- DL manuals

- Samson

- Valve Positioners

- 3730-1

- Mounting And Operating Instructions

Samson 3730-1 Mounting And Operating Instructions - 4.1.2 Type 3277 Actuator

EB 8384-1 EN

19

Attachment to the control valve – Mounting parts and accessories

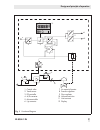

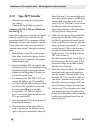

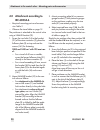

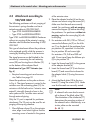

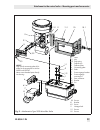

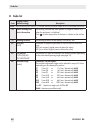

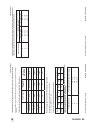

4.1.2 Type 3277 Actuator

−

Required mounting parts and accesso-

ries: Table 2

−

Observe the travel table on page 15.

Actuators with 175 to 750 cm² effective ar-

eas (see Fig. 4)

Mountthepositionerontheyoke.Thesignal

pressure is routed to the actuator over the

connectionblock(12),foractuatorswithfail-

safeaction"actuatorstemextends"internal-

lythroughaholeinthevalveyokeandfor

"actuatorstemretracts"throughanexternal

pipe.

1. Placefollowerclamp(3)ontheactuator

stem,alignitandscrewtightsothatthe

mounting screw is located in the groove

oftheactuatorstem.

2. Mountcoverplate(10)withnarrowside

ofthecut-out(Fig. 4,ontheleft)pointing

towards the signal pressure connection.

Makesurethatthegasket(14)pointsto-

wardstheactuatoryoke.

3. Foractuatorswith355,700or750 cm²,

removethefollowerpin(2)ontheM le-

ver(1)onthebackofthepositionerfrom

pin position 35,repositionitinthehole

forpinposition50 and screw tight.

Foractuators175,240and350 cm²

with15 mmtravel,keepthefollowerpin

(2)inpinposition35.

4. Insertformedseal(15)intothegrooveof

the positioner housing.

5. Placepositioneronthecoverplatein

suchamannerthatthefollowerpin(2)

restsonthetopofthefollowerclamp(3).

Marking

2

10 14

15

1 2

3

11 11.1

SUPPLY

13

B

C

1.1

1.2

12

12.1

12

12.2

12.1

12

16

16

16

12.2

SUPPLY

View A

View B

View C

SUPPL

Y

G

G 3/8

A

Mlever

Cut-outof

coverplate(10)

Actuator stem extends

Actuator stem retracts

Connection

block(old)with

switchplate(13)

Actuator stem

1

Lever

1.1 Nut

1.2 Diskspring

2

Follower pin

3

Follower clamp

10

Cover plate

11

Cover

11.1 Vent plug

12

Connectionblock

12.1 Screw

12.2 Stopperorconnectionfor

external piping

13

Switchplate

14

Gasket

15

Moldedseal

16

Gasket

extends

retracts

Fig. 4: Direct attachment – Signal pressure connection for Type 3277 Actuator with 175 to 750 cm²

Summary of 3730-1

Page 1

Mounting and operating instructions eb 8384-1 en (1300-1610) firmware version 2.20 edition august 2016 series 3730 type 3730-1 electropneumatic positioner type 3730-1.

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8384-1 en 3 1 important safety instructions ..........................................................................6 2 article code ..................................................................................................7 3 design and principle of operation ....................

Page 4

4 eb 8384-1 en contents 7.4 settingotherparameters ..............................................................................48 7.5 initialization .................................................................................................50 7.6 faults .........................................

Page 5

Eb 8384-1 en 5 firmware revisions 2.02(old) 2.10(new) newresetfunctionincodep0(seesection 7.8) newmanualadjustmentfunctionincodep14(seesection 7.9) 2.10(old) 2.11(new) internal revisions 2.11(old) 2.12(new) internal revisions 2.12(old) 2.20(new) parametercodeschanged(seesection 8onpage 54).

Page 6

6 eb 8384-1 en important safety instructions 1 important safety instructions foryourownsafety,followtheseinstructionsconcerningthemounting,startupandopera- tionofthepositioner: − thedeviceistobemounted,starteduporoperatedonlybytrainedandexperienced personnelfamiliarwiththeproduct.Accordingtothesemou...

