Rayburn 370 sfw to ensure safety, satisfaction and maximum service, this cooker should be installed by a suitably qualified and competent person. The provision of a central heating facility, requires that the hot water systems involved, conform fully to good plumbing practice and established standar...

Page no. 1. Technical data .................................................................................................................................. 3 2. Specification ..............................................................................................................................

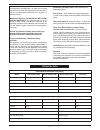

Technical data 3 manufactured smokeless fuel (ancit) mode total output (kw) room output (kw) boiler output (kw) efficiency winter 21.6 8.2 13.4 72.7 summer 12.2 4.3 7.9 69.8 typical refuelling interval to obtain nominal outputs: 2.0 hrs flue gas temperature at nominal output: 231-260 o c flue gas ma...

Specification warning:- this appliance must not be used without water connected, otherwise damage to the boiler may be caused and/or heat damage to surrounding surfaces. General gross weight: 400kg flue outlet diameter: 150mm max water pressure: 1.79 bar minimum flue draught: 15 pa boiler water capa...

The non-combustible hearth must be solid and level and together with the walls adjacent to the cooker and chimney, conform to current building regulations. The cooker and chimney flue installation should be in accordance with the relevant recommendations of the british codes of practice bs 8303, bs ...

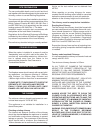

The position of available types of flue layouts are shown in figs. 2, 3 and 4, the cooker flue chamber is adaptable to provide either top or back flue outlets, by means of the reversible loose socket. (a) rear flue outlet this must only be used where there is a brick flue immediately behind the cook...

There are two isokern pumice liners which are also recommended. One is the standard 175mm diameter and the other is a 170mm thin wall. The thin wall has a smaller outer diameter and is designed to fit an ex- isting chimney system. Both have a lifetime guaran- tee. In fig. 3, the cooker is connected ...

Apply fire cement to the socket in the hob. Attach a short length of 6” (150mm) i.D. Pipe approx. 10” (250mm) long to the outlet of the flue box by means of fire cement. Place the flue box on the hob and the pipe into the wall and consolidate the fluebox and pipe into the fire cement. Apply 3 or 4 c...

After completing the installation, the heating contrac- tor should demonstrate to the user the operation of the appliance and the routine cleaning method. The protective grease should be removed from the hotplate before lighting. Check that the system is full of water and free from air locks. For th...

10 exploded view.

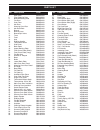

11 parts list 1. Spin valve b00032axx 2. Front cleaning door b00164bxx 3. Bonnet blanking plate b00296axx 4. Fire door b00558axx 5. Oven door b00559axx 6. Ash door b00560axx 7. Warming oven door b00561axx 8. Ash door back b00562axx 9. Bonnet b00571axx 10. Bonnet cover b00572axx 11. Bonnet spin valve...

With aga rangemster’s policy of continuous prod- uct improvement, the company reserves the right to change specifications and make modifications to the appliance described at any time. Manufactured by aga rangemaster station road ketley telford shropshire tf1 5aq england www.Rayburn-web.Co.Uk www.Ag...