- DL manuals

- RKI Instruments

- Measuring Instruments

- GX-6000

- Operator's Manual

RKI Instruments GX-6000 Operator's Manual

Summary of GX-6000

Page 1

Www.Rkiinstruments.Com gx-6000 operator’s manual part number: 71-0362 revision: f released: 11/6/17.

Page 2: Warning

Gx-6000 operator’s manual warning read and understand this instruction manual before operating instrument. Improper use of the gas monitor could result in bodily harm or death. Periodic calibration and maintenance of the gas monitor is essential for proper operation and correct readings. Please cali...

Page 3: Table Of Contents

Gx-6000 operator’s manual table of contents table of contents chapter 1: introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 about the gx-6000 . . . . ....

Page 4

Table of contents gx-6000 operator’s manual chapter 3: operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 start up . . . . . . . . . . . . . . . . . ....

Page 5

Gx-6000 operator’s manual table of contents data logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 chapter 4: calibration mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 overview . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Table of contents gx-6000 operator’s manual replacing a sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 replacing the hydrophobic filter and wire mesh disk . . . . . . . . . . . . . . 123 pid sensor maintenance . . . . . . . . . . . . . . . . . . . . . ...

Page 7

Gx-6000 operator’s manual table of contents viewing the rom/sum of the instrument . . . . . . . . . . . . . . . . . . . . 171 turning the password function on or off . . . . . . . . . . . . . . . . . . . 171 restoring the default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172...

Page 8

Table of contents gx-6000 operator’s manual ir calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199 ir bump testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199 replacing an ir sensor . . . . . . ....

Page 9

Gx-6000 operator’s manual table of contents tube and tube holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227 tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tube holder . . . . . . . . . . . . . . . ...

Page 10: Chapter 1: Introduction

1 • overview gx-6000 operator’s manual chapter 1: introduction overview this chapter briefly describes the gx-6000 gas monitor. This chapter also describes the gx-6000 operator’s manual (this document). Table 1 at the end of this chapter lists the specifications for the gx-6000. About the gx-6000 us...

Page 11

Gx-6000 operator’s manual about the gx-6000 • 2 • stel and twa (when used in normal mode) and over range alarms • peak readings (when used in normal mode) • built-in time function • lunch break feature • rf shielded high impact plastic case • csa “c/us” classification for class i, division i, groups...

Page 12: Specifications

3 • specifications gx-6000 operator’s manual specifications table 1: standard sensor specifications/alarm points table 2: gx-6000 specifications combustible gas, methane (ch 4 ) calibration standard** oxygen (o 2 ) hydrogen sulfide (h 2 s) carbon monoxide (co) vocs, isobutylene calibration standard*...

Page 13

Gx-6000 operator’s manual specifications • 4 indication accuracy combustible gas (lel), catalytic type sensor • -10°c to 40 ° c: 5% of full scale • -20°c to 50 ° c: 6% of full scale oxygen • ± 0.5% o 2 hydrogen sulfide • ± 5% of reading or ± 2 ppm h 2 s (whichever is greater) carbon monoxide • ± 5% ...

Page 14

5 • specifications gx-6000 operator’s manual other accessories • alkaline battery pack • rechargeable li-ion battery pack • 115 vac charger • 12 vdc charger • hose/probes of various lengths, see “general parts list” on page 137. • voc zero filter (optional for instruments with a high range pid senso...

Page 15: About This Manual

Gx-6000 operator’s manual about this manual • 6 about this manual although the gx-6000 can support up to 6 sensors, this manual specifically describes an instrument with the four standard sensors and a pid sensor. See the appendices for descriptions of other sensors. The gx-6000 operator’s manual us...

Page 16: Chapter 2: Description

7 • overview gx-6000 operator’s manual chapter 2: description overview this chapter describes the gx-6000 instrument and accessories. Instrument description the gx-6000 includes the case, lcd, control buttons, flashlight led, alarm leds, infrared communication port, buzzer, vibrator, printed circuit...

Page 17: Lcd

Gx-6000 operator’s manual instrument description • 8 lcd a digital lcd (liquid crystal display) is visible through a clear plastic window in the top case. The lcd simultaneously shows the gas reading for all installed sensors. The lcd also shows information for each of the gx- 6000’s operating modes...

Page 18: Alarm Leds

9 • instrument description gx-6000 operator’s manual alarm leds five sets of red alarm leds (light emitting diodes) border the lcd. The alarm leds alert you to gas, low battery, and failure alarms. Infrared communications port an infrared (ir) communications port is located on the front of the case,...

Page 19: Sensors

Gx-6000 operator’s manual instrument description • 10 sensors the gx-6000 uses five sensors to monitor combustible gas, oxygen (o 2 ), carbon monoxide (co), hydrogen sulfide (h 2 s), and isobutylene (ibl) simultaneously. The sensors are located inside the gx-6000 and are held in their sockets by the...

Page 20: Filters

11 • instrument description gx-6000 operator’s manual top left corner of the sensor block. The standard calibration for a pid channel is to isobutylene. A pid channel can be factory setup for and calibrated to other gases. Regardless of the calibration gas, the pid channel will still detect and resp...

Page 21: Batteries

Gx-6000 operator’s manual instrument description • 12 held in place by the filter holder and are located in the bottom of the case chamber where the filter holder is installed. Batteries three aa-size alkaline batteries or a rechargeable lithium ion battery pack (4.1 vdc) power the gx-6000. Instrume...

Page 22: Included Accessories

13 • included accessories gx-6000 operator’s manual included accessories included accessories consist of the tapered rubber nozzle, belt clip, rubber boot, wrist strap, and the sample hose/probe. Tapered rubber nozzle a cone shaped 4 inch long rubber nozzle is included with the gx-6000 as standard. ...

Page 23: Screen Protector

Gx-6000 operator’s manual included accessories • 14 figure 2: sample hose and probe screen protector the clear screen protector can be installed over the gx-6000’s lcd to prevent it from getting scratched. 1 . Remove the gx-6000’s rubber boot. 2 . Orient the gx-6000 so that the lcd is as horizontal ...

Page 24: Other Accessories

15 • other accessories gx-6000 operator’s manual 12 . Reinstall the rubber boot. Other accessories several other accessories are available for the gx-6000. This section describes the voc zero filter, the dilution fitting, and the din rail. Detailed instructions regarding the use of the dilution fitt...

Page 25: External Dilution Fitting

Gx-6000 operator’s manual other accessories • 16 external dilution fitting a 1:1 external dilution fitting is available for the gx-6000. It is designed to mate with the inlet fitting and accept the sample hose and probe. The fitting is made with brass and nickel plated brass and is appropriate for u...

Page 26

17 • other accessories gx-6000 operator’s manual 2 . Install the charger(s) on the din rail. Seat the top of the din rail in the top slot on the back of the charger. Press the bottom of the charger toward the din rail until it locks into place. Figure 6: installing a charger on the din rail 3 . Slid...

Page 27

Gx-6000 operator’s manual other accessories • 18 figure 8: 1-charger installation figure 9: 4-charger installation 5 . To remove any charger(s) from the din rail: a. Remove the clamps by pushing on the bottom of the clamp and pulling on the top of the clamp. B. Slide the charger(s) off the din rail....

Page 28: Chapter 3: Operation

19 • overview gx-6000 operator’s manual chapter 3: operation overview this chapter explains how to use the gx-6000 to perform confined space entry monitoring or general area monitoring in normal mode. There are three operational modes in normal mode: measuring mode, display mode, and calibration mod...

Page 29

Gx-6000 operator’s manual start up • 20 1 . Connect the tapered rubber nozzle or the sample hose and probe to the gx-6000’s quick connect inlet fitting. 2 . Press and briefly hold down the power/enter button. Release the button when you hear a beep. 3 . If lunch break is turned on (see “updating the...

Page 30

21 • start up gx-6000 operator’s manual 4 . If cal reminder is set to on, the screen that appears next depends on how cal exprd is set in maintenance mode (see “updating the calibration expired setting” on page 150). • if the unit is due for calibration and cal exprd is set to confirm to use, then t...

Page 31

Gx-6000 operator’s manual start up • 22 the gx-6000 cannot be used until a successful calibration has been performed. Press and release the power/enter button to enter calibration mode. See “chapter 4: calibration mode” on page 68 for instructions to calibrate the gx-6000. Note: in this situation, e...

Page 32

23 • start up gx-6000 operator’s manual 5 . If bump reminder is set to on (factory setting is off), the screen that appears next depends on how bump exprd is set in maintenance mode (see “updating the bump expired setting” on page 155). • if the unit is due for bump testing and bump exprd is set to ...

