- DL manuals

- Riso

- Printer

- Comcolor X1 Series

- Technical Manual

Riso Comcolor X1 Series Technical Manual

ComColor Series (Revision 2.4)

Maintenance

[ 1-1 ]

Chapter 1. Maintenance Notes

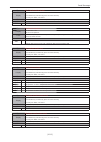

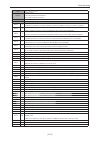

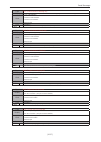

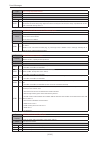

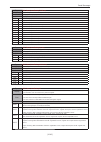

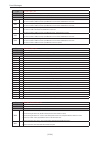

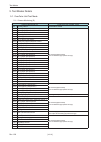

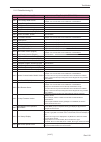

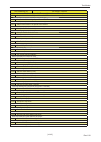

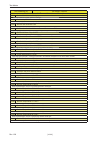

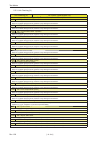

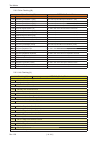

Contents

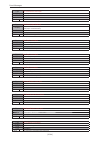

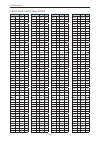

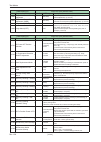

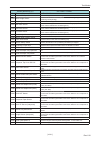

[ Handling of Lithium Battery ] ............................................................. 1-2

1.Precautions ........................................................................1-5

1-1.General precautions ................................................................... 1-5

1-3.Other precautions for inspection and maintenance .................... 1-7

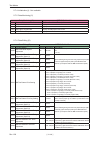

2.Tools ...................................................................................1-9

2-1.List of general tools .................................................................... 1-9

2-2.List of special tools for servicing ComColor ............................. 1-10

3.Printer setup procedure ..................................................1-15

3-1.Confirmations to be performed during printer setup ................. 1-15

3-2.Setup Wizard ............................................................................ 1-15

Summary of Comcolor X1 Series

Page 1

Comcolor series (revision 2.4) maintenance [ 1-1 ] chapter 1. Maintenance notes contents [ handling of lithium battery ] ............................................................. 1-2 !! Warning !! ........................................................................................ 1-3 1.Prec...

Page 2: Caution

Comcolor series (revision 2.4) [ 1-2 ] maintenance perchlorate material-special handling may apply, see www.Dtsc.Ca.Gov/hazardouswaste/perchlorate this product may contain certain substances which are restricted when disposed. Therefore, be sure to consult your contracted service dealer. Caution [ h...

Page 3: Important Safety Precautions

Comcolor series (revision 2.4) maintenance [ 1-3 ] press the sub power key, after the machine main power is off and power cord is unplugged, to discharge the electrical charge remaining in the capacitors on the power supply unit. The main power lamp is still lit after the machine power is turned off...

Page 4

Comcolor series (revision 2.4) [ 1-4 ] maintenance (4) always connect electrical connectors firmly. 1) to avoid electrical failure: the connectors must be connected firmly together and onto the pcbs. 2) protection of the electrical components: the electrical components may be damaged due to short ci...

Page 5: 1. Precautions

Comcolor series (revision 2.4) maintenance [ 1-5 ] 1. Precautions 1-1. General precautions * unplug the power cord from the ac outlet before performing maintenance. * be careful to avoid getting neckties, clothing, or long hair tangled in moving parts. * if you must perform work while the machine po...

Page 6

Comcolor series (revision 2.4) [ 1-6 ] maintenance cleaning is repeated several times, the print heads may need to be replaced. * differences between display and print colors - the colors on prints may differ slightly from the colors seen on your display device. - the difference in the colors may be...

Page 7

Comcolor series (revision 2.4) maintenance [ 1-7 ] 1-3.Other precautions for inspection and maintenance precautions for inspections * if a defect or abnormality is found during inspections, correct the problem and replace parts, if necessary. Precautions for parts removal * when ascertaining the loc...

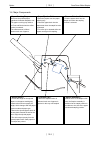

Page 8: 1-4.Sensors

Comcolor series (revision 2.4) [ 1-8 ] maintenance 1-4.Sensors * be sure to turn off power before disconnecting or connecting sensors. Photosensor types * in general, photo sensors can be divided into four types: the interrupt type (u-shaped), the actuator type, the reflection type, and the transmis...

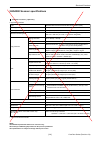

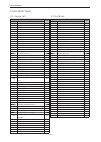

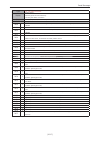

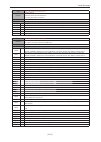

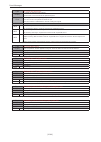

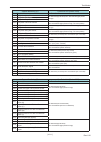

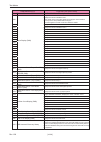

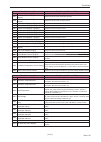

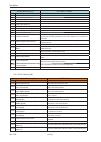

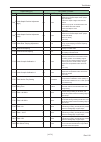

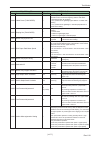

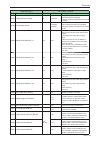

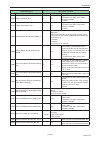

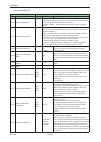

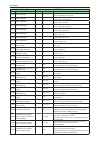

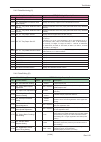

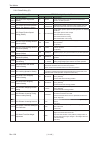

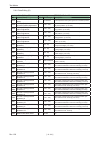

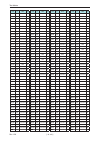

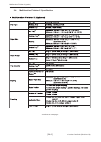

Page 9: 2.Tools

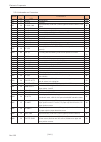

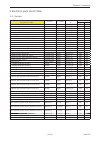

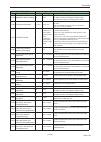

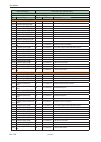

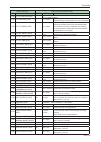

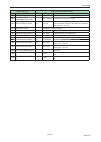

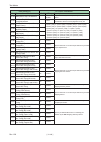

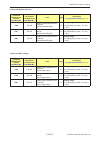

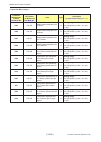

Comcolor series (revision 2.4) maintenance [ 1-9 ] type tip size shaft length, etc. Phillips screwdriver no. 2 no. 2 no. 2 no. 1 (250 mm) (100 mm–150 mm) (stubby type) (75 mm–100 mm) standard screwdriver 6 mm 3 mm 1.8 mm (100 mm–150 mm) (100 mm–150 mm) (precision type) nut driver (box driver) 8 mm 7...

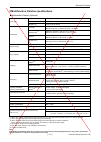

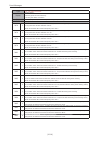

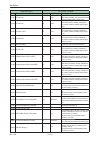

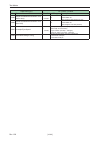

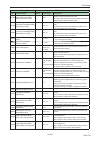

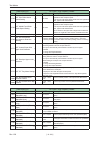

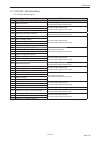

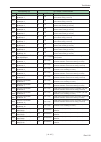

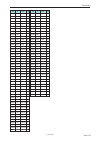

Page 10

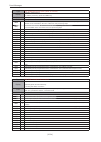

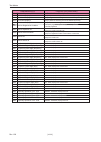

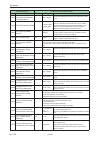

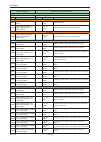

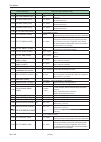

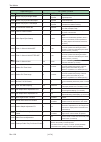

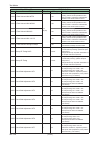

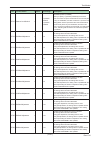

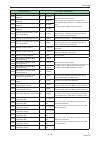

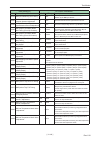

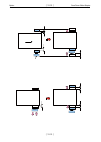

Comcolor series (revision 2.4) [ 1-10 ] maintenance 2-2.List of special tools for servicing comcolor comcolor lifting jig. The machine lifting jig must be comcolor dedicted type to prevent an accident. Lint-free paper towel this is used to wipe ink off inside the machine. The paper towel must be lin...

Page 11

Comcolor series (revision 2.4) maintenance [ 1-11 ] 5.5mm 7.0mm ij matte paper (a3 or ledger size) comcolor dedicated matte paper is required for executing image adjustment. Lupe required to check the print quality. Air filter required when working on the ink flow system to prevent dust from enterin...

Page 12

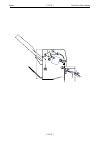

Comcolor series (revision 2.4) [ 1-12 ] maintenance or at least 250mm in shaft length 15mm or less long screw driver or rachet wrench either of these tools will become necessary in mounting the front bottom cover on the machine during the machine installation. Normal millimeter size screw driver wit...

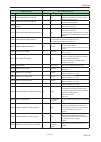

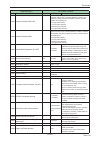

Page 13

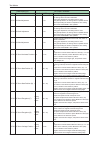

Comcolor series (revision 2.4) maintenance [ 1-13 ] print head positioning jig required in removing and replacing the print head on the machine. One piece comes with the machine. If extra pieces are needed, order the required quantity as spare part. Plastic forceps needed in working on the ink flow ...

Page 14

Comcolor series (revision 2.4) [ 1-14 ] maintenance laptop pc required in making the image adjustments on comcolor machines when there is no hs4000 scanner is not available. Canon lide scanner is also needed. Canon lide scanner required in making the image adjustments on comcolor machines when there...

