10 9 brown blue yellow/green black blue blue brow...

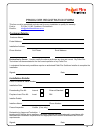

Page 41

Producer registration form this form must be completed and returned for every installation to qualify for warranty. Post to: p o box 11-245, sockburn, christchurch email to: info@pelletfiresolutions.Co.Nz customer details: customer name: postal address: installation address: phone number cell phone ...