- DL manuals

- Riso

- Printer

- MZ770

- User Manual

Riso MZ770 User Manual

Summary of MZ770

Page 1

024-36004-004.

Page 3

1 riso shall not be responsible for any damage or expense that might result from the use of this manual. As we are constantly improving our products, the machine may differ in some respects from the illustrations used in this manual. Riso shall not be liable for any direct, incidental, or consequent...

Page 4: Contents

2 contents welcome to the mz7 series model ..................................................................................... 7 about this user’s guide...................................................................................................... 7 icons used in this manual ..................

Page 5: Functions For Master-Making

Contents 3 functions for master-making 68 selecting image processing mode [image] ...................................................................... 68 processing photos with dot screen [dot process] ........................................................... 70 adjusting photo contrast [contras...

Page 6: Functions For Printing

Contents 4 functions for printing 110 changing the print speed [print speed adjustment] ..................................................... 110 printing at high speed [150ppm]..................................................................................... 111 setting “150ppm” ...................

Page 7: 176

Contents 5 storage and scan modes (option) 176 about storage ................................................................................................................. 176 storable original data .....................................................................................................

Page 8: Maintenance

Contents 6 maintenance 226 cleaning .......................................................................................................................... 226 thermal print head ..........................................................................................................227 platen g...

Page 9: About This User’S Guide

Welcome to the mz7 series model 7 welcome to the mz7 series model thank you for your purchase of this printing machine. This machine is a digital duplicator with the following functions. • this machine is equipped with two colour drums, allowing anyone to easily print in two colours. • this machine ...

Page 10: Icons Used In This Manual

Icons used in this manual 8 icons used in this manual the following icons are used in this manual. About the notation the following icons are used throughout the document. A warning: ignoring this warning could cause death or serious injury. B caution: ignoring this caution could cause injury or dam...

Page 11

Icons used in this manual 9 the notation for operational instructions and function descriptions the following conventions are used to explain functions and operations. 1) chapter title 2) operation procedure the operational procedures are outlined in steps. Follow these steps. 3) display shows the s...

Page 12: Before Starting to Use

Safety guide - installation 10 before starting to use safety guide - installation this section describes the precautions to be observed when installing the machine. Read this section before install- ing the machine. Note: • your dealer will help you to determine a proper location for the machine at ...

Page 13

Before starting to use safety guide - handling and operation 11 safety guide - handling and operation this section describes the precautions to be observed when handling the machine. Read this section before operat- ing the machine. Operation environment important!: • operate the machine under the f...

Page 14

Before starting to use safety guide - handling and operation 12 consumables important!: • for ink and master roll, it is recommended to use the products specified by riso. • store consumables such as master roll and ink properly. Do not store consumables in the following places: – locations that are...

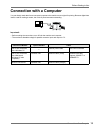

Page 15: Connection With A Computer

Before starting to use connection with a computer 13 connection with a computer you can directly send data from a connected computer to the machine as an original for printing. Because digital data itself is used for making a master, the finish of prints becomes outstanding. Important!: • before mak...

Page 16: Paper Recommendations

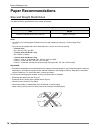

Before starting to use paper recommendations 14 paper recommendations size and weight restrictions the table shows the specifications of the usable print paper. Note: • up to 555 mm of vertical paper dimension may be used (loaded) by setting up "custom paper entry". ) p.171 • the minimum size paper ...

Page 17

Before starting to use paper recommendations 15 note: • paper with a horizontal grain direction can cause problems with paper pass. Use paper with a vertical grain direc- tion. • images are not output onto the entire area of usable print paper. )p.17 riso does not assure that paper outside the above...

Page 18: Originals

Before starting to use originals 16 originals size and weight restrictions usable originals are as follows. • originals are scanned according to the size of paper placed on the paper feed tray when masters are made; for the same width, the positions of the feed tray paper guides. When the placed pap...

Page 19

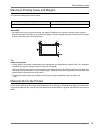

Before starting to use originals 17 maximum printing areas and margins the maximum printing areas are as follows. Important!: • no matter which size of originals is printed, the margins indicated on the figure are required for the originals. Reduce the original if necessary to fit it inside of the m...

Page 20: Getting Acquainted

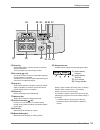

Function and name of each part 18 getting acquainted function and name of each part 1) master disposal box 1 ()p.218) holds discarded masters. 2) feed tray descent button ()p.32) lowers the paper feed tray when changing or adding paper. 3) paper feed pressure adjustment lever ()p.31) adjusts the pap...

Page 21

Getting acquainted function and name of each part 19 16) print drum release button ()p.220) unlocks the print drum for removal. 17) print drum 1 ()p.220) 18) front cover 19) ink cartridge ()p.216) 20) print drum handle ()p.220) 21) counter counts the number of copies (total print counter) and the nu...

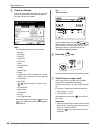

Page 22: Control Panel

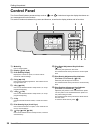

Getting acquainted control panel 20 control panel the control panel features permanent keys such as and . It also has a large-size display that shows var- ious messages and function buttons. This section introduces hardware key names and functions, as well as the display window and its functions. 1)...

Page 23

Getting acquainted control panel 21 13) start key starts master-making or printing process or executes specified operations. The key is lighted only when the key is active. 14) proof key ()p.116) use when you want to check print result after adjusting the print position, for example. This allows you...

Page 24: Display

Getting acquainted display 22 display the screens and their various stages when the power is turned on, after a brief display of the start-up screen, the initial screen appears. Power on start-up screen (ex.) note: • start-up screen settings select [start-up screen] on the admin. Screen. Initial scr...

Page 25

Getting acquainted display 23 selecting a mode touch the mode button on the mode screen to view the basic screens of the various modes. 1) colour mode select the print type (2-colour print/1-colour print (drum 1 only or drum 2 only)) to display the operation selec- tion screen (mastermake/printing)....

Page 26

Getting acquainted display 24 2) scan mode (option) touch [scanning] to display the scan basic screen. Note: • see “storage and scan modes” ()p.176) for information about scan mode. 3) link mode (option) touch [link print] to display the link basic screen. Note: • refer to “when using a linked print...

Page 27

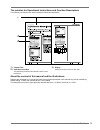

Getting acquainted display 25 basic screen layout the name and function of each area of the basic screens are explained below. The display of the basic screen differs depending on whether you are scanning a paper document or printing from a computer. Note: • the display for each basic screen differs...

Page 28

Getting acquainted display 26 printing from a computer data 1) tab area (“selections” and “admin.” tabs are disabled) touch a tab to display its screen. 2) job properties area properties of the current print job is displayed. Refers to the computer data ready for print output. 3) job operation area ...

Page 29

Getting acquainted display 27 other screens selections screen quickly change settings for a function or open its screen. Up to 9 functions can be displayed for quick access. ()p.167) functions screen access to a variety of functions. Admin. Screen changes the default values of various functions..

Page 30

Getting acquainted display 28 buttons on touch screen select buttons by lightly touching with a finger. Touch again to cancel the selection. Avoid pressing with excessive force. Not selected. Frequently used buttons selected. Activates/executes a setting. Buttons in grey cannot be selected. Cancels ...

Page 31

Getting acquainted display 29.

Page 32: Basic Operations

Preparing to print 30 basic operations preparing to print first, set up the paper feed tray and paper receiving tray of the machine. Turning the power on 1 turn the power on. 2 select a mode. This example is for “dual-colour printing”. 3 touch [mastermake] on the opera- tion selection screen. The ma...

Page 33

Basic operations preparing to print 31 setting up the paper feed tray and loading paper important!: • do not use unsuitable paper, or mix paper of different sizes. Doing so can cause paper jams and damage the machine. ) p.14 1 open the paper feed tray. Pull the paper feed tray to open until it comes...