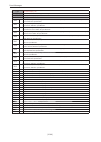

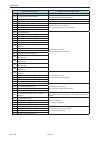

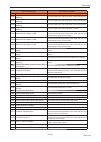

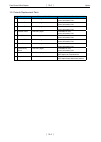

Page 15: 3.Printer Setup Procedure

Comcolor series (revision 2.4) maintenance [ 1-15 ] 3.Printer setup procedure 3-1.Confirmations to be performed during printer setup * follow the installation instruction guide (inculded in the shipment) step-by-step. * after opening the package, the machine control card and the ink cartridges must ...

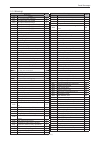

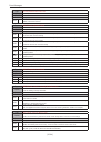

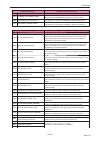

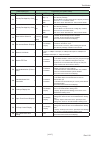

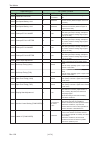

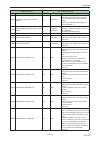

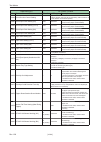

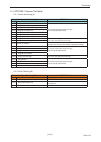

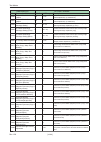

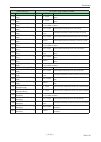

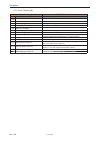

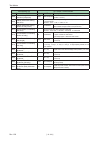

Page 16

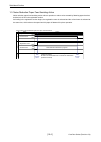

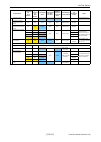

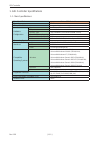

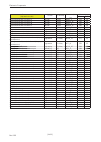

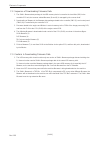

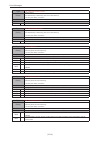

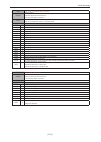

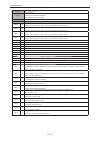

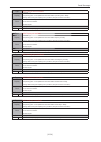

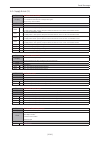

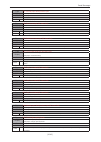

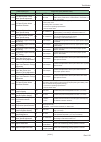

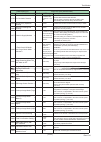

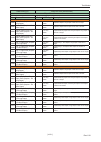

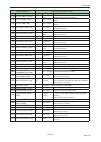

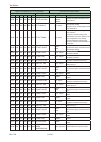

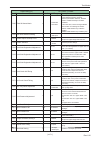

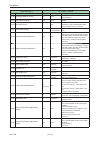

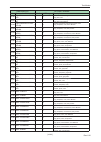

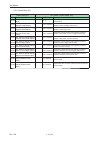

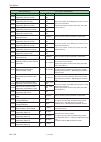

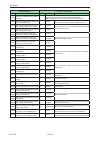

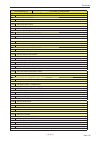

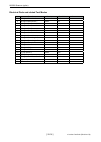

Comcolor series (revision 2.4) [ 1-16 ] maintenance pages on the lcd display items notes 00 setup wizard cover page - 01 displayed language - 02 metric/inch switch - 03 time zone setting - 04 clock/date - 05 network setting - 06 function key entry - 07 color mode selectable only when hs4000 scanner ...

Page 17

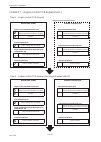

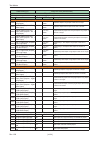

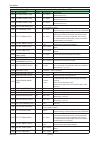

Comcolor series (revision 2.4) maintenance [ 1-17 ] time zone setting select the correct time zone of the country in which the machine is installed. The time zone setting can only be set on the setup wizard. Clock/date set the year, month, day, hour and minute. Also select in which order the year, m...

Page 18

Comcolor series (revision 2.4) [ 1-18 ] maintenance color mode selects the default color mode for the copy and scanner modes. The selection is available only whe hs4000 scanner is connected. Since it is only selecting the default setting, the selection can be changed to another on each operation. Ou...

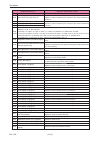

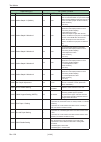

Page 19

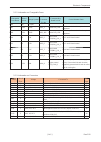

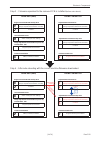

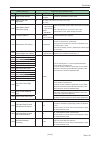

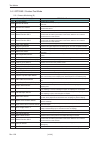

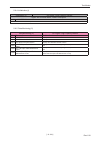

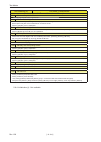

Comcolor series (revision 2.4) maintenance [ 1-19 ] need to change the setting to on. Need to change the setting to permitted. Security level setting selection of the security level from the three choices. Refer to the chart given below for the details on the three security settings. Admin. Settings...

Page 20

Comcolor series (revision 2.4) [ 1-20 ] maintenance user category selection of the user category. The difference is in the selection tab. The items in the selections tab can be changed. Different same same.

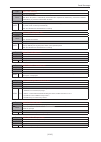

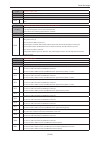

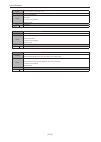

Page 21: Contents

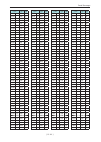

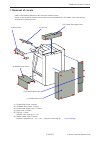

Machine covers [ 2-1 ] comcolor series (revision 2.4) contents 1.Exterior covers ................................................................................... 2-2 2.Removal .............................................................................................. 2-3 2-1.Operation panel as...

Page 22

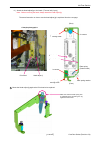

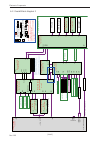

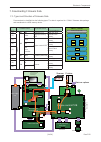

Machine covers [ 2-2 ] comcolor series (revision 2.4) comcolor top right cover top left cover rear cover face-down receiving tray switchback guide operation panel rear left cover external paper feed tray cover left bottom side cover tray cover front left cover front right cover right side cover rear...

Page 23

Machine covers [ 2-3 ] comcolor series (revision 2.4) metal bottom plate a b operation panel 2-2.Front bottom cover this cover is not assembled on the machine. It needs to be mounted on the machine at the time of the machine installation. * two screws, one in the center and the other on the right ha...

Page 24

Machine covers [ 2-4 ] comcolor series (revision 2.4) center inner cover right inner cover and right front door as an assembly. Left inner cover and left front door as an assembly. Right inner cover and right front door as an assembly. Left inner cover and left front door as an assembly. 2-3.Front d...

Page 25

Machine covers [ 2-5 ] comcolor series (revision 2.4) 2-4.Rear cover it is best to remove the rear cover with the left rear cover and right rear cover attached for easier replacement. * left and right top covers should be removed first for smooth removal and replacement of the rear cover. Rear cover...

Page 26

Machine covers [ 2-6 ] comcolor series (revision 2.4) front door lock mechanism screw screw screw screw front door lock mechanism front view rear view 2-5.Front door lock mechanism it is best to remove the rear cover with the left rear cover and right rear cover attached for easier replacement. 1) r...

Page 27

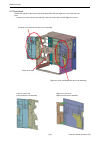

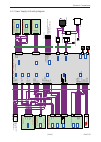

Machine covers [ 2-7 ] comcolor series (revision 2.4) grounding plate. Controller pcb box supporting screw on the right. Supporting screw on the left. 2-6.Opening the pcbs and ink supply unit to the service mode. 1) remove the left and right top covers. 2) remove the rear cover assembly (rear cover ...

Page 28

Machine covers [ 2-8 ] comcolor series (revision 2.4) controller pcb ink supply unit engine controll pcb power supply unit the following photograph indicates the screw numbers used to identify the screws mentioned on the exploration on the previous page..

Page 29

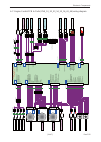

Machine covers [ 2-9 ] comcolor series (revision 2.4) paper elevation motor head drive ic cooling fan 1 head drive ic cooling fan 2 ink cooling fan 1 ink cooling fan 2 maintenance unit drive motor bellows arm drive motor switchback motor switchback clutch registration motor upper transfer motor re-f...

Page 30

Machine covers [ 2-10 ] comcolor series (revision 2.4) ink circulation pump tray 1 elevation motor internal paper feed motor.

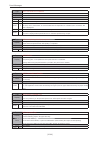

Page 31: Contents

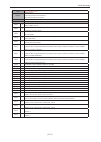

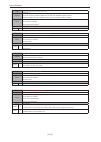

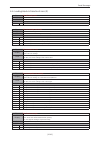

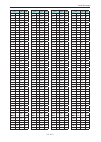

Structural overview [ 3-1 ] comcolor series (revision 2.4) chapter 3. Structural overview contents 1.Comcolor series specifications........................................................ 3-2 2.Hs4000 scanner specifications ........................................................ 3-8 3.Multifunction...

Page 32

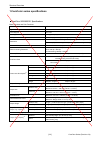

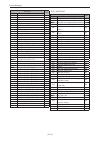

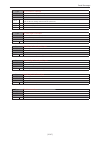

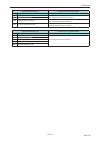

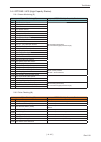

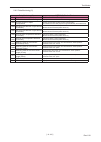

Structural overview [ 3-2 ] comcolor series (revision 2.4) 1.Comcolor series specifications comcolor 9050/9050r specifications basic functions and print functions model se-h301 type console color support full color print type line-type inkjet system ink type oil-based pigment ink (cyan, magenta, yel...

Page 33

Structural overview [ 3-3 ] comcolor series (revision 2.4) note: this machine specification sheet is for reference only. Check with your marketing department for the precise specification of the comcolor to your country. The specifications are subject to change without prior notice. * 1 within 10 mi...

Page 34

Structural overview [ 3-4 ] comcolor series (revision 2.4) comcolor 7050/7050r/3050/3050r specifications basic functions and print functions model comcolor 7050/7050r:se-m301 comcolor 3050/3050r:se-m401 type console color support full color print type line-type inkjet system ink type oil-based pigme...

