- DL manuals

- Raypak

- Recording Equipment

- B6000

- Installation And Operating Manual

Raypak B6000 Installation And Operating Manual

Summary of B6000

Page 1

Catalog no.: 5000.51j effective: 10-14-05 replaces: 06-15-03 b6000 boiler management system installation and operating manual part no. 240564 tm system control boiler monitor.

Page 2

Page 2 is a registered trademark of underwriters laboratories inc. ® is a registered trademark of underwriters laboratories-canada inc.® ______________________________________________________________________________________ before operating this product, please read these instructions completely..

Page 3: Important Notice:

B6000 boiler management system (bms) contents equipment quantity b6000 system control 1 b6000 boiler monitor, installed on boiler(s) as ordered outdoor temperature sensor assy. (064140) 1 water temperature sensor assy. (064139) 1 optional equipment as ordered check packaging for damage or missing co...

Page 4: Table of Contents

Page 4 table of contents page contents 3 getting started 5 foreword 5 installation and mounting 7 mechanical installation 7 electrical installation 8 check your power source 8 air temperature sensor 9 water temperature sensor 10 important configuration note 12 wiring - air and water sensors 12 commu...

Page 5: Foreword

Page 5 thank you for selecting the raypak b6000 boiler management system (bms). It is our sincere hope that you will enjoy its power, ease of use and energy saving features. Getting started to learn about the b6000 bms, simply install it and start using it. The following steps will outline the thing...

Page 6

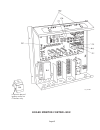

Page 6 each boiler monitor module contains • the boiler on-off power switch. • the boiler manual override switch, which allows the boiler to operate independently in the event of a system control failure. • standard indicator lights: "power on" - green, indicates the boiler is powered. "manual overr...

Page 7: Installation And Mounting

Installation and mounting the system control module should be mounted on a permanent base not subject to vibrations, moisture or dust. It should be mounted with the display screen at a convenient height for reading and for access to the alarm silence button located on the top of the cabinet. Dimensi...

Page 8: Check Your Power Source

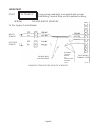

Cb white ground black green a b c pidoma vom a sub-panel containing the disconnect switches and surge suppressors is required at or near the equipment location(s). For accessibility remove the lower interior panel, by removing the four (4) access screws. Install conduit as appropriate. Note: shielde...

Page 9: Air Temperature Sensor

Page 9 air temperature sensor • installation fig. #9040 typical air temperature sensor air temperature sensor installation notes: • locate on coldest side of building, usually (north or west) side. • install the sensor in a shaded area, out of direct sunlight. • locate no higher than 2/3 way up side...

Page 10: Water Temperature Sensor

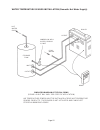

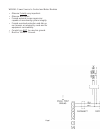

Water temperature sensor • installation the water sensor should be installed in the system supply. Multiple boilers single boiler water sensor typical water sensor water temperature sensor installation notes: • locate sensor in system piping within a minimum of three (3) feet or prior to the first t...

Page 11

Water temperature sensor installation (domestic hot water supply) page 11 simplified diagram of typical piping (piping layout may vary per specific application) air temperature sensor must be installed across air temperature sensor contacts. The sensor is not activated and can be left stored in b600...

Page 12

Page 12 important configuration note: if your system control module is supplied with a single field wiring teminal strip use "alternate" wiring. (see page 36-38) wiring - air and water sensors to the system control module water sensor outdoor sensor system control terminal tb 2 belden #8132 or belde...

Page 13

Communication (rs 485) wiring system control boiler monitor • use belden #9842 cable or equivalent (see note). Polarity must be observed. Make use of wire color coding to ensure proper polarity. • the shielding foil wrapper - bare wire (drain) - must be grounded. Grounding is done at the system cont...

Page 14

Wiring: wiring: wiring: wiring: wiring: p p p p po oo oow w w w wer sour er sour er sour er sour er source to system contr ce to system contr ce to system contr ce to system contr ce to system control and boiler mod- ol and boiler mod- ol and boiler mod- ol and boiler mod- ol and boiler mod- ules. U...

Page 15

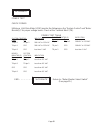

Power test check power utilizing a volt-ohm-meter (vom) monitor the following on the "system control module" and "boiler monitor(s)" for proper voltage levels. Power test table module test points indication system control tb1-1- tb1-2 108 vac to 132 vac system control tb1-1- tb1-3 108 vac to 132 vac...