Page 34

Basic operations preparing to print 32 adding or replacing paper when you add paper or replace with paper of a different size at the time of printing, press the feed tray descent but- ton to lower the paper feed tray. • press the feed tray descent button to lower the paper feed tray. • if you press ...

Page 35

Basic operations preparing to print 33 setting up the paper receiving tray 1 open the paper receiving tray. Pull the paper receiving tray down until it comes to a rest. 2 position the receiving tray paper guides. 1) raise the receiving tray paper guides. 2) hold their lower part and slide them to fi...

Page 36

Basic operations preparing to print 34 closing the paper receiving tray remove all printed copies and follow the steps below to close the paper receiving tray. 1) slide the paper stopper to the edge of the paper receiving tray. 2) fold in the paper stopper. 3) pull up the paper arrangers, slide the ...

Page 37: Basic Process

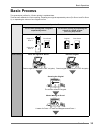

Basic operations basic process 35 basic process the general print job flow for 2-colour printing is explained here. There are two methods for 2-colour printing: preparing two originals separated by colour (for drum 1 and for drum 2), or separating the colours of one original into two. Process operat...

Page 38

Basic operations basic process 36 master-making proof copy (1) a one colour proof copy is printed using only drum 1. Place the original for drum 2. Scan the original. Makes a master on drum 2. A master for drum 2 is made and wrapped around drum 2. Process operation flow for 2-colour printing with 2 ...

Page 39

Basic operations basic process 37 master-making proof copy (2) a 2-colour proof copy is printed. Printing print the specified number of copies are printed. Process operation flow for 2-colour printing with 2 originals separated by colour: for 2-colour printing by separating the colours of a single o...

Page 40

Basic operations 2-colour printing with 2 originals 38 2-colour printing with 2 originals a total of 2 originals (for drum 1, for drum 2) are printed. Important!: • use paper that is 182 mm × 257 mm (b5) or larger. 1 turn the power on. Note: • when the power is off, both the display and the key are ...

Page 41

Basic operations 2-colour printing with 2 originals 39 3 load paper. See )p.31 for details on how to load the paper. 4 set up the paper receiving tray. See )p.33 for details on how to set up the paper receiving tray. 5 place the original for drum 1. Place the original on the platen glass or in the o...

Page 42

Basic operations 2-colour printing with 2 originals 40 important!: • the adf unit can accommodate originals of 90mm × 140 mm and above. Smaller originals should be placed on the platen glass. • do not place multiple originals of differing sizes or otherwise unsuitable originals into the adf unit. Do...

Page 43

Basic operations 2-colour printing with 2 originals 41 once the masters are made, one proof copy from drum 1 alone is printed, and the master making basic screen for drum 2 appears. In step 5, if two originals have been placed together in the adf unit, one proof copy from drum 1 only is printed, and...

Page 44

Basic operations 2-colour printing with 2 originals 42 once the scan has completed, the master is made for drum 2. Once the masters are made, a 2-colour proof copy is printed, then the print basic screen appears. Note: • when “auto process” is selected, the process will be different. ) p.81 11 check...

Page 45

Basic operations 2-colour printing with 2 originals 43 note: • press the key to interrupt printing opera- tion currently underway. • if the machine is inactive for a certain period of time, it determines that the current job is com- pleted, even if the actual printing is still in progress. When the ...

Page 46: [Easy 2Colour]

Basic operations 2-colour printing with 1 original [easy 2colour] 44 2-colour printing with 1 original [easy 2colour] one original is scanned, is divided into drum 1 and drum 2, and a dual-colour print is made. Important!: • use paper that is 182 mm × 257 mm (b5) or larger. Easy 2colour types there ...

Page 47

Basic operations 2-colour printing with 1 original [easy 2colour] 45 red colour separates the colours of an original printed in black and light red. The master of the black portion of the original is created on drum 1, the red portion on drum 2 (drums are reversed if [sw.Colour] is selected). Note: ...

Page 48

Basic operations 2-colour printing with 1 original [easy 2colour] 46 hand writing--2 separates handwriting written using the recommended pen or red pencil on originals from black printed images by a riso printer or ink-jet printer (documents printed with a lighter shade of black, or with water-based...

Page 49

Basic operations 2-colour printing with 1 original [easy 2colour] 47 separation sheet separates the original using a separate sheet (area specification sheet) that is written on using the recommended pen for the desired area. The master of the portion outside the specified area is created on drum 1,...

Page 50

Basic operations 2-colour printing with 1 original [easy 2colour] 48 tip: about the specified area, separation sheet use the recommended pen to create the area to be specified. If you specify the area with a non-recommended pen, separation may not properly occur. • make sure to properly connect the ...

Page 51

Basic operations 2-colour printing with 1 original [easy 2colour] 49 operating procedures for easy 2colour 1 turn the power on. Note: • if the key is lit, the machine is in energy saving mode. Press the key to cancel energy saving mode. 2 select dual-colour printing. 1) touch [dual-colour]. Note: • ...

Page 52

Basic operations 2-colour printing with 1 original [easy 2colour] 50 tip: using the gauge cover the gauge cover allows you to align original images precisely on the platen glass even if they are not squared on the sheet. Shift the original sheet along the grid lines printed on the cover, touching it...

Page 53

Basic operations 2-colour printing with 1 original [easy 2colour] 51 8 press the key. The machine scans the original, separates col- ours, then creates masters in a sequence. Note: • if you set “preview” in step 7, the print process will temporarily stop once separation is com- plete. ) p.107 once t...

Page 54

Basic operations 2-colour printing with 1 original [easy 2colour] 52 9 check the proof copy result. When a proof copy is printed, the print basic screen will be displayed automatically. Check the proof copy; e.G., print position and den- sity. If necessary, change print position and density. • print...

Page 55

Basic operations 2-colour printing with 1 original [easy 2colour] 53 12 press the key when print job is complete. The setting returns to its default value. Note: • after printing is completed, the master remains on the print drum. To protect confidential docu- ments from unauthorised duplication, us...

Page 56

Basic operations 2-colour printing with 1 original [easy 2colour] 54 setting an original with the separation sheet for the “separation sheet”, you must scan the area specification sheet prior to scanning the original. 1 place the area specification sheet. When placing on the platen glass place the o...

Page 57

Basic operations 2-colour printing with 1 original [easy 2colour] 55 2) touch [easy 2colour]. The easy 2colour screen appears. 3) touch the button of the separation to use. Note: • the part for which a master is being made (either the “outside of area” or the “inside of area”) is displayed in the lo...

Page 58

Basic operations 2-colour printing with 1 original [easy 2colour] 56 5 place the original. When placing on the platen glass remove the area specification sheet from the platen glass and place the original as described in step 1. Note: • scrap books, etc. Should be placed on platen glass. When placin...

Page 59: Printing With 1-Colour

Basic operations printing with 1-colour 57 printing with 1-colour either drum 1 or drum 2 is used to print one colour. Important!: • for 1-colour printing, either drum 1 or drum 2 may be used, but we recommend using mainly drum 1. 1 turn the power on. Note: • if the key is lit, the machine is in ene...

Page 60

Basic operations printing with 1-colour 58 4 set up the paper receiving tray. See)p.33 for details on how to set up the paper receiving tray. 5 place the original. When placing on the platen glass place the original face down on platen glass. Align centre on the top edge, and close platen cover. Not...

Page 61

Basic operations printing with 1-colour 59 7 press the key. The original is scanned, separated, and a master made. Tip: auto idling wait for a moment if “idling” is displayed. Once idling has stopped, making of the master begins. Factory default is set to idle automatically at the beginning of the m...

Page 62

Basic operations printing with 1-colour 60 10 press the key. The specified number of copies will be printed. Note: • press the key to interrupt printing opera- tion currently underway. • if the machine is inactive for a certain period of time, it determines that the current job is com- pleted, even ...