Page 7: 2 Article Code

Eb 8384-1 en 7 article code 2 article code positioner type 3730-1 x x 0 0 0 0 0 0 0 x 0 0 x 0 0 0 withlcdandautotune, setpoint4to20 ma,twosoftwarelimitcontacts explosion protection without 0 atex:ii2gex iaiict6gb;ii2dextbiiict80°cdbip66 1 fm/csa: classi,zone0aex iaiic;classi,ii,iii,div.1,groupsa–g; ...

Page 8: Ation

8 eb 8384-1 en design and principle of operation 3 design and principle of oper- ation the electropneumatic positioner is mounted on pneumatic control valves and is used to assignthevalveposition(controlledvariable x)tothecontrolsignal(setpointw).Thepo- sitioner compares the electric control signal ...

Page 9

Eb 8384-1 en 9 design and principle of operation fig. 1: functional diagram 1 control valve 2 travel sensor 3 pdcontroller 4 a/d converter 5 microcontroller 6 i/p converter 7 aircapacitybooster 8 pressureregulator 9 flow regulator 10 volume restriction 11 limit contacts 12 display % s mm % mm w x q ...

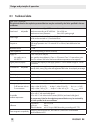

Page 10: 3.1 Technical Data

10 eb 8384-1 en design and principle of operation 3.1 technical data type 3730-1positioner the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Rated travel adjustable directattachmenttotype3277: 3.6to 30 mm attachmentaccordingtoi...

Page 11

Eb 8384-1 en 11 design and principle of operation type 3730-1positioner the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Electrical connections onem20 x 1.5cableglandfor6to12 mmclampingrange secondm20 x 1.5threadedconnectionad...

Page 12

12 eb 8384-1 en design and principle of operation explosion protection certificates type 3730 certification type of protection/comments -1 stcc number 972 0ex iaiict6x; 2ex s ii t6 x date 2017-10-01 -11 ec type examination certificate number ptb 04atex2033 ii2gex iaiict6gb; ii2dextbiiict80°cdbip66 d...

Page 13

Eb 8384-1 en 13 design and principle of operation type 3730 certification type of protection/comments -1 8 certificateof conformity number ptb 04atex2114x ii3gexnaiit6gc, ii3gex iciict6gc; ii3dextciiicip66dct80°c date 2008-02-26 number rucde.08.B.00113 2exnaiict6/t5/t4gcx; 2ex iciict6/t5/t4gcx; extc...

Page 14: Valve – Mounting Parts and

14 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4 attachment to the control valve – mounting parts and accessories notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protective film ...

Page 15

Eb 8384-1 en 15 attachment to the control valve – mounting parts and accessories travel tables note: the m lever is included in the scope of delivery. S, l, xl levers for attachment according to iec 60534-6 (namur) are available as accessories (see table 3 on page 39). The xxl lever is available on ...

Page 16: 4.1 Direct Attachment

16 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 1 − observe the travel table on page 15. Actuator with 120 cm² (seefig. 3) dependingonthetypeofpositionerattach- ment,t...

Page 17: 4.1 Direct Attachment

Eb 8384-1 en 17 attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 1 − observe the travel table on page 15. Actuator with 120 cm² (seefig. 3) dependingonthetypeofpositionerattach- ment,t...

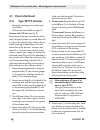

Page 18: 4.1.2 Type 3277 Actuator

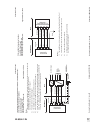

18 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 − observe the travel table on page 15. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mountthepositionerontheyoke.Thesignal pre...

Page 19: 4.1.2 Type 3277 Actuator

Eb 8384-1 en 19 attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 − observe the travel table on page 15. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mountthepositionerontheyoke.Thesignal pre...

Page 20: Iec 60534-6

20 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 − observe the travel table on page 15. The positioner is attached to the control valve usinganamurbracket(10). 1. Screwthetwob...

Page 21: Iec 60534-6

Eb 8384-1 en 21 attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 − observe the travel table on page 15. The positioner is attached to the control valve usinganamurbracket(10). 1. Screwthetwob...