Page 35

Structural overview [ 3-5 ] comcolor series (revision 2.4) * 1 within 10 minutes after the last print job * 2 when using plain paper and recycled paper (85 g/m 2 (23-lb bond)), and density setting 3 (standard) chart used: print measurement pattern [color measurement sample 2 (jeita standard pattern ...

Page 36

Structural overview [ 3-6 ] comcolor series (revision 2.4) comcolor 7010/7010r/3010/3010r specifications basic functions and print functions model comcolor 7010/7010r:se-l301 comcolor 3010/3010r:se-l401 type console color support full color print type line-type inkjet system ink type oil-based pigme...

Page 37

Structural overview [ 3-7 ] comcolor series (revision 2.4) * 1 within 10 minutes after the last print job * 2 when using plain paper and recycled paper (85 g/m 2 (23-lb bond)), and density setting 3 (standard) chart used: print measurement pattern [color measurement sample 2 (jeita standard pattern ...

Page 38

Structural overview [ 3-8 ] comcolor series (revision 2.4) memo.

Page 39

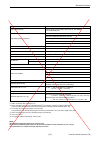

Structural overview [ 3-9 ] comcolor series (revision 2.4) note: this machine specification sheet is for reference only. Check with your marketing department for the precise specification. The specifications are subject to change without prior notice. Scanner hs4000 (optional) copy/scan functions * ...

Page 40

Structural overview [ 3-10 ] comcolor series (revision 2.4) memo.

Page 41

Structural overview [ 3-11 ] comcolor series (revision 2.4) multifunction finisher (optional) * 1 w hen color printing on pa per that is longer than 432 mm (17"), the image printed beyond 432 mm (17") may be distorted . * 2 w hen using plain paper and recycled pa per (85 g/ m 2 (23-lb bond)) * 3 w h...

Page 42

Structural overview [ 3-12 ] comcolor series (revision 2.4) memo.

Page 43

Structural overview [ 3-13 ] comcolor series (revision 2.4) ic card authentication kit (optional) applicable card iso 14443 typea/typec (felica /mifare ) radio law category guided read-write communication equipment power source power received from usb port operating environment temperature: 15ºc to ...

Page 44

Structural overview [ 3-14 ] comcolor series (revision 2.4) memo.

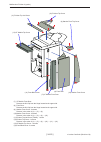

Page 45: 5.Structural Overview

Structural overview [ 3-15 ] comcolor series (revision 2.4) 5.Structural overview 5-1. Overall block structure the unit consists of the following blocks. 1) external paper feed section this section feeds a single sheet of paper from paper stacked in the paper feed tray, sending it to the registratio...

Page 46

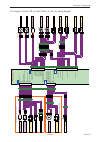

Structural overview [ 3-16 ] comcolor series (revision 2.4) external paper feed section switchback section paper ejection section (face down) paper transfer section bp section internal paper feed section paper ejection section (face up) registration section waste ink section ink flow section overall...

Page 47

Structural overview [ 3-17 ] comcolor series (revision 2.4) paper receiving tray unit switchback unit a vertical paper feed unit b vertical paper feed unit a internal paper feed unit external paper feed unit switchback unit b upper transfer unit paper elevation unit registration roller unit face dow...

Page 48

Structural overview [ 3-18 ] comcolor series (revision 2.4) pressurized ink tank air valve negative pressure ink tank air valve bellows unit pressurized ink tank negative pressure ink tank circulation pump overflow pan ink supply unit structure of ink supply unit (rear of the machine).

Page 49

Structural overview [ 3-19 ] comcolor series (revision 2.4) external paper feed internal paper feed printing paper elevation face up paper ejection/finisher upper transfer switchback face down paper ejection waste ink tank print heads ink cartridges switchback external paper feed internal paper feed...

Page 50

Structural overview [ 3-20 ] comcolor series (revision 2.4) 2) paper transfer sensors • the status of paper transferred from the paper feed tray is checked by vertical paper feed sensors 1–5. If the timing of paper is detected to be off as it passes vertical paper feed sensor 5, the transfer speed i...

Page 51

Structural overview [ 3-21 ] comcolor series (revision 2.4) 5-3. Overview of ink flow path • ink flow paths can be broadly divided into two types of paths: paths to supply the ink required in printing and a waste ink path for ink from print head cleaning and other maintenance. • ink from ink cartrid...

Page 52

Structural overview [ 3-22 ] comcolor series (revision 2.4) ink supply unit 3) schematic diagram of ink path tag rfid board joint ink cartridge direction of cartridge attachment/removal s m s m s ink supply valve (solenoid) from other colors joint connection/ disconnection motor ink level detection ...

Page 53

Structural overview [ 3-23 ] comcolor series (revision 2.4) 4) cross section of ink supply unit.

Page 54

Structural overview [ 3-24 ] comcolor series (revision 2.4) memo.

Page 55: Contents

External paper feed section [ 4-1 ] comcolor series (revision 2.4) chapter 4. External paper feed section contents 1. Mechanisms ....................................................................................... 4-2 1-1. Basic structure .............................................................

Page 56: 1. Mechanisms

External paper feed section [ 4-2 ] comcolor series (revision 2.4) paper guides elevation mechanism paper guide lever elevator motor external paper feed unit paper feed tray unit paper feed tray paper width potentiometer paper feed tray paper length detection sensor 1. Paper feed tray unit • the pap...

Page 57

External paper feed section [ 4-3 ] comcolor series (revision 2.4) upper limit adjustment assembly paper feed roller assembly scraper roller paper feed stay assembly paper feed pressure assembly pickup roller stripper unit assembly paper feed tray upper limit sensor a paper feed tray upper limit sen...

Page 58

External paper feed section [ 4-4 ] comcolor series (revision 2.4) paper feed pressure lever 2. External paper feed unit this unit feeds paper in the paper feed tray to the paper transfer section, one sheet at a time. Feeding starts when paper reaches the feeding position by means of the elevator. A...

Page 59

External paper feed section [ 4-5 ] comcolor series (revision 2.4) during printing after the paper feed tray is raised, paper is fed one sheet at a time by the paper feed rollers, and the paper feed tray is repeatedly raised to maintain the same upper limit position. This operation to maintain the u...

Page 60

External paper feed section [ 4-6 ] comcolor series (revision 2.4) 3. Elevator switch • used to raise or lower the paper feed tray manually. → when in the lower limit position pressing the switch once raises the elevator to the upper limit position and positions it. Pressing the switch again as the ...

Page 61

External paper feed section [ 4-7 ] comcolor series (revision 2.4) 1-3. Paper feed mechanism paper in the paper feed tray is fed to the paper transfer section one sheet at a time. Feeding starts when paper reaches the feeding position by means of the elevator. After each sheet is separated by the pa...

Page 62

External paper feed section [ 4-8 ] comcolor series (revision 2.4) 2. Paper stripping mechanism paper in the paper feed tray is sent between the pickup roller and stripper plate by rotation of the scraper. Additionally, paper is carefully handled by the pickup roller and stripper plate so that only ...

Page 63

External paper feed section [ 4-9 ] comcolor series (revision 2.4) 1-4. Paper size detection mechanism paper size is detected by the following two methods. 1. Paper transfer system: paper length is detected by the timing of activation and deactivation of top edge sensor 1. 2. System: paper size is d...

Page 64

External paper feed section [ 4-10 ] comcolor series (revision 2.4) 1-5. Paper volume detection mechanism the amount of paper left in the paper feed tray is determined by the status of paper volume detection sensors a and b when the paper feed tray is at the upper limit position. Detection is only p...

Page 65

External paper feed section [ 4-11 ] comcolor series (revision 2.4) 1-6. Multiple paper feed detection mechanism a multiple paper feed occurs when multiple loaded sheets are accidentally transferred on top of each other. This condition is detected to prevent problems from the sheets striking and dam...

Page 66

External paper feed section [ 4-12 ] comcolor series (revision 2.4) 1-7. Noise reduction paper feed assisting action noise reduction paper feed assisting action refers to operation to reduce noise created by flattening paper that has buckled as it is fed in the registration section. As feeding in th...

Page 67: 2. Disassembly

External paper feed section [ 4-13 ] comcolor series (revision 2.4) 2-1. Elevator motor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Lower the paper feed tray to the lower limit and turn the unit off. 3. Remove the center inner cover. (refer to chapter 2.) 4...

Page 68

External paper feed section [ 4-14 ] comcolor series (revision 2.4) 2-2. Paper feed tray unit removing the unit 1. Turn off the machine power and disconnect the power cable from the power source. 2. Lower the paper feed tray to the lower limit and turn the unit off. 3. Remove the wire harness cover ...

Page 69

External paper feed section [ 4-15 ] comcolor series (revision 2.4) 2-3. Paper feed tray paper detection sensor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper feed tray unit. (refer to the instructions for removal.) 3. Remove the paper guides....

Page 70

External paper feed section [ 4-16 ] comcolor series (revision 2.4) 2-5. Paper feed tray paper length detection sensor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper feed tray unit. (refer to the instructions for removal.) 3. Remove the paper ...

Page 71

External paper feed section [ 4-17 ] comcolor series (revision 2.4) 2-9. External paper feed unit 1. Turn off the machine power and disconnect the power cable from the power source. 2. Lower the paper feed tray to the lower limit and turn the unit off. 3. Remove the rear cover center assembly. (refe...

Page 72

External paper feed section [ 4-18 ] comcolor series (revision 2.4) 10. Remove the elevator motor assembly. (see section 2) hold the external paper feed tray to prevent it from dropping when removing the motor. 11. Remove the external paper feeding tray. (see section 2) 12. Remove the elevator suppo...

Page 73

External paper feed section [ 4-19 ] comcolor series (revision 2.4) 18. Remove the connector. (1 pc) 19. Remove the external paper feed motor assembly. (see section 2-8.) 20. Remove the external paper feed unit. (it3c screw 4x8 (4 pcs)) machine rear view connectors wire saddle external paper feed mo...