Page 63

Basic operations printing with 1-colour 61 tip: 1-colour printing with drum 2 we generally recommend that drum 1 be used for 1-colour printing, but you can also use only drum 2. However the procedure differs slightly from drum 1. The following restrictions apply: when removing drum 1 and using only ...

Page 64: [Direct Print]

Basic operations printing from a computer data [direct print] 62 printing from a computer data [direct print] the machine can receive and print the original data created on a computer. The data will be digitally processed, thus achieving high quality prints. Important!: • first, install a proper pri...

Page 65

Basic operations printing from a computer data [direct print] 63 printing computer data 1 make sure the machine is on. Check the control panel. Note: • when the power is off, both the display and the key are off. Turn the power on. ) p.31 • if the key is lit, the machine is in energy saving mode. Th...

Page 66

Basic operations printing from a computer data [direct print] 64 5 check the display. Check the owner name and preview to make sure that the received data is the data to be printed. Set other functions as needed. Note: • the following functions can be used here: – preview – skip page – clear all – p...

Page 67

Basic operations printing from a computer data [direct print] 65 note: • you can also adjust the print position, the den- sity, and the speed while print process is in progress. • entering the number of copies using the print quantity keys will override the number sup- ported by the print driver. 8 ...

Page 68

Basic operations printing from a computer data [direct print] 66 changing output directions output can be controlled from the master making/print basic screens. Master making basic screen • [preview] you can check the master making image of the page currently awaiting creation. Note: • in “preview”,...

Page 69

Basic operations printing from a computer data [direct print] 67 changing stop timing stop timing as set on the printer driver takes priority by default. However, the settings can be changed on the machine while the machine is halted. Note: • if “auto print” is set to on on the machine driver, press...

Page 70: Functions For Master-Making

Selecting image processing mode [image] 68 functions for master-making selecting image processing mode [image] in order to make a master best suited for the original document, select an appropriate mode depending on whether original contain only text (line), photo, or both of them. Note: • default i...

Page 71

Functions for master-making selecting image processing mode [image] 69 3 touch [ok]. The following screen appears. Returns to the master making basic screen. Image processing mode is updated. Note: • some functions are not available in certain image processing mode settings. : available — : not avai...

Page 72: [Dot Process]

Functions for master-making processing photos with dot screen [dot process] 70 processing photos with dot screen [dot process] “dot process” function processes photo originals with dot screening in order to print more clearly. Select from four types of dot patterns. Note: • “dot process” is not avai...

Page 73

Functions for master-making processing photos with dot screen [dot process] 71 the following screen appears. Returns to the functions screen. Dot process set- ting is updated..

Page 74: Adjusting Photo Contrast

Functions for master-making adjusting photo contrast [contrast adj] 72 adjusting photo contrast [contrast adj] for originals that have ill-defined photos, adjust the contrast to print more clearly. There are two ways to adjust contrast. Important!: • if the “image” is set to “line”, “duo” or “pencil...

Page 75: Adjusting Photo Gradation

Functions for master-making adjusting photo gradation [tone curve] 73 adjusting photo gradation [tone curve] you can adjust the light and shadow portions of a photo by 3 tones respectively. Important!: • if the “image” is set to “line”, “tone curve” cannot be used. 1 touch [functions] on the master ...

Page 76

Functions for master-making adjusting photo gradation [tone curve] 74 returns to the functions screen. Tone curve set- ting is updated..

Page 77: [Contrast]

Functions for master-making selecting scanning contrast for the original [contrast] 75 selecting scanning contrast for the original [contrast] scanning contrast can be adjusted to accommodate background colour or ink density of the original. Specify by selecting auto or numeric levels (1-5). In the ...

Page 78: Enlarging/reducing Originals

Functions for master-making enlarging/reducing originals [standard ratio] [free] [margin+] [zoom] 76 enlarging/reducing originals [standard ratio] [free] [margin+] [zoom] the document can be printed enlarged or reduced. The following methods can be used to enlarge/reduce the origi- nal. Auto automat...

Page 79

Functions for master-making enlarging/reducing originals [standard ratio] [free] [margin+] [zoom] 77 enlargement and reduction by standard ratio [standard ratio] [margin+] 1 touch [size] on the master making basic screen. 2 touch the button corresponding to the desired size. Touch [100%] to restore ...

Page 80

Functions for master-making enlarging/reducing originals [standard ratio] [free] [margin+] [zoom] 78 magnification/reduction of a changed aspect ration [free] 1 touch [size] on the master making basic screen. 2 touch [free]. 3 touch or to adjust zoom ratio in horizontal or vertical directions. The r...

Page 81

Functions for master-making enlarging/reducing originals [standard ratio] [free] [margin+] [zoom] 79 enlarging and reducing with the zoom function [zoom] 1 touch [size] on the master making basic screen. 2 touch [zoom]. 3 touch or to change ratio. The reproduction size can be increased/ decreased in...

Page 82: Using Custom-Sized Paper

Functions for master-making using custom-sized paper [paper] 80 using custom-sized paper [paper] the machine automatically detects standard-sized paper in the paper feed tray to create a correct size master for printing. However, because non-standard paper sizes cannot be detected, they must be manu...

Page 83: Automatic Printing

Functions for master-making automatic printing [auto-process] 81 automatic printing [auto-process] master-making and printing can be performed automatically in sequence. When “auto-process” is selected, simply enter number of copies to print, then press the key. Important!: • if you are using the ad...

Page 84: [Book Shadow]

Functions for master-making printing from bound documents [book shadow] 82 printing from bound documents [book shadow] this function erases the shadows appearing in the binding “spine” in the centre as well as in the peripheral area when printing from magazines and books. The printer automatically d...

Page 85

Functions for master-making printing from bound documents [book shadow] 83 1 touch [functions] on the master making basic screen. 2 touch [book shadow]. 3 touch the shadow processing method. • [erase]: erases shadows near the centre and around the original. • [halftone]: photo processes the centre s...

Page 86: Saving Ink

Functions for master-making saving ink [ink saving] 84 saving ink [ink saving] selecting “ink saving” makes a master that requires less ink when printing. Important!: • the ink conservation process may result in lighter prints than usual. • “contrast” and “print density adjustment” functions are not...

Page 87: [2 Up]

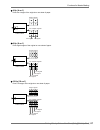

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 85 printing side-by-side on one sheet [2 up] [multi-up print] “multi-up” function prints multiple originals on one sheet. 2 up prints two copies of the same original side-by-side on one sheet of paper. Multi-up pr...

Page 88

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 86 original orientation and print results the orientation of the original differs depending upon the number of images. The orientation and print results for each possibility is shown below. Important!: • leave a m...

Page 89

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 87 4 up (4 on 1) prints four images of the original on one sheet of paper. 8 up (8 on 1) prints eight images of the original on one sheet of paper. 16 up (16 on 1) prints 16 images of the original on one sheet of ...

Page 90

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 88 for multi-up tickets: “multi-up tickets” cannot be used with multiple originals. The number of images printed is determined by the width of the ticket. Orientation of print paper always place paper in the paper...

Page 91

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 89 enlargement/reduction ratio for “multi-up print”, the magnification/reduction ratio of the original differs depending upon the original size and the multi-up type, as well as the size of the print paper. The si...

Page 92

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 90 2 up operation 1 select a colour mode. Select 1-colour or 2-colour print. Note: • see )p.23 for how to select a colour mode. 2 place an original and load paper. • when 2-colour printing with 2 originals )p.38 •...

Page 93

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 91 operation for multi-up printing 1 select a colour mode. Select 1-colour or 2-colour print. Note: • see )p.23 for how to select a colour mode. 2 place an original and load paper. If you set the original and prin...

Page 94

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 92 5 touch [single] for single-original, touch [multiple] for multiple-origi- nal. Except for the original placement method, opera- tions for “single-original” and “multiple-original” are basically the same. This ...

