- DL manuals

- Rayburn

- Kitchen Appliances

- 370 SFW

- Installation Instructions Manual

Rayburn 370 SFW Installation Instructions Manual

RAYBURN 370 SFW

To ensure safety, satisfaction and maximum service,

this Cooker should be installed by a suitably qualified

and competent person.

The provision of a Central Heating facility, requires that the hot water systems involved,

conform fully to good plumbing practice and established standards.

INSTALLATION INSTRUCTIONS

Summary of 370 SFW

Page 1

Rayburn 370 sfw to ensure safety, satisfaction and maximum service, this cooker should be installed by a suitably qualified and competent person. The provision of a central heating facility, requires that the hot water systems involved, conform fully to good plumbing practice and established standar...

Page 2

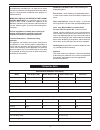

Page no. 1. Technical data .................................................................................................................................. 3 2. Specification ..............................................................................................................................

Page 3

Technical data 3 manufactured smokeless fuel (ancit) mode total output (kw) room output (kw) boiler output (kw) efficiency winter 21.6 8.2 13.4 72.7 summer 12.2 4.3 7.9 69.8 typical refuelling interval to obtain nominal outputs: 2.0 hrs flue gas temperature at nominal output: 231-260 o c flue gas ma...

Page 4

Specification warning:- this appliance must not be used without water connected, otherwise damage to the boiler may be caused and/or heat damage to surrounding surfaces. General gross weight: 400kg flue outlet diameter: 150mm max water pressure: 1.79 bar minimum flue draught: 15 pa boiler water capa...

Page 5

The non-combustible hearth must be solid and level and together with the walls adjacent to the cooker and chimney, conform to current building regulations. The cooker and chimney flue installation should be in accordance with current issues of british standards bs en 15287-1:2007 design, installatio...

Page 6

Where the chimney is believed to have previously served an open fire installation it is possible that the higher flue gas temperature from a closed appliance may loosen deposits that were previously firmly ad- hered, with the consequent risk of flue blockage. It is therefore recommended that the chi...

Page 7

Flue layouts in fig. 2. The cooker is installed in an existing recess. There must be a clearance of not less than 150mm between the top of the flue pipe and any overhanging brickwork. Any cavities or pockets above the register plate should as far as possible be filled and if necessary the flue pipe ...

Page 8

8 fig.5 especially airtight properties:- if the cooker is being fitted in a property where the design air permeability is less than 5m 3 / (h.M 2 ) (nor- mally newer properties built from 2006), then a per- manent ventilation must be fitted to provide 550mm 2 of ventilation for each kw of rated outp...

Page 9

9 alternatively the pipe thermostat (a) can be wired in parallel with another pipe thermostat (b) which is wired in series with a timeclock and room thermostat. In this instance priority can be given to hot water by setting the pipe thermostat (a) to approx. 85 o c used only to prevent boiling, the ...

Page 10

Check all seals for soundness and check that the flue is functioning correctly and that all products of com- bustion are vented safely to atmosphere via the chim- ney terminal. On completion of the installation and commissioning ensure that the operating instructions for the stove are left with the ...

Page 11

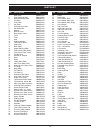

11 exploded view.

Page 12

12 parts list 1. Spin valve b00032axx 2. Front cleaning door b00164bxx 3. Bonnet blanking plate b00296axx 4. Fire door b00558axx 5. Oven door b00559axx 6. Ash door b00560axx 7. Warming oven door b00561axx 8. Ash door back b00562axx 9. Bonnet b00571axx 10. Bonnet cover b00572axx 11. Bonnet spin valve...

Page 13

13 notes.

Page 14

Notes 14.

Page 15

15 notes.

Page 16

With aga rangemster’s policy of continuous prod- uct improvement, the company reserves the right to change specifications and make modifications to the appliance described at any time. Manufactured by aga rangemaster station road ketley telford shropshire tf1 5aq england www.Rayburn-web.Co.Uk www.Ag...

Page 17: Rayburn 370 Sfw

Rayburn 370 sfw this appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces while in use or until the appliance has thoroughly cooled....

Page 18

Page no. 1. Schematic ........................................................................................................................................ 3 2. Summer operation...........................................................................................................................

Page 19

1. Blanking plate 2. 6” flue box 3. Trivet 4. Hob 5. Towel rail 6. Oven thermometer 7. Main oven door 8. Front cleaning door 9. Warming oven door 10. Base frame 11. Ashpit door 12. Boiler thermostat 13. Riddling cover 14. Fire door 15. Hotplate 16. Cleaning panel to hotplate 17. Hotplate covers 18. ...

Page 20

(i.E. When central heating is not in use). The fire-box of this cooker can not be modified to reduce the boiler output while cooking. Therefore if cooking is carried out during the summer months then adequate dissipation of the heat produced be allowed for in your central heating circuit to ensure t...

Page 21

Some attention should be paid to the amount of ash that is allowed to build up in the firebox. Wood has better burning characteristics if a bed of ash is al- lowed to build up, riddling only being necessary to level up the fire (for cooking, for example). Coal or smokeless fuels, on the other hand, ...

Page 22

Thermostat with manual override the air supply to the fire is controlled by the thermo- stat probe inserted into the boiler and the control knob attached to the ash door. The automatic thermostat has 6 settings which control the heat to which the boiler water will rise for central heating purposes. ...

Page 23

7 this plate is fitted by removing the hotplate and slid- ing the insulating plate down between the boiler and oven side. Make sure that the spacing projections are facing the oven and the top flange is resting on the boiler. Replace the hotplate. The boiler insulating plate may be used with the sum...

Page 24

8 the insulating covers retain most of the heat that would otherwise be radiated into the kitchen. They also retain the heat in the hotplates so that rapid heat- ing of cooking utensils will result when one or both of them are lifted for cooking purposes. (see fig. 11) for best cooking results use h...

Page 25

Grate removal lift the back of the grate and push it in towards the back of the boiler until the front of the bars pass the front casting. Tilt the grate up on the right hand side, drop down the left hand side towards the back of the boiler and pass the grate through the opening in the front casting...

Page 26

10 note - do not slam shut the doors as this will lead to damage to the door handles. Air supply a permanent unobstructed air vent communicated directly to outside air or an adjacent room which itself has a permanent air vent to outside is required. Any air inlet grilles must be positioned so that t...

Page 27

11 properly installed, operated and maintained this stove will not emit fumes into the dwelling. Occa- sional fumes from de ashing and re fuelling may occur. However, persistent fume emission is poten- tially dangerous and must not be tolerated. If fume emission does persist, then the following imme...

Page 28

1. Poor chimney draught (a) obstruction (a) clear and clean (b) too low (b) raise height above ridge (c) too wide (c) fit flue liner 15 to 23 c.M. (d) crack in wall (d) repair cracks (e) shared by another unit (e) cut of other unit. 2. Excessive chimney draught (a) high chimney (a) open flue cover o...

Page 29

13 notes.

Page 30

14 notes.

Page 31

15 notes.

Page 32

Manufactured by aga rangemaster station road ketley telford shropshire tf1 5aq england www.Rayburn-web.Co.Uk www.Agacookshop.Co.Uk with aga rangemaster’s policy of continuous product improvement, the company reserves the right to change specifications and make modifica- tions to the appliance descri...