Page 74

External paper feed section [ 4-20 ] comcolor series (revision 2.4) 2-10. Stripper interlock switch 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the external paper feed unit. 3. Remove the stripper interlock switch assembly. (round tip it3c screw 3x6 ...

Page 75

External paper feed section [ 4-21 ] comcolor series (revision 2.4) 2-12. Paper feed tray upper safety switch 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper feed cover. (binding screw 3x8 (2 pcs)) 3. Remove the three connectors. 4. Remove the ...

Page 76

External paper feed section [ 4-22 ] comcolor series (revision 2.4) 2-13. Paper feed tray elevation switch 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper feed cover. (binding screw 3x8 (2 pcs)) 3. Remove the three connectors. 4. Remove the upp...

Page 77

External paper feed section [ 4-23 ] comcolor series (revision 2.4) 2-17. Stripper plate 1. Turn off the machine power and disconnect the power cable from the power source. 2. Lower the sliding lock on the left side of the stripper unit and slide the locking knob down. 3. Push the removal lever on t...

Page 78

External paper feed section [ 4-24 ] comcolor series (revision 2.4) memo.

Page 79: 3. Adjustment

External paper feed section [ 4-25 ] comcolor series (revision 2.4) 3. Adjustment 3-1. Upper limit position adjustment (1) standard adjustment (perform mainly if the upper limit position has changed due to wear of the scraper roller) insert a phillips screwdriver in the adjustment hole on the paper ...

Page 80

External paper feed section [ 4-26 ] comcolor series (revision 2.4) 3-2. Adjusting the paper width potentiometer (1) adjusting the paper width potentiometer • test mode no.1421 : set the paper guides at a width of 297 mm and activate. • test mode no.1422: set the paper guides at a width of 105 mm an...

Page 81: Contents

Registration section [ 5-1 ] last update : 2012/09/07 15:38 comcolor series (revision 2.4) chapter 5. Internal paper feed contents 1. Mechanisms ....................................................................................... 5-2 1-1. Basic structure .............................................

Page 82: 1. Mechanisms

Registration section [ 5-2 ] comcolor series (revision 2.4) 1. Mechanisms 1-1. Basic structure the internal paper feed section is a unit that transfers paper from the internal paper feed tray unit to vertical paper feed unit b. It is comprised of the internal paper feed unit and internal paper feed ...

Page 83

Registration section [ 5-3 ] comcolor series (revision 2.4) 1-2. Internal paper feed action (1) pull the internal paper feed tray unit toward the front to supply paper. (2) after paper is supplied, once a tray is loaded in the main unit, the tray elevator motor is activated and the bottom plate is r...

Page 84

Registration section [ 5-4 ] comcolor series (revision 2.4) • paper is easy to remove when a tray is pulled out because the stripper plate and pickup roller are separated. • the end paper guide can be smoothly adjusted to match the length of paper. • action of elevator motor the following actions ar...

Page 85

Registration section [ 5-5 ] comcolor series (revision 2.4) 1-5. Paper volume detection mechanism this the amount of paper left is detected from the position of the tray bottom plate (by the paper volume detection sensor) and whether there is paper left (indicated by the paper detection sensor). The...

Page 86

Registration section [ 5-6 ] comcolor series (revision 2.4) 1-6. Paper size detection mechanism paper size is detected by the following two methods. 1. Paper transfer system: paper length is detected by the timing of activation and deactivation of top edge sensor 1. 2. System: the pattern formed by ...

Page 87

Registration section [ 5-7 ] comcolor series (revision 2.4) 1-7. Assist action for information about the assist action of the internal paper feed tray, see section 1-4, "assist action," in chapter 6, "registration section.".

Page 88

Registration section [ 5-8 ] comcolor series (revision 2.4) 1-8. Paper transfer action (1) paper feeding (internal paper feed clutch 1 on) (2) vertical paper feed clutch 1 on (30 ms after internal paper feed clutch 1 on) (3) internal paper feed clutch 1 off (simultaneously vertical paper feed sensor...

Page 89

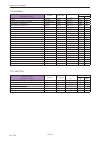

Registration section [ 5-9 ] comcolor series (revision 2.4) paper transfer: paper transfer action 1. Name ou ti n notes 2. 3. 2. 3. 5. 6. 1. 4. Timing start transfer started finish transfer ended 4. 5. 6. 7. 8. "not arrived" error 1. Error : external paper feed motor lock error (error: 1034) : inter...

Page 90

Registration section [ 5-10 ] comcolor series (revision 2.4) internal paper feed clutch 2 paper feed roller 2 vertical paper feed sensor 3 vertical paper feed clutch 1 vertical paper feed sensor 5 vertical paper feed roller 5 vertical paper feed roller 3 vertical paper feed clutch 2 vertical paper f...

Page 91

Registration section [ 5-11 ] comcolor series (revision 2.4) paper transfer (tray 2) timing chart paper transfer: paper transfer action 1. Name ou ti n notes 2. 3. 2. 3. 5. 6. 1. 4. Timing start transfer started finish transfer ended 4. 5. 6. 7. 8. "not arrived" error 1. Error internal paper feed mo...

Page 92

Registration section [ 5-12 ] comcolor series (revision 2.4) internal paper feed clutch 3 paper feed roller 3 vertical paper feed sensor 3 vertical paper feed clutch 1 vertical paper feed sensor 5 vertical paper feed roller 5 vertical paper feed roller 3 vertical paper feed clutch 2 vertical paper f...

Page 93

Registration section [ 5-13 ] comcolor series (revision 2.4) paper transfer: paper transfer action 1. Name 2. 3. 2. 3. 5. 1. 4. Timing start transfer started finish transfer ended 4. 5. 6. 7. "not arrived" error : external paper feed motor lock error (error: 1034) : internal paper feed motor lock er...

Page 94

Registration section [ 5-14 ] comcolor series (revision 2.4) memo.

Page 95

Registration section [ 5-15 ] comcolor series (revision 2.4) 2. Disassembly 2-1. Internal paper feed unit (tray 1) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to cha...

Page 96

Registration section [ 5-16 ] comcolor series (revision 2.4) 15. Remove the mounting screw of the internal paper feed unit (tray 1) in back. (it3c screw 4x8 (1 pc)) 16. Remove the mounting bracket of the internal paper feed unit (tray 1) in front. (it3c screw 4x8 (3 pcs)) 17. Disconnect the wire con...

Page 97

Registration section [ 5-17 ] comcolor series (revision 2.4) 2-2. Internal paper feed unit (tray 2) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to chapter 2.) 4. Rem...

Page 98

Registration section [ 5-18 ] comcolor series (revision 2.4) 2-3. Internal paper feed unit (tray 3) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to chapter 2.) 4. Rem...

Page 99

Registration section [ 5-19 ] comcolor series (revision 2.4) 2-4. Internal paper feed motor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Remove the left top cover. (refer to chapter 2.) 4. Put t...

Page 100

Registration section [ 5-20 ] comcolor series (revision 2.4) 2-5. Internal paper feed clutches 1, 2 and 3. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Put the power supply unit in maintenance p...

Page 101

Registration section [ 5-21 ] comcolor series (revision 2.4) 2-7. Paper detection sensors of trays 1 to 3 (3 sets) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Follow the instruction given on the previous pages of this chapter and remove the internal paper f...

Page 102

Registration section [ 5-22 ] comcolor series (revision 2.4) 2-9. Internal paper feed rollers 1, 2 and/or 3. (scraper and pickup rollers) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Pull out and remove all three internal paper feed trays from the machine. 3...

Page 103

Registration section [ 5-23 ] comcolor series (revision 2.4) 2-10. Elevator motors for trays 1, 2 and 3. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Put the power supply unit in maintenance pos...

Page 104

Registration section [ 5-24 ] comcolor series (revision 2.4) 2-11. Set interlock switch for trays 1, 2 and 3. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Put the power supply unit in maintenanc...

Page 105

Registration section [ 5-25 ] comcolor series (revision 2.4) 2-13. Paper size detection sensors (1 to 4) for trays 1, 2 and 3. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Pull out and remove all three internal paper feed trays from the machine 3. Remove the...

Page 106

Registration section [ 5-26 ] comcolor series (revision 2.4) memo.

Page 107: 3. Adjustment

Registration section [ 5-27 ] comcolor series (revision 2.4) 3. Adjustment 3-1. Stripper plate angle adjustment adjust the stripper angle by pulling out the tray and turning the stripper angle adjust dial in the stripper section of the internal paper feed unit. Adjustment is possible in a range of 1...

Page 108

Registration section [ 5-28 ] comcolor series (revision 2.4) 3-3. Internal paper feed tray - end fence & slider (sensor actuator) position adjustment the paper size in the internal paper feed trays are detected by the position of the end fence in the tray. If the position between the end fence and t...

Page 109

Registration section [ 5-29 ] comcolor series (revision 2.4) 4) remove the flat gear; m1x36x4. 5) slide the slider to match the 3 mm diameter positioning hole on the slider against the 3 mm diameter hole on the tray. 6) while the two 3 mm hole are aligned, put back the previously removed flat gear; ...

Page 110

Registration section [ 5-30 ] comcolor series (revision 2.4) memo.

Page 111: Contents

Registration section [ 6-1 ] comcolor series (revision 2.4) chapter 6. Registration section contents 1. Mechanisms ....................................................................................... 6-2 1-1. Basic structure ...........................................................................

Page 112: 1. Mechanisms

Registration section [ 6-2 ] comcolor series (revision 2.4) 1. Mechanisms 1-1. Basic structure the registration section transfers paper into the printing area from the internal or external paper feed unit or switchback unit. This section is comprised of vertical paper feed units b and a, the registr...

Page 113

Registration section [ 6-3 ] comcolor series (revision 2.4) 1-2. Vertical paper feed unit b mechanism paper feeding from tray 1 1) vertical paper feed clutch 1 is activated about 30 ms after the paper feed start signal is received, and vertical paper feed roller 4 starts rotating. 2) the internal pa...