Page 33

Gx-6000 operator’s manual start up • 24 • if the unit is due for bump testing and bump exprd is set to cannot use, then the following screen displays and the buzzer sounds in a double pulsing pattern. The gx-6000 cannot be used until a successful bump test has been performed. Press and release the p...

Page 34

25 • start up gx-6000 operator’s manual • if the unit is due for bump testing and bump exprd is set to no effect, then the following alert screen displays and the buzzer sounds in a double pulsing pattern. If you want to enter calibration mode, press and release the power/enter button. If you do not...

Page 35: Ch4 O2

Gx-6000 operator’s manual start up • 26 7 . The battery voltage screen appears for a few seconds. 8 . The active gases screen appears for a few seconds indicating which channels are active and their target gas. 4:07 battery voltage 4.5v battery type alkaline latching gas %lel % ppm ppm p ppm ch4 o2 ...

Page 36: Voc P

27 • start up gx-6000 operator’s manual 9 . The full scale values and the gas alarm setpoints are displayed by five screens in sequence: the full scale screen, the low alarm screen, high alarm screen, stel alarm screen, and twa alarm screen. Each screen remains on the lcd for three seconds. 10 . If ...

Page 37: Performing A Demand Zero

Gx-6000 operator’s manual start up • 28 11 . If the gx-6000 experiences a sensor failure during start up, a screen indicating which sensor failed appears and the buzzer sounds a double pulsing tone once per second. In the example below, the ch 4 sensor has failed. If you wish to continue, press and ...

Page 38: Turning Off The Gx-6000

29 • measuring mode, normal operation gx-6000 operator’s manual 3 . If you suspect any low-level voc background in the area, you will need to use the voc zero filter. Note: if you have both a voc and a co 2 sensor installed, you will need to follow the directions in “performing a demand zero for ins...

Page 39: Monitoring An Area

Gx-6000 operator’s manual measuring mode, normal operation • 30 monitoring an area 1 . Start up the gx-6000 as described above in “start up” on page 19. It is now in measuring mode. 2 . Take the gx-6000 to the monitoring area. Put the probe tip in the area to be monitored. Note: if the particle filt...

Page 40: Using Optional Sample Hoses

31 • measuring mode, normal operation gx-6000 operator’s manual using optional sample hoses the standard sample hose for the gx-6000 is 3 feet long. Optional samples hoses and probes with longer hoses are available from 5 - 50 feet in 5 foot increments (see “general parts list” on page 137). If you ...

Page 41

Gx-6000 operator’s manual measuring mode, normal operation • 32 table 5: lel hydrocarbon conversions • the gx-6000 provides the catalytic combustible sensor with some protection against exposure to high levels of combustible gas which can damage the sensor. It does this by turning off the combustibl...

Page 42: Voc Detection

33 • measuring mode, normal operation gx-6000 operator’s manual voc detection when monitoring for vocs using the pid sensor, keep the following in mind: • regardless of what gas the pid sensor is calibrated to (factory calibration is to isobutylene), the pid sensor will still detect and respond to a...

Page 43: Snap Log Mode

Gx-6000 operator’s manual measuring mode, normal operation • 34 snap log mode the snap logging function in snap log mode allows the user to record data at a specific time and have it saved to the data logger. The data is assigned a snap log id and is saved with the station id that was in use when th...

Page 44

35 • measuring mode, normal operation gx-6000 operator’s manual note: if the gx-6000 detects an alarm condition while in snap log mode, it will automatically exit snap log mode and return to measuring mode. You may then reenter snap log mode and take snap logs while the instrument is still in alarm....

Page 45: Measuring Mode, Alarms

Gx-6000 operator’s manual measuring mode, alarms • 36 measuring mode, alarms this section covers alarm indications in measuring mode. It also describes how to reset the gx-6000 after an alarm has occurred and how to respond to an alarm condition. Note: false alarms may be caused by radio frequency (...

Page 46

37 • measuring mode, alarms gx-6000 operator’s manual twa or stel concentration of co, h 2 s, or high range voc rises above the twa or stel alarm setting. • affected channel display alternates between gas reading and twa or stel • alarm led arrays flash in circle sequence once per second • backlight...

Page 47: Responding To Alarms

Gx-6000 operator’s manual measuring mode, alarms • 38 responding to alarms this section describes response to gas, over range, battery, sensor failure, clock failure, system failure, man down, and panic alarms. Responding to gas alarms 1 . Determine which gas alarm has been activated. 2 . Follow you...

Page 48

39 • measuring mode, alarms gx-6000 operator’s manual 3 . Reset or silence the alarm as necessary or allowed. Table 7 below summarizes resetting and silencing alarms for all alarm latching and alarm silence combinations that are possible. See “updating the alarm latching setting” on page 158 and “up...

Page 49

Gx-6000 operator’s manual measuring mode, alarms • 40 2 . Follow your established procedure for an extreme gas condition. Note: if your instrument has both a low range pid sensor and a high range pid sensor installed and if you are monitoring for gases in the higher range, the low range pid channel ...

Page 50

41 • measuring mode, alarms gx-6000 operator’s manual 4 . If the sensor failure condition continues after you have replaced the sensor, contact rki instruments, inc. For further instructions. Responding to clock failure alarms a clock failure alarm occurs if the unit’s internal clock malfunctions. 1...

Page 51

Gx-6000 operator’s manual measuring mode, alarms • 42 2 . The error code meanings are shown in the table below: 3 . If the error code is anything but 022 as shown above, the instrument cannot be used. Contact rki instruments, inc. As soon as possible. If the error code is 022, you may press and rele...

Page 52: Display Mode

43 • display mode gx-6000 operator’s manual responding to a panic alarm if the user is in a dangerous situation or feels that others must be alerted to any sort of problem, holding the shift ▼ (panic) button will initiate a panic alarm. 1 . Press and release the reset button to silence and reset the...

Page 53: Tips For Using Display Mode

Gx-6000 operator’s manual display mode • 44 tips for using display mode • to enter display mode and scroll from one menu item to the next or skip an item when a question is asked, press and release the disp/lock button. • to enter an item, press and release the power/enter button. • to change a flas...

Page 54: Pid Gas Name Screen

45 • display mode gx-6000 operator’s manual pid gas name screen the standard pid channel is configured for and calibrated to isobutylene. If calibration to a different gas is required for an application, the pid channel can also be configured for other gases. Regardless of what gas the pid sensor is...

Page 55

Gx-6000 operator’s manual display mode • 46 2 . Use the ▲air and shift ▼ (panic) buttons to scroll through the letter and list options. To view the gas names behind a letter, user list, or recent list, press and release the power/enter button when the cursor is next to the desired letter. 3 . Use th...

Page 56: Peak Screen

47 • display mode gx-6000 operator’s manual 7 . To return to the pid gas name screen, press and release the disp/ lock button one more time. Peak screen the peak screen displays the highest (lowest for oxygen) concentrations detected since the gx-6000 was turned on. Peak readings are stored in the g...

Page 57: Stel Screen

Gx-6000 operator’s manual display mode • 48 stel screen the stel screen displays the short term exposure limit (stel) readings for h 2 s, co, and high range voc only. The stel reading is the average reading over the last 15 minutes. Twa screen the twa screen displays the time weighted average (twa) ...

Page 58: View Alarm Settings Screen

49 • display mode gx-6000 operator’s manual view alarm settings screen the view alarm settings screen gives you the option to view the gas alarm settings for all active channels. To view the gas alarm settings, do the following: 1 . With the view alarm settings screen displayed, press and release th...

Page 59: Voc

Gx-6000 operator’s manual display mode • 50 2 . Pressing and releasing the power/enter button while in a settings screen will cause the instrument to simulate that condition. The buzzer, led’s, and vibration will activate. Press and release the power/ enter button again to stop the simulated alarm. ...

Page 60: Time In Operation Screen

51 • display mode gx-6000 operator’s manual time in operation screen the time in operation screen displays the length of time since the gx-6000 was turned on if the lunch break feature is turned off. With lunch break set to off, the time in operation is reset when the gx-6000 is turned off. See “upd...

Page 61: Log Time Remaining Screen

Gx-6000 operator’s manual display mode • 52 log time remaining screen the data logging screen displays the time remaining until the data logger memory is full. Log clear screen caution: once you clear the data logger, you cannot retrieve any data previously stored in the data logger. The log clear s...

Page 62

53 • display mode gx-6000 operator’s manual to clear the data logger memory, do the following: 1 . With the log clear screen displayed, press and release the power/enter button. The following screen appears asking you to confirm that you want to clear the data logger memory. 2 . If you do not want t...