Page 95

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 93 9 press the key. Starts scanning of the original. After this, please follow the same operations for normally making a master for 1-colour and 2-col- our mode. Important!: • to change the original, replace it wi...

Page 96

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 94 operation for multi-up tickets for “multi-up tickets”, the specification of the short edge size of the original (the width) is used to calculate the number of images that can be printed on one sheet of paper (p...

Page 97

Functions for master-making printing side-by-side on one sheet [2 up] [multi-up print] 95 6 touch or to specify the short edge size of the original (the width). Important!: • if you have enlarged/reduced size in step 8 (setting print functions), be careful about the fol- lowing points. • specify the...

Page 98: [Oneside Mastermake]

Functions for master-making switching masters of just one drum [oneside mastermake] 96 switching masters of just one drum [oneside mastermake] when 2-colour printing, you can switch just one of the two originals and print. This is a handy function when printing different letters using the same lette...

Page 99

Functions for master-making switching masters of just one drum [oneside mastermake] 97 the following screen appears. Returns to the functions screen. Oneside mas- termake setting is updated. 5 place the changed original. Place on platen glass or in adf unit (option). See “2-colour printing with 2 or...

Page 100

Functions for master-making switching masters of just one drum [oneside mastermake] 98 10 press the key. The specified number of copies will be printed. Note: • press the key to interrupt printing opera- tion currently underway..

Page 101: Printing Area

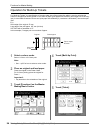

Functions for master-making making a master that utilizes the maximum printing area [max. Scan] 99 making a master that utilizes the maximum printing area [max. Scan] when a master is made, automatic paper size detection and image size adjustment applies to allow appropriate print margins. This is t...

Page 102: Reproducing The Master

Functions for master-making reproducing the master [renew page] 100 reproducing the master [renew page] the data from the last master-making process is temporarily stored on the machine. Using this data, another master can be reproduced without repeating steps to scan the same original. “auto page r...

Page 103

Functions for master-making reproducing the master [renew page] 101 recreating a master 1 touch [functions] on the print basic screen. 2 touch [renew page]. The display screen for 2-colour and 1-colour printing are different. For 2-colour printing the drum selection screen appears. Touch the button ...

Page 104

Functions for master-making reproducing the master [renew page] 102 using auto page renewal in order to use “auto page renewal”, you must enable it in “admin.” prior to use. If “auto page renewal” is activated and “auto page renewal” is set to “on” , “auto page renewal” can be executed during a prin...

Page 105: Printing

Functions for master-making cutting the top margin of the original and printing [top margin] 103 cutting the top margin of the original and printing [top margin] you can cut the top portion of the margin to between 0 to 99 mm and make a master. This feature enables you to skip the registration marks...

Page 106

Functions for master-making cutting the top margin of the original and printing [top margin] 104 4 touch [on]. 5 touch or to specify the cut width. You can set from 0 to 99 mm. Note: • print quantity keys can also be used to enter a value. 6 touch [ok]. Returns to the functions screen. Top margin se...

Page 107: [Side Margin]

Functions for master-making adjusting the side margins of the master [side margin] 105 adjusting the side margins of the master [side margin] if you are using the adf unit to print multiple originals and need to move the left and right margins to make a master, use “side margin” for one simple opera...

Page 108

Functions for master-making adjusting the side margins of the master [side margin] 106 note: • print quantity keys can also be used to enter a value. 5 touch [ok]. Returns to the functions screen. Side margin set- ting is updated. Important!: • by using “side margin”, the opposite side of the side m...

Page 109: Master

Functions for master-making checking the print image prior to making master [preview] 107 checking the print image prior to making master [preview] you can check what the actual master will look like by previewing an image of the scanned original or an image of data sent from a computer. This functi...

Page 110

Functions for master-making checking the print image prior to making master [preview] 108 actions available on the preview screen 1) rotate image button allows you to rotate the displayed image 90 degrees. 2) drum 1 original 3) drum 2 original 4) scroll button the image moves in the direction of the...

Page 111

Functions for master-making checking the print image prior to making master [preview] 109 4 make necessary settings. You can configure print functions to apply to the new original as needed. 5 press the key. A scan of the original begins, and can be pre- viewed on the preview screen. 6 check the pre...

Page 112: Functions For Printing

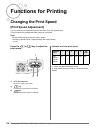

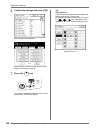

Changing the print speed [print speed adjustment] 110 functions for printing changing the print speed [print speed adjustment] you can select the print speed from five levels; from 60 to 120 copies/minute. The print speed may be adjusted while printing is in progress. Note: • set the default print s...

Page 113: Printing At High Speed

Functions for printing printing at high speed [150ppm] 111 printing at high speed [150ppm] by using “150ppm”, you can print faster than if you were to simply adjust the “print speed”. Setting “150ppm” by registering to the direct access area, you can set “150ppm” by a single touch during a printing ...

Page 114: Adjusting The Print Density

Functions for printing adjusting the print density [print density adjustment] 112 adjusting the print density [print density adjustment] you can select the print density from five levels, by each drum. The print density may be adjusted while printing is in progress. Important!: • “print density” is ...

Page 115: Adjusting The Print Position

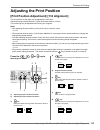

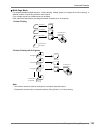

Functions for printing adjusting the print position [print position adjustment] [1=2 alignment] 113 adjusting the print position [print position adjustment] [1=2 alignment] the print position on the paper can be adjusted for each drum. Adjustment range vertical direction: ±15mm horizontal direction:...

Page 116

Functions for printing adjusting the print position [print position adjustment] [1=2 alignment] 114 the print basic screen shows current vertical/horizon- tal adjustment. Adjusting the print position of both drums together 1 adjust the print position of one of the drums. The adjustments display on t...

Page 117

Functions for printing adjusting the print position [print position adjustment] [1=2 alignment] 115 note: • if both drums were adjusted separately, it is adjusted to match the position of the last- adjusted drum. Tip: making fined adjustments to the print posi- tion if the settings are such that “fi...

Page 118: Printing Proof Copies

Functions for printing printing proof copies [proof] 116 printing proof copies [proof] after making adjustments to the print position or density, check the print quality in a proof copy. Proof copies are not counted towards the number of copies displayed on the print quantity display. Note: • the ma...

Page 119: Paper

Functions for printing prevent paper jams when using special paper [d-feed check] 117 prevent paper jams when using special paper [d-feed check] this printer monitors for multiple paper feeds. If a feed of more than one sheet is detected, the print job automatically stops and “d-feed check” is execu...

Page 120: Keeping Printed Copies Dry

Functions for printing keeping printed copies dry [interval] 118 keeping printed copies dry [interval] by allowing the drum to skip a rotation during printing and extend the printed paper ejection interval, the ink has time to dry, preventing it from leaving marks on the back of the next sheet. Skip...

Page 121

Functions for printing keeping printed copies dry [interval] 119 the following screen appears. Returns to the functions screen. Interval setting is updated..

Page 122: [Eject Wing Control]

Functions for printing ejecting paper using pre configured setting [eject wing control] 120 ejecting paper using pre configured setting [eject wing control] the following steps retrieves pre-configured custom settings for the paper ejection wing. Use this feature to eject certain printing paper that...

Page 123: Off

Functions for printing turning the air blower and separation fan off [paper eject adj] 121 turning the air blower and separation fan off [paper eject adj] the machine normally uses an air blower and a separation fan to eject the printed paper from the drum (using a jet of air). When printing flyers,...

Page 124: Advanced Features

Automatic sorting into groups [programme] 122 advanced features automatic sorting into groups [programme] you can use “programme” to divide one original into several groups and programme each group to print a different number of copies or sets. For multiple originals, you can change the number of co...

