- DL manuals

- Saeco

- Coffee Maker

- Syntia

- Service Manual

Saeco Syntia Service Manual - Chapter 4

Summary of Syntia

Page 1

Syntia service manual revision 01 february 2010 all parts of this document are the property of saeco international group. All rights reserved. This document and all the information herein is provided without liability deriving from any errors or omissions. Furthermore, no part may be reproduced, use...

Page 2: Table of Contents

Page 1. Introduction 1.1 documentation required 1 1.2 tools and equipment required 1 1.3 material 1 1.4 safety warnings 1 1.5 xsmall range 2 1.6.1 external machine parts 3 1.6.2 internal machine parts 4 2. Technical specifications 2.1 technical specifications 1 2.2 machine parameters and performance...

Page 3: Table of Contents

Table of contents page 5. Service mode rev.01 5.1.1 digital test mode 1 5.1.2 focus test mode 5 5.2. Error codes 7 6. Service & maintenance 6.1 repair schedule 1 6.2 service schedule 1 6.3 final test 2 7. Disassembly rev.01 7.1 outer elements disassembly 1 7.2 coffee spout disassembly 2 7.3.1 disass...

Page 4: Chapter 1

Saeco international group rev.01 february 2010 syntia chapter 1 introduction.

Page 5

Syntia 01 introduction saeco international group rev.01 february 2010 page 1 / 04 1.1 documentation required the following documentation is needed for repair procedures: instruction booklet for specific model • technical documentation for specific model (diagrams, exploded drawings) • 1.2 tools and ...

Page 6

Syntia 01 introduction saeco international group rev.01 february 2010 page 2 / 04 1.5. Syntia range syntia dgt syntia focus display interface x led interface x painted details x x water/steam valve x x alarm led x x automatic rinse x x automatic dosage x x frother x x dispensed coffee memory capacit...

Page 7

Syntia 01 introduction saeco international group rev.01 february 2010 page 3 / 04 1.6.1 external machine parts 03 grinding adjustment knob pre-ground coffee compartment coffee bean container cover cup rack grounds drawer service hatch brew group drip tray full indicator dispensing pipe protection ho...

Page 8

Syntia 01 introduction saeco international group rev.01 february 2010 page 4 / 04 1.6.2 internal machine parts boiler insulation and boiler coffee grinder side door microswitch coffee grinder motor pwr/cpu card temperature sensor pump water level sensor.

Page 9: Chapter 2

Saeco international group rev.01 february 2010 syntia chapter 2 technical specifications.

Page 10

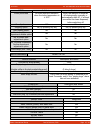

Syntia 02 technical specifications saeco international group rev.01 february 2010 page / 02 2.1. Technical specifications 2.2. Machine parameters and performance power supply and output: 240 v~ 50 hz 1400 w - 230 v~ 50/60 hz 1400 w - 120 v~ 60 hz 1500 w - 100 v~ 50/60 hz 1300 w temperature monitorin...

Page 11

Syntia 02 technical specifications saeco international group rev.01 february 2010 page / 02 rinse initial rinse final rinse when performed at coffee machine activation when the boiler temperature is ≤ 50°c when the machine is switched off electronically, manually or automatically after 60', if at le...

Page 12: Chapter 3

Saeco international group rev.01 february 2010 syntia chapter 3 brief instructions rev.01 february 2010

Page 13

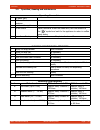

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 1 / 07 3.1. Customer and programming menu indications causes solutions machine at correct temperature - for coffee bean dispensing - for hot water dispensing proceed with the dispensing process machine at correct temper...

Page 14

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 2 / 07 ok - indications causes solutions machine in pre-heating phase for coffee, hot water and steam dispensing. Wait until heated (see bar) the appliance is rinsing - wait until end of operation wait until end of oper...

Page 15

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 3 / 07 indications causes solutions descaling cycle (press the aroma/pre-ground coffee key for 5 sec) 1) pour the descaler into the water tank 6) open the hot water valve 2) open the hot water valve 7) rinsing in progre...

Page 16

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 4 / 07 menu (commands and programming) you can go to the programming menu only in “stand-by” mode press the on/off button to put the machine in stand-by. Stand-by. When the machine is in stand-by, press the button “ “ t...

Page 17

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 5 / 07 indications status causes solutions fixed fixed machine at correct temperature - for coffee bean dispensing - for hot water dispensing proceed with the dispensing process fixed fixed machine at correct temperatur...