Page 114

Registration section [ 6-4 ] comcolor series (revision 2.4) 1-3. Vertical paper feed unit a mechanism 1) paper from the trays (1–3), passing through the internal paper feed and vertical paper feed unit b, is detected by upstream sensors (vertical paper feed sensors 4 and 3). After a specific period,...

Page 115

Registration section [ 6-5 ] comcolor series (revision 2.4) vertical paper feed roller 5 vertical paper feed sensor 5 progression of paper drive side guide plate driven side guide plate fulcrum (appearance when closed) (appearance when open) jam release lever points of attachment (affixed to unit fr...

Page 116

Registration section [ 6-6 ] comcolor series (revision 2.4) 1-4. Assist action assist control by the vertical paper feed unit is as follows. Assist control by the vertical paper feed section (paper feeding from the internal paper feed tray) serves the following two purposes. 1. To control slippage d...

Page 117

Registration section [ 6-7 ] comcolor series (revision 2.4) 1-5. Registration roller mechanism the registration roller section is comprised of the registration rollers (made of rubber), the guide rollers (plastic), the registration sensor, and top edge sensor 1. The registration and guide rollers ar...

Page 118

Registration section [ 6-8 ] comcolor series (revision 2.4) 1-6. Paper position detection unit mechanism this unit is between the registration rollers and the head that is closest to the registration area. The unit is comprised of a section for paper lift/crease detection (including paper retainer),...

Page 119

Registration section [ 6-9 ] comcolor series (revision 2.4) plate spring for correcting torsion reference for attachment (front) reference for attachment (rear) registration rollers top edge sensor 1 top edge sensor 2 transfer belt suction fan paper lift detection sensor on (lift detected) (1) paper...

Page 120

Registration section [ 6-10 ] comcolor series (revision 2.4) 1-7. Detection mechanism for leading and trailing edges (1) paper detection leading and trailing edges are constantly detected by top edge sensors 1 and 2 (incorporated in the head holder). (2) ink drop timing leading-edge detection data f...

Page 121: 2. Disassembly

Registration section [ 6-11 ] 2. Disassembly 2-1. Vertical paper feed unit a 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to chapter 2.) 4. Remove the rear cover cent...

Page 122

Registration section [ 6-12 ] 2-2. Vertical paper feed sensor 5 (vertical paper feed unit a) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove vertical paper feed unit a. (refer to the instructions for removal.) 3. Remove the sensor cover plate. (w sems sc...

Page 123

Registration section [ 6-13 ] 2-4. Vertical paper feed unit b 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the bottom left-side cover. (refer to chapter 2.) 3. Remove the rear cover center assembly. (refer to chapter 2.) 4. Remove the left inner cover...

Page 124

Registration section [ 6-14 ] 2-5. Vertical paper feed sensor 1 (vertical paper feed unit b) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove vertical paper feed unit b. (refer to the instructions for removal.) 3. Remove the sensor bracket for sensor 1. (...

Page 125

Registration section [ 6-15 ] 2-9. Vertical paper feed roller 1 (vertical paper feed unit b) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove vertical paper feed unit b. (refer to the instructions for removal.) 3. Remove pulley assembly s2m30. (6 mm dia. ...

Page 126

Registration section [ 6-16 ] 2-13. Internal feed paper jam door interlock switch (vertical paper feed unit b) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the external paper feed unit. (refer to chapter 4.) 3. Remove vertical paper feed unit b. (refe...

Page 127

Registration section [ 6-17 ] 2-16. Registration motor assembly 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Put the engine control pcb in maintenance position. (pan-head screw 4x8 (2 pcs)) 4. R...

Page 128

Registration section [ 6-18 ] 2-17. Registration sensor (send) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Open vertical paper feed unit a. 3. Unhook the plastic hook of the sensor cover from the sensor bracket, and then unhook the relay connector. 4. Remov...

Page 129

Registration section [ 6-19 ] 2-19. Top edge sensor 1 (send) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Unhook the plastic hook of the sensor cover from the mounting bracket, and then unhook the relay connector. 3. Remove top edge sensor 1 (send). Note: af...

Page 130

Registration section [ 6-20 ] 2-21. Registration roller 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to chapter 2.) 4. Remove the rear cover center assembly. (refer t...

Page 131

Registration section [ 6-21 ] 2-22. Guide roller note: be careful not to touch print heads during this work. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to chapter 2...

Page 132

Registration section [ 6-22 ] 2-23. Paper position detection unit 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the left inner cover. (refer to chapter 2.) 4. Remove the rear cover center assembly...

Page 133

Registration section [ 6-23 ] 2-24. Paper lift detection sensor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper position detection unit. (refer to the instructions for removal.) 3. Remove the paper lift detection sensor assembly. (w sems screw ...

Page 134

Registration section [ 6-24 ] comcolor series (revision 2.4) memo.

Page 135: 3. Adjustment

Registration section [ 6-25 ] comcolor series (revision 2.4) 3. Adjustment 3-1. Adjustment to make the registration roller and bp unit parallel adjust the alignment of the registration roller after replacing the registration roller or registration roller unit. Refer to chapter 11, section 3, "adjust...

Page 136

Registration section [ 6-26 ] comcolor series (revision 2.4) > loading position 2: place an a4 size sheet (297 mm) sideways in the position shown on the photograph below left. Confirm that the outside edge of the black plastic plate on the bp unit in the front is approximately 70 mm from the edge of...

Page 137

Registration section [ 6-27 ] comcolor series (revision 2.4) 4) close the right front cover. 5) execute the following cis shading compensation test modes, depending on the paper loading position. Loading position 1: test mode 2461 (shading compensation for the left and right cis at same time) loadin...

Page 138

Registration section [ 6-28 ] comcolor series (revision 2.4) 2. An error occurs if paper is not detected. (see note 2 on this page.) • w59-0228-1: edge detection error when confirming action of the left cis • w59-0228-2: edge detection error when confirming action of the right cis • w59-0228-3: edge...

Page 139

Registration section [ 6-29 ] comcolor series (revision 2.4) 2. No reference paper during shading compensation (w58-0226-4) criteria: if the average maximum value of five measurements outside the cis masking area (the area 400 pixels from the left and right edges) after black adjustment is 6,600 or ...

Page 140

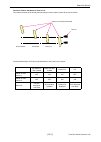

Registration section [ 6-30 ] comcolor series (revision 2.4) [registration sensor] & [top edge sensor 1] sensitivity adjustment sequence: top edge sensor 1 (receive) top edge sensor 1 (send) registration roller registration sensor (receive) transfer belt registration sensor (send) place a white shee...

Page 141

Registration section [ 6-31 ] comcolor series (revision 2.4) 2. Top edge sensor 2 (reflecting type sensor) make following adjustment when the tope edge sensor 2 is replaced. 1) confirm that the bp unit is all the up to the printing position. If not, activate test mode no.2405 to raise the bp unit to...

Page 142

Registration section [ 6-32 ] comcolor series (revision 2.4) memo.

Page 143: Chapter 7. Bp Section

Bp section [ 7-1 ] comcolor series (revision 2.4) chapter 7. Bp section contents 1. Mechanisms ....................................................................................... 7-2 1-1. Basic structurecdr4 ................................................................ 7-2 1-2. Raising and lo...

Page 144: 1. Mechanisms

Bp section [ 7-2 ] comcolor series (revision 2.4) 1. Mechanisms 1-1. Basic structure the bp unit is comprised of the transfer belt, transfer belt motor, belt platen, transfer belt fan (6), and the belt hp sensor. 1. Paper received from the registration rollers is transferred and conveyed to the pape...

Page 145

Bp section [ 7-3 ] comcolor series (revision 2.4) 1-2. Raising and lowering of the belt platen the bp unit is raised or lowered to move into the printing or idle position. 1. The bp unit is raised or lowered by means of four wires suspended from the head holder. (see figure 5.) 2. The wires are held...

Page 146

Bp section [ 7-4 ] comcolor series (revision 2.4) 1-3. Paper transfer mechanism 1. The bp unit keeps paper against the belt during transfer by means of suction fans (6). 2. The belt forms the shape of a trapezoid around the drive roller, driven roller, guide roller, and two tension rollers. It is dr...

Page 147

Bp section [ 7-5 ] comcolor series (revision 2.4) 1-5. Paper suction action this action applies suction to paper in the printing section. Because there is only a head gap of about 1.5 mm, paper that lifts up as it is transferred may damage the head. Suction is required when paper is transferred unde...

Page 148

Bp section [ 7-6 ] comcolor series (revision 2.4) 1-6. Ink drop position adjustment ink drop position adjustment in the bp unit refers to compensating for inconsistency in ink impact. Two types of adjustment are performed in ink drop position adjustment: belt profile and roller profile compensation....

Page 149

Bp section [ 7-7 ] comcolor series (revision 2.4) convenient test modes to know for the bp contact detection mechanism test mode number process name description 2170 bp hit detection (rl) on: contact detected / off: contact not detected 2171 bp hit detection (rr) on: contact detected / off: contact ...

Page 150

Bp section [ 7-8 ] comcolor series (revision 2.4) 1-8. Gap adjuster mechanism mechanism for switching the gap between the print head and paper a mechanism for adjusting the distance between the head nozzle surface and paper on the belt platen, by means of the protrusion below the head unit. Four hea...

Page 151

Bp section [ 7-9 ] comcolor series (revision 2.4) place the bp tension spring over the rotary guide by matching the marking on the green colored line shown on the sketch on the left. The green colored line indicates how the spring guide hook should be pushed up. Push the bp tension spring and spring...

Page 152

Bp section [ 7-10 ] comcolor series (revision 2.4) detects loose wires (caused by winding the wires in the reverse, for example). Micro-switch to detect loose wire. 1-9. Bp wire loose detection mechanism.