Page 125

Advanced features automatic sorting into groups [programme] 123 multi-page mode for multiple originals (multiple copies for 1-colour printing, multiple groups of 2 originals for 2-colour printing), a different number of copies are printed for each original. From a single original, up to 9999 copies ...

Page 126

Advanced features automatic sorting into groups [programme] 124 combination (only possible with 2-colour printing) a 2-colour original is used to make a master on drum 1 and drum 2. The 1-colour print for just drum 1 is grouped in the same way as for “single page” programme and prints. The 2-colour ...

Page 127

Advanced features automatic sorting into groups [programme] 125 how to programme print there are two ways to print in sets using “programme” printing feature. • programme, then print (without saving the settings) • retrieve a saved programme, then print (when programme is registered) tip: choose fro...

Page 128

Advanced features automatic sorting into groups [programme] 126 setting up for programmed printing note: • both the touch screen and print quantity keys (and related keys) may be used for this operation. 1 press the key. Note: • press the key and skip to step 3) of the “single page mode”. Press the ...

Page 129

Advanced features automatic sorting into groups [programme] 127 important!: • to save the current programmed printing setting, touch [entry/call]. Once [ok] is touched, the setting cannot be saved. See “saving programmes” ()p.129) for further information. For multi-page mode 1) enter the number of c...

Page 130

Advanced features automatic sorting into groups [programme] 128 3) touch or to specify the number of 2-colour copies to print. Note: • the print quantity keys can also be used to enter a value. • the number of copies assigned for “ print” will apply to all groups and cannot be changed from group to ...

Page 131

Advanced features automatic sorting into groups [programme] 129 saving programmes store frequently-used programme settings for later retrieval and printing. A total of 12 settings (single page mode, multi-page mode mode or combination print) can be stored. 1 create and enter a programmed printing se...

Page 132

Advanced features automatic sorting into groups [programme] 130 touch [ok] on the programme screen to print from a saved programme..

Page 133

Advanced features automatic sorting into groups [programme] 131 renaming a programme programme names can be changed to better describe their usage or purpose. 1 touch [programme] on the func- tions screen. Note: • if [programme] is already highlighted, touching it will again display the programme sc...

Page 134

Advanced features automatic sorting into groups [programme] 132 5 touch to delete the current name note: • you can also press the key to delete. 6 touch character buttons to enter a new name. Change capitalization be selecting [small] or [capital] button. ) p.132 7 when entered, touch [ok]. The foll...

Page 135

Advanced features automatic sorting into groups [programme] 133 clearing programmes 1 press the key. Note: • alternatively, from the master making basic screen, touch [functions] then [programme] to display the programme type screen. 2 touch [programme list]. 3 touch [clear]. 4 select a programme to...

Page 136

Advanced features automatic sorting into groups [programme] 134 retrieving a programme retrieve a stored programme and modify its settings. 1 press the key. Note: • alternatively, from the master making basic screen, touch [functions] then [programme] to display the programme type screen. 2 touch [p...

Page 137

Advanced features automatic sorting into groups [programme] 135 making changes to stored programmes 1 retrieve a programme to modify. Follow steps 1 and 3 in “retrieving a programme” ()p.134). 2 make changes to the programme. Modify number of copies or sets in the current screen. Note: • see “settin...

Page 138

Advanced features automatic sorting into groups [programme] 136 programming example printing questions and answers divided by class this example uses “easy 2colour” and “programme” together. The original is a sheet of paper with test questions (black, 1 colour) with the answers written in using a re...

Page 139

Advanced features automatic sorting into groups [programme] 137 3 setting [combination]. 1) press the key. Note: • alternatively, from the master making basic screen, touch [functions] then [programme] to display the programme type screen. 2) touch [combination]. 3) input the number of test copies f...

Page 140

Advanced features automatic sorting into groups [programme] 138 5) touch and specify “2” (the number of cop- ies for the answer key to each group) the print quantity keys can also be used to enter a value. 6) touch [ok] and the print screen closes. The screen returns to the combination print screen....

Page 141

Advanced features automatic sorting into groups [programme] 139 once the master is made on drum 1, one proof copy will be printed from drum 1 only. A master will then be made on drum 2. Once the master is made on drum 2, a single 2-colour proof copy will be printed. After a proof copy has been print...

Page 142: Using Job Memory Functions

Advanced features using job memory functions [job memory] 140 using job memory functions [job memory] save the settings of the last print job into job memory. Simply retrieve those job memory settings when doing a sim- ilar print job. Up to 10 jobs can be saved. The following attributes can be saved...

Page 143

Advanced features using job memory functions [job memory] 141 storing job memory 1 set various settings for a print job. 2 touch [functions] on the master making basic screen. Note: • job memory screen can also be invoked by pressing the key on the print quantity keys. Skip to step 4. 3 touch [job m...

Page 144

Advanced features using job memory functions [job memory] 142 6 touch [ok]. The following screen appears. Returns to the job memory screen. Settings are updated. Each job memory can be named for your con- venience. See step 3 in “renaming a job mem- ory” ()p.143)..

Page 145

Advanced features using job memory functions [job memory] 143 renaming a job memory 1 touch [functions] on the master making basic screen. Note: • job memory screen can also be invoked by pressing the key on the print quantity keys. Skip to step 4. 2 touch [job memory]. 3 touch [rename]. 4 select a ...

Page 146

Advanced features using job memory functions [job memory] 144 6 touch character buttons to enter a new name. Change capitalization by selecting [small] or [capital] button. ) p.132 7 when entered, touch [ok]. Returns to the job memory screen. The name is updated. 8 touch [close]. The following scree...

Page 147

Advanced features using job memory functions [job memory] 145 retrieving a job memory and printing 1 place an original and load paper. When 2-colour printing with 2 originals )p.38 when 2-colour printing (easy 2colour) with 1 original )p.44 when printing with 1 colour )p.57 2 touch [functions] on th...

Page 148

Advanced features using job memory functions [job memory] 146 6 confirm the settings and touch [ok]. The following screen appears. Returns to the functions screen. Ready to print using the retrieved job settings. 7 press the key. The master is made and copies printed in accord- ance with the job mem...

Page 149

Advanced features using job memory functions [job memory] 147 clearing job memory 1 touch [functions] on the master making basic screen. Note: • job memory screen can also be invoked by pressing the key on the print quantity keys. Skip to step 3. 2 touch [job memory]. 3 touch [clear]. 4 select a job...

Page 150

Advanced features using job memory functions [job memory] 148 5 touch [ok]. 6 touch [close]. The following screen appears. Returns to the functions screen..

Page 151: Extending The Reserve Period

Advanced features extending the reserve period [reservation] 149 extending the reserve period [reservation] this function is useful when the machine is connected to a computer. When the machine is inactive for a certain period of time, it determines that the current job is completed, even if the act...

Page 152: Idling Action

Advanced features idling action [idling action] 150 idling action [idling action] when the machine has not been used for an extended period of time, or when the print drum is replaced, the first several copies may be printed too light. By performing “idling action” before making a master, high print...

Page 153

Advanced features idling action [idling action] 151 note: • if displays in the screen message area, this indicates that the “auto idling” time has elapsed. If you make a master in this status, “idling action” is executed..

Page 154: [Confidential]

Advanced features protecting confidential documents [confidential] 152 protecting confidential documents [confidential] master left on the print drum is capable of printing even after the print job is completed. By using the “confidential” feature, the master on the print drum is discarded, thus pre...

Page 155

Advanced features protecting confidential documents [confidential] 153 4 touch [ok]. The following screen appears. The current master is discarded, and a new mas- ter is set on the print drum..

Page 156: Showing Usage Status

Advanced features showing usage status [digital copy count] 154 showing usage status [digital copy count] the machine can record and display the following information: a4 and under: total number of copies a4-sized and smaller that have been printed. Above a4: total number of copies larger than a4 th...