Page 22: Vdi/vde 3847

22 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 thefollowingpositionerswithairpurgingof theactuator'sspringchambercanbeat- tachedaccordingtovdi/vde 3847: − type3730-1xx0000000x006000 − type3730-1xx0000000x007000 type3730-1xx00...

Page 23: Vdi/vde 3847

Eb 8384-1 en 23 attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 thefollowingpositionerswithairpurgingof theactuator'sspringchambercanbeat- tachedaccordingtovdi/vde 3847: − type3730-1xx0000000x006000 − type3730-1xx0000000x007000 type3730-1xx00...

Page 24

24 eb 8384-1 en attachment to the control valve – mounting parts and accessories 7. Insertthescrews(13.1)throughthemid- dleholesoftheadapterblock(13). 8. Placetheconnectingplate(12)together withtheseal(12.1)ontothescrews(13.1) correspondingtothefail-safeaction"ac- tuatorstemextends"or"actuatorstem r...

Page 25

Eb 8384-1 en 25 attachment to the control valve – mounting parts and accessories attachment to namur rib (see fig. 8) − requiredmountingpartsandaccesso- ries:table 4onpage 39 − observethetraveltableonpage 15. 1. Series 240 valves, actuator size up to 1400-60 cm²:screwthetwobolts(14)to thebracketofth...

Page 26

26 eb 8384-1 en attachment to the control valve – mounting parts and accessories 5. Inserttheformedseal(6.2)inthegroove oftheadapterbracket. 6. Inserttheformedseal(17.1)intotheturn- board(17)andmounttheturnboardto theadapterblock(13)usingthescrews (17.2). 7. Mounttheblankplate(18)totheturn- boardusi...

Page 27

Eb 8384-1 en 27 attachment to the control valve – mounting parts and accessories 5. Inserttheformedseal(6.2)inthegroove oftheadapterbracket. 6. Inserttheformedseal(17.1)intotheturn- board(17)andmounttheturnboardto theadapterblock(13)usingthescrews (17.2). 7. Mounttheblankplate(18)totheturn- boardusi...

Page 28: Micro-Flow Valve

28 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 − observe the travel table on page 15. Thepositionerisattachedtothevalveyoke usingabracket. 1. Fastenthebracket(9....

Page 29: Micro-Flow Valve

Eb 8384-1 en 29 attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 − observe the travel table on page 15. Thepositionerisattachedtothevalveyoke usingabracket. 1. Fastenthebracket(9....

Page 30: Ators

30 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.5 attachment to rotary actu- ators − required mounting parts and accesso- ries: table 5 − observe the travel table on page 15. The positioner is mounted to the rotary actu- atorusingtwopairsofbrackets. Priortoattachin...

Page 31

Eb 8384-1 en 31 attachment to the control valve – mounting parts and accessories 5. Mountconnectingplate(6)orpressure gaugebracket(7)withpressuregauges onthepositioner,makingsurethetwo seals are seated properly. Double-acting springlessrotaryactuatorsrequirethe useofareversingamplifieronthecon- nect...

Page 32: 4.5.3 Heavy-Duty Version

32 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.5.3 heavy-duty version − required mounting parts and accesso- ries: table 5 bothmountingkitscontainallthenecessary mountingparts.Thepartsfortheactuator sizeusedmustbeselectedfromthemount- ingkit. Prepareactuator,andmo...

Page 33

Eb 8384-1 en 33 attachment to the control valve – mounting parts and accessories 90°. 6. Mountconnectingplate(6)forrequired g ¼connectingthreadorpressure gaugebracket(7)withpressuregauges onthepositioner,makingsurethetwo seals(6.1)areseatedproperly.Double- actingspringlessrotaryactuatorsrequire theu...

Page 34: Double-Acting Actuators

34 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.6 reversing amplifier for double-acting actuators fortheusewithdouble-actingactuators,the positionermustbefittedwithareversingam- plifier,e.G.Thesamsontype 3710revers- ingamplifier(seemountingandoperating instructions...

Page 35

Eb 8384-1 en 35 attachment to the control valve – mounting parts and accessories a 1 1.5 1.6 1.3 6.2 6 6.1 1.2 1.1 1 1.6 z a 2 1.4 a 1 a 2 z a 1 output 38 supply 9 output 38 supply 9 1.3 1.2 1.1 from the positioner control signals to the actuator 1 reversingamplifier 1.1 specialscrews 1.2 gasket 1.3...

