- DL manuals

- Samson

- Control Unit

- 3222/2780 series

- Mounting And Operating Instructions

Samson 3222/2780 series Mounting And Operating Instructions

Mounting and

Operating Instructions

EB 5866 EN

Tr

anslat

ion of original instruct

ions

Edition July 2016

Type 3222/5857

Type 3222/5757-3

Type 3222/5757-7

Type 3222/5825

Type 3222/5725-7

Type 3222/2780-1

Type 3222/2780-2 with Type 3760

Positioner

Electric Control Valves

Types 3222/5857, 3222/5824, 3222/5825, 3222/5757-3,

3222/5757-7, 3222/5724-3, 3222/5724-8, 3222/5725-3,

3222/5725-7, 3222/5725-8

Pneumatic Control Valves

Type 3222/2780

Summary of 3222/2780 series

Page 1

Mounting and operating instructions eb 5866 en tr anslat ion of original instruct ions edition july 2016 type 3222/5857 type 3222/5757-3 type 3222/5757-7 type 3222/5825 type 3222/5725-7 type 3222/2780-1 type 3222/2780-2 with type 3760 positioner electric control valves types 3222/5857, 3222/5824, 32...

Page 2

2 eb 5866 en note on these mounting and operating instructions these mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling samson devices. Î for the safe and proper use of these instructions, read them carefully and keep...

Page 3

Contents eb 5866 en 3 1 safety instructions and measures ...................................................................5 1.1 notes on possible severe personal injury .........................................................8 1.2 notes on possible personal injury ...................................

Page 4

4 eb 5866 en contents 8 malfunctions ...............................................................................................31 8.1 troubleshooting ...........................................................................................31 8.2 emergency action .................................

Page 5

Eb 5866 en 5 safety instructions and measures 1 safety instructions and measures intended use the samson type 3222 valve is designed for use in temperature control circuits in hvac plants (e.G. For dhw heating). The valve is primarily combined with the following samson actuators: − as electric contr...

Page 6

6 eb 5866 en safety instructions and measures qualifications of operating personnel the control valve must be mounted, started up, serviced, and repaired by fully trained and qualified personnel only; the accepted industry codes and practices are to be observed. Ac- cording to these mounting and ope...

Page 7

Eb 5866 en 7 safety instructions and measures responsibilities of the operator the operator is responsible for proper operation and compliance with the safety regulations. Operators are obliged to provide these mounting and operating instructions as well as the referenced documents to the operating ...

Page 8

8 eb 5866 en safety instructions and measures 1.1 notes on possible severe personal injury danger ! Risk of bursting in pressure equipment. Control valves and pipelines are pressure equipment. Improper opening can lead to valve components bursting. Î before starting any work on the control valve, de...

Page 9

Eb 5866 en 9 safety instructions and measures 1.2 notes on possible personal injury warning ! Crush hazard arising from moving parts. The pneumatic control valve (type 3222/2780) contains moving parts (actuator and plug stems), which can injure hands or fingers if inserted into the valve. Î while wo...

Page 10

10 eb 5866 en safety instructions and measures 1.3 notes on possible property damage notice ! Risk of damage to the electric control valve due to the power supply exceeding the permissible tolerances. The electric control valves are designed for use according to regulations for low-volt- age install...

Page 11: 2 Markings On The Device

Eb 5866 en 11 markings on the device 2 markings on the device 2.1 valve nameplate samson 1 2 3 4 5 kvs 6 Δp 7 1 type designation 2 configuration id 3 date of manufacture 4 model number 5 max. Permissible temperature 6 k vs coefficient 7 max. Perm. Differential pressure the nameplate (48) is affixed ...

Page 12: Ation

12 eb 5866 en design and principle of operation 3 design and principle of oper- ation the medium flows through the single-seated globe valve in the direction indicated by the arrow. The position of the plug determines the flow rate across the area released be- tween plug (1) and seat (5). The valve ...

Page 13

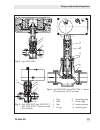

Eb 5866 en 13 design and principle of operation 1 5 3 7 1 plug 3 body 5 seat 7 o-ring 8 connecting piece 11 guide nipple 14 insulating section 15 insulating pipe 1 5 3 7 11 8 5 1 14 15 11 fig. 2: type 3222/2780-1 fig. 3: type 3222/5875, type 3222/5757-3, type 3222/5757-7 · version for water, oil, an...