Page 16

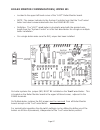

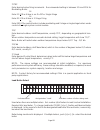

Switch position boiler number switch 1 2 3 4 5 6 7 8 8 o o o o o o o o 7 o o o o o o o o 6 o o o o o o o o 5 o o o o o o o o 4 o o o o o o o o 3 o o o o x x x x 2 o o x x o o x x 1 o x o x o x o x important: the boiler monitor control board has a series of dip switches which iden- tify the boiler(s)...

Page 17

Boiler monitor communications jumper w1 • located in the upper left hand corner of the "last" boiler monitor board. • note: the jumper indicates to the system controller logic that the "last" wired boiler has been communicated with over the rs485 buss link. • definition: the "last" wired boiler is p...

Page 18

Optional boiler monitor • wiring • contact authorized raypak representative for other wiring options dia. #2 page 18 note: tighten terminal strip clamping screws 20 lbs - in (2.26n.M) breakage from over torquing is not covered under warranty. Use copper conductors only. For supply connections use wi...

Page 19

Page 19 field wiring - multiple boilers dia. #7.

Page 20

Installation verification procedure register before proceeding any further, please verify that the user registration form has been completed and mailed (reference: registration card ). Mechanical installation verify installation has been completed (reference: mechanical installation ). Air temperatu...

Page 21

Page 21 system control/display familiarization the system is set up by using the selector buttons and the displays on the system control module. There are ten or more displays. Each display provides information regarding the system operating parameters and system component status. Some displays prov...

Page 22: V X . X X X X

Page 22 note: nite setback feature must be set at the b6000 bms control panel to "on". This results in display change that shows nite rather than day. The bms can change "setback times" up to six selections for each of the seven days. Warning warning warning warning warning warning when the initiali...

Page 23: O U T D O O R

Displays system temperatures * indicates selectable item program the system control module to meet the design conditions of the installation. Return to system temperature display by pressing the "menu" button until screen appears as below. Current outdoor air current system target temperature temper...

Page 24: S T A T U S :

Boiler status operating status of boiler *boiler ok or fault indicator pushing "+" or "-" buttons will show status of other boiler(s) in system readout readout ok - boiler operation normal fault indications: max temp - target exceeds max temp -not a fault- thermostat - operating aquastat - not a fau...

Page 25

Page 25 green red amber green red power manual call pump low system control on over- for on water display ride heat cutoff ok x x x system operating normally lwco x x x x low water in boiler low pres water x x x water pressure too low lo press gas x x x gas pressure below setting high press gas x x ...

Page 26: S E T

Primary control parameters *system water temperature *reset ratio * rise is the temperature rise in desired at outdoor ratio of outdoor temperature system when all boilers are at full temperature of 70°. To water system temperature. Rate. (Ðt of system) range 1 -99 range 40 - 200 range: 0.0:1 to 20:...

Page 27: Suggested Guidelines

Push select ratio – sets the desired change in system water temperature increases as the outdoor temperature decreases. The reset ratio is expressed as follows: 2:1 for every 2 degree change in outdoor temperature the sytem temperature will change 1 degree. Temperature °f e.G: set = 135°f ratio outd...

Page 28: S T E P

Page 28 *c band is a range of temperature above and below the target temperature. Range 1-9 default value is 3°f. *o/cdb, outdoor cutoff deadband is the number of degrees below o/c where o/c reset occurs. Range 1-9 default value is 4°f. *o/c maximum outdoor temperature that heat is desired, set at 7...

Page 29: L E A D

L e a d # o f b o i l e r s x x *step enter desired valve firing increments. Recommended setting is between 5% and 20% for modulating boiler. Or enter 1s if gas valve is an on-off or single stage or enter 2s if gas valve is 2 stage firing or enter 20% if the control boilers include modulating and 2 ...

Page 30: P U M P

Lead lag, night set back automatic lead lag *lead change hours designated lead boiler will change when remaining hours reaches 0. Range 0-225 hrs. Default value is 100 hrs. If set at 0 hours lead will not change. Hours remaining will automatically total. Enter the desired number of hours of lead boi...

Page 31: * X X : X X P M

Night setback "off" indicates the system is in the normal or design operating mode. "on" indicated the system is operating in a programmed night setback mode. Lead lag, night set back automatic lead lag *set time of day ** day of week *** on or off this screen shows the time and day of the week. Def...

Page 32

Page 32 set back example: period setback setback "on" "off" day 1 xx:xx 05:00 am monday 2 10:00 pm xx:xx monday 1 xx:xx 05:00 am tuesday 2 10:00 pm xx:xx tuesday 1 xx:xx 05:00 am wednesday 2 10:00 pm xx:xx wednesday 1 xx:xx 05:00 am thursday 2 10:00 pm xx:xx thursday 1 xx:xx 05:00 am friday 2 10:00 ...