Page 63: Pump Off Screen

Gx-6000 operator’s manual display mode • 54 pump off screen warning: the gx-6000 is not a gas monitoring device while the pump is off. Note: the item appears in display mode only if the pump off disp menu item in maintenance mode is turned on. The factory setting for pump off disp is off. This featu...

Page 64: Select User Id Screen

55 • display mode gx-6000 operator’s manual select user id screen this screen only appears in display mode if the id display item in maintenance mode is set to on. Use this screen to select a user id from the user id list in the gx-6000’s memory. The current user id is displayed. A user id can be up...

Page 65

Gx-6000 operator’s manual display mode • 56 to select a different user id: 1 . With the select user id screen displayed, press and release the power/enter button. The current user id will be displayed and it will be flashing. 2 . Use the ▲air and shift ▼ (panic) buttons to scroll through the availab...

Page 66: Select Station Id Screen

57 • display mode gx-6000 operator’s manual select station id screen this screen only appears in display mode if the id display item in maintenance mode is set to on. Use this screen to select a station id from the station id list in the gx-6000’s memory. The current station id is displayed. A stati...

Page 67

Gx-6000 operator’s manual display mode • 58 to select a different station id: 1 . With the select station id screen displayed, press and release the power/enter button. The current user id will be displayed and it will be flashing. 2 . Use the ▲air and shift ▼ (panic) buttons to scroll through the a...

Page 68: Viewing Snap Logger Data

59 • display mode gx-6000 operator’s manual viewing snap logger data the snap logging screen allows you to view data from previous snap logs. For information on how to use the snap logging feature, see “snap log mode” on page 34. 1 . With the snap logging screen displayed, press and release the powe...

Page 69: Peak Bar Screen

Gx-6000 operator’s manual display mode • 60 4 . To view the data in a snap log id, press and release the power/enter button. The gas readings that were taken during the snap log are displayed. You can use the ▲air and shift ▼ (panic) buttons to scroll through the different snap logs. The gas reading...

Page 70: Gas Display Screen

61 • display mode gx-6000 operator’s manual 3 . Press and release the power/enter button to save the setting and return to the peak bar screen. To return to the peak bar screen without saving any changes, press and release the disp/lock button. Gas display screen the gas display screen allows the us...

Page 71: Lcd Flip Screen

Gx-6000 operator’s manual display mode • 62 1 . With the gas display screen showing, press and release the power/ enter button. The available choices will appear. 2 . Use the ▲air and shift ▼ (panic) buttons to move the cursor next to the desired setting. 3 . Press and release the power/enter button...

Page 72

63 • display mode gx-6000 operator’s manual if invert select is set to off, the instrument’s lcd will not flip and can only be read when the instrument is right side up. A lock symbol will appear at the top of the screen to indicate that the lcd’s position is fixed. 1 . With the gas display screen s...

Page 73: Lcd Background Color Flip

Gx-6000 operator’s manual display mode • 64 1 . With the cat (lel) sensor protection screen displayed, press and release the power/enter button. The current setting will be displayed along with a warning about no %lel alarms if the catalytic lel sensor is turned off. 2 . Use the ▲air or shift ▼ (pan...

Page 74: Language Screen

65 • display mode gx-6000 operator’s manual 2 . Use the ▲air and shift ▼ (panic) buttons to display the desired setting. 3 . Press and release the power/enter button to return to the lcd background flip screen. To return to the lcd background flip screen without saving any changes, press and release...

Page 75: Data Logging

Gx-6000 operator’s manual data logging • 66 data logging note: the gx-6000 only logs data while in normal mode. If the gx-6000 is used in leak check mode or bar hole mode, no downloadable data will be logged while it is in either of these two modes. The gx-6000 features the ability to log data to it...

Page 76

67 • data logging gx-6000 operator’s manual for a complete description of the data logger management program and procedures for downloading data to a computer, see the gx-6000 data logger management program operator’s manual. 1 minute 60 hours 3 minutes 180 hours 5 minutes 300 hours 10 minutes 600 h...

Page 77: Chapter 4: Calibration Mode

Gx-6000 operator’s manual overview • 68 chapter 4: calibration mode overview this section describes the gx-6000 in calibration mode. In calibration mode, you can move through a menu of screens to do the following: • perform a fresh air (zero) adjustment • perform a span adjustment on all channels si...

Page 78: Calibration Supplies and

69 • calibration supplies and equipment gx-6000 operator’s manual calibration supplies and equipment to calibrate the gx-6000, you will need: • known calibrating samples of the gases being detected. The combustible and toxic gas samples should have concentrations between 10 and 50% of the full scale...

Page 79: Entering Calibration Mode

Gx-6000 operator’s manual entering calibration mode • 70 entering calibration mode to enter calibration mode, do the following: 1 . Find a fresh-air environment. This is an environment free of toxic or combustible gases and of normal oxygen content (20.9%). 2 . While in measuring mode, press and hol...

Page 80: Calibration Method

71 • calibrating using the auto calibration method gx-6000 operator’s manual calibrating using the auto calibration method this method allows you to calibrate the ch 4 (%lel sensor), oxygen, h 2 s, co, and voc (pid sensor) sensors simultaneously. It is designed for use with either the rki 5-gas cali...

Page 81: Voc

Gx-6000 operator’s manual calibrating using the auto calibration method • 72 4 . The calibration mode screen displays with the cursor next to air cal. 5 . Press and release the power/enter button. The fresh air reading screen will display. 6 . If you suspect any low-level voc background in the area,...

Page 82: Voc

73 • calibrating using the auto calibration method gx-6000 operator’s manual 8 . The gx-6000 will indicate that it is adjusting the zero reading for a few seconds and then it will prompt you to release the ▲air button. 9 . Release the ▲air button. The fresh air adjustment will finish, the fresh air ...

Page 83

Gx-6000 operator’s manual calibrating using the auto calibration method • 74 performing a span adjustment 1 . Install the demand flow regulator onto the 4-gas or 5-gas calibration cylinder. 2 . Connect the sample tubing to the demand flow regulator. 3 . Install the sample hose and probe on the gx-60...

Page 84

75 • calibrating using the auto calibration method gx-6000 operator’s manual 6 . To check or update the gas concentrations, use the ▲air and shift ▼ (panic) buttons to put the cursor next to concentration and press and release the power/enter button to display the calibration gas values screen. The ...

Page 85

Gx-6000 operator’s manual calibrating using the auto calibration method • 76 10 . Press and release the power/enter button to save the change. The calibration gas value stops flashing. 11 . Repeat step 7 through step 10 for any other channels that need to be changed. 12 . When you are done adjusting...

Page 86: 0 20.9

77 • calibrating using the auto calibration method gx-6000 operator’s manual 15 . Press and release the power/enter button. The first of the gas select screens, the standard four sensors screen, will be displayed. In addition to the standard four sensors screen, there is a separate screen for each i...

Page 87: 50 12.0

Gx-6000 operator’s manual calibrating using the auto calibration method • 78 if you do not want to proceed with the calibration, press and release the disp/lock button to return to the gas select screen. If you do want to continue with the calibration, proceed to the next step. 17 . Connect the tubi...

Page 88

79 • calibrating using the auto calibration method gx-6000 operator’s manual 21 . If you were using a 5-gas calibration cylinder, continue to step 22. If you were using a 4-gas calibration cylinder: a. Remove the tubing from the rigid tube on the probe. B. Unscrew the 4-gas cylinder from the regulat...

Page 89

Gx-6000 operator’s manual calibrating using the auto calibration method • 80 24 . Press and release the power/enter button. The first of the gas select screens, the standard four sensors screen, will be displayed. In addition to the standard four sensors screen, there is a separate screen for each i...

Page 90: Voc

81 • calibrating using the auto calibration method gx-6000 operator’s manual 25 . With the voc channel’s gas select screen displayed, press and release the power/enter button. The target gas selection screen will display. This screen allows you to select the gas you want to use for calibration. Isob...

Page 91: Voc

Gx-6000 operator’s manual calibrating using the auto calibration method • 82 28 . If you are using a 5-gas calibration cylinder, continue with step 29. If you are using a pid only calibration cylinder: a. Connect the tubing from the regulator to the rigid tube on the probe. Allow the gx-6000 to draw...

Page 92: Returning To Measuring Mode

83 • calibrating using the auto calibration method gx-6000 operator’s manual if the pid channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the pid sensor failed to calibrate. The buzzer and alarm leds activate in a double pulsing...

Page 93: Calibration Method

Gx-6000 operator’s manual calibrating using the single calibration method • 84 calibrating using the single calibration method single calibration allows you to calibrate one channel at a time. This is useful if you only want to calibrate one or two channels. Setting the fresh air reading 1 . While i...