Page 18

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 6 / 07 notice signals segnali di allarme indications status causes solutions blinking machine in alarm status - put the hot water/steam tap knob back in the correct position - the brew group is not inserted - close the ...

Page 19

Syntia 03 brief instructions saeco international group rev.01 february 2010 page 7 / 07 3.2. Operation, cleaning and maintenance cleaning and technical servicing a empty the dregs drawer when indicated b empty the drip tray as necessary c clean the water tank weekly d clean the coffee bean container...

Page 20: Chapter 4

Saeco international group rev.01 february 2010 syntia chapter 4 operating logic.

Page 21

Syntia 04 operating logic saeco international group rev.01 february 2010 page / 06 4.1. Water circuit compensation valve 16/18 bar steam hose connection steam hose compensation valve water outlet turbine 1400 w boiler to brewi ng uni t water tank rapid connection steam valve pump traditional water s...

Page 22

Syntia 04 operating logic saeco international group rev.01 february 2010 page / 06 4.2. Control ringnut and valve no description 1 mushroom valve cap 2 spring for mushroom valve 3 mushroom valve support 4 mushroom valve 5 sealing or 1 2 3 4 5 when dispensing coffee the mushroom valve opens at 4 bar ...

Page 23

Syntia 04 operating logic saeco international group rev.01 february 2010 page / 06 notes: * only with pre-brewing 4.3. Coffee cycle operating diagram ms status off single microswitch gear motor on switching on when the machine is switched on, the gear motor repositions itself as follows: - it acts o...

Page 24

Syntia 04 operating logic saeco international group rev.01 february 2010 page / 06 temperature sensor an ntc is used as a temperature sensor; in the event of overheating this reduces boiler ele- ment power consumption. The electronic system detects the current boiler temperature from the drop in vol...

Page 25

Syntia 04 operating logic saeco international group rev.01 february 2010 page / 06 4.6. Coffee grinder function 2 3 4 5 6 1 4.7. Low bean level detection, dose quantity adjustment, coffee grinder blocked t1 v t2 t3 t4 t without beans n=100% with beans n=100% without beans n=50% with beans n=50% cera...

Page 26

Syntia 04 operating logic saeco international group rev.01 february 2010 page / 06 06 4.8 dose self-learning (sas) the aim of this function is to automatically regulate the average dose of ground coffee (self- learning); this occurs by means of an algorithm based on three pieces of information detec...

Page 27: Chapter 5

Saeco international group rev.01 february 2010 syntia chapter 5 service mode rev.01 february 2010

Page 28

Syntia 05 service mode saeco international group rev.01 february 2010 page 1 / 07 5.1. Digital test mode to enter test mode place the control knob in the water position 1. Keep the espresso coffee key pressed 2. Switch the appliance on from the 0/i button 3. Located at the rear of it release the esp...

Page 29

Syntia 05 service mode saeco international group rev.01 february 2010 page 2 / 07 lev. Pos. Knob display key function notes l2 initial condition: unit inserted, dregs drawer inserted, water tank full, side door closed, control knob in coffee position. Remove water tank tank-h2o display changes from ...

Page 30

Syntia 05 service mode saeco international group rev.01 february 2010 page 3 / 07 lev. Pos. Knob display key function notes l3 initial status with no keys pressed bring the unit to the “work” position cur= --- indicates the gearmotor absorption; this value must be: without brewing unit inserted lowe...

Page 31

Syntia 05 service mode saeco international group rev.01 february 2010 page 4 / 07 lev. Pos. Knob display key function notes l4 initial status with no keys pressed and valve in water position water supplied by the steam hose: the number indicating flow meter pulses (imp) must increase. L/h must be be...

Page 32

Syntia 05 service mode saeco international group rev.01 february 2010 page 5 / 07 5.1.2 focus test mode lev. Pos. Knob symbol button status press function l1 initial led status at level 1 if the screen does not change from the initial status, replace the interface card and/or the jp21 flat cable. Pr...

Page 33

Syntia 05 service mode saeco international group rev.01 february 2010 page 6 / 07 boiler lev. Pos. Knob symbol status press function l5 if the symbol appears, the boiler sensor is interrupted. Check the boiler sensor wiring and/or the connection on the cpu/power card (jp13) if the the current absorp...

