- DL manuals

- Saeco

- Coffee Maker

- Xsmall Plus

- Service Manual

Saeco Xsmall Plus Service Manual

XSMALL

SERVICE MANUAL

Revision 00

All parts of this document are the property of Saeco International Group. All rights reserved.

This document and all the information herein is provided without liability deriving from any

errors or omissions. Furthermore, no part may be reproduced, used or collected, except

where express authorisation has been provided in writing or through a contractual agreement.

Saeco Int.

Rev. 00 / Jul. 2008

XSMALL

Summary of Xsmall Plus

Page 1

Xsmall service manual revision 00 all parts of this document are the property of saeco international group. All rights reserved. This document and all the information herein is provided without liability deriving from any errors or omissions. Furthermore, no part may be reproduced, used or collected...

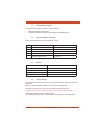

Page 2: Contents

Saeco int. Rev. 00 / aug. 2008 xsmalll page 1. Introduction 1.1 documentation required 1 1.2 tools and equipment required 1 1.3 material 1 1.4 safety warnings 1 1.5 xsmall range 2 1.6.1 external machine parts 3 1.6.2 internal machine parts 4 2. Technical specifi cations 2.1 technical speci fi cation...

Page 3: Contents

Saeco int. Rev. 00 / jul. 2008 xsmall contents next 5. Troubleshooting 5.1. Test mode 1 5.2. Draining the boiler (steam out) 2 6. Servicing & maintenance 6.1 repair schedule 1 6.2 service schedule 1 6.3 final test 2 7. Disassembly 7.1 disassembling the outer elements 1 7.2 disassembling the electron...

Page 4: Chapter 1

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 1 introduction.

Page 5

Xsmall 01 introduction saeco int. Rev. 00 / jul. 2008 page 1 / 4 1.1 documentation required the following documentation is needed for repair procedures: instruction booklet for speci fi c model. • technical documentation for speci fi c model (diagrams, exploded drawings). • 1.2 tools and equipment r...

Page 6

Page 2 / 4 rev. 00 / jul. 2008 saeco int. 01 introduction xsmall 1.5. Xsmall range xsmall plus xsmall steam painted details x water/steam valve x x alarm led x x automatic rinse x x automatic dosage x x frother x dispensed coffee memory capacity x x automatic shutdown (after 60’ inactivity) x x xsma...

Page 7

Xsmall 01 introduction saeco int. Rev. 00 / jul. 2008 page 3 / 4 15 18 17 24 1.6.1 external machine parts coffee bean tank lid coffee bean tank dreg drawer coffee dispenser cup rack drip tray full indicator drip tray brewing unit service hatch 13 water tank hot water/steam dispensing hose steam hose...

Page 8

Page 4 / 4 rev. 00 / jul. 2008 saeco int. 01 introduction xsmall 1.6.2 internal machine parts turbine pump boiler pw/cpu p.C.B. Power cable connector valve coffee grinder motor coffee grinder.

Page 9: Chapter 2

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 2 technical specifications.

Page 10

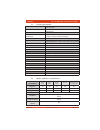

Saeco int. Rev. 00 / jul. 2008 page 1 / 4 xsmall 02 technical specifications 2.1. Technical specifi cations 2.2. Machine parameters and performance power supply and output: 230 v~ 50/60 hz 1500 w - 120 v~ 60 hz 1500 w - 100 v~ 50/60 hz 1300 w temperature monitoring: variable resistor sensor (ntc) - ...

Page 11

Page 2 / 4 rev. 00 / jul. 2008 saeco int. 02 technical specifications xsmall rinse initial rinse final rinse when performed when the coffee maker is activated when the boiler temperature is ≤ 50°c when the machine is switched off electronically, manually or auto- matically after 60’, if at least one...

Page 12: Chapter 3

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 3 brief instructions.

