- DL manuals

- Samson

- Controller

- 3271

- Mounting And Operating Instructions

Samson 3271 Mounting And Operating Instructions

Summary of 3271

Page 1

Mounting and operating instructions eb 8310-8 en tr anslat ion of original instruct ions edition february 2017 type 3271 pneumatic actuator actuator area: 1400-250 cm².

Page 2

2 eb 8310-8 en note on these mounting and operating instructions these mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling samson devices. Î for the safe and proper use of these instructions, read them carefully and ke...

Page 3

Contents eb 8310-8 en 3 1 safety instructions and measures ...................................................................5 1.1 notes on possible severe personal injury .........................................................7 1.2 notes on possible personal injury .................................

Page 4

4 eb 8310-8 en contents 7 servicing.....................................................................................................26 7.1 preparation for return shipment .....................................................................26 7.2 ordering spare parts and operating supplies ........

Page 5

Eb 8310-8 en 5 safety instructions and measures 1 safety instructions and measures intended use the samson type 3271 actuator is designed for operating a mounted globe valve. In com- bination with the valve, the actuator is used to shut off the flow of liquids, gases or vapors in the pipeline. Depen...

Page 6

6 eb 8310-8 en safety instructions and measures personal protective equipment we recommend wearing the following personal protective equipment when handling the type 3271 pneumatic actuator: − protective gloves when mounting or removing the actuator Î check with the plant operator for details on fur...

Page 7

Eb 8310-8 en 7 safety instructions and measures referenced standards and regulations according to the ignition risk assessment performed in accordance with en 13463-1:2009, section 5.2, the non-electrical actuators do not have their own potential ignition source even in the rare incident of an opera...

Page 8

8 eb 8310-8 en safety instructions and measures 1.2 notes on possible personal injury warning ! Crush hazard arising from moving parts. The actuator contains moving parts (actuator stem), which can injure hands or fingers if inserted into the actuator. Î do not insert hands or fingers into the yoke ...

Page 9

Eb 8310-8 en 9 safety instructions and measures 1.3 notes on possible property damage notice ! Risk of damage to the actuator due to incorrectly attached lifting equipment. The eyebolt or swivel lifting hook on the top diaphragm case is intended for mounting and removing the actuator as well as lift...

Page 10: 2 Markings On The Device

10 eb 8310-8 en markings on the device 2 markings on the device 2.1 actuator nameplate the nameplate is stuck on the diaphragm casing. It includes all details required to identify the device: 2 configuration id 3 serial number 4 actuator area 5 bench range in bar 6 bench range in psi 7 operating tra...

Page 11

Eb 8310-8 en 11.

Page 12: Ation

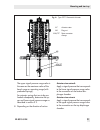

12 eb 8310-8 en design and principle of operation 3 design and principle of oper- ation the type 3271 pneumatic actuators with 1400-250 cm², actuator area contain a roll- ing diaphragm (a4) and internal springs (a10). They are mounted on samson se- ries 240, 250, 280, 290, and 590 valves. The signal...

Page 13

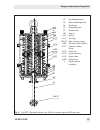

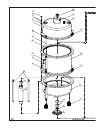

Eb 8310-8 en 13 design and principle of operation a16 a1 a10 a88 a180 a127 a4 a5 a2 s a8 a7 a26/27 a170 a173 a174 a1 top diaphragm case a2 bottom diaphragm case a4 diaphragm a5 diaphragm plate a7 actuator stem a8 ring nut a10 spring a16 vent plug a26/27 stem connector clamp a88 rod (anti-rotation fi...

Page 14: Action "actuator Stem

14 eb 8310-8 en design and principle of operation 3.3.2 version with direction of action "actuator stem retracts" (fe) when the signal pressure is reduced or the control signal fails, the springs move the ac- tuator stem upward and open a mounted globe valve. The valve closes when the signal pressur...

Page 15

Eb 8310-8 en 15 design and principle of operation table 1: dimensions in mm and weights in kg actuator area cm² 1400 travel mm 250 height h 800 h4 rated fa 415 h4 max fa 420 h4 max fe 170 h6 85 h7 1) 110 diameter Ød 534 Ød2 40 Ød (thread) m100 x 2 air connection a g 1/1 npt weight approx. Kg 417 1) ...

Page 16: 4.1 Unpacking

16 eb 8310-8 en measures for preparation 4 measures for preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the deliv- ery note. 2. Check the shipment for transportation damage. Report any damage to samson and the forw...

Page 17: 4.2.1 Transporting

Eb 8310-8 en 17 measures for preparation 4.2.1 transporting the actuator can be transported using lifting equipment (e.G. Crane or forklift). Î leave the actuator in its transport con- tainer or on the pallet to transport it. Î observe the transport instructions. Transport instructions − protect the...

Page 18: 4.3 Storage

18 eb 8310-8 en measures for preparation 4. Mount the actuator to the valve. See sec- tion 5.1. 5. Remove slings after mounting. We recommend using a hook with safety latch (see fig. 3). The safety latch prevents the slings from slipping during lifting and transporting. Lifting the entire control va...