Page 14: 3.2 Versions

14 eb 5866 en design and principle of operation 3.2 versions intermediate insulating piece an intermediate insulating piece is available for insulated pipes. Electric actuators the electric actuators can be controlled ei- ther using a three-step signal or, in the ver- sion with positioner, with cont...

Page 15

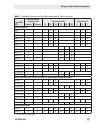

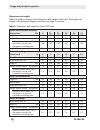

Eb 5866 en 15 design and principle of operation table 1: available versions and possible combinations (valve/actuator) type/tro- vis fail-safe action: actuator stem nominal size dn thread size g extends retracts 15 20 25 32 40 50 ½ ¾ 1 electric actuators 5857 – – • • • – • • • 5824-10 – – • • • – • ...

Page 16: 3.3 Technical Data

16 eb 5866 en design and principle of operation 3.3 technical data the nameplates on the valve and actuator provide information on the control valve version. See section 2.1 and the associated actuator documentation. Table 2: technical data for type 3222 nominal size globe valve with male thread con...

Page 17

Eb 5866 en 17 design and principle of operation table 3: nominal sizes and k vs coefficients nominal size globe valve with male thread connection or with flanged body dn 15 20 25 32 40 50 connection size globe valve with female thread g ½ ¾ 1 – – – k vs coefficients 4 1) · 3.6 2) 6.3 1) · 5.7 2) 8 1...

Page 18

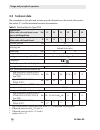

18 eb 5866 en design and principle of operation dimensions and weights table 5 provides a summary of the dimensions and weights of the valve. The lengths and heights in the dimension diagrams are shown on page 19 onwards. Table 5: dimensions and weights for type 3222 valve valves with male thread co...

Page 19

Eb 5866 en 19 design and principle of operation valves with female thread connection size g ½ ¾ 1 – width across flats sw 30 36 46 – length l4 mm 65 75 90 – female thread g ½ ¾ 1 – weight without actuator kg (approx.) 1.2 1.4 1.5 – version for water above 150 °c and steam or version with intermediat...

Page 20

20 eb 5866 en design and principle of operation dimension diagrams for electric control valves Ø12 55 80 11 l l1 h2 114 x 70 h3 r d sw l l1 146 x 103* 113 h2 h3 r d sw type 3222/5857: dn 15 to 25 type 3222/5757-3: dn 15 to 25 type 3222/5757-7: dn 15 to 25 type 3222/5824: dn 15 to 50 type 3222/5825: ...

Page 21

Eb 5866 en 21 design and principle of operation dimension diagrams for pneumatic control valves sw r d l l1 h3 h2 130 Ø168 sw r d l l1 230 Ø168 h2 h3 type 3222/2780-1: dn 15 to 50 type 3222/2780-2: dn 15 to 50 table 6: weights of electric actuators type 5857 5824 5825 weight kg (approx.) 0.7 0.75 1....

Page 22: 4 Preparation

22 eb 5866 en preparation 4 preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the deliv- ery note. 2. Check the shipment for transportation damage. Report any damage to sam- son and the forwarding agent (refer to del...

Page 23

Eb 5866 en 23 preparation − protect the control valve against moisture and dirt. Store it at a relative humidity of less than 75 %. In damp spaces, prevent condensation. If necessary, use a drying agent or heating. − make sure that the ambient air is free of acids or other corrosive media. − observe...

Page 24: 5 Mounting and Start-Up

24 eb 5866 en mounting and start-up 5 mounting and start-up samson valves are delivered ready for use. The valve and actuator are delivered separately and must be assembled on site. The procedure to mount and start up the valve are described in the following. We recommend first installing the valve ...

Page 25

Eb 5866 en 25 mounting and start-up support or suspension depending on the valve version and mount- ing position, the control valve and pipeline must be supported or suspended. The plant engineering company is responsible in this case. Premature wear and leakage due to insuffi- cient support or susp...

Page 26: 5.1.2 Additional Fittings

26 eb 5866 en mounting and start-up Î locate the vent plug on the opposite side to the workplace of operating personnel. Risk of personal injury when the actuator vents. − install the control valve in such a way that the actuator does not vent at eye level. − use suitable silencers and vent plugs. −...