Page 94

85 • calibrating using the single calibration method gx-6000 operator’s manual 3 . If you suspect any low-level voc background in the area, you will need to use the voc zero filter. Note: if you have both a voc and a co 2 sensor installed, you will need to follow the directions in “performing a dema...

Page 95: Voc

Gx-6000 operator’s manual calibrating using the single calibration method • 86 6 . Release the ▲air button. The fresh air adjustment will finish, the fresh air readings will be displayed momentarily, and then the instrument will return to the calibration mode screen. 7 . If the voc zero filter was u...

Page 96

87 • calibrating using the single calibration method gx-6000 operator’s manual 5 . Press and release the power/enter button. The select sensor screen appears. 6 . Move the cursor next to the sensor you want to calibrate with the ▲air and shift ▼ (panic) buttons. In the example above, the ch 4 sensor...

Page 97: Ch4

Gx-6000 operator’s manual calibrating using the single calibration method • 88 9 . Use the ▲air and shift ▼ (panic) buttons to move the cursor next to the gas you want to use for calibration. Continue to step 10. 10 . Press and release the power/enter button to proceed to the single calibration appl...

Page 98

89 • calibrating using the single calibration method gx-6000 operator’s manual 15 . Repeat step 6 through step 14 for any other channels you want to calibrate. Make sure you use an appropriate calibration cylinder for each sensor. Caution: when calibrating the oxygen sensor, verify the concentration...

Page 99: Performing A Bump Test

Gx-6000 operator’s manual performing a bump test • 90 performing a bump test note: the bump disp menu item in maintenance mode is factory set to off. The bump test menu item will not appear unless bump disp is set to on. See “updating the bump display setting” on page 152 for instructions. Note: the...

Page 100

91 • performing a bump test gx-6000 operator’s manual 6 . The calibration mode screen displays with the cursor next to air cal. 7 . Move the cursor next to the bump test menu item by using the shift ▼ (panic) button. Cal cal mode air cal auto cal single cal bump test normal mode cal cal mode air cal...

Page 101

Gx-6000 operator’s manual performing a bump test • 92 8 . Press and release the power/enter button. The first of the gas select screens, the standard four sensors screen, will be displayed. In addition to the standard four sensors screen, there is a separate screen for each installed smart sensor, a...

Page 102: 0 20.9

93 • performing a bump test gx-6000 operator’s manual 10 . With the desired sensor screen displayed, connect the tubing from the demand flow regulator to the rigid tube on the probe then quickly press and release the power/enter button to proceed to the bump in progress screen. The instrument will c...

Page 103: 50 12.0

Gx-6000 operator’s manual performing a bump test • 94 c. Disconnect the tubing from the probe. 12 . When auto cal in the bump parameters menu item in maintenance mode is set to on: if all channels pass the bump test: a. The results screen appears. You can scroll between the bump test results and the...

Page 104: 50 18.0

95 • performing a bump test gx-6000 operator’s manual b. At the end of the calibration, the instrument displays the results from both the bump test and the calibration. Use the ▲air and shift ▼ (panic) button to scroll between the calibration/bump test results, the bump test gas readings, and the ca...

Page 105: Chapter 5: User Mode

Gx-6000 operator’s manual overview • 96 chapter 5: user mode overview this section describes the gx-6000 in user mode. See table 12 below for a list of the items found in user mode, the page that the menu item’s instructions can be found on, and a short description of the menu item. Tips for using u...

Page 106: Entering User Mode

97 • entering user mode gx-6000 operator’s manual entering user mode warning: the gx-6000 is not in operation as a gas detector while in user mode. 1 . Take the gx-6000 to a non-hazardous location and turn it off if it is on. 2 . Press and hold the ▲air and shift ▼ (panic) buttons, then press and ho...

Page 107: Setting The Date And Time

Gx-6000 operator’s manual setting the date and time • 98 8 . The main menu displays. It has 7 menu items. 9 . Use the ▲air or shift ▼ (panic) button to move the cursor up and down the menu items. Setting the date and time note: the example screen shown below assumes a date format setting of mm/dd/yy...

Page 108: Setting The Date Format

99 • setting the date format gx-6000 operator’s manual setting the date format the date can be displayed in three ways, mm/dd/yyyy (factory setting), dd/mm/yyyy, or yyyy/mm/dd. 1 . From the main menu, place the cursor next to date format. 2 . Press and release power/enter. The date format screen app...

Page 109

Gx-6000 operator’s manual configuring the channels • 100 4 . Press and release power/enter. The available configuration options are shown. The current setting for the channel will be flashing. 5 . Use ▲air and shift ▼ (panic) to move the cursor next to the desired configuration for the selected chan...

Page 110

101 • updating the language setting gx-6000 operator’s manual 9 . Press and release power/enter to save the changes and return to the main menu. Updating the language setting the language menu item allows you to select the language for the gx- 6000’s user interface. The available choices are english...

Page 111

Gx-6000 operator’s manual turning the password function on or off • 102 2 . Press and release the power/enter button. The rom and checksum values for your unit will be displayed. 3 . The first line displays the rom number. The rom number indicates the firmware version number. In the above example, t...

Page 112: Exiting User Mode

103 • exiting user mode gx-6000 operator’s manual 4 . If you selected off, press and release power/enter to save the setting and return to the main menu. If you selected on, continue with step 5. 5 . Press and release power/enter. The set password screen appears. 0000 is at the bottom of the screen ...

Page 113: Chapter 6: Maintenance

Gx-6000 operator’s manual overview • 104 chapter 6: maintenance overview this chapter describes troubleshooting procedures for the gx-6000. It also includes procedures for replacing and recharging the batteries and replacing various consumable parts. Warning: rki instruments, inc. Recommends that se...

Page 114

105 • troubleshooting gx-6000 operator’s manual • the unit indicates flow failure and does not recover when reset is pressed and released. • the probe tube is clogged. • the hydrophobic filter disk in the probe is dirty. • the sample hose has a kink or obstruction. • the pump is malfunctioning. 1. I...

Page 115: Batteries

Gx-6000 operator’s manual replacing or recharging the batteries • 106 replacing or recharging the batteries warning: to prevent ignition of a hazardous atmosphere, batteries must only be changed or charged in an area known to be nonhazardous. Avertissement:pour éviter l’inflammation d’une atmosphère...

Page 116

107 • replacing or recharging the batteries gx-6000 operator’s manual 3 . Push the battery cover latch toward the bottom of the instrument. Figure 11: releasing battery cover latch 4 . Grasp the end of the battery cover that’s closest to the bottom of the instrument and lift it up. Figure 12: openin...

Page 117

Gx-6000 operator’s manual replacing or recharging the batteries • 108 6 . Carefully install the new aa alkaline batteries according to the battery diagram inside the battery compartment. Figure 13: installing the alkaline batteries 7 . Close the battery cover and secure the battery cover latch by pu...

Page 118

109 • replacing or recharging the batteries gx-6000 operator’s manual 5 . Slide the battery pack release latch to the right with one hand and lift up on the battery pack with the other. Figure 14: releasing the battery pack 6 . Slide the battery pack away from the instrument. 7 . Install a new batte...

Page 119: Instrument

Gx-6000 operator’s manual replacing or recharging the batteries • 110 recharging the lithium ion battery pack in the instrument caution: to be used only with lithium ion battery pack p/n 49-1619. Charge only with rki charger model bc-6000, p/n 49-2182, or rki charger model bc-6000dc, p/n 49-2183. Us...

Page 120

111 • replacing or recharging the batteries gx-6000 operator’s manual if using a dc powered charging station, plug the 12 vdc vehicle plug adapter into a vehicle’s 12 vdc power socket. Figure 17: connecting the charging station’s dc adapter the construction of the charging stations allows them to be...

Page 121: Instrument

Gx-6000 operator’s manual replacing or recharging the batteries • 112 figure 18: putting the gx-6000 into the charging station 5 . When a full charge has been reached, approximately 3 hours, the red led on the charging station will turn off. Remove the gx-6000 from the charging station and unplug th...

Page 122

113 • replacing or recharging the batteries gx-6000 operator’s manual 2 . Confirm that the power adapter’s dc output cord is plugged into the charger. 3 . If using an ac powered charging station, plug the ac adapter into an electrical outlet. Figure 19: connecting the charging station’s ac adapter t...

Page 123

Gx-6000 operator’s manual replacing or recharging the batteries • 114 if using a dc powered charging station, plug the 12 vdc vehicle plug adapter into a vehicle’s 12 vdc power socket. Figure 20: connecting the charging station’s dc adapter the construction of the charging stations allows them to be...

Page 124: Hydrophobic Filter Disk

115 • replacing the probe’s particle filter and hydrophobic filter disk gx-6000 5 . Insert the battery pack into the charging station as shown in figure 21 below so that the metal contacts on the back of the battery pack come into contact with the metal contacts in the charging station. When proper ...