Page 153: 2. Disassembly

Bp section [ 7-11 ] comcolor series (revision 2.4) 2. Disassembly caution : do not remove the front frame of the bp unit. (the front frame is positioned with a factory jig.) 2-1. Removing the bp unit note: be careful not to touch the print head during this work. 1. Turn off the machine power and dis...

Page 154

Bp section [ 7-12 ] comcolor series (revision 2.4) 8. Loosen the mounting screws of the elevation guide (it3c screw 4x8 (4 pcs)), slide the guide upward, and affix it temporarily by tightening one of the four screws. 9. Unhook the wires from the wire hooks on the bp unit (in 4 positions). 10. Unhook...

Page 155

Bp section [ 7-13 ] comcolor series (revision 2.4) 2-2. Transfer belt motor assembly 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the bp front cover. (binding screw 4x8 (3 pcs)) 3. Remove the belt hp sensor. (w sems screw 3x12 (1 pc)) 4. Remove the re...

Page 156

Bp section [ 7-14 ] comcolor series (revision 2.4) 2-4. Bp upper limit sensor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Move the maintenance unit manually to the retracted position. 3. Remove the sensor cover plate. (it3c screw 3x6 (1 pc)) 4. Disconnect t...

Page 157

Bp section [ 7-15 ] comcolor series (revision 2.4) 2-6. Belt shaft fg sensor assembly (encoder) note: do not remove unless the sensor is actually damaged. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the bp unit. (refer to the instructions for removal...

Page 158

Bp section [ 7-16 ] comcolor series (revision 2.4) 6. Remove the belt tension shaft from the rear of the bp unit. (6 mm dia. E-ring (1 pc)) 7. Remove the belt guide shaft from the rear of the bp unit. (6 mm dia. E-ring (1 pc)) 8. Remove the drive roller bearing from the rear of the bp unit. (8 mm di...

Page 159

Bp section [ 7-17 ] comcolor series (revision 2.4) 12. Remove the driven roller, with the encoder attached, from over the top of the bp unit. (unhook the bearing from the frame.) 13. Pull out the driven roller from the rear of the bp unit. 14. Remove the guide pulley mounting bracket. (it3c screw 4x...

Page 160

Bp section [ 7-18 ] comcolor series (revision 2.4) 17. Turn the bp unit up-side-down on the table, and then remove the rear frame of the belt platen unit. (w sems screw 4x10 (4 pcs), p-tight screw 3x8 (1 pc), and binding p-tight screw 4x10 (6 pcs)). Note: keeping the unit facing down prevents four m...

Page 161

Bp section [ 7-19 ] comcolor series (revision 2.4) 2-9. Bp lift wires removing the bp lift wires involve working inside the print head carriage, such as working on the print head pcbs and the print head flat cables are involved. The instructions for the bp lift wire replacement procedure is therefor...

Page 162

Bp section [ 7-20 ] comcolor series (revision 2.4) memo.

Page 163: 3. Adjustment

Bp section [ 7-21 ] comcolor series (revision 2.4) 3. Adjustment 3-1. Ink drop position enhancement adjustment the particular unevenness of the transfer belt along with vibration and eccentricity of transfer rollers causes inconsistency in ink droplet position. However, the precision of ink droplet ...

Page 164

Bp section [ 7-22 ] comcolor series (revision 2.4) in this compensation, the amount of eccentricity existing on the transfer belt rollers is quantified and applied on the ink drop timing. The roller profile parameters must be re-input by test modes after the encoder is once removed from the transfer...

Page 165

Bp section [ 7-23 ] comcolor series (revision 2.4) print out samples of test mode numbers 1478 and 1479 head binding area uneven in color, density and width. The binding area is smooth in width and in color density. The binding area is not smooth in the width and color density. Good bad.

Page 166

Bp section [ 7-24 ] comcolor series (revision 2.4) 3-2. Transfer belt alignment perform this adjustment when replacing the transfer belt or after the belt was removed for replacement of the fan motor, rollers, or other parts. Inaccurate positioning of the belt causes deformation of the belt edge sur...

Page 167

Bp section [ 7-25 ] comcolor series (revision 2.4) the position of the bp belt edge against the flange on the belt driven roller can only be checked at one location,at the left-front of the bp unit. At no other location the observation can be made. Use a mirror and a flashlight to confirm the bp bel...

Page 168

Bp section [ 7-26 ] comcolor series (revision 2.4) flange roller transfer belt (top surface) correct: belt edge aligned with the flange incorrect: deflected incorrect: lifted incorrect: separation driven roller flange belt edge drive roller bp belt insulation plate bp belt belt edge left-hand side r...

Page 169

Bp section [ 7-27 ] comcolor series (revision 2.4) 3-3. Adjustment to make the bp unit and registration roller parallel if the bp unit and registration roller are not parallel, when the registration roller transfers a sheet aligned on its leading edge to the bp unit, it will be transferred crooked, ...

Page 170

Bp section [ 7-28 ] comcolor series (revision 2.4) memo.

Page 171: Contents

Paper transfer section [ 8-1 ] comcolor series (revision 2.4) chapter 8. Paper transfer section contents 1. Mechanisms ....................................................................................... 8-2 1-1. Basic structure .......................................................................

Page 172: 1. Mechanisms

Paper transfer section [ 8-2 ] comcolor series (revision 2.4) 1. Mechanisms 1-1. Basic structure the paper transfer section, which handles paper feeding, is comprised of the paper elevation unit and upper transfer unit. 1-2. Paper elevation unit mechanism the paper elevation unit is comprised of the...

Page 173

Paper transfer section [ 8-3 ] comcolor series (revision 2.4) 1-3. Upper transfer unit mechanism the upper transfer unit is comprised of the upper transfer motor and upper transfer rollers 3–5. This unit transfers paper from the paper elevation unit to switchback unit b or the face down paper ejecti...

Page 174

Paper transfer section [ 8-4 ] comcolor series (revision 2.4) description 1) when printing starts, the upper transfer rollers start rotating. (except during simplex printing when face up paper ejection is specified.) during simplex printing, rollers of the upper transfer unit rotate at the same circ...

Page 175: 2. Disassembly

Paper transfer section [ 8-5 ] comcolor series (revision 2.4) 2. Disassembly 2-1. Paper elevation motor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Put the controller pcb box in maintenance pos...

Page 176

Paper transfer section [ 8-6 ] comcolor series (revision 2.4) 2-3. Paper elevation in sensor (paper elevation unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper elevation unit. (refer to the instructions for removal.) 3. Remove the paper ele...

Page 177

Paper transfer section [ 8-7 ] comcolor series (revision 2.4) 2-6. Driven roller (paper elevation unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper elevation unit. (refer to the instructions for removal.) 3. Remove the mounting base of the ...

Page 178

Paper transfer section [ 8-8 ] comcolor series (revision 2.4) 2-8. Flipper sensor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2.) 3. Remove the two stoppers and pull out the upper transfer unit. (round tip it...

Page 179

Paper transfer section [ 8-9 ] comcolor series (revision 2.4) 2-10. Upper transfer roller 3 (upper transfer unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the upper transfer unit. (refer to the instructions for removal.) 3. Remove the clip. 4. Rem...

Page 180

Paper transfer section [ 8-10 ] comcolor series (revision 2.4) memo.

Page 181: Contents

Paper ejection section [ 9-1 ] comcolor series (revision 2.4) chapter 9. Paper ejection section contents 1. Mechanisms ....................................................................................... 9-2 1-1. Basic structure .......................................................................

Page 182: 1. Mechanisms

Paper ejection section [ 9-2 ] 1. Mechanisms 1-1. Basic structure the face down paper ejection section is comprised of the fd paper ejection unit, fd fence unit, and (optionally) the paper receiving tray unit. Comcolor series (revision 2.4) fd paper ejection unit fd fence unit paper receiving tray u...

Page 183

Paper ejection section [ 9-3 ] comcolor series (revision 2.4) flipper solenoid face down paper ejection motor encoder paper ejection sensor paper ejection roller (driven) when a jam is cleared jam release lever paper ejection roller (drive) end wall full detection sensor de-electricity brush.

Page 184

Paper ejection section [ 9-4 ] comcolor series (revision 2.4) 1-2. Fd paper ejection unit the basic structure of the fd paper ejection unit is shown below. Normal action of the face down paper ejection unit normal action of the face down paper ejection unit is not affected by the action of other uni...

Page 185

Paper ejection section [ 9-5 ] comcolor series (revision 2.4) > flipper sensor on (calculation/measurement started) (1) being transferred flipper sensor flipper on timing reached (2) target sheet previous sheet target sheet previous sheet flipper sensor off (3) target sheet next sheet (4) off timing...

Page 186

Paper ejection section [ 9-6 ] comcolor series (revision 2.4) > paper path switching: paper transfer action 1. Name ou ti n notes 2. 3. 4. 2. 3. 5. 6. 1. 4. Timing start transfer started finish transfer ended 5. 6. 7. 8. 1. Error 2. Fd paper ejection flipper solenoid on/off: : flipper sensor "not ar...

Page 187

Paper ejection section [ 9-7 ] 1-4. Paper receiving full detection mechanism fd paper receiving full detection is described below. Paper receiving full detection relies on the fd paper ejection full sensor. After detection by the fd paper ejection full sensor, the fd paper ejection motor remains on ...

Page 188

Paper ejection section [ 9-8 ] 1-5. Fd fence unit the paper ejection fence is moved to match the paper size so that paper can be uniformly ejected without transferred paper becoming disorderly. Unit structure the face down paper fence unit is summarized below. Fence movement 1. Determination of fenc...

Page 189

Paper ejection section [ 9-9 ] 2. Home positioning the fd paper ejection fence moves to the home position in the following situations. • when the unit is turned on • during recovery after an emergency stop when the fence was moving • when the unit is reset 1-6. Paper receiving tray unit (optional) t...

Page 190

Paper ejection section [ 9-10 ] comcolor series (revision 2.4) memo.