Page 27: The Valve

Eb 5866 en 27 mounting and start-up 3. Lift the valve to the site of installation (see section 4.2). Observe the flow direction through the valve. The arrow on the valve indicates the direction of flow. 4. Version with flanges: make sure that the correct flange gaskets are used. 5. Version with thre...

Page 28: 5.3 Quick Check

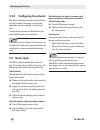

28 eb 5866 en mounting and start-up 5.2.2 configuring the actuator the electric actuator versions with positioner as well as electric actuators with process controllers can be adapted to the control task. Configure the actuator as described in the associated actuator documentation. For electric cont...

Page 29: 6 Operation

Eb 5866 en 29 operation 6 operation immediately after completing mounting and start-up (see section 5), the valve is ready for use. Type 3222/2780: crush hazard arising from moving parts (actuator and plug stem). Do not insert hands or finger into the yoke while the valve is in operation. Type 3222/...

Page 30: 7 Servicing

30 eb 5866 en servicing 7 servicing the control valve was checked by samson before it left the factory. − the product warranty becomes void if ser- vicing or repair work not described in these instructions is performed without pri- or agreement by samson's after-sales service department. − only use ...

Page 31: 8 Malfunctions

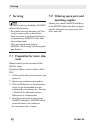

Eb 5866 en 31 malfunctions 8 malfunctions depending on the operating conditions, check the valve at certain intervals to prevent possi- ble failure before it can occur. Operators are responsible for drawing up a test plan. Samson's after-sales service department can support you to draw up an inspect...

Page 32: 8.2 Emergency Action

32 eb 5866 en malfunctions 8.2 emergency action the valve, on which the electric actuator with fail-safe action is mounted, is moved to its fail-safe position upon power supply failure (voltage supply, signal pressure). See sec- tion 3.1. Operators are responsible for emergency ac- tion to be taken ...

Page 33: Sembly

Eb 5866 en 33 decommissioning and disassembly 9 decommissioning and disas- sembly risk of bursting in pressure equipment. Control valves and pipelines are pressure equipment. Improper opening can lead to bursting of the valve. − before starting any work on the control valve, depressurize all plant s...

Page 34: 9.3 Removing The Actuator

34 eb 5866 en decommissioning and disassembly 3. Remove the valve from the pipeline (see section 4.2). 9.3 removing the actuator from the valve see associated actuator documentation. 9.4 disposal Î observe local, national, and internation- al refuse regulations. Î do not dispose of components, lubri...

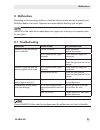

Page 35: 10 Appendix

Eb 5866 en 35 appendix 10 appendix 10.1 after-sales service contact samson's after-sales service de- partment for support concerning servicing or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service de- partment at aftersalesservice@samson.De. Addresses of ...

Page 36

36 eb 5866 en samson aktiengesellschaft weismüllerstraße 3 60314 frankfurt am main telefon: 069 4009-0 · telefax: 069 4009-1507 e-mail: samson@samson.De revison 01 ce _m od ul _d _d e_ en_ re v0 1. Doc x modul/module d / n° ce-ped-d-sam 001-13-deu samson erklärt in alleiniger verantwortung für folge...

Page 37

Eb 5866 en 37 samson aktiengesellschaft weismüllerstraße 3 60314 frankfurt am main telefon: 069 4009-0 · telefax: 069 4009-1507 e-mail: samson@samson.De revison 01 modul/module h / n° ce-ped-h-sam 001-13-deu samson erklärt in alleiniger verantwortung für folgende typen / explaines in sole resposibil...

Page 38

38 eb 5866 en samson aktiengesellschaft weismüllerstraße 3 60314 frankfurt am main telefon: 069 4009-0 · telefax: 069 4009-1507 e-mail: samson@samson.De revison 01 modul/module h / n° ce-ped-h-sam 001-13-deu samson erklärt in alleiniger verantwortung für folgende typen / explaines in sole resposibil...

Page 39

Eb 5866 en 39.

Page 40: Eb 5866 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 5866 en 2017-05-16 · engl ish.