Page 125

Gx-6000 operator’s manual replacing the probe’s particle filter and hydrophobic filter 2 . Grasp each end of the clear probe body firmly and unscrew the two halves from each other. The top half includes the probe tube and the bottom half includes the sample hose. Figure 22: replacing the particle fi...

Page 126: Replacing The H

117 • replacing the h 2 s scrubber disk and the charcoal filter gx-6000 operator’s caution: if you are replacing filters in a probe intended for chlorine detection, do not install the particle filter. 8 . Carefully screw the top half onto the bottom half disk while keeping the probe oriented with th...

Page 127

Gx-6000 operator’s manualreplacing the h 2 s scrubber disk and the charcoal filter • 118 4 . To replace the h 2 s scrubber disk, remove the old one from its recess in the sensor gasket and replace it with the new one making sure that it is properly seated. You do not have to remove the sensor gasket...

Page 128

119 • replacing the h 2 s scrubber disk and the charcoal filter gx-6000 operator’s 6 . Ensure that the sensor gasket is installed properly. The flow fitting connections need to be facing up and cannot be skewed sideways. The gasket must be pushed down in the center and secured under the gasket align...

Page 129: Replacing A Sensor

Gx-6000 operator’s manual replacing a sensor • 120 replacing a sensor 1 . Verify that the gx-6000 is off. 2 . Use a small phillips screwdriver to unscrew the four screws holding the flow chamber to the rest of the gx-6000’s case. 3 . Grasp the sides of the flow chamber and lift it away from the rest...

Page 130

121 • replacing a sensor gx-6000 operator’s manual figure 25: replacing a sensor caution: when replacing a sensor, verify that the sensor is properly aligned with its socket before inserting it into the socket. The co and h 2 s sensors have alignment slots which match up with alignment tabs in the s...

Page 131

Gx-6000 operator’s manual replacing a sensor • 122 fitting connections need to be facing up and cannot be skewed sideways. The gasket must be pushed down in the center and secured under the gasket aligning tabs. Failure to install the sensor gasket appropriately may result in inaccurate gas readings...

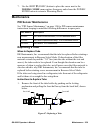

Page 132: Wire Mesh Disk

123 • replacing the hydrophobic filter and wire mesh disk gx-6000 operator’s 13 . Calibrate the new sensors as described in “chapter 4: calibration mode” on page 68. Replacing the hydrophobic filter and wire mesh disk 1. Verify that the gx-6000 is off. 2. Locate the clear plastic filter holder at th...

Page 133: Pid Sensor Maintenance

Gx-6000 operator’s manual pid sensor maintenance • 124 6. Using a small flat head screwdriver, carefully pry the wire mesh disk and hydrophobic filter from the gasket. Do not remove the gasket. 7. Carefully install the new hydrophobic filter and/or wire mesh disk making sure the wire mesh disk is on...

Page 134

125 • pid sensor maintenance gx-6000 operator’s manual 7 . Place the pid sensor face down on a flat clean working surface. Note: do not touch the lamp window with your fingers as this may contaminate the window with finger oil. At this point it is recommended that the finger cots be used on the fing...

Page 135

Gx-6000 operator’s manual pid sensor maintenance • 126 11 . If the spring in the lamp cavity comes out, place it back into the lamp cavity. 12 . Hold the lamp in one hand being careful not to touch the lamp window with your fingers. 13 . With the other hand collect a small amount of aluminum oxide p...

Page 136

127 • pid sensor maintenance gx-6000 operator’s manual 18 . Hold the electrode stack between the thumb and forefinger of one hand and place the window end of the lamp inside the o-ring seal in the electrode stack with the other hand as shown below. Figure 31: reinstalling the electrode lamp 19 . Twi...

Page 137

Gx-6000 operator’s manual pid sensor maintenance • 128 pushed down in the center and secured under the gasket aligning tabs. Failure to install the sensor gasket appropriately may result in inaccurate gas readings. Figure 32: sensor gasket seating 26 . Insert the flow chamber back into the instrumen...

Page 138

129 • pid sensor maintenance gx-6000 operator’s manual replacing the pid sensor’s lamp if cleaning the pid lamp does not resolve any calibration problems you may be having, the lamp may need to be replaced. Ordering the correct replacement lamp it’s important to order the correct replacement lamp fo...

Page 139

Gx-6000 operator’s manual pid sensor maintenance • 130 7 . Place the pid sensor face down on a flat clean working surface. 8 . Hold the pid sensor steady on the working surface with one hand and using the other hand, locate the tabs on the electrode stack removal tool and insert them into the slots ...

Page 140

131 • pid sensor maintenance gx-6000 operator’s manual 13 . Hold the electrode stack between the thumb and forefinger of one hand and place the window end of the new lamp inside the o-ring seal in the electrode stack with the other hand as shown below. Take care not to touch the lamp window. Figure ...

Page 141

Gx-6000 operator’s manual pid sensor maintenance • 132 pushed down in the center and secured under the gasket aligning tabs. Failure to install the sensor gasket appropriately may result in inaccurate gas readings. Figure 35: sensor gasket seating 21 . Insert the flow chamber back into the instrumen...

Page 142

133 • pid sensor maintenance gx-6000 operator’s manual replacing the pid sensor’s electrode stack the electrode stack can last for the life of the pid sensor if the gx-6000 is used in a very clean, controlled environment. When used in a heavily contaminated or dirty environment, the electrode stack ...

Page 143

Gx-6000 operator’s manual pid sensor maintenance • 134 8 . Hold the pid sensor steady on the working surface with one hand and using the other hand, locate the tabs on the electrode stack removal tool and insert them into the slots on the side of the pid sensor near the face. Figure 36: using remova...

Page 144

135 • pid sensor maintenance gx-6000 operator’s manual figure 37: reinstalling electrode lamp 14 . Twisting the lamp slightly during insertion will help to ensure the lamp window is snug against the stack's front electrode. The lamp should be supported by the o-ring. 15 . Continuing to hold the elec...

Page 145

Gx-6000 operator’s manual pid sensor maintenance • 136 20 . Place the sensor gasket and filters back over the sensors ensuring that it seals with the sensors and the flow fittings. The flow fitting connections need to be facing up and cannot be skewed sideways. The gasket must be pushed down in the ...

Page 146: General Parts List

137 • general parts list gx-6000 operator’s manual general parts list table 16 lists part numbers for the gx-6000’s replacement parts and accessories. Table 16: general parts list part number description 06-1248rk-03 calibration kit tubing, 3 foot length 13-0112rk wrist strap 13-6022 din rail, 4” lo...

Page 147

Gx-6000 operator’s manual general parts list • 138 49-1120rk aa size alkaline battery 49-1619 li-ion battery pack 49-1620 alkaline battery pack 49-2182-01 battery charger, bc-6000, with 100 - 240 vac adapter 49-2183 battery charger, bc-6000, with 12 vdc adapter 51-1500rk pid sensor replacement lamp,...

Page 148

139 • general parts list gx-6000 operator’s manual 81-0154rk-02 calibration cylinder, aluminum, 58 liter; four-gas (ch 4 /o 2 / h 2 s/co) 81-0154rk-04 calibration cylinder, aluminum, 34 liter; four-gas (ch 4 /o 2 / h 2 s/co) 81-1054rk regulator, demand-flow type (for 58- and 103-liter aluminum or st...

Page 149: Overview

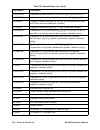

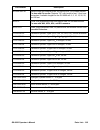

Gx-6000 operator’s manual overview • 140 appendix a: maintenance mode overview this appendix describes the gx-6000 in maintenance mode. The gx-6000 is factory-set to suit most applications. Update settings in maintenance mode only if required for your specific application. Maintenance mode items and...

Page 150

141 • overview gx-6000 operator’s manual • check (pg.153) • 10% • 20% • 30% • 40% • 50% 30% • cal time (pg.153) • 90 sec • 120 sec 90 sec • auto cal (pg.153) • on • off on • escape return to bump parameters menu n/a • bump reminder (pg.154) • on • off off • bump interval (pg.154) 0-30 days 30 days •...

Page 151

Gx-6000 operator’s manual overview • 142 language (pg.160) • english • japanese • italian • spanish • german • french • portuguese • russian • korean english lunch break (pg.161) • on • off off auto zero (pg.161) • on • off off demand zero (pg.162) • on • off on zero follower (pg.162) for each chann...

Page 152

143 • overview gx-6000 operator’s manual bar hole time (pg.165) • 30 sec • 45 sec • 60 sec 30 sec co display (pg.165) • on • off off man down (pg.166) • man down (pg.166) • on • off off • panic (pg.167) • on • off on • warning 1 time (pg.167) 10 - 75 sec 60 sec • warning 2 time (pg.167) 60 - 90 sec ...