Page 36: Stainless Steel Housings

36 eb 8384-1 en attachment to the control valve – mounting parts and accessories 4.7 attaching positioners with stainless steel housings positionerswithstainlesssteelhousingsre- quiremountingpartsthatarecompletely madeofstainlesssteelorfreeofaluminum. Note: the pneumatic connecting plate and pressur...

Page 37

Eb 8384-1 en 37 attachment to the control valve – mounting parts and accessories fe: theairpurgingfunctionisautomatically provided. Attachment according to iec 60534-6 (namur rib or attachment to rod-type yokes) and to rotary actuators thepositionerrequiresanadditionalportfor theexhaustairthatcanbec...

Page 38

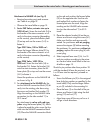

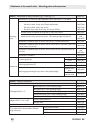

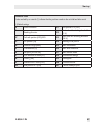

38 eb 8384-1 en attachment to the control valve – mounting parts and accessories table 2: direct attachment to type 3277 actuator (fig. 5) order no. Mounting parts standardversionforactuators175,240,350,355,700,750 cm² 1400-7453 versioncompatiblewithpaintforactuators175,240,350,355,700,750 cm² 1402-...

Page 39

Eb 8384-1 en 39 attachment to the control valve – mounting parts and accessories table 3: attachment to namur ribs or control valves with rod-type yokes (20 to 35 mm rod diameter) according to iec 60534-6 (fig. 5 and fig. 9) travel in mm lever for actuator order no. 3.5to17.7 s type3271-5with60/120c...

Page 40

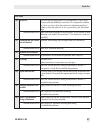

40 eb 8384-1 en attachment to the control valve – mounting parts and accessories table 5: attachment to rotary actuators (fig. 10 and fig. 11) order no. Mounting parts attachmentacc.Tovdi/vde3845(september2010),seesection 11.1fordetails actuatorsurfacecorrespondstofixinglevel1 sizeaa1toaa4,versionwi...

Page 41: 5 Connections

Eb 8384-1 en 41 connections 5 connections warning! Risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. Notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protect...

Page 42

42 eb 8384-1 en connections thebenchrangeiswrittenonthenameplate either as the spring range or signal pressure range depending on the actuator. The direc- tionofactionismarkedfa or fe,orbya symbol. Actuator stem extends fa (air to open) fail-close(forglobeandanglevalves): requiredsupplypressure=uppe...

Page 43

Eb 8384-1 en 43 connections selecting cables and wires observeclause 12 of en 60079-14: 2008 (vde 0165,part 1)forinstallationofthein- trinsicallysafecircuits. Clause 12.2.2.7applieswhenrunningmulti- corecablesandwireswithmorethanone intrinsicallysafecircuit. Theradialthicknessoftheinsulationofa cond...

Page 44

44 eb 8384-1 en connections notice malfunctioning of the positioner! The set point must not fall below 3.7 ma while the positioner is run- ning. Accessories cable glands m20 x 1.5 order no. Blackplastic (6to12 mmclampingrange) 8808-1011 blue plastic (6to12 mmclampingrange) 8808-1012 nickel-platedbra...

Page 45: 6 Operation

Eb 8384-1 en 45 operation 5.2.4 switching amplifier foroperationofthelimitcontacts,switching amplifiersmustbeconnectedintheoutput circuit.Toensuretheoperatingreliabilityof thepositioner,theamplifiersshouldcomply withthelimitvaluesoftheoutputcircuits conformingtoen 60947-5-6. Observetherelevantregula...

Page 46: 6.2 Volume Restriction Q

46 eb 8384-1 en operation 6.2 volume restriction q the volume restriction serves to adapt the air outputcapacitytothesizeoftheactuator. Depending on the air passage at the actua- tor,twofixedsettingsareavailable(seesec- tion 7.1). Reading iconsassignedtocertaincodesandfunc- tionsareindicatedonthedis...

Page 47: 7 Start-Up

Eb 8384-1 en 47 start-up 7 start-up notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protective film from the pneumatic connections. 2.Mount the positioner on the control valve. 3. Connect the supply air. 4. Conne...