Page 13

Xsmall 03 brief instructions saeco int. Rev. 00 / jul. 2008 page 1 / 3 indications causes solutions fixed machine at correct temperature - for coffee dispensing - for hot water dispensing - for steam dispensing blinks slowly machine in pre-heating phase for coffee, hot water and steam dispensing. Bl...

Page 14

Page 2 / 3 rev. 00 / jul. 2008 saeco int. 03 brief instructions xsmall indications causes solutions fixed coffee bean container empty dreg drawer full fill the coffee bean tank. Empty the dreg drawer while the machine is switched on. If the drawer is emptied before the indication appears and the dra...

Page 15

Xsmall 03 brief instructions saeco int. Rev. 00 / jul. 2008 page 3 / 3 3.2. Operation, cleaning and maintenance cleaning and technical servicing a empty the coffee dreg drawer when indicated b empty the drip tray as necessary or when indicated c clean the water tank weekly d clean the coffee bean co...

Page 16: Chapter 4

Saeco int. Rev. 0 / jul. 2008 xsmall chapter 4 operating logic.

Page 17

Saeco int. Rev. 00 / jul. 2008 page 1 / 6 xsmall 04 operating logic 4.1. Water circuit boiler turbine brewing unit coffee dispenser water collection tank pump compensation valve water tank w ater / steam control ringnut presblock valve compensation valve 16/18 bar steam hose connection steam hose co...

Page 18

Page 2 / 6 rev. 00 / jul. 2008 saeco int. 04 operating logic xsmall 4.2. Control ringnut and valve no. Description 1 mushroom valve cap 2 spring for mushroom valve 3 mushroom valve support 4 mushroom valve 5 sealing or 1 2 3 4 5 closed for coffee when dispensing coffee the mushroom valve opens at 4 ...

Page 19

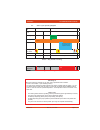

Saeco int. Rev. 00 / jul. 2008 page 3 / 6 xsmall 04 operating logic 4.3. Coffee cycle operating diagram main switch on start stop time coffee grinder heating pump brewing unit gear motor status heating ready coffee cycle approx. 45 secs. Pulses (dosage) pump operation (tur- bine pulses) in accord- a...

Page 20

Page 4 / 6 rev. 00 / jul. 2008 saeco int. 04 operating logic xsmall temperature sensor an ntc is used as a temperature sensor; in the event of overheating this reduces resistor consumption. The electronic system detects the current boiler temperature from the drop in voltage and adjusts it according...

Page 21

Saeco int. Rev. 00 / jul. 2008 page 5 / 6 xsmall 04 operating logic 4.6. Coffee grinder function ceramic coffee grinder the coffee grinder is driven by a direct current motor (1) using a worm screw helicoidal wheel transmission (2). The worm screw (2) drives a plastic gear wheel (3), which turns the...

Page 22

Page 6 / 6 rev. 00 / jul. 2008 saeco int. 04 operating logic xsmall 4.8 dose self-learning the aim of this modi fi cation process is to ensure that, with an algorithm based on three pieces of information (listed below) detected by the machine p.C.B., the average dose is adjusted automatically (self-...

Page 23: Chapter 5

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 5 troubleshooting.

Page 24

Saeco int. Rev. 00 / jul. 2008 page 1 / 2 xsmall 05 test mode 5.1. Test mode to enter test mode, proceed as follows: make sure the machine is unplugged. - turn the selector to the water position and press and hold the espresso coffee key while you plug the machine in. Con fi rmation that the machine...

Page 25

Page 2 / 2 rev. 00 / jul. 2008 saeco int. 05 test mode xsmall lev. Pos. Selector led key function notes l1 on brewing unit microswitch gear motor rises (brewing unit in work position) on brewing unit microswitch gear motor falls (brewing unit in home position) off power con- sumption of the unit in ...

Page 26: Chapter 6

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 6 servicing & maintenance.

Page 27

Saeco int. Rev. 00 / jul. 2008 page 1 / 2 xsmall 06 servicing xx maintenance action 1 visual inspection (transport damage) 2 machine data check (rating plate) 3 operational check / problem analysis 4 opening machine 5 visual inspection 6 operational tests 7 repairing the faults encountered 8 checkin...

