Installation & operating instructions catalog no. 6200.51p effective: 05-24-10 replaces: 04-09-07 p/n 240251 rev. 17 warning: if these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or death. For your safety: do not store or use gasolin...

2 water chemistry (corrosive water voids all warranties) for your health and the protection of your pool equipment, it is essential that your water be chemically balanced. The following levels must be used as a guide for bal- anced water. Recommended level(s) fiberglass pools fiberglass spas other p...

Contents 3 water chemistry 2 warnings 4 pay attention to these terms 4 receiving equipment 5 general specifications 5 installation 5 code requirements 5 base installation 5 clearances 6 combustion air (indoor units only) 6 venting connections 7 gas supply connections 8 water connections 10 controls ...

4 danger: indicates the presence of immediate hazards which will cause severe person- al injury, death or substantial property damage if ignored. Warning: indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial property damage if ignored. ...

5 receiving equipment on receipt of the equipment, visually check for exter- nal damage to the carton or the shipping crate. If the carton or shipping crate is damaged, make a note on the bill of lading and report the damage to the carrier immediately. Remove the heater from the carton or shipping c...

6 clearances all heaters for clearances from combustible surfaces, see table a below. We require a minimal vertical clearance of three feet between the upper surface of the flue outlet to a noncombustible material. For servicing, provide at least 24" in front of the heater on models 926-1826 & 48" i...

7 2. Free ventilation air 1 sq. In. Per 1000 btu input within 12" of the ceiling level. Venting connections drafthood (indoor) models 962-1826 locate and assemble as shown in fig. 3. Secure with screws supplied in envelope in carton. Models 2100-4001 have built-in drafthoods that must be properly ve...

8 at the time of removal of an existing heater, the follow- ing steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remain- ing connected to the common venting system are not in operation. (a) seal any unused op...

9 manometer gas pressure test at gas valve gas pressure test at heater manual shutoff valve gas pressure test upstream model no. 1” 1-1/4” 1-1/2” 2” 2-1/2” 3” 4” n p n p n p n p n p n p n p 926/962 15 20 45 45 110 150 360 400 1083/1125 10 15 35 35 80 120 300 300 1178/1223 25 25 60 85 220 200 1287/13...

The time clock may be used for this purpose with instructions not to override this sequence manually. See wiring diagram section for electrical hookup loca- tion of the fireman switch in the electrical circuit. Controls flow switch this dual purpose control shuts off the boiler in the case of a pump...

11 water pressure switch on models 926-1223 built with a unitherm governor (ug), a water pressure switch is provided in the heater to shut down the gas valves in the event the water sup- ply to the heater is interrupted. It is very important to verify that the switch electrically opens and shuts off...

12 raypak recommends the installation of an air bleed vent at a suitable location (usually the highest point in the plumbing) to remove air from the piping system. These units should be available at your local whole- sale supplier. Raypak does not provide this item. Models 1287 through 4001 are equi...

13 2. Lace metal strapping or clamps, (not provid- ed) through the ¾” slots on the cover and fasten securely to pipe as shown in fig. 15 & 16. Do not over-tighten clamps. Fig. 13: poolstat control fig. 14: control cover fig. 15: hose clamp slots fig. 16: insert clamps 3. Remove either the left or ri...

14 to adjust the temperature: 1. Both isolation valves must be fully open. 2. Adjust bypass valve "a" 1/2 open and balancing valve "b" fully open. (see piping configuration page 15, 16 & 17) 3. Fire your raypak pool heater and adjust bypass valve "a" to obtain a heater inlet temperature approximatel...

15 6. As the pool temperature rises to the desired tem- perature as controlled by the pool aquastat, small adjustments to valves "a" and "b" will be required for optimum performance. Heater temperatures should be checked regularly to prevent heater condensation. The heater inlet temperature can be h...

16 blended water temperature (thermometer at heater inlet) heater outlet temperature thermometer heater thermostat recommended field installed isolation valves for service t i t o t c piping configurations for raytherm commercial pool heaters.