Page 157: Master

Advanced features rotating the original 180 degrees to make a master [rotate] 155 rotating the original 180 degrees to make a master [rotate] when you are direct printing, you can rotate the original data received from a computer 180 degrees to make a mas- ter. Important!: • “rotate” can also be set...

Page 158: Proof and Print

Advanced features proof and print (with the optional adf unit installed) [adf semi-auto] 156 proof and print (with the optional adf unit installed) [adf semi-auto] selecting “auto process” with the optional adf unit installed automatically performs the complete printing job, but you cannot check pro...

Page 159

Advanced features proof and print (with the optional adf unit installed) [adf semi-auto] 157 5 press the key. After a master is made, a proof copy is printed and the job stops. 6 check the proof copy. Make adjustments if needed. 7 press the key. The machine prints specified number of copies. Master ...

Page 160: Changing Default Settings

Advanced features changing default settings [admin.] 158 changing default settings [admin.] the default settings can be modified to best suit your needs. They may be edited as needed. Important!: • depending upon the usage environment, some of the “admin.” features may not be available (the “admin.”...

Page 161

Advanced features changing default settings [admin.] 159 [default] image processing change the default setting for the “image processing mode”. Line/photo/duo (text and photo)/pencil scanning contrast change the default setting for the “scanning contrast”. • contrast range: lighter/standard/darker •...

Page 162

Advanced features changing default settings [admin.] 160 [system] custom paper entry specify paper dimensions before using non-standard sized paper. ) p.171 irregular fitter specifies to scan custom-size originals as standard- sized. Off, a3, b4, a4, a4r, b5, b5r folder renaming changes the folder n...

Page 163

Advanced features changing default settings [admin.] 161 [system] energy saving mode select to activate sleep mode or shutdown power when the machine is inactive for a set period of time. • off “energy saving mode” is not activated. Power is turned on/off using the power switch. • auto sleep the mac...

Page 164

Advanced features changing default settings [admin.] 162 [system] minimum print q’ty set minimum number of copies to print. This prevents master from being made when a smaller quantity is entered for printing. Important!: • this setting can be locked to prevent alteration. Consult your dealer (or au...

Page 165

Advanced features changing default settings [admin.] 163 [link mode] only displayed when a linked printer is connected. Link properties ) p.198 linked printer if only one linked printer (sold separately) is attached to the machine (there are no other linked printers or networked computers), it is “o...

Page 166

Advanced features changing default settings [admin.] 164 customising the default settings the default settings can be changed when the machine is not in operation. Make sure there is no pending or current print job operation. Note: • on the admin. Screen, the current setting is displayed on the righ...

Page 167

Advanced features changing default settings [admin.] 165 additional setup screen available button style choosing a button makes it the default. Additional setup screen available numeric value style touch to increase/decrease value. Numbers may be entered using the print quantity keys. Additional set...

Page 168

Advanced features changing default settings [admin.] 166 additional setup screen available data specification type a screen to specify the stored data displays. See )p.186 for details on specifying the data. 5 touch [ok]. Skip to step 6 if there is no additional setup screen. Note: • touch [cancel] ...

Page 169: Selections Tab

Advanced features setting up direct access area and selections tab [directaccess entry] [selections entry] 167 setting up direct access area and selections tab [directaccess entry] [selections entry] frequently-accessed functions for each mode can be placed on “direct access” area in the basic scree...

Page 170

Advanced features setting up direct access area and selections tab [directaccess entry] [selections entry] 168 in the following steps, the “direct access” area configuration screen is shown in the upper-left, and the “selections” configuration screen is shown in the bottom-right. When both screens a...

Page 171

Advanced features setting up direct access area and selections tab [directaccess entry] [selections entry] 169 5 select a button to assign a function. Note: • if the button has a function already assigned, the newly selected function will overwrite. 6 select a function to assign. Note: • touch or to...

Page 172

Advanced features setting up direct access area and selections tab [directaccess entry] [selections entry] 170 9 touch . Returns to the original basic screen..

Page 173: [Custom Paper Entry]

Advanced features registering a custom paper size [custom paper entry] 171 registering a custom paper size [custom paper entry] non-standard paper sizes must be pre-entered into memory. Once a paper size is stored into memory, it can be retrieved with the [paper] button from the master making basic ...

Page 174

Advanced features registering a custom paper size [custom paper entry] 172 5 touch an unused button. A button already associated with another size is greyed out. 6 enter the paper size. Facing towards the paper feeding direction (into paper feed tray), enter w (width) and h (height). Touch either , ...

Page 175

Advanced features registering a custom paper size [custom paper entry] 173 12 touch [ok] when done. Note: • to change a name, repeat from step 8. 13 confirm the name and touch [close]. The following screen appears. Returns to the admin. Screen. Paper size is updated. Tip: printing on extended paper ...

Page 176

Advanced features registering a custom paper size [custom paper entry] 174 deleting a custom paper size 1 touch [custom paper entry] on the admin. Screen. 2 touch [clear]. 3 select the paper size to delete. 4 touch [ok]. Returns to the custom paper entry screen. The selected paper size is deleted. 5...

Page 177

Advanced features registering a custom paper size [custom paper entry] 175.

Page 178: Storage and Scan Modes

About storage 176 storage and scan modes (option) about storage storage is a function that allows you to save original data to memory. Storage memory is available when optional document storage card dm-32cf or document storage card dm- 128cf is attached. You can use the editor function to edit scann...

Page 179

Storage and scan modes (option) about storage 177 retrieving storage data you can do the following when printing with stored data. • repeatedly retrieve and print previously stored data. This saves you the trouble of rescanning documents when printing the same materials. ) p.177 • if the stored data...

Page 180: Mode)

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 178 converting hard-copy to stored data (scan mode) about scan mode scan mode is a function that allows you to scan a hard-copy original with the machine's scanner to save as storage data. You can repeatedly retrieve and...

Page 181

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 179 scanning an original for 1-colour printing 1 select a scan mode. See )p.23 for information about selecting a scan mode. 2 place the original. See step 5 of "1-colour printing" ()p.49). Go to step 4 if you are not spe...

Page 182

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 180 4) touch [change]. 5) touch the button of the colour to set and then touch [ok]. Note: • the previously set colour name displays on the change screen. Returns to the colour screen. The colour setting is updated. 6) t...

Page 183

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 181 scanning originals (2) for 2-colour printing originals from drum 1 and drum 2 are read and stored as one piece of data. 1 select a scan mode. See )p.23 for information about selecting a scan mode. 2 place the origina...

Page 184

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 182 8 touch [ok]. The colour specified for the original is confirmed and the screen returns to the scan basic screen. 9 apply the required settings to the original for drum 1. Set the required functions for scanning the ...

Page 185

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 183 setting data information settings for the data to be scanned and stored are configured on the scan basic screen. 1 select a scan mode. See )p.178 for information about selecting a scan mode. The data name, save locat...

Page 186

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 184 2) touch the button of the folder in which to save data. Note: • the folder name of the “directory” folder can be changed in “admin.”. ()p.160) 3) touch [ok]. The “directory” folder is confirmed and the screen return...

Page 187

Storage and scan modes (option) converting hard-copy to stored data (scan mode) 185 specifying paper size specify the size at which to save the scanned original. If the original is standard-sized, it will be saved as-is with [auto]. If the original is custom-sized, use the format screen to save at s...

Page 188: [Storage Memory]

Storage and scan modes (option) retrieving stored data and printing [storage memory] 186 retrieving stored data and printing [storage memory] retrieving storage data 1 touch [functions] on the master making basic screen. 2 touch [storage memory]. The storage selection screen appears. 3 touch the sto...