Page 28

Page 2 / 2 rev. 00 / jul. 2008 saeco int. 06 servicing xx maintenance xsmall test procedure support/ tool standard tolerance espresso 2-3 espressos for adjustment purposes measuring beaker same amount 15% coffee 2-3 coffees for adjustment purposes measuring beaker same amount 15% noise standard amou...

Page 29: Chapter 7

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 7 disassembly.

Page 30

Saeco int. Rev. 00 / jul. 2008 page 1 / 9 xsmall 07 disassembly 7.1. Disassembling the outer elements disassembling the top cover 1/2) remove the dreg drawer, water tank, mushroom fi nger protection device on the coffee container lid and coffee container, then loosen the screws shown. 3/4 ) slide ou...

Page 31

Page 2 / 9 rev. 00 / jul. 2008 saeco int. 07 disassembly xsmall disassembling the hatch 1 ) detach the hatch by pressing the fastenings. 2 ) lift the fastenings shown. 3 ) slot for pins. 1 2 3 disassembling the power p.C.B. 1 ) loosen the screw shown and remove the p.C.B. Protection. 2 ) slide out t...

Page 32

Saeco int. Rev. 00 / jul. 2008 page 3 / 9 xsmall 07 disassembly disassembling the boiler pin 1 ) loosen the screws shown and remove the boiler pin. 7.4. Disassembling the boiler pin 7.3. Disassembling the control knob and coffee keys disassembling the top cover to remove the coffee keys from the con...

Page 33

Page 4 / 9 rev. 00 / jul. 2008 saeco int. 07 disassembly xsmall 7.5. Gear motor gear motor 1 ) loosen the screws holding the boiler pin in place, remove it and loosen the other screws shown. 2 ) the following are located inside the compartment protected by the casing: - electric motor (a) with gears...

Page 34

Saeco int. Rev. 00 / jul. 2008 page 5 / 9 xsmall 07 disassembly 1 ) remove the boiler pin. 2 ) remove the boiler. 3 ) remove the gear. 4 ) loosen the screws shown. 7.6. Disassembling the boiler 7.7. Disassembling the valve 1 ) loosen the screws shown. 2 ) loosen the screw and remove the plastic supp...

Page 35

Page 6 / 9 rev. 00 / jul. 2008 saeco int. 07 disassembly xsmall 7.8. Disassembling the pump and turbine slide out the support as shown. Remove connection 1 , slide out the silicone hoses. To prevent annoying vibrations when reassembling the pump, take extra care when positioning spring 2 . At this p...

Page 36

Saeco int. Rev. 00 / jul. 2008 page 7 / 9 xsmall 07 disassembly 1) boiler connection. 2) other connections. Replacing the hoses 1) use a suitable pair of pliers to remove the clamp (as illustrated). 2) tighten the clamp as illustrated. 7.10. Fitting and removing oetiker clamps 1 1 2 2.

Page 37

Page 8 / 9 rev. 00 / jul. 2008 saeco int. 07 disassembly xsmall 1) to remove the coffee grinder, simply slide it out and remove its connections. 2) when replacing it, make sure the spring (a) and the coffee pipe (b) are positioned correctly. 7.11. Disassembling the coffee grinder 1 2 a b.

Page 38

Saeco int. Rev. 00 / jul. 2008 page 9 / 9 xsmall 07 disassembly 1) to remove the upper grinder support, use a hex key to exert pressure, turning it clockwise in order to release the grinder support from the bayonet coupling. 2) to remove the grinder from the upper support, turn it anti-clockwise unt...

Page 39: Chapter 9

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 9 water circuit diagram.

Page 40

9.1. Water circuit diagram.

Page 41: Chapter 10

Saeco int. Rev. 00 / jul. 2008 xsmall chapter 10 electrical diagram.

Page 42

10.1 wiring diagram.