Page 153: Using Maintenance Mode

Gx-6000 operator’s manual tips for using maintenance mode • 144 tips for using maintenance mode • when in the main menu, the cursor (>) indicates which menu item will be selected if the power/enter button is pressed and released. • use the shift ▼ (panic) button to move the cursor down through the m...

Page 154

145 • using maintenance mode gx-6000 operator’s manual 3 . The screen that appears will depend on the setting of user mode’s password item. If user mode’s password is set to off (factory setting), continue with step 4. If user mode’s password is set to on, continue with step 6. 4 . If user mode’s pa...

Page 155

Gx-6000 operator’s manual using maintenance mode • 146 7 . The appearance of the password screen will be affected by maintenance mode’s password setting. 8 . If maintenance mode’s password is set to off, continue to step 11. 9 . If maintenance mode’s password is set to on (factory setting), enter th...

Page 156: Setting The Date And Time

147 • using maintenance mode gx-6000 operator’s manual 12 . The main menu displays. It displays eight menu items at a time. 13 . Use the ▲air or shift ▼ (panic) button to move the cursor up and down through the menu items. Additional items are available above and below the items currently displayed ...

Page 157: Setting The Date Format

Gx-6000 operator’s manual using maintenance mode • 148 setting the date format the date can be displayed in three ways, mm/dd/yyyy (factory setting), dd/mm/yyyy, or yyyy/mm/dd. 1 . From the main menu, place the cursor next to date format. 2 . Press and release power/enter. The date format screen app...

Page 158

149 • using maintenance mode gx-6000 operator’s manual updating calibration settings the cal setting menu item in maintenance mode has a sub menu with 5 menu items: cal reminder, cal interval, cal exprd, cal check gas, and escape. 1 . From the main menu, place the cursor next to cal setting. 2 . Pre...

Page 159

Gx-6000 operator’s manual using maintenance mode • 150 2 . Press and release power/enter. The set calibration interval screen appears. 3 . Use ▲air or shift ▼ (panic) to display the desired setting. Tip: press and hold ▲air or shift ▼ (panic) to rapidly scroll through the settings. 4 . Press and rel...

Page 160

151 • using maintenance mode gx-6000 operator’s manual updating the calibration check gas setting this item defines which sensors are used to update the calibration reminder screen. With cal check gas set to 4 gas (factory setting), the calibration dates for only the standard 4 sensors (lel, o2, h2s...

Page 161

Gx-6000 operator’s manual using maintenance mode • 152 updating the bump display setting with bump disp set to on, the bump test menu item will appear in calibration mode. With bump disp set to off (factory setting), the bump test menu item will not appear in calibration mode. 1 . From the bump sett...

Page 162

153 • using maintenance mode gx-6000 operator’s manual 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to save the setting. The value will stop flashing. Updating the check setting the check is the bump test tolerance value and is represented as a pe...

Page 163

Gx-6000 operator’s manual using maintenance mode • 154 2 . Press and release power/enter. The current auto cal setting will begin to flash. 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to save the setting. The setting will stop flashing. Returning...

Page 164

155 • using maintenance mode gx-6000 operator’s manual 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to save the setting. The instrument will return to the bump setting screen. Updating the bump expired setting this item defines what indication is ...

Page 165: Updating Alarm Parameters

Gx-6000 operator’s manual using maintenance mode • 156 updating the bump check gas setting this item defines which sensors are used to update the bump test reminder screen. With bump check gas set to 4 gas (factory setting), the bump test dates for only the standard 4 sensors (lel, o2, h2s, and co) ...

Page 166

157 • using maintenance mode gx-6000 operator’s manual updating the alarm point settings this menu item allows you to update one or more alarm points (the reading at which the gx-6000 recognizes the alarm condition). See table 1 on page 3 for alarm point factory settings. 1 . From the alarm setting ...

Page 167

Gx-6000 operator’s manual using maintenance mode • 158 6 . Use ▲air and shift ▼ (panic) to adjust the alarm point or alarm operation (oxygen only) to the desired setting. Keep the following in mind: • alarm 1 cannot be set higher than alarm 2 and alarm 2 cannot be set lower than alarm 1. • in additi...

Page 168

159 • using maintenance mode gx-6000 operator’s manual 1 . From the alarm setting menu, place the cursor next to alarm latching. 2 . Press and release power/enter. The alarm latching screen appears. 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to ...

Page 169

Gx-6000 operator’s manual using maintenance mode • 160 1 . From the main menu, place the cursor next to pump off disp. 2 . Press and release power/enter. The pump off display screen appears. 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to save the...

Page 170

161 • using maintenance mode gx-6000 operator’s manual 3 . Use ▲air or shift ▼ (panic) to move the cursor in front of the desired language. If you do not wish to select a new language, press and release disp/ lock. The unit will return to the main menu. 4 . Press and release power/enter to save the ...

Page 171: Zero Follower Settings

Gx-6000 operator’s manual using maintenance mode • 162 2 . Press and release power/enter. The fresh air adjust screen appears. 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to save the setting and return to the main menu. Updating the demand zero s...

Page 172

163 • using maintenance mode gx-6000 operator’s manual 1 . From the main menu, place the cursor next to ir auto range. 2 . Press and release power/enter. The ir auto range screen appears. 3 . Use ▲air or shift ▼ (panic) to move the cursor in front of the desired setting. 4 . Press and release power/...

Page 173

Gx-6000 operator’s manual using maintenance mode • 164 turning the key tone noise on or off with key tone set to on (factory setting), the instrument will beep every time a button is pressed. With key tone set to off, the instrument will not beep when a button is pressed. 1 . From the main menu, pla...

Page 174

165 • using maintenance mode gx-6000 operator’s manual this setting is factory set to off when a unit is shipped unless the instrument is ordered for bar hole measurement or leak checking use. See and “appendix e: using the gx-6000 in leak check mode” for a discussion of leak check mode. See “append...

Page 175

Gx-6000 operator’s manual using maintenance mode • 166 2 . Press and release power/enter. The co display screen appears. 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . Press and release power/enter to save the setting and return to the main menu. Updating the man down settings t...

Page 176

167 • using maintenance mode gx-6000 operator’s manual updating the panic setting with panic set to on (factory setting), a panic alarm can be manually initiated by holding down the shift ▼ (panic) button. With panic set to off, a panic alarm cannot be manually initiated. See “measuring mode, alarms...

Page 177

Gx-6000 operator’s manual using maintenance mode • 168 4 . Press and release power/enter to save the setting and return to the man down menu screen. Updating the alarm time setting the alarm time is the amount of time that has to pass between a man down detection and the main alarm. It can be set in...

Page 178

169 • using maintenance mode gx-6000 operator’s manual updating the data log interval setting this setting indicates how often the gx-6000 saves readings to the data logger. The following interval times can be selected: 10 minutes, 5 minutes (factory setting), 3 minutes, 2 minutes, 1 minute, 30 seco...

Page 179

Gx-6000 operator’s manual using maintenance mode • 170 returning to the maintenance mode menu 1 . From the log setting screen, place the cursor next to escape. 2 . Press and release power/enter. The instrument will return to the main menu. Adjusting the low flow setpoint if your instrument repeatedl...

Page 180

171 • using maintenance mode gx-6000 operator’s manual 5 . Connect a flow meter with a valve to the inlet of the instrument and adjust it to 0.2 lpm ± 0.1 lpm. This will be the low flow setpoint. You do not need to adjust anything at the instrument. 6 . Press and release the power/enter button to sa...

Page 181

Gx-6000 operator’s manual using maintenance mode • 172 3 . Use ▲air or shift ▼ (panic) to display the desired setting. 4 . If you selected off, press and release power/enter to save the setting and return to the main menu. If you selected on, continue with step 5. 5 . Press and release power/enter. ...

Page 182

173 • using maintenance mode gx-6000 operator’s manual warning: when the gx-6000 is restored to its default configuration, the zero and span values for each channel are reset. You must recalibrate all active channels if you restore the gx-6000 to its default configuration. 1 . From the main menu, pl...

Page 183: Exiting Maintenance Mode

Gx-6000 operator’s manual using maintenance mode • 174 exiting maintenance mode 1 . From the main menu, place the cursor in front of start measure at the bottom of the menu. 2 . Press and release power/enter. 3 . The unit will begin its start-up sequence..

Page 184: Overview

175 • overview gx-6000 operator’s manual appendix b: maintenance mode 2 overview this appendix describes the gx-6000 in maintenance mode 2. The gx-6000 is factory-set to suit most applications. Update settings in maintenance mode 2 only if required for your specific application. A description of the...