Page 189

Storage and scan modes (option) retrieving stored data and printing [storage memory] 187 from the storage retrieve, you can confirm retrieved data and specify output settings. See )p.188 for operational details. 5 touch [retrieve]. The storage data is retrieved and storage mode basic screen appears....

Page 190

Storage and scan modes (option) retrieving stored data and printing [storage memory] 188 using the storage retrieve screen each section of the storage retrieve screen is shown below. 1) a thumbnail is displayed for each page. 2) if the data contains multiple pages, touch to change page. 3) touch to ...

Page 191

Storage and scan modes (option) retrieving stored data and printing [storage memory] 189 changing the data order you can change the order of the storage data displayed on the storage data selection screen. Note: • the factory setting is “date - ascend”. 1 touch [sorting]. Note: • [sorting] is inacti...

Page 192: Print Job

Storage and scan modes (option) overlaying storage data onto a 1-colour print job [overlay] 190 overlaying storage data onto a 1-colour print job [overlay] when 1-colour printing, you can overlay stored data onto a hard-copy original. For example, this function can be used to overlay a stamp over mu...

Page 193

Storage and scan modes (option) overlaying storage data onto a 1-colour print job [overlay] 191 “overlay” is set and the screen returns to the functions screen. 6 print. For subsequent operations, see step 6 of “1-col- our printing” ()p.58). Tip: overlaying storage data the stored data overlays at t...

Page 194: Storage Data

Storage and scan modes (option) 2-colour printing with the original and storage data [stamp] 192 2-colour printing with the original and storage data [stamp] when 2-colour printing, you can create a master of the hard-copy original on one drum 1 and a master of the storage data on drum 2 in order to...

Page 195

Storage and scan modes (option) 2-colour printing with the original and storage data [stamp] 193 specify the name data to insert. Stamp data must be pre-specified from storage data. See )p.176 for information on creating storage data. 1 touch [stamp data] on the admin. Screen. See )p.158 for operati...

Page 196

Storage and scan modes (option) 2-colour printing with the original and storage data [stamp] 194 5 touch [close]. Note: • to deselect the stamp data, touch [unselect]. • to change the stamp data, touch [change data]. The storage selection screen appears. 6 touch . Note: • once specified, the stamp d...

Page 197

Storage and scan modes (option) 2-colour printing with the original and storage data [stamp] 195 2-colour printing with [stamp] pre-select 2-colour printing. 1 place an original and load paper. Place the original on platen glass or in adf unit (option). See the “basic operations” chapter for informa...

Page 198: When Using A Linked Printer

Print functions for using linked printers 196 when using a linked printer (sold separately) print functions for using linked printers the machine may be connected with linked printers for more economical printing operations. Important!: • the optional risorinc-net is required in order to connect the...

Page 199

When using a linked printer (sold separately) print functions for using linked printers 197 link mode function the original is scanned on the machine and printed from the linked printer. ) p.202 special linked printer functions such as double-sided printing can be achieved. Original linked printer p...

Page 200: Setting Up A Linked Printer

When using a linked printer (sold separately) setting up a linked printer [link properties] 198 setting up a linked printer [link properties] linked printer data must be entered in the machine in order to operate. Important!: • make sure that the linked printer is physically connected to the machine...

Page 201

When using a linked printer (sold separately) setting up a linked printer [link properties] 199 functions description how to enter total trays enter total number of trays other than the standard tray. Important!: • if the number is less than the number of trays set in other options, other options wi...

Page 202

When using a linked printer (sold separately) setting up a linked printer [link properties] 200 *1 the tray number may differ depending upon the model of the linked printer. Punch set “punch” on if the device has the capability. Also set the tray number *1 used by the “punch” function. Off: no punch...

Page 203

When using a linked printer (sold separately) setting up a linked printer [link properties] 201 setting up a linked printer 1 touch [link mode] on the admin. Screen. 2 touch [link properties]. 3 select a tab for the linked printer. Note: • up to 6 linked printers may be entered. 4 select the button ...

Page 204: Printer

When using a linked printer (sold separately) printing scanned original from a linked printer [link mode] 202 printing scanned original from a linked printer [link mode] the mode in which an original is scanned into the machine and printed from a linked printer is called “link mode”. In link mode, t...

Page 205

When using a linked printer (sold separately) printing scanned original from a linked printer [link mode] 203 3) touch [ok]. Tip: using a linked printer's universal tray if the linked printer’s paper feed tray is set to “universal”, the “universal” button is displayed on the machine's feed tray scre...

Page 206

When using a linked printer (sold separately) printing scanned original from a linked printer [link mode] 204 5 enter the number of copies using the print quantity keys. The number is displayed on the print quantity dis- play. Note: • to change the number, press the key, then re-enter the correct nu...

Page 207: Printer

When using a linked printer (sold separately) using optional functions on a linked printer 205 using optional functions on a linked printer steps for setting up optional functions are shown below. These are available when the linked printer has an optional device such as a sorter or a duplex unit in...

Page 208

When using a linked printer (sold separately) using optional functions on a linked printer 206 configurable functions : initial setting (factory default) functions description screens and steps related admin. Settings counter display displays the number of printed copies for each linked printer reco...

Page 209

When using a linked printer (sold separately) using optional functions on a linked printer 207 important!: • some optional functions may not be enabled concurrently, depending on the model and option configuration of the linked printer. Printer collate select to retain original page order of the mul...

Page 210: Duplex Printing

When using a linked printer (sold separately) duplex printing [duplex] 208 duplex printing [duplex] double-sided printing is possible when a duplex unit (option) is installed to a linked printer. Note: • the “duplex” settings can be made from either master making or print functions screens. Linked p...

Page 211

When using a linked printer (sold separately) duplex printing [duplex] 209 5 place the original. Note: • for information about placing the original, see step 4, “printing from a paper document or book”.()p.39) • to scan a single sheet of an original, place it on the platen glass. • when duplex print...

Page 212

When using a linked printer (sold separately) duplex printing [duplex] 210 note: • pressing the key without placing the sec- ond original will also result in the linked printer printing one side only. • setting adjustment can be made on the follow- ing functions after placing the second original and...

Page 213

When using a linked printer (sold separately) duplex printing [duplex] 211.

Page 214: Replacing Consumables

Check for remaining amount of consumables 212 replacing consumables check for remaining amount of consumables the machine checks and reports on remaining amount of ink, master, as well as the space left in the disposal box. Note: • the report may not be displayed if detection fails. • the reported a...

Page 215: Replacing The Master Roll

Replacing consumables replacing the master roll 213 replacing the master roll when the master roll is depleted, a message is displayed and the machine stops. Replace with a new master roll. Important!: • for the master roll, it is recommended to use the products specified by riso. • keep the power o...

Page 216

Replacing consumables replacing the master roll 214 5 open the master roll holder. 6 remove the depleted master core. Note: • dispose the depleted master core according to the disposal rule of your local community. ) p.223 7 install a new master roll. Remove the plastic shrink wrap from the new mast...

Page 217

Replacing consumables replacing the master roll 215 tip: if you cannot insert the master insert the leading edge of the master using the fol- lowing steps. 1) raise the master guide flap turn the dial on the edge of the master guide flap towards the rear and raise the master guide flap. 2) pull out ...

Page 218: Replacing The Ink Cartridge

Replacing consumables replacing the ink cartridge 216 replacing the ink cartridge when the ink is depleted, a message is displayed and the machine stops. Replace with a new ink cartridge. B caution: • ink may be left on the area around the print drum, so take care not to smudge your hands or clothes...

Page 219

Replacing consumables replacing the ink cartridge 217 note: • you can store the ink cartridge cap on the right side of the platen glass. 4 insert the new ink cartridge. Align the arrow on the ink cartridge to the mark on the drum unit, and insert until it stops. 5 lock the ink cartridge. Turn the in...