Page 191: 2. Disassembly

Paper ejection section [ 9-11 ] comcolor series (revision 2.4) 2. Disassembly 2-1. Removing the unit 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the left top cover. (refer to chapter 2.) 3. Remove the screws affixing the paper receiving tray unit, an...

Page 192

Paper ejection section [ 9-12 ] comcolor series (revision 2.4) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the left top cover. (refer to chapter 2.) 3. Remove the fd paper receiving tray unit. 4. Remove the fd fence unit. 5. Unplug the wire connector...

Page 193

Paper ejection section [ 9-13 ] comcolor series (revision 2.4) 2-2. Fd paper ejection fence motor (fd fence unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the fd fence unit. (refer to the instructions for removal.) 3. Unplug the motor wire connect...

Page 194

Paper ejection section [ 9-14 ] paper ejection section comcolor series (revision 2.4) 2-4. Fd paper ejection full detection sensor (fd paper ejection unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the fd paper ejection unit. (refer to the instruct...

Page 195

Paper ejection section comcolor series (revision 2.4) 2-7. Fd paper ejection flipper solenoid (fd paper ejection unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper ejection unit. (refer to the instructions for removal.) 3. Remove the solenoi...

Page 196

Paper ejection section [ 9-16 ] comcolor series (revision 2.4) 2-10. Fd ejection driven roller (fd paper ejection unit) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the paper ejection unit. (refer to the instructions for removal.) 3. Remove the socket...

Page 197: 3. Adjustment

Paper ejection section [ 9-17 ] comcolor series (revision 2.4) 3. Adjustment 3-1. Fd paper ejection flipper solenoid (fd paper ejection unit) the flipper and its adjustment position must be checked each time the flipper solenoid is replaced. 1. With the solenoid in activated condition (the plunger i...

Page 198

Paper ejection section [ 9-18 ] comcolor series (revision 2.4) 3-2. Phase adjustment of the fence rack (fd fence unit) when replacing the fd paper ejection fence motor of the fence unit, adjust the phase of the fence rack gears in assembly. 1. Open wide the both fence rack gears, all the way maximum...

Page 199: Contents

Switchback section [ 10-1 ] comcolor series (revision 2.4) chapter 10. Switchback section contents 1. Mechanisms ..................................................................................... 10-2 1-1. Basic structure ........................................................................ 10...

Page 200: 1. Mechanisms

Switchback section [ 10-2 ] comcolor series (revision 2.4) 1. Mechanisms 1-1. Basic structure the switchback section, which handles paper feeding in duplex printing, is comprised of switchback units a and b. 1-2. Mechanisms of switchback units a and b the switchback unit incorporates the switchback ...

Page 201

Switchback section [ 10-3 ] comcolor series (revision 2.4) unit positioning pins upper transfer out sensor attachment section upper transfer motor switchback unit b upper transfer roller 6 switchback unit a switchback sensor switchback clutch re-feed sensor jam release lever jam release dial switchb...

Page 202

Switchback section [ 10-4 ] comcolor series (revision 2.4) summary of switchback section action switchback motor stopped (stops at last 30 mm of the trailing edge, emerging from the switchback roller) switchback roller starts (normal rotation) (30 ms after upper transfer out sensor activated) (1) sw...

Page 203

Switchback section [ 10-5 ] comcolor series (revision 2.4) switchback section timing chart paper transfer: paper transfer action 1. Name ou t in note s 2. 3. 2. 3. 5. 1. 4. Timing start paper transfer started finish paper transfer ended 4. 5. 6. 7. 8. 1. Error : switchback sensor "paper not arrived"...

Page 204

Switchback section [ 10-6 ] comcolor series (revision 2.4) 1-3. Noise reduction paper feed assisting action noise reduction paper feed assisting action refers to operation to reduce noise created by flattening paper that has buckled as it is fed in the registration section. As feeding in the registr...

Page 205: 2. Disassembly

Switchback section [ 10-7 ] comcolor series (revision 2.4) 2. Disassembly 2-1. Switchback motor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the rear cover center assembly. (refer to chapter 2.) 3. Remove the left top cover. (refer to chapter 2.) 4. P...

Page 206

Switchback section [ 10-8 ] comcolor series (revision 2.4) 2-3. Switchback unit a 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the external paper feed unit. (refer to chapter 4 of this book) 3. Remove the fd paper receiving tray. (refer to chapter 4 o...

Page 207

Switchback section [ 10-9 ] comcolor series (revision 2.4) 7. Remove the re-feed motor. (roud tip it3c screw 4x8 (2 pcs)) 8. Remove two wire connectors. (4 and 6 pins in back.) 9. Open the jam release door. 10. Remove the safety cover plate. (round tip it3c screw 3x6 (1 pc)) 11. Remove the external ...

Page 208

Switchback section [ 10-10 ] comcolor series (revision 2.4) 13. Remove switchback unit a. (round tip it3c screw 4x8 (4 pcs)) 2-4. Switchback unit b 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the center inner cover. (refer to chapter 2 of this book) ...

Page 209

Switchback section [ 10-11 ] comcolor series (revision 2.4) 2-5. Switchback door interlock switch (switchback unit a) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove switchback unit a. (refer to the instructions in this chapter.) 3. Remove the switchback...

Page 210

Switchback section [ 10-12 ] comcolor series (revision 2.4) 2-7. Re-feed sensor (switchback unit a) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove switchback unit a. (refer to the instructions in this chapter.) 3. Unplug the wire connector of the re-fee...

Page 211

Switchback section [ 10-13 ] comcolor series (revision 2.4) 2-10. Upper transfer out sensor (switchback unit b) 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the switchback unit b. (refer to the instructions in this chapter.) 3. Remove the out sensor a...

Page 212

Switchback section [ 10-14 ] comcolor series (revision 2.4) memo.

Page 213: Contents

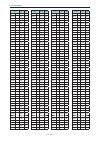

Ink flow section [ 11a-1 ] comcolor series (revision 2.4) chapter 11a. Ink flow section contents 1. Mechanisms ...................................................................................11a-2 1-1. Ink supply mechanisms ........................................................11a-2 1-2. Ink pa...

Page 214: 1. Mechanisms

Ink flow section [ 11a-2 ] comcolor series (revision 2.4) 1. Mechanisms 1-1. Ink supply mechanisms the ink supply mechanism is comprised of mechanisms to supply ink to the printer and heads, a mechanism for ink circulation, and a mechanism for generating purging pressure to recover from head nozzle ...

Page 215

Ink flow section [ 11a-3 ] comcolor series (revision 2.4) tag rfid board joint ink cartridge direction of cartridge attachment/removal ink supply valve (solenoid) from other colors joint connection/ disconnection motor ink level detection sensor heater pressurized ink tank air chamber in common to a...

Page 216

Ink flow section [ 11a-4 ] comcolor series (revision 2.4) 1-3. Ink circulation unit structure ink cartridge holder unit this unit holds the four ink cartridge units and controls ink supply based on "no ink" signals from the printer. The unit has an antenna for receiving data from ink cartridge tags....

Page 217

Ink flow section [ 11a-5 ] comcolor series (revision 2.4) heat exchanger tower pressurized ink tank air valve negative pressure ink tank air valve pressurized ink tank negative pressure ink tank ink overflow pan pressurized ink tank common air chamber heater ink circulation pump negative pressure in...

Page 218

Ink flow section [ 11a-6 ] comcolor series (revision 2.4) negative pressure ink tank this tank, positioned lower than the head nozzles, also stores ink separately for all four colors. An ink level detection sensor is incorporated in the tank, for detecting the level of ink in the tank. (the sensor d...

Page 219

Ink flow section [ 11a-7 ] comcolor series (revision 2.4) structure of circulation pump view with the cover removed one-way valve ink flows only in the direction indicated. Flow in the opposite direction is stopped. Made of soft rubber. From the negative pressure ink tank to the heat sink (heat exch...

Page 220

Ink flow section [ 11a-8 ] comcolor series (revision 2.4) bellows unit comprised of the bellows and motor connected to the common air chamber, in turn connected to the negative pressure ink tank for each color. Raising and lowering the bellows adjusts the pressure in the negative pressure ink tank. ...

Page 221

Ink flow section [ 11a-9 ] comcolor series (revision 2.4) bellows unit sensors sensors are incorporated at four positions on the bottom of the bellows unit to detect the position of the bellows, which rises and lowers. Bellows sensor the unit is stopped when the bellows sensor detects that the bello...

Page 222

Ink flow section [ 11a-10 ] comcolor series (revision 2.4) head unit ink bus the print head unit is arranged in the order c, k, m, and y relative to the paper feed direction, and all the heads face the same direction. The ink bus is positioned over the second row of the heads of another color. (for ...

Page 223

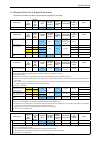

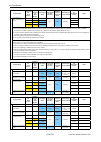

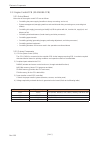

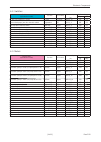

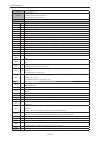

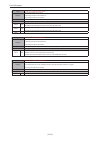

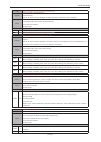

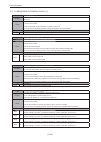

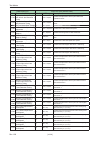

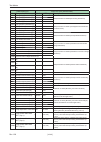

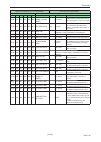

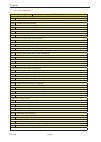

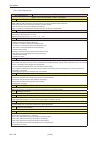

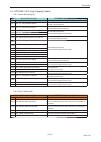

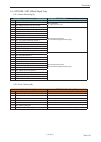

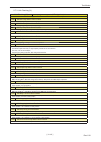

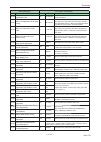

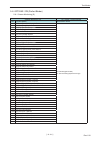

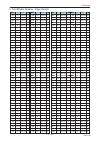

Ink flow section [ 11a-11 ] comcolor series (revision 2.4) 1-4. Standard action of ink supply mechanisms the status of principal units during various printer operations is as follows. Printer status pressurized ink tank sensor negative pressure ink tank sensor ink supply valve pressurized ink tank a...