Page 33: A P C O N S T

*pconst is the proportional ratio which causes the boiler to step up or down, faster or slower (over- shoot or undershoot) and finally end up offset from desired tem- perature. Default is 1/3. *dconst is the derivative ratio which tells the system how first to react to differing changes in water tem...

Page 34: B P C O N S T

Page 34 *pconst proportional ratio which causes the boiler to step up or down, faster or slower. *wait wait as time controller hesitates before acting on a temperature change. *dconst derivative ratio speeds or slows boiler response compensating for overshoot and undershoot. *pconst is the proportio...

Page 35: T E M P :

T e m p : x x x ( x x x ) m : x x x x % x x x % x x x % x x x % x x x % tandard initialize lead lag, night set back initialize y - yes n - no version # of software. * this will initialize all previous selectable values to default values. Should not be used unless operator wants to reprogram new valu...

Page 36

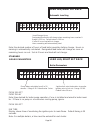

Page 36 important start "alternate" if your system module(s) are supplied with a single field wiring terminal strip use this method for wiring. Wiring - air and water sensors to the system control module water sensor outdoor sensor belden #8132 or belden #9842 dia. #10 air/water temperature sensor s...

Page 37

Page 37 "alternate" continued communication (rs 485) wiring from: system control module to: boiler module • shielded communications cable - belden #9842 must be used. Polarity must be observed. Make use of wire color coding to ensure polarity. • the shielding [foil wrapper - bare wire (drain)] must ...

Page 38

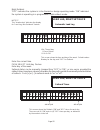

Wiring: power source to control and boiler modules • observe polarity very important. • observe wire colors • provide external surge suppressor capable of maintaining system integrity. • provide overload protection and discon- nect means as required by code and for equipment serviceability. • condui...

Page 39

"alternate" power test check power utilizing a volt-ohm-meter (vom) monitor the following on the "system control" and "boiler monitor(s)" for proper voltage levels. Check at the terminal block (tb). Power test table system control indication from: to: tb pin 1 tb pin 2 108 vac to 132 vac tb pin 1 sp...

Page 40

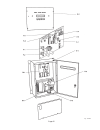

Page 40 fig. # 9458.

Page 41

Page 41 fig. # 9459.

Page 42: System Control Board

System control board page 42 fig. # 9460

Page 43

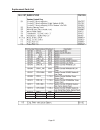

Page 43 replacement parts list new part # cp10.0_ _ _ cp10.0n _ _ cp10.0nmn 90fi 90ei 900d.

Page 44

Replacement parts list page 44.

Page 45

Page 45 boiler monitor control box located in place of ignition control on c2 boilers only. Fig. # 9461.

Page 46

Replacement parts list call out b 6000 system part no. Boiler monitor control box b-1 control pc board 004795f b-2 power/manual or override switch 650745 b-3 transformer, 120/8.5 vac c.T. 064921 b-4 transformer, 120/24 vac c.T. 650495 b-5 transformer, 120/24 vac (c2 units only) 650495 b-6 ignition c...

Page 47

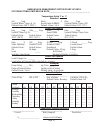

B6000 boiler management system start-up data system settings entered on date:_____________________________________ temperature scale °f or °c standard set _____ deg. Ratio _____ : 1 rise _____ deg. System water temp. @ oc reset ratio-outdoor: system design temp. Diff. Default value 100°f (38°c) defa...

Page 48

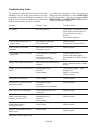

Page 48 the procedures outlined below assume that the initial installation / turn on / power up procedures have been completed and that the b6000 was operational. This guide is a basic instruction to determine if an authorized raypak representative should be contacted. If you follow the instructions...

Page 49

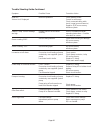

Trouble shooting guide-continued symptom boiler # x "not on line" displayed outdoor temp. Sensor readings are high. Sensor reading 220°f. Sensor reading - 35°f. Low water cut-off alarm. Power lamp off on boiler monitor. Pump not running. Off at flow switch. Off on high limit. Corrective action check...

Page 50

Limited warranty b6000, y-series, e-4 & accessories scope of warranty : raypak, inc. ("raypak") warrants to the original owner the control system to be free from defects in materials and workmanship under normal use and service for the applicable warranty period. In accordance with the terms of this...

Page 51

Design and specifications subject to change without notice. This symbol on the nameplate means the product is listed by underwriters laboratories, inc. ® raypak, inc., 2151 eastman avenue, oxnard, ca 93030 • (805) 278-5300 • fax (800) 872-9725 litho in u.S.A. Www.Raypak.Com ul ®.