Page 220

Replacing consumables emptying the master disposal box 218 emptying the master disposal box used masters are held in the master disposal box. When the master disposal box is full, a message displays and the machine stops. Discard the used masters. B caution: • wash immediately with soap if you shoul...

Page 221

Replacing consumables emptying the master disposal box 219 3 place the master disposal box into position. Insert the master disposal box until it stops..

Page 222: Replacing The Print Drum

Replacing consumables replacing the print drum 220 replacing the print drum when replacing with a colour drum to change colours, or when removing jammed paper, follow the steps to remove print drum. Be sure to use a colour drum specifically designed and approved for use with this machine. B caution:...

Page 223

Replacing consumables replacing the print drum 221 4 remove the print drum. Use both hands to lift the print drum straight up to remove from the rail. Proceed with replacing the drum, removing the paper jam, etc.. B caution: • do not touch the connector on the print drum. Neglecting this may result ...

Page 224

Replacing consumables replacing the print drum 222 installing the print drum 1 place the print drum on the rail. Align the mark on the print drum with the mark on the guide, and place the print drum hori- zontally onto the guide. Note: • if the print drum was manually rotated, be sure to turn it bac...

Page 225

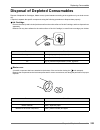

Replacing consumables disposal of depleted consumables 223 disposal of depleted consumables dispose of depleted ink cartridges, master cores, ejected masters according to the regulations in your local commu- nity. If required, separate the specific components using the following procedures to dispos...

Page 226

Replacing consumables disposal of depleted consumables 224 ejected master note: • it is made of carbon and hydrogen compounds. If fully combusted, it will turn into water and carbon dioxide. Parts materials master material plastic, japanese paper ink material soy oil, petroleum hydrocarbons, water, ...

Page 227

Replacing consumables disposal of depleted consumables 225.

Page 228: Maintenance

Cleaning 226 maintenance cleaning the print quality may suffer if parts such as thermal print head of the master making unit, scanner glass of the adf unit (option), white roller, etc. Are contaminated with dust, dirt, ink, white-out, etc.. Follow the steps below for periodic cleaning. A warning: • ...

Page 229

Maintenance cleaning 227 thermal print head clean the thermal print head each time you replace the master roll. Open the master making unit cover, and gently wipe the thermal print head in the back of the unit several times with a soft cloth or tissue. B caution: • since the thermal print head is ve...

Page 230

Maintenance cleaning 228 scanner glass and white sheet of adf unit (option) gently wipe the scanner glass, and the white sheet several times with a soft cloth or tissue. B caution: • since the platen glass is very delicate, avoid shocks or scratches with a hard object. Pressure roller if the pressur...

Page 231

Maintenance cleaning 229 the exterior use a soft cloth to gently wipe down the entire printer on a regular basis in order to prevent the exterior from getting dirty. If using a cleaning agent, use one recommended by your authorised service representative. B caution: • because the machine exterior is...

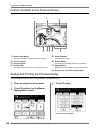

Page 232: Troubleshooting

When a message displays 230 troubleshooting when a message displays refer to the following information to determine the cause and take appropriate actions when the machine stops oper- ating and a message is displayed. Error message layout a message and a troubleshooting illustration will be displaye...

Page 233

Troubleshooting when a message displays 231 t00-000:service call error (in alphabetical order) a00-000:paper jam errors (in alphabetical order) message possible cause action !!Battery replacement!! Call service the battery is low or depleted. Contact your dealer (or authorised service representative...

Page 234

Troubleshooting when a message displays 232 b00-000:optional device error (in alphabetical order) master mis-feed pull out master making unit and rewind master roll, then reset master in place the master is improperly installed. Pull out the master making unit, rewind the master and reinstall. ) p.2...

Page 235

Troubleshooting when a message displays 233 linked printer in error a service call error has occurred on the linked printer. Check the linked printer and resolve the error. No ip address assigned to this printer contact your network administrator ip address for the machine is not properly set. Conta...

Page 236

Troubleshooting when a message displays 234 c00-000:consumable errors (in alphabetical order) d00-000:installation error (in alphabetical order) message possible cause action load paper in standard feed tray no printing paper in the paper feed tray. Load paper into the paper feed tray. ) p.31 master...

Page 237

Troubleshooting when a message displays 235 print drum 1 is not set in place press drum release button and pull out print drum once after button lights the print drum is locked but not pushed in properly. Press the print drum release button . Remove the print drum after the button is lit and reinsta...

Page 238

Troubleshooting when a message displays 236 wrong-type ink cartridge installed in print drum 2 or cannot read ink info replace ink cartridge or contact dealer/riso office inappropriate ink cartridge is installed. Properly install a correct ink cartridge. ) p.216 important!: • use the ink cartridge s...

Page 239

Troubleshooting when a message displays 237 j00-000:paper jam error displays when the original document or printing paper is jammed inside the machine or the adf unit (option). The location of the paper jam is indicated by the flashing icon ( - ) in the illustration. Refer to the table below ( - ) a...

Page 240

Troubleshooting when a message displays 238 paper is jammed in the print drum area. 1) pull out the print drum. ) p.220 2) remove the jammed paper. 3) return the print drum in place. 4) touch [ok]. B caution: • be careful not to touch the separation hook when putting your hands inside to remove pape...

Page 241

Troubleshooting when a message displays 239 pop-up message layout pop-up messages communicates various operational statuses. You can continue operation over some of them, but depending upon the context, others will require your action before operations can be resumed. E00-000:maintenance call (in al...

Page 242

Troubleshooting when a message displays 240 f00-000:warning messages (in alphabetical order) message symptom action acquiring linked printer configuration data please wait a moment the machine system is retrieving linked printer information. Link mode printing is disabled while the retrieval is unde...

Page 243

Troubleshooting when a message displays 241 either of masters is made in ink saving process operate dual-colour printing? One of the masters on either drum 1 or drum 2 was created in “ink saving” mode, while the other master is of regular printing quality. Proceeding to print with existing set of ma...

Page 244

Troubleshooting when a message displays 242 original undetected reset original the machine failed to detect the original document. The original document may not be placed. Re-position the original to clear the pop- up message. • when resuming the print job; touch [continue]. (alternatively, press th...

Page 245

Troubleshooting when a message displays 243 printing is not available for this setting with print drum 2 set print drum to be used in drum position 1 and re-select printing mode drum 2 may be used for single colour printing, but certain limitations apply. Current settings do not support single colou...

Page 246

Troubleshooting when a message displays 244 consumable information screen in order to assure optimum printing, the machine acquires information from the consumables. If acquired matching information is not proper, the consumable information screen is shown. Enter appropriate values. The icon on the ...

Page 247

Troubleshooting when a message displays 245 a confirmation screen displays when done. Press the key to approve selection. Returns to the basic screen. Note: • master information input screen may also display. If so, enter master information as well. ) p.245 master information input screen this scree...

Page 248

Troubleshooting when a message displays 246 a confirmation screen displays when done. Press the key to approve selection. Returns to the basic screen. Screen display description values [h4] master density select the standard density to be applied during creation of the master. 1 (light) - 10 (dark) ...

Page 249: Troubleshooting

Troubleshooting troubleshooting 247 troubleshooting if you run into a problem, consult the following chart first to find answers before calling for a repair. Problem possible cause action the machine does not start up when the power switch is pressed. You may have pressed the power switch while the ...

Page 250

Troubleshooting troubleshooting 248 an error indication does not disappear even though consumables (ink, master roll) are set. The consumables (ink, master roll) have not been correctly set. After inserting the ink cartridge, turn it clockwise ( ) to lock. Or set the ink cartridge again. ) p.216 set...

Page 251

Troubleshooting troubleshooting 249 the unwanted background of an original is picked up on copies. If newspaper or coloured paper is used as an original, the background is picked up on copies. Lighten the “contrast” and create a new master. ) p.75 dirt is found on printed copies. The platen glass (a...

Page 252