Page 224

Ink flow section [ 11a-12 ] comcolor series (revision 2.4) printer status pressurized ink tank sensor negative pressure ink tank sensor ink supply valve pressurized ink tank air valve negative pressure ink tank air valve bellows pump sensor position ink circulation pump notes cartridge replacement d...

Page 225

Ink flow section [ 11a-13 ] comcolor series (revision 2.4) printer status pressurized ink tank sensor negative pressure ink tank sensor ink supply valve pressurized ink tank air valve negative pressure ink tank air valve bellows pump sensor position ink circulation pump notes filling the system with...

Page 226

Ink flow section [ 11a-14 ] comcolor series (revision 2.4) memo.

Page 227: 2. Disassembly

Ink flow section [ 11a-15 ] comcolor series (revision 2.4) 2. Disassembly 2-1. Cutting the ink tubes follow this ink tube cutting procedure when instructed in replacing certain ink circulation parts. 1. Cut the ink tubes at the cut-mark line. Use a nipper to cut the ink tube. The nipper should cut t...

Page 228

Ink flow section [ 11a-16 ] comcolor series (revision 2.4) 3. The cutting angle should be within 1.5 mm (approx. 10 degrees) from the imprinted marking. 4. Check with the eye for any left over tube on the cut area. If any leftover piece(s) are left on the tube, cut the leftover piece off. 5. Insert ...

Page 229

Ink flow section [ 11a-17 ] comcolor series (revision 2.4) 2-2. Ink spill prevention from the ink cartridge holder unit follow this procedure before swing opening the ink cartridge holder unit in the vertical open position to prevent ink spillage from the ink cartridge holder. Ignoring this procedur...

Page 230

Ink flow section [ 11a-18 ] comcolor series (revision 2.4) 7. Make four cuts of ink absorbent papers in the shape of about 150 mm x 200 mm rectangular shape, and then fold each piece into approx. 20 mm x 100 mm piece. 8. Hook these four folded papers between the ink cartridge holder and ink tubes of...

Page 231

Ink flow section [ 11a-19 ] comcolor series (revision 2.4) 10. Remove one thumb screw and one it screw 4x8 (1 pc) from the ink cartridge holder unit and the unit to the vertical position. > caution: make sure to remove the ink absorbent paper the each time the ink cartridge is pulled out or plugged ...

Page 232

Ink flow section [ 11a-20 ] comcolor series (revision 2.4) 2-3. Removing the scissor clamps scissor clamps, used for clamping tubes, are attached on the top of the head holder cover. Remove them as follows. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Open t...

Page 233

Ink flow section [ 11a-21 ] comcolor series (revision 2.4) 2-4. Bellows unit 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the left and right top covers, rear cover, and right-side cover. (refer to the section on covers in chapter 2.) 3. Open the power...

Page 234

Ink flow section [ 11a-22 ] comcolor series (revision 2.4) 7. Remove the bellows unit mounting screws. (it screw 4x8 (4 pcs)), and remove the bellows unit from the machine caution: 1. If the bellows unit contains ink from the past ink overflow, the ink may drip out from the bellows air tube if the b...

Page 235

Ink flow section [ 11a-23 ] comcolor series (revision 2.4) note: test mode 2711 (head replacement mode) will be done later in the procedure. 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the 4 scissor clamps from the head holder cover. (refer to the "r...

Page 236

Ink flow section [ 11a-24 ] comcolor series (revision 2.4) note: insert drainage tubes so that they go into the groove (ink drain port) on the overflow pan. 6. Disconnect the four drainage tubes on the overflow pan side. Insert the ends in the port in the overflow pan. Sponge exists.> note: be caref...

Page 237

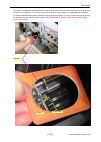

Ink flow section [ 11a-25 ] comcolor series (revision 2.4) following photographs show how the ink drainage tubes should be inserted into the ink drain port of the overflow pan. Ink drain port of the overflow pan in which the end of the ink drainage tube should be inserted. Ink drain port of the over...

Page 238

Ink flow section [ 11a-26 ] comcolor series (revision 2.4) 7. Unplug the air tube between the negative pressure ink tank common air chamber and negative pressure ink tank air valve, on the air valve side. 8. Drop the unplugged end of the air tube into the overflow pan in order that any overflown ink...

Page 239

Ink flow section [ 11a-27 ] comcolor series (revision 2.4) in replacing the ink supply valve(s) , negative pressure ink tank(s) or entire ink circulation system , do all the following steps including [10] to [15]. In replacing only the ink bus , skip the steps [10] , [12] , [13] and [14] , as the in...

Page 240

Ink flow section [ 11a-28 ] comcolor series (revision 2.4) 17. Connect back the air tube between the air chamber (in common to the negative pressure ink tanks) and negative pressure ink tank air valve, unplugged in step-7, on the negative pressure ink tank air valve. 19. Proceed to the replacement o...

Page 241

Ink flow section [ 11a-29 ] comcolor series (revision 2.4) 2-6. Initial ink filling caution: the machine must have test mode no. 2711 set to [1] and power turned off in order to make the initial ink filling action without dripping ink on the bp belt from the print heads on the next machine power on....

Page 242

Ink flow section [ 11a-30 ] comcolor series (revision 2.4) before going to step-1, bellow, confirm that the flat cable has a good fold, or the ink cartridge joint drive motor may hit on the flat cable, when the ink cartridge holder unit is raised up, and damage the cable. 1. Follow the instructions ...

Page 243

Ink flow section [ 11a-31 ] comcolor series (revision 2.4) 2-7. Removing the head holder cover the procedure for removing the head holder cover is as follows. This procedure applies during disassembly and assembly of all sections in the head unit. 1. Turn off the machine power and disconnect the pow...

Page 244

Ink flow section [ 11a-32 ] comcolor series (revision 2.4) 6. Remove the stoppers at two positions (it3c screw 4x8 (1 pc) and remove the upper transfer unit. 7. Open the ink cartridge holder unit to the vertical position following the instruction given in the, “ink spill prevention from the ink cart...

Page 245

Ink flow section [ 11a-33 ] comcolor series (revision 2.4) 8. Disconnect the connector and remove the sensor bracket. (it screw 3x6 (2 pcs)) 9. Remove the head holder cover. (it screw 3x6 (6 pcs)) engraved arrow marks on the head holder cover indicates the position of the mounting screws in all 6 po...

Page 246

Ink flow section [ 11a-34 ] comcolor series (revision 2.4) 2-8. Ink cartridge 1. Open the right front cover. 2. Pull and remove the ink cartridges for replacement. The ink cartridge is now separated from the joint portion connected to the ink path. 3. Load new ink cartridges and close the front cove...

Page 247

Ink flow section [ 11a-35 ] comcolor series (revision 2.4) 8. Using scissor clamps, clamp the tubes between the ink cartridges and ink supply valves, near the ink supply valve port on all four colors. (4 scissor clamps) 9. Disconnect the tubes between the ink cartridges and ink supply valves from th...

Page 248

Ink flow section [ 11a-36 ] comcolor series (revision 2.4) 12. Wait few minutes for the ink from the ink cartridge holder unit to drain down into the waste ink tank. Then at the three-way joint of the ink drain tubes, use scissor clamps to clamp the tubes from the overflow pan of the ink cartridge h...

Page 249

Ink flow section [ 11a-37 ] comcolor series (revision 2.4) assembly precautions 1. Thread the ink drain tube of the ink cartridge holder unit from inside to the outside of the machine frame. Push the ink drain tube through and down until the plastic band hits the machine frame and stops. 2. On the r...

Page 250

Ink flow section [ 11a-38 ] comcolor series (revision 2.4) 2-10. Cartridge holder joint drive motor 1. Turn off the machine power and disconnect the power cable from the power source. 2. Open the right front cover. 3. Remove the ink cartridges. (4 cartridges) 4. Remove the left and right top covers....

Page 251

Ink flow section [ 11a-39 ] comcolor series (revision 2.4) 4. Unhook the rfid pcb from the two plastic hooks, and then pull out the rfid pcb. 2-11. Ink cartridge rfid pcb 1. Turn off the machine power and disconnect the power cable from the power source. 2. When removing the rfid pcb for the black c...

Page 252

Ink flow section [ 11a-40 ] comcolor series (revision 2.4) 2-12. Ink supply valve 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the left and right top covers, rear cover, and right side cover. (refer to the section on covers in chapter 2.) 3. Remove th...

Page 253

Ink flow section [ 11a-41 ] comcolor series (revision 2.4) 10. Cut the ink supply tube at the cut-marking located above the negative pressure ink tank, and cap the cut end of the ink tube, and cap the cut end of the ink tube with the rubber cap included in the replacement kit. 11. Also cap the cut t...

Page 254

Ink flow section [ 11a-42 ] comcolor series (revision 2.4) 14. Use the rubber cap included in the ink supply valve replacement kit to cap the unplugged end of the ink tube on the previous step and dispose of the tube together with the ink supply valve. Assembly precautions (1) replace the drainage t...

Page 255

Ink flow section [ 11a-43 ] comcolor series (revision 2.4) 2-13. Negative pressure ink tank 1. Turn off the machine power and disconnect the power cable from the power source. 2. Remove the left and right top covers, rear cover, and right side cover. (refer to the section on covers in chapter 2.) 3....

Page 256

Ink flow section [ 11a-44 ] comcolor series (revision 2.4) 13. Unplug the wire connector to the ink detection sensor on the negative pressure ink tank from the tank to remove. 14. Unplug the wire connector from the extension wire from the ink pump pcb for the negative pressure ink tank to remove. 15...