Page 185: Using Maintenance Mode 2

Gx-6000 operator’s manual using maintenance mode 2 • 176 using maintenance mode 2 warning: the gx-6000 is not in operation as a gas detector while in maintenance mode 2. 1 . Take the gx-6000 to a non-hazardous location and turn it off if it is on. 2 . Press and hold the ▲air and shift ▼ (panic) butt...

Page 186

177 • using maintenance mode 2 gx-6000 operator’s manual 7 . The appearance of the password screen will be affected by maintenance mode’s password setting but the procedure for entering maintenance mode 2 is unaffected. 8 . Enter the password for maintenance mode 2 by using the ▲air and shift ▼ (pan...

Page 187

Gx-6000 operator’s manual using maintenance mode 2 • 178 10 . The main menu displays. 11 . Use the ▲air or shift ▼ (panic) button to move the cursor up and down through the menu items. Changing the gas combination the gas comb menu item allows you to turn channels on and off. Note: a smart sensor ch...

Page 188: Exiting Maintenance Mode 2

179 • using maintenance mode 2 gx-6000 operator’s manual 5 . If you want to continue with the change, press and release power/ enter to accept the setting. If you want to exit this screen without saving the change, press and release disp/lock to return to the main menu. 6 . Repeat step 3 - step 5 fo...

Page 189: Overview

Gx-6000 operator’s manual overview • 180 appendix c: ess-03 toxic sensors overview the ess-03 sensors are used to monitor levels of a variety of toxic gases. This appendix describes the gx-6000’s ess-03 sensors. It also includes instructions to replace an ess-03 sensor. Table 19 below lists the avai...

Page 190: Interference

181 • interference gx-6000 operator’s manual channel from one type of ess-03 sensor to another and the gx-6000 will automatically load all the sensor parameters and configure the ess-03 channel for the new sensor. See “replacing the ess-03 sensor or changing sensor type” on page 190 for instructions...

Page 191

Gx-6000 operator’s manual start up and normal operation • 182 start up and normal operation for instructions to startup and use a gx-6000 that includes an ess-03 sensor, reference “start up” on page 19, “measuring mode, normal operation” on page 29, and “measuring mode, alarms” on page 36. Follow th...

Page 192: Ess-03 Calibration

183 • ess-03 calibration gx-6000 operator’s manual ess-03 calibration an ess-03 channel can be calibrated using the auto calibration method or the single calibration method. Note: ess-03 calibration must be done with the hose and probe attached. If you are calibrating a chlorine sensor, be sure the ...

Page 193

Gx-6000 operator’s manual ess-03 calibration • 184 2 . When you review the auto calibration values, confirm that the ess-03’s auto calibration gas value matches the calibration cylinder. A. If you need to change an hcn channel’s auto calibration value, the procedure is slightly different since ph 3 ...

Page 194

185 • ess-03 calibration gx-6000 operator’s manual 4 . If you were using a 5-gas (standard 4-gas plus ess-03) calibration cylinder to calibrate the standard 4 sensors, continue to step 5. If you were using a 5-gas (standard 4-gas plus pid) calibration cylinder or a 4-gas calibration cylinder/pid-onl...

Page 195

Gx-6000 operator’s manual ess-03 calibration • 186 7 . Press and release the power/enter button. The first of the gas select screens, the standard four sensors screen, will be displayed. In addition to the standard four sensors screen, there is a separate screen for each installed smart sensor, and ...

Page 196: Hcn

187 • ess-03 calibration gx-6000 operator’s manual 10 . If you are calibrating an hcn sensor, an alternative gas screen will appear. The hcn sensor can be calibrated using hcn or ph 3 . This screen allows you to select which gas you want to use. 11 . Use the ▲air and shift ▼ (panic) buttons to move ...

Page 197: Hcn

Gx-6000 operator’s manual ess-03 calibration • 188 13 . If you are using a 5-gas (standard 4-gas plus ess-03) calibration cylinder, continue with step 14. If you are using an ess-03 only calibration cylinder: a. Connect the tubing from the regulator to the rigid tube on the probe. Allow the gx-6000 ...

Page 198: Hcn

189 • ess-03 calibration gx-6000 operator’s manual if the ess-03 channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the ess-03 sensor failed to calibrate. The buzzer and alarm leds activate in a double pulsing pattern. Press and ...

Page 199: Ess-03 Bump Testing

Gx-6000 operator’s manual ess-03 bump testing • 190 ess-03 bump testing see “performing a bump test” on page 90 for instructions to perform a bump test. Note: rki instruments, inc. Recommends that you dedicate a regulator for use with chlorine (cl 2 ) gas and that you do not use that dedicated regul...

Page 200: Parts List

191 • parts list gx-6000 operator’s manual dummy sensor should be installed in the smart sensor 2 position. See the figure below for the location of the smart sensor 1 and 2 positions. Figure 39: smart sensor positions parts list table 23: ess-03 gx-6000 parts list part number description 80-0006-xx...

Page 201

Gx-6000 operator’s manual parts list • 192 80-0006-xxp-01 sample hose with integral probe, no particle filter, no scrubber section. For use with cl 2 sensor. Replace “xx” with length in feet. 3 foot hose is standard. Available lengths for the gx-6000 are 3, 5, 10, 15, 20, 25, and 30 feet. 80-0172 pr...

Page 202: Overview

193 • overview gx-6000 operator’s manual appendix d: infrared sensors overview the infrared sensors are used to monitor levels of methane, combustible gas, and carbon dioxide. This appendix describes the gx-6000’s infrared sensors and includes instructions to use a gx-6000 that has one or more infra...

Page 203: Description

Gx-6000 operator’s manual description • 194 the infrared methane sensor is known to respond to the following combustible gases: • acetone • ethane • ethanol • hexane • ipa • isobutane • mek • methanol • propane • styrene • toluene the infrared methane sensor is known to not or to poorly respond to t...

Page 204: Scrubber

195 • description gx-6000 operator’s manual co 2 scrubber a carbon dioxide scrubber is factory-shipped with gx-6000s that have an ir co 2 sensor installed. The scrubber is for use when setting the carbon dioxide sensor’s zero reading only. A single piece of tubing connects both ends of the scrubber ...

Page 205: Ir Ch

Gx-6000 operator’s manual ir hc start up and normal operation • 196 ir hc start up and normal operation for instructions to startup and use a gx-6000 that includes an infrared hydrocarbon sensor, reference “start up” on page 19, “measuring mode, normal operation” on page 29, and “measuring mode, ala...

Page 206: Ir Co

197 • ir co 2 start up and normal operation gx-6000 operator’s manual ir co 2 start up and normal operation for instructions to startup and use a gx-6000 that includes an infrared co 2 sensor, reference “start up” on page 19, “measuring mode, normal operation” on page 29, and “measuring mode, alarms...

Page 207

Gx-6000 operator’s manual ir co 2 start up and normal operation • 198 2 . Connect the tubing to the gx-6000’s inlet fitting. Be sure the arrow on the filter is pointing toward the inlet fitting. Figure 42: co2 scrubber connected to gx-6000 3 . Wait one minute for the fresh air sample to flow through...

Page 208: Ir Calibration

199 • ir calibration gx-6000 operator’s manual 7 . Remove the co 2 scrubber from the voc zero filter. Be sure the voc zero filter’s tubing stays on the voc zero filter. 8 . Reattach the co 2 scrubber’s tubing to the open end of the scrubber. 9 . Remove the voc zero filter from the gx-6000’s inlet fi...

Page 209: Replacing An Ir Sensor

Gx-6000 operator’s manual replacing an ir sensor • 200 replacing an ir sensor when replacing a sensor, you may either replace it with another of the same sensor or you may install a different ir sensor. If a different one is installed, the gx-6000 will load the sensor parameters and configure the ir...

Page 210: Parts List

201 • parts list gx-6000 operator’s manual figure 44: smart sensor positions parts list table 27: infrared sensors parts list part number description 33-6015rk co 2 scrubber 33-6092 voc zero filter, charcoal, with tubing stubs and plugs (for instruments that include an ir co 2 sensor and a pid senso...

Page 211

Gx-6000 operator’s manual parts list • 202 81-0018rk-01 calibration cylinder, 50 %lel isobutane in air, 34 liter steel 81-0018rk-03 calibration cylinder, 50 %lel isobutane in air, 103 liter steel 81-0019rk calibration cylinder, 10 %vol isobutane in nitrogen, 17 liter steel 81-0071rk-01 calibration c...

Page 212: Overview

203 • overview gx-6000 operator’s manual appendix e: using the gx-6000 in leak check mode overview this chapter explains how to operate the gx-6000 in leak check mode. Leak check mode is used to pinpoint small leaks of combustible gas from valves, flanges, connections, and other potential leak point...

