- DL manuals

- Raypak

- Recording Equipment

- B6000

- Installation And Operating Manual

Raypak B6000 Installation And Operating Manual

Summary of B6000

Page 1

1 catalog no.: 5000.59b effective date: 4-09-08 replaces: 3-15-99 t-3 raypak b6000 modbus system protocol interface t-3 communications interface raypak b6000 boiler controller to modbus interface card installation and operating manual p/n 240729 rev. 3.

Page 2

2 table of contents 1.0 contents (as shipped) ----------------------------------------------------------------------------------- 3 2.0 forward ----------------------------------------------------------------------------------------------------- 3 3.0 installation and mounting ----------------------...

Page 3

3 t-3 (raypak b6000 system protocol interface) contents quantity compact disc (cd) 1 t-3 1 eprom (cpx.Xnmn) in small black esd box 1 check packaging for damage or missing components. Important notice: these instructions are intended for the use by qualified personnel only, specifically trained and e...

Page 4

4 t-3 installation and mounting the t-3 module should be mounted on a permanent base not subject to vibrations, moisture or dust. It should be readily accessible, for serviceability. Dimensions and weight 15 3/4” h 14 lbs 8” w 5 3/4” d mechanical installation mount the system protocol interface with...

Page 5

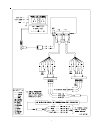

5 wiring t-3 1. Turn off power to the b6000 system control box. 2. Open front door of system protocol interface gateway enclosure. 3. Remove four screws and the lower cover, revealing the field wiring blocks. 4. Attach wires from interface card to the field wiring side of left terminal block (n+, n-...

Page 6

6 b6000 system control board check your power source ac = 108 volts ac minimum, 132 volts max ab = 108 volts ac minimum, 132 volts max bc = must be less than 1.0 volts ac.

Page 7

7.

Page 8

8 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234 123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012...

Page 9

9 11.1. Product specifications the t-3 card is a hardware product designed to be the communications front end for the raypak b6000 boiler control and a modbus master host. The product includes the following functionality: modbus slave specifications • protocol modes: rtu mode with crc-16 error check...

Page 10

10 11.2.0 slave port functionality 11.2.1 modbus communications the t-3 modbus slave card runs the rtu version of the modbus protocol. This capability allows the module to communicate data from a raypak b6000 boiler control to a modbus master host, and vice-versa. The module supports both point-to-p...

Page 11

11 11.2.1.4 data integrity as in all good protocols, there must exist a level of data integrity checking to verify, with some degree of assurance, the quality of the transmitted data. The modbus protocol supports two types of error checking: • rtu mode: 16 bit cyclic redundancy check (crc-16) • one ...

Page 12

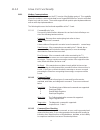

12 11.3.0 hardware setup 11.3.1.1 1500 interface card setup 11.3.1.1 connecting power to the t-3 card the t-3 card requires an external source of dc voltage. The dc source voltage should be between 9v and 30v. The power is connected to tb1, located near the two 9 pin serial port connec- tions. The c...

Page 13

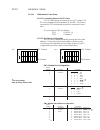

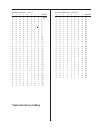

13 example addresses = 0 to 33 example addresses = 34 to 63 8 7 6 5 4 3 2 1 address 8 7 6 5 4 3 2 1 address 0 0 0 0 0 0 0 0 invalid 0 0 1 0 0 0 1 0 34 0 0 0 0 0 0 0 1 1 * 0 0 1 0 0 0 1 1 35 0 0 0 0 0 0 1 0 2 0 0 1 0 0 1 0 0 36 0 0 0 0 0 0 1 1 3 0 0 1 0 0 1 0 1 37 0 0 0 0 0 1 0 0 4 0 0 1 0 0 1 1 0 38...

Page 14

14 the parameters are defined as follows: modbus slave address: each of the separate drop offs of a modbus host must have a different slave address. The slave address is selected by encoding the slave address in a binary form using the dip switches. 11.3.1.3 t-3 jumper configurations the t-3 card ha...

Page 15

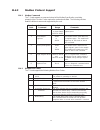

15 11.4.0 modbus protocol support 11.4.1 modbus commands the t-3 card supports a command subset of the modbus specification consisting primarily of the function codes required to read and write data. The following sections detail the different commands supported by the card. Function address slave d...

Page 16

16 11.5.0 diagnostics several hardware diagnostics capabilities have been implemented using the led indicator lights on the front of the t-3 card. The possible conditions as indicated by the lights are: 11.5.1 led indicators several hardware diagnostics capabilities have been implemented using the l...

Page 17

17 11.6.0 prosoft support, service and warranty 11.6.1 technical support prosoft technology survives on its ability to provide meaningful support to its customers. Should any questions or problems arise, please feel free to contact us at: prosoft technology, inc. 9801 camino media suite 105 bakersfi...

Page 18

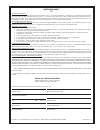

18 limited warranty t-3 scope of warranty: raypak, inc. (“raypak”) warrants to the original owner the t-3 to be free from defects in materials and workmanship under normal use and service for the applicable warranty period. In accordance with the terms of this limited warranty, raypak will furnish a...

Page 19

19 appendix a modbus register map a-1.

Page 20

20 a-2 raypak modbus register assignments function function function type 2 4 3,6 description r/w 30001 40001 setpoint day setpoint (desired water temp @70f) r/w 30002 40002 nitesetback night setback (desired water temp @ 70f) r/w 30003 40003 ratio out 1-200 = 0.1 - 20.0 in 0.1 increments r/w 30004 ...

Page 21

21 r 10215 6 high limit (0 = normal, 1 = alarm) r 10216 7 thermostat - operating aquastat (not fault) (0 = normal, 1 = aquastat) r 10217 8 manual override (0 = normal, 1 = alarm) r 10218 9 flow switch (0 = normal, 1 = alarm) r 10219 10 no pilot (0 = normal, 1 = alarm) 30045 40045 bit boiler #2 statu...

Page 22

22 30049 40049 bit boiler #6 status word boiler #6 r 10289 0 boiler not on line (0 = normal, 1 = alarm) r 10290 1 boiler operation (0 = firing, 1 = ready) r 10291 2 low water cutoff (0 = normal, 1 = alarm) r 10292 3 low pressure water (0 = normal, 1 = alarm) r 10293 4 low pressure gas (0 = normal, 1...

Page 23

23 r 30070 40070 ts - boiler start times (sec) boiler #1 r 30071 40071 ts - boiler start times (sec) boiler #2 r 30072 40072 ts - boiler start times (sec) boiler #3 r 30073 40073 ts - boiler start times (sec) boiler #4 r 30074 40074 ts - boiler start times (sec) boiler #5 r 30075 40075 ts - boiler s...

Page 24

24 raypak, inc. 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 • fax (805) 278-5489 litho in u.S.A. Www.Raypak.Com.