Page 48: Tion

48 eb 8384-1 en start-up overview · position of the volume restric- tion q* signal pressure transit time ≥1 s connection at the side minside maxside connectionattheback minback maxback * intermediate settings are not permitted. Notice malfunction due to changed start-up settings. Initialize an initi...

Page 49

Eb 8384-1 en 49 start-up parameter codes codesmarkedbyanasterisk(*)indicatethatthepositionerneedstobere-initializedafterwards [...]defaultsettings p0 statusindication p11 endpositionw>[off] p1 reading direction p12 limit value a1 switching threshold [2 %] p2* fail-safeposition[ato]/ato p13 limit val...

Page 50: 7.5 Initialization

50 eb 8384-1 en start-up 7.5 initialization notice the process is disturbed by the move- ment of the actuator stem. Do not initialize the positioner while the process is running; only perform an initialization during start-up with the shut-off valves closed. A signal pressure above the maxi- mum per...

Page 51: 7.6 Faults

Eb 8384-1 en 51 start-up afterasuccessfulinitialization,thepositioner runsinclosed-loopoperationindicatedby the closed-loopoperationiconandcon- trolpositionin%predeterminedbytheset point on the display. Amalfunctionleadstotheprocessbeingin- terrupted. The faultindicationiconisdis- played.Seesection ...

Page 52: 7.7 Zero Calibration

52 eb 8384-1 en start-up turn g rst press to reset the error. Theresetprocedurecanbecanceledby pressing when esc appears. 7.7 zero calibration incaseofinconsistenciesintheclosedposi- tionofthevalve,e.G.Withsoft-seatedplugs, itmightbenecessarytorecalibratezero. Startthezerocalibrationbyactivatingcode...

Page 53: 7.9 Manual Mode

Eb 8384-1 en 53 start-up 7.9 manual mode thevalvepositioncanbemovedasfollows using the manual modefunction: turn code p17 press andholdforsixseconds. 6-5-4-3-2-1- is counted down on the display. − themanualsetpoint(wman)isindicat- edonthedisplayofan initialized posi- tioner. − the lever position i...

Page 54: 8 Code List

54 eb 8384-1 en code list 8 code list code display, values [default setting] description note:codesmarkedbyanasterisk(*)indicatethatthepositionerneedstobere-initializedafterwards p0 status reading with basic information thereadingindicatesthevalvepositionorangleofrotationin% whenthepositionerisiniti...

Page 55

Eb 8384-1 en 55 code list code display, values [default setting] description note:codesmarkedbyanasterisk(*)indicatethatthepositionerneedstobere-initializedafterwards p5 characteristic 0to8[0] characteristicselection:0,1,2forglobevalves, 0to8withrotaryactuators(p3=90°) 0 linear 1 equalpercentage 2 r...

Page 56

56 eb 8384-1 en code list code display, values [default setting] description note:codesmarkedbyanasterisk(*)indicatethatthepositionerneedstobere-initializedafterwards p13 limit a2 0to100 %[98 %] softwarelimitvaluea2isdisplayedorcanbechangedinrelation totheoperatingrange(stepsof0.5 %). P14 info w ini...

Page 57

Eb 8384-1 en 57 code list error codes e0 zero error onlywithtight-closingfunctionp10(endpositionw thezeropointhasshiftedbymorethan5 %comparedtoinitializa- tion. Error can occur when the positioner's attachment position is shiftedorwhenthevalvetrimisworn,particularlywithsoft-sealed plugs. Recommended...

Page 58

58 eb 8384-1 en code list error codes e7 actuator does not move nosupplyair,mountingblocked. Noinputsignalorinputsignalbelow3.7 ma recommended action checksupplyair,positionermountingandmainputsignal. Re-initializethepositioner. E8 travel signal at lower/ upper limit wrongpinposition,wronglever,wron...

Page 59: 9 Maintenance

Eb 8384-1 en 59 maintenance 9 maintenance thepositionerdoesnotrequireanymainte- nance. Therearefilterswitha100 µmmeshsizein thepneumaticconnectionsforsupplyand outputwhichcanberemovedandcleaned, ifrequired. Themaintenanceinstructionsofanyup- stream supply air pressure reducing stations mustbeobserve...