Page 213

Gx-6000 operator’s manual start up, leak check mode • 204 gx-6000’s quick connect inlet fitting. 2 . Press and briefly hold down the power/enter button. Release the button when you hear a beep. The normal mode select screen displays. 3 . Use the ▲air or shift ▼ (panic) button to scroll to the leak c...

Page 214: Ch4

205 • start up, leak check mode gx-6000 operator’s manual c. If the catalytic combustible sensor fails, it is not possible to enter leak check mode. Press and release the reset button to acknowledge the failure and return to the normal mode select screen. Replace the failed sensor. If any other sens...

Page 215: Leak Testing

Gx-6000 operator’s manual leak testing • 206 3 . Press and hold the ▲air button. The display prompts you to hold the ▲ air button. 4 . Continue to hold the ▲air button until the display prompts you to release it. The gx-6000 will set the fresh air reading for the ch 4 channel. Start up is complete a...

Page 216: Locating A Leak

207 • leak testing gx-6000 operator’s manual check mode even if you enter normal mode and return to leak check mode or turn the unit off and on unless the buzzer is manually turned on. To turn the buzzer off or on while in leak check mode: 1 . Press and hold the shift ▼ (panic) and reset buttons for...

Page 217: Peak Hold Mode

Gx-6000 operator’s manual leak testing • 208 peak hold mode peak hold mode allows the user to view the peak methane reading for the operating session while viewing the current methane reading. To enter peak hold mode: 1. Turn the gx-6000 on as described in “turning on the gx-6000, leak check mode” o...

Page 218: Ch4

209 • leak testing gx-6000 operator’s manual 3 . Press and hold the shift ▼ (panic) button, then press and hold the ▲air button and hold both until you hear a beep. The station id select screen will display and the current station id will be in the middle of the screen. 4. To exit snap log mode and ...

Page 219: Ch4

Gx-6000 operator’s manual leak testing • 210 button. 8. In order to get a base, or background, reading, take the instrument a few feet away from where you intend to test. To save the base reading, press and release the power/enter button. Note: if the gas concentration exceeds the display range valu...

Page 220

211 • leak testing gx-6000 operator’s manual note: if the gas concentration exceeds the display range without exceeding 5000 ppm, “over” will be displayed but the actual gas reading at that time will be recorded when you press and release power/enter. For example, if the display range is 500 ppm but...

Page 221

Gx-6000 operator’s manual leak testing • 212 3 . If snap logs have been taken, the screen indicates the year, month, day, and time that the most recent snap log was taken. The number near the bottom of the screen indicates the snap log id number. The first snap log that is taken is given an id of 00...

Page 222: Ch4

213 • leak testing gx-6000 operator’s manual 4:07 ch4 f . S . 1000 ppm 5000 ppm peak rec data date 5/20/2015 mm/dd/yyyy 3:47 number 003 tank 5 rec data date 5/20/2015 mm/dd/yyyy 3:45 number 002 tank 5 rec data date 5/20/2015 mm/dd/yyyy 3:40 number 001 tank 5 4:07 ch4 f . S . 100 ppm 5000 ppm base re...

Page 223

Gx-6000 operator’s manual leak testing • 214 snap log data that was taken in leak check mode operation will have 2 sequential screens that are part of one data set. One screen is for the base reading and the other screen is for the peak reading. “base” and “peak” will appear in the gas reading scree...

Page 224: Overview

215 • overview gx-6000 operator’s manual appendix f: using the gx-6000 in bar hole mode overview this chapter explains how to operate the gx-6000 in bar hole mode. Bar hole mode is used to perform consistent checks of bar holes when tracking down underground gas leaks. When the gx-6000 is in bar hol...

Page 225: Start Up, Bar Hole Mode

Gx-6000 operator’s manual start up, bar hole mode • 216 start up, bar hole mode this section explains how to start up the gx-6000 in bar hole mode and get it ready for operation. Turning on the gx-6000, bar hole mode warning: gas alarms are not active when the gx-6000 is in bar hole mode. Caution: i...

Page 226

217 • start up, bar hole mode gx-6000 operator’s manual 3 . Use the ▲air or shift ▼ (panic) button to scroll to the bar hole mode select screen. 4 . With the bar hole mode select screen displayed, press and release the power/enter button to begin the bar hole mode startup sequence. Note: if no butto...

Page 227: Ch4

Gx-6000 operator’s manual start up, bar hole mode • 218 6 . The gx-6000 is now operating in bar hole mode. The pump is off and the following screen appears. The combustible gas and oxygen channels are displayed along with the battery charge level and station id. Note: if the oxygen sensor fails or i...

Page 228: Bar Hole Testing

219 • bar hole testing gx-6000 operator’s manual bar hole testing in bar hole mode, the you can initiate sampling for a fixed time period to monitor for combustible gas and oxygen in a bar hole. The factory set time is 30 seconds. To change the bar hole sampling time, see “setting the bar hole measu...

Page 229: Ch4

Gx-6000 operator’s manual bar hole testing • 220 3 . Use the ▲air and shift ▼ (panic) buttons to scroll to the desired station id and press and release power/enter. The unit will return to the bar hole measuring screen. 4 . Take the gx-6000 to the bar hole that will be tested. 5 . Insert the probe i...

Page 230: Ch4

221 • bar hole testing gx-6000 operator’s manual 6 . At the end of the sample period, the pump will shut off and the buzzer will sound, then the peak combustible gas reading and the minimum oxygen reading for the sample period will be displayed. The peak combustible gas reading will also be visually...

Page 231: Ch4

Gx-6000 operator’s manual bar hole testing • 222 • when the purge is complete, the screen will return to the initial bar hole mode screen. 8 . If other bar holes will be tested, proceed to the next bar hole and repeat steps step 5 - step 7. 9 . To cancel a bar hole measurement or fresh air purge tha...

Page 232: Alarms

223 • alarms gx-6000 operator’s manual appendix g: using the gx-6000 in inert mode inert mode is used to measure the combustible gas and/or oxygen level in a purged environment. In order for the instrument to operate in inert mode, the oxygen alarm must be set to h-hh operation meaning that both ala...

Page 233: Start Up And Operation

Gx-6000 operator’s manual start up and operation • 224 note: if inert mode is set to off in maintenance mode, the inert item will not appear in the alarm points menu. 2 . Select inert (not o2) in order to view or change inert mode’s oxygen alarm points. Start up and operation 1 . Connect the tapered...

Page 234: Voc

225 • start up and operation gx-6000 operator’s manual note: if no button is pressed for 20 seconds, the unit will proceed into whichever mode is displayed. 5 . The warm-up will proceed as described in “turning on the gx-6000” on page 19. 6 . Once the warm-up sequence has finished, the instrument wi...

Page 235: Overview

Gx-6000 operator’s manual overview • 226 appendix h: 10.0 ev/benzene pid sensor overview this appendix describes the gx-6000’s 10.0 ev/benzene sensor (rki part number pid-003l). The 10.0 ev/benzene pid sensor detects vocs in the 0-100.00 ppm range when used in measuring mode. It is optimized for ben...

Page 236: Sensor Description

227 • sensor description gx-6000 operator’s manual sensor description the pid sensor is a cylindrical sensor with a diffusion opening on the front and 3 pins on the back. It is installed in a white housing that has three sockets on the bottom that mate with the gx-6000 instrument. The pid sensor mus...

Page 237: Tube Holder

Gx-6000 operator’s manual start up • 228 tube holder the tube holder attaches to the gx-6000’s inlet fitting. It has a breakaway feature ensuring that the gx-6000 will not be damaged by hitting the tube holder on something when it is installed. The tube holder should only be used in benzene select m...

Page 238: Display Mode

229 • display mode gx-6000 operator’s manual display mode display mode for a 10.0 ev/benzene pid instrument appears and functions as described in “display mode” on page 43 with the following exceptions: • a benzene select mode screen is now the first item in display mode. Benzene select mode is desc...

Page 239: Measuring Mode

Gx-6000 operator’s manual measuring mode • 230 measuring mode the 10.0 ev/benzene sensor detects vocs in the 0-100.00 ppm range in measuring mode. See “measuring mode, normal operation” on page 29 for a complete description of measuring mode. If the 10.0 ev/benzene pid sensor is one of two pid senso...

Page 240

231 • benzene select mode gx-6000 operator’s manual 1 . Enter display mode by pressing the disp/lock button while in measuring mode. The benzene select mode screen appears. 2 . Press and release the power/enter button to enter benzene select mode. 3 . The pump will stop and the instrument will promp...

Page 241: Bnz