Page 34

Syntia 05 service mode saeco international group rev.01 february 2010 page 7 / 07 error codes description 01 the grinder is blocked (burrs jammed or sensor not reading properly) 03 the brewing unit is blocked in work position (microswitch not released in up position after 3", torque error trying to ...

Page 35: Chapter 6

Saeco international group rev.01 february 2010 syntia chapter 6 servicing and maintenance.

Page 36

Syntia 06 servicing and maintenance saeco international group rev.01 february 2010 page 1 / 02 action 1 visual inspection (transport damage) 2 machine data check (rating plate) 3 operational check / problem analysis 4 opening machine 5 visual inspection 6 operational tests 7 repairing the faults enc...

Page 37

Syntia 06 servicing and maintenance saeco international group rev.01 february 2010 page 2 / 02 test procedure support/tool standard tolerance espresso 2-3 espressos for adjustment purposes measuring beaker same amount 15% coffee 2-3 coffees for adjustment purposes measuring beaker same amount 15% no...

Page 38: Chapter 7

Saeco international group rev.01 february 2010 syntia chapter 7 disassembly rev.01 february 2010

Page 39

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 disassembling the top cover 1) remove the grounds drawer, water tank, coffee container lid, drip tray, brewing unit, steam wand covering cap, pannarello and control knob cover 2) unscrew the screws shown and remove the fi...

Page 40

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 1) unscrew the screw shown 2) slide out the fork clip 3) unscrew the screws shown and remove the support 4) coffee dispenser assembly parts disassembling the rear cover unscrew the screws shown disassembling the side door...

Page 41

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 1) unscrew the screw shown, remove the lid, glass, frame, keypad and seal 2) release the display support 3) unscrew the screws shown and remove the spring washer 4) parts 5) release the control knob circuit board 6) relea...

Page 42

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 1) loosen the screw shown and remove the card protection 2) slide out the card, removing all connections 1 2 7.5. Gearmotor disassembly 2 a b d e f c 4 h l 3 b p 1 1) loosen the screws holding the boiler pin in place, rem...

Page 43

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 1) remove the coffee grinder noise reduction cover 2) remove the boiler insulation 3) unscrew the screws shown 4) loosen the screw and remove the plastic support. Disconnect the hoses and the connections 7.6. Boiler disas...

Page 44

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 6) remove the screws shown to remove the insert on the base of the casing 7) remove the screws shown and disconnect the valve from the water connections 7) remove the screws shown and disconnect the valve from the mesh ho...

Page 45

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 1) boiler connection 2) other connections replacing the hoses 1) use a suitable pair of pliers to remove the clamp (as illustrated) 2) tighten the clamp as illustrated 7.9. Oetiker clamps assembly and disassembly 1 1 2 2 ...

Page 46

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 1) to remove the coffee grinder, simply slide it out and remove its connections 2) when replacing it, make sure the spring (a) and the coffee pipe (b) are positioned correctly 7.10. Coffee grinder disassembly 1 2 a b 08.

Page 47

Syntia 07 disassembly saeco international group rev.01 february 2010 page / 09 7.11. Grinder adjustment/assembly and disassembly 1) to remove the upper grinder support, using a hex key push down and turn clockwise to release the grinder support from the bayonet coupling 2) to remove the grinder blad...

Page 48: Chapter 8

Saeco international group rev.01 february 2010 syntia chapter 8 notes.

Page 49

Syntia 08 notes saeco international group rev.01 february 2010 page / 01 01.

Page 50: Chapter 9

Saeco international group rev.01 february 2010 syntia chapter 9 water circuit diagram.

Page 51

Syntia 09 water circuit diagram saeco international group rev.01 february 2010 page / 01 9.1. Water circuit diagram steam tube pipe fit ting rac cor do tubo vapor e sili cone tube - tubo sili cone 5x10 9972.176 (130mm) sili cone tube - tubo sili cone 5x10 9912.122 (290mm) sili cone tube - tubo sili ...

Page 52: Chapter 10

Saeco international group rev.01 february 2010 syntia chapter 10 electrical diagram.

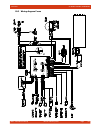

Page 53

Syntia 10 electrical diagram saeco international group rev.01 february 2010 page / 01 10.1 wiring diagram digital 01.

Page 54

Syntia 10 electrical diagram saeco international group rev.01 february 2010 page / 01 10.2 wiring diagram focus.