Page 60: 11 Dimensions In Mm

60 eb 8384-1 en dimensions in mm 11 dimensions in mm pressure gaugebracket or connecting plate attachmentaccordingtoiec 60534-6 lever mm s =17 m =50 l =100 xl =200 direct attachment m20 x 1.5 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 58 58 fig. 18: namur and direct attachment.

Page 61

Eb 8384-1 en 61 dimensions in mm attachment according to vdi/vde 3847totype 3277 attachment according to vdi/vde 3847toanamur rib 62 164 38 200 16 4 164 13 62 24 lever(seefig. 21) fig. 19: attachment according to vdi/vde 3847.

Page 62

62 eb 8384-1 en dimensions in mm 56 86 130 80 166 30 86 Ø 101 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 reversing amplifier (optional)* heavy-duty version a 1 z a 2 output a1 output a2 supply (9) 50 80 58 130 49 59 79 76 50 150 reversing amplifier (optional)* connecting plate g ¼o...

Page 63

Eb 8384-1 en 63 dimensions in mm x z y 16 10...17 lever x y z s 17 mm 25 mm 33 mm m 25 mm 50 mm 66 mm l 70 mm 100 mm 116 mm xl 100 mm 200 mm 216 mm fig. 21: lever 11.1 fixing levels according to vdi/vde 3845 (september 2010) a m6 c b 25 m min Ød Ød fixinglevel2(bracketsurface) fixinglevel1(actuators...

Page 64

64 eb 8384-1 en.

Page 65

Eb 8384-1 en 65.

Page 66

66 eb 8384-1 en.

Page 67

Eb 8384-1 en 67.

Page 68

68 eb 8384-1 en.

Page 69

Eb 8384-1 en 69.

Page 70

70 eb 8384-1 en.

Page 71

Eb 8384-1 en 71.

Page 72

72 eb 8384-1 en.

Page 73

Eb 8384-1 en 73.

Page 74

74 eb 8384-1 en.

Page 75

Eb 8384-1 en 75.

Page 76

76 eb 8384-1 en a ddendum page 1 rev isi on cont ro l numb er: 2 / june 08 a ddendum t o eb 8384- 1en 1 2 an d 3 4 11 / 12 41 / 42 an d 51 / 52 44 / 45 28v 20v 16v 115m a 60m a 25 / 52m a 1w 250mw 64 / 169mw 6nf 16 nf 3 0nf 0µh 0µh 100µh 28v 300 28v dio de t6 t5 t4 - 4 0° c .. . 5 5° c - 4 0° c .. ....

Page 77

Eb 8384-1 en 77 a ddendum page 3 rev isi on cont ro l numb er: 2 / june 08 a ddendum t o eb 8384- 1en 51+ 52- 44+ 45- induct ive li m it s w itch ci rcui t 4 lim it s w itch (soft w are) ci rcui t 3 model 3 730-13 e/p- p osi tioner # e # e 11+ 12- 41+ 42- cont rol signa l ci rcui t 1 lim it s w itch...

Page 78

78 eb 8384-1 en a dd en du m p age 5 rev isi on cont ro l numb er: 2 / june 08 a ddendum t o eb 8384- 1en 1 2 an d 3 4 11 / 12 41 / 42 an d 51 / 52 44 / 45 28v 20v 16v 115m a 60m a 25 / 52m a 1w 250mw 64 / 169mw 6nf 16 nf 3 0nf 0µh 0µh 100µh 28v 280 115m a 1w 28v # 0m a t6 t5 t4 - 4 0° c .. . 5 5° c...

Page 79

Eb 8384-1 en 79 a dd en du m p age 7 rev isi on cont ro l numb er: 2 / june 08 a ddendum t o eb 8384- 1en ¡ ¢ ¡ 51+ 52- 44+ 45- induct ive li m it s w itch ci rcui t 4 lim it s w itch (soft w are) ci rcui t 3 model 3 730-13 e/p- p osi tioner # e # e 11+ 12- 41+ 42- cont rol signa l ci rcui t 1 lim i...

Page 80: Eb 8384-1 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8384-1 en 20 16 -0 8- 12 · en gl ish.