17 blended water temperature (thermometer at heater inlet) heater outlet temperature thermometer heater thermostat recommended field installed isolation valves for service t i t o t c models 2100 thru 4001 piping configurations for raytherm commercial pool heaters.

18 external auxiliary bypass valve (where required) 926-1223 models only an auxiliary bypass valve should be used when flow rates exceed 120 gpm (usually a high performance pump size larger than two hp will exceed this flow rate). This valve is required to complement the func- tion of the automatic ...

19 low water cutoff automatically shuts down burner whenever water level drops below probe. A 3 to 5 second time delay prevents premature lockout due to temporary condi- tions such as power failure or air pockets. Standard on cal code heaters. High & low gas pressure switches pressure switches sense...

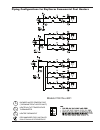

20 wiring diagram—models 926–1223.

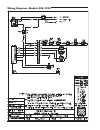

21 wiring diagram—models 1287–1826.

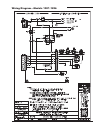

22 wiring diagram—models 2100–2500

23 wiring diagram—models 3001–4001.

24 servicing general location of controls models 926-1826 models 2100-4001 temperature control the pool water temperature is controlled by the pool thermostat. The heater water temperature high limit is controlled by the manual reset high limit. Pressure switch the pressure switch, or heater actuato...

25 two-speed pumps in some cases, the flow on the low speed is insufficient to operate the heater. This is apparent when the pres- sure switch cannot be further adjusted or if the heater makes banging noises. In these cases, the pump must be run at high speed when heating the water. Pilot safety the...

26 after start-up pilot system checkout procedure 1. Turn on power to the ignition systems and turn gas supply off. 2. Check ignition module as follows: a. Set the thermostat above pool water tempera- ture to turn heater on. B. Watch for continuous spark at the pilot burner. C. Time the spark operat...

27 servicing procedures tube cleaning procedure (typical) establish a regular inspection schedule, the frequency depending on the local water condition and severity of service. Do not let the tubes clog up solidly. Clean out deposits over 1/16" in thickness. Although the illustration shows the mecha...

28 main burner and orifice removal 1. Remove screws and burner hold down bracket. Note: if the heat exchanger is sooted badly, the burner hold-down bracket and spacer can become distorted from direct flame impingement and this usually necessitates replacement of these parts. 2. Lift burners from slo...

29 combustion chamber removal to remove the combustion chamber you must first have removed the heat exchanger. Unbolt metal com- bustion chamber retainer from top and remove combustion chamber panels individually. Control well replacement remove top, sensing bulb and clip. Collapse well tube at the ...

30 4. Take garden hose and wash heat exchanger, mak- ing sure soot is removed from between fins. (avoid excessive water against refractory). 5. Reassemble; when heater is fired, some steam will form from wet refractory. This is normal. Unitherm governor replacement 1. Shut off water, gas and electri...

31 winterizing your heater when heaters installed outdoors in freezing climate areas are to be shut down for the winter, please observe the following step-by-step procedure: 1. Remove the drain plug or open the drain cock located on the inlet-outlet header. On larger heaters with external unitherm g...

32 important notice these instructions are primarily intended for the use of qualified personnel specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be required by some states to be licensed....

33 outer jacket very hot (paint blistered) *broken refractory caused by shipping damage or improper combustion………………………….. Excessive sooting of heat exchanger…………………………... Calculate temperature in °f/hr……... Filter not running long enough…….... Dirty filter…………………………….. Gas line or meter under- size...

34 note: before troubleshooting, familiarize yourself with the start-up and checkout procedure. Check line voltage power, low voltage transformer, limit controller, thermostat (controller) and wiring. Pull ignition lead and check spark at module. Spark okay? Yes • check ignition cable, ground wiring...

35 raytherm commercial swimming pool heaters limited warranty raytherm type p sizes 0926-4001 scope: raypak, inc. ("raypak") warrants to the original owner that all parts of this boiler which are actually manufactured by raypak will be free from failure under normal use and service for the specified...

36 www.Raypak.Com raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (805) 278-5468 litho in u.S.A..