Samson 3372 Mounting and operating instructions - 4.3 Changing The Type of

20

EB 8313-3 EN

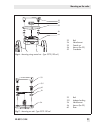

Mounting on the valve

4.3 Changing the type of

mounting

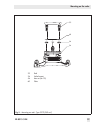

AType3372Actuator(120 cm²)whichhas

already been mounted using a central nut

can also be mounted later to a valve bonnet

suitable for mounting using rods. This re-

quires a plate (60) and two adapter bush-

ings (33.1) with hexagonal section to adapt

it to the diameter of the rods (33).

The conversion in the other direction is also

possible. This requires a crossbeam (59) and

two nuts (54).

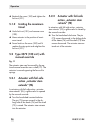

4.3.1 Conversion of mounting

using a central nut to

rods

See Table 1 on page 10 for conversion

from Form B to Form C

Fig. 6 and Fig. 7

Î

Undo the two screws on the stem connec-

tor and remove it from the actuator stem

and plug stem.

Î

Undo the central nut (35) and lift the ac-

tuator off the valve bonnet (34).

Î

To undo the two hex nuts (54), the rods

(33) must be held stationary using an

open-end wrench (SW 22). Remove the

crossbeam (59).

Î

Position the plate (60) and screw the two

adapter bushings (33.1) onto the thread

of the rods (33). This adapts the diame-

ter of the rods to the holes in the valve

bonnet (34).

Î

Place the rods (33) on the valve bonnet

(34) and tighten both hex nuts (54) alter-

nately.

Î

Mount the stem connector between the

actuator stem and plug stem, ensuring

the travel linkage runs parallel to the

support element.

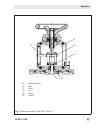

4.3.2 Conversion of mounting

using rods to a central

nut

See Table 1 on page 10 for conversion

from Form C to Form B

Fig. 6 and Fig. 7

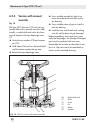

Î

Undo the two screws on the stem connec-

tor and remove it from the actuator stem

and plug stem.

Î

Unscrew the hex nuts (54) from the

adapter bushings (33.1) and lift the actu-

ator of the valve bonnet (34).

Î

Unscrew the adapter bushings (33.1)

with hexagonal part from the rods (33)

and remove the plate (60).

Î

Place the crossbeam (59) on the rods

(33) with the bent sides facing away

from the actuator housing. Fasten with

hex nuts (54).

Î

Place the actuator on the valve bonnet

(34) and fasten with central nut (35).

Î

Mount the stem connector between the

actuator stem and plug stem, ensuring

the travel linkage runs parallel to the

support element.