Page 19

Eb 8310-8 en 19 measures for preparation than 75 %. In damp spaces, prevent con- densation. If necessary, use a drying agent or heating. − make sure that the ambient air is free of acids or other corrosive media. − the permissible storage temperature of standard control valves is –20 to +65 °c. Cont...

Page 20: 5 Mounting and Start-Up

20 eb 8310-8 en mounting and start-up 5 mounting and start-up samson control valves are delivered ready for use. In special cases, the valve and actu- ator are delivered separately and must be assembled on site. The procedure to mount and start up the actuator are described in following. Risk of act...

Page 21

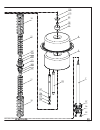

Eb 8310-8 en 21 mounting and start-up a7 actuator stem a8 ring nut a26/27 stem connector clamps a8 a7 a26/27 fig. 4: type 3271 pneumatic actuator the upper signal pressure range value is the same as the maximum value of the bench range or operating range (with preloaded springs). For actuator spring...

Page 22: Thrust

22 eb 8310-8 en mounting and start-up 9. Screw on the stem connector nut by hand until it touches the actuator stem (a7). 10. Turn the stem connector nut a further quarter turn and secure this position with the lock nut. 11. Position clamps of the stem connector (a26/27) and screw them tight. 12. Al...

Page 23

Eb 8310-8 en 23 mounting and start-up example: preloading is required for a signal pressure range of 0.8 to 2.55 bar. 20 % of this span corresponds to 0.27 bar. Therefore, the signal pressure range is shifted by –0.25 bar to 1.15 to 2.55 bar. The new low- er signal pressure range value is 1.15 bar a...

Page 24: 5.2.3 Adapting The Travel

24 eb 8310-8 en mounting and start-up 5.2.3 adapting the travel range in some cases, the valve and actuator have different rated travels. Depending on the di- rection of action, proceed as follows: direction of action: actuator stem extends always use actuators with preloaded springs when the valve'...

Page 25: 6 Operation

Eb 8310-8 en 25 operation 6 operation crush hazard arising from moving parts (ac‑ tuator and plug stem). Do not insert hands or fingers into the yoke while the valve is in operation. Risk of personal injury when the actuator vents. Wear eye protection when working in close proximity to the control v...

Page 26: 7 Servicing

26 eb 8310-8 en servicing 7 servicing risk of personal injury as well as risk of ac‑ tuator damage due to incorrect service or re‑ pair. − do not perform service and repair work on your own. − contact samson's after‑sales service de‑ partment for service and repair work. 7.1 preparation for return s...

Page 27: 8 Malfunctions

Eb 8310-8 en 27 malfunctions 8 malfunctions depending on the operating conditions, check the actuator at certain intervals to prevent possible failure before it can occur. Operators are responsible for drawing up an inspection plan. Troubleshooting malfunction possible reasons recommended action act...

Page 28: Sembly

28 eb 8310-8 en decommissioning and disassembly 9 decommissioning and disas- sembly risk of bursting in the actuator. Actuators are pressurized. Improper opening can lead to actuator components bursting. Before starting any work on the actuator, de‑ pressurize all plant sections concerned and the ac...

Page 29

Eb 8310-8 en 29 decommissioning and disassembly a1 top diaphragm case a2 bottom diaphragm case a20 hexagon screw a21 hexagon nut a22 hexagon bolt (preloading) a23 hexagon nut (preloading) a24 blanking plug a25 washer a180 distance ring a22 a23 a24 a25 a20 a21 a1 a180 a2 fig. 6: actuator with clampin...

Page 30: 10 Annex

30 eb 8310-8 en annex 10 annex 10.1 after-sales service contact samson's after-sales service de- partment for support concerning service or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service de- partment at aftersalesservice@samson.De. Addresses of samson...

Page 31: 10.2 Spare Parts

Eb 8310-8 en 31 annex 10.2 spare parts 1 top diaphragm case 2 bottom diaphragm case 4 diaphragm 5 diaphragm plate 7 actuator stem 8 ring nut 10 spring (external) 11 spring (internal) 16 vent plug 17 o-ring 18 screw fitting 20 hexagon bolt 21 hexagon nut 22 hexagon bolt (preloading) 23 hexagon nut (p...

Page 32

32 eb 8310-8 en 20 25 21 22 181 84 23 182 24 10 11 187 184 183 171 183 126 172 126 170 88 173 42 42 41 8 303 100 101 101 176 175 82 35 17 4 5 7 27 26 29 127 184 187 11 10 1 180 16 107 2.

Page 33

Eb 8310-8 en 33 20 25 21 22 181 84 23 182 24 10 11 187 184 183 171 183 126 172 126 170 88 173 42 42 41 8 303 100 101 101 176 175 82 35 17 4 5 7 27 26 29 127 184 187 11 10 1 180 16 107 2.

Page 34

34 eb 8310-8 en.

Page 35

Eb 8310-8 en 35.

Page 36: Eb 8310-8 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8310-8 en 2017-03-15 · engl ish.