- DL manuals

- Samson

- Valve Positioners

- 3730 Series

- Mounting And Operating Instructions

Samson 3730 Series Mounting And Operating Instructions

Summary of 3730 Series

Page 1

Series 3730 electropneumatic positioner type 3730-1 mounting and operating instructions eb 8384-1 en firmware version 2.0x edition january 2006 fig. 1 · type 3730-1.

Page 2

Contents page 1 design and principle of operation . . . . . . . . . . . . . . . . . . . 6 2 attachment to the control valve – mounting parts and accessories . . . . 8 2.1 direct attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 2.1.1 type 3277-5 actuator. . . . . . . . . . . . . . ...

Page 3

Eb 8384-1 en 3 safety instructions general safety instructions 4 the positioner may only be assembled, started up or operated by trained and experienced personnel familiar with the product. According to these mounting and operating instructions, trained personnel refers to individuals who are able t...

Page 4

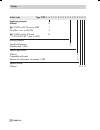

4 eb 8384-1 en versions article code type 3730-1 x 0 0 0 0 0 0 0 0 x 0 0 x 0 0 0 explosion protection without ii 2 g eex ia iic t6 acc. To atex ex ia/ex n acc. To fm/csa ii 3 g eex na/nl ii t6 and ii 3 d ip 65 t 80 °c acc. To atex 0 1 3 8 housing material standard aluminum stainless steel 1.4581 0 1...

Page 5

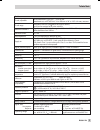

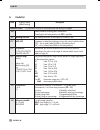

Eb 8384-1 en 5 technical data positioner travel, adjustable direct attachment to type 3277: 3.6 to 30 mm attachment acc. To iec 60534-6: 3.6 to 200 mm or 24° to 100° with rotary actuators travel range adjustable within the initialized travel/angle of rotation; travel can be restricted to 1 5 at the ...

Page 6: Design

1 design and principle of operation the electropneumatic positioner is mounted to pneumatic control valves and is used to assign the valve position (controlled variable x) to the control signal (reference variable w). The dc control signal received from a control unit is compared to the travel or ro...

Page 7

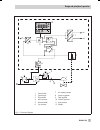

Eb 8384-1 en 7 design and principle of operation fig. 2 · functional diagram % s mm % mm w x q pd a2 a1 4 5 3 11 12 6 7 8 10 1 w 9 x y 2 7 air capacity booster 8 pressure regulator 9 flow regulator 10 volume restriction 11 limit switches 12 display 1 control valve 2 travel sensor 3 pd controller 4 a...

Page 8: Attachment To The Control

2 attachment to the control valve – mounting parts and accessories the positioner can be attached either di- rectly to a samson type 3277 actuator or according to iec 60534-6 (namur) to con- trol valves with cast yokes or rod-type yokes as well as to rotary actuators according to vdi/vde 3845. For a...

Page 9

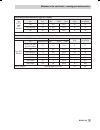

Eb 8384-1 en 9 attachment to the control valve – mounting parts and accessories travel table for direct attachment to type 3277 actuator type 3277-5 and 3277 actuators actuator size cm 2 rated travel mm adjustment range at positioner min. Travel max. Required lever assigned pin position 120 7.5 4.8 ...

Page 10

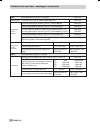

10 eb 8384-1 en attachment to the control valve – mounting parts and accessories table 1 direct attachment to type 3277-5 actuator order no. Mounting parts for actuators with 120 cm 2 effective diaphragm area 1400-7452 accessories for the actuator switchover plate (old) for actuator type 3277-5xxxxx...

Page 11

Eb 8384-1 en 11 attachment to the control valve – mounting parts and accessories table 4 attachment to rotary actuators (vdi/vde 3845 for all sizes of fixing level 2) see figs. 7 and 8 mounting parts with follower clamp and coupling wheel vdi/vde 3845 for all sizes of fixing level 2 for type 3278 ac...

Page 12: 2.1

2.1 direct attachment 2.1.1 type 3277-5 actuator refer to table 1 on page 10 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 9! Actuator with 120 cm ² depending on the type of positioner attach- ment, the signal pressure is routed ei...

Page 13

Eb 8384-1 en 13 attachment to the control valve – mounting parts and accessories fig. 3 · direct attachment – signal pressure connection for type 3277-5 actuator with 120 cm 2 9 11 supply 9 output 38 5 6 4 7 6 10 10.1 3 2 1 15 6.1 1.1 1.2 14 8 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 followe...

Page 14: 2.1.2 Type 3277 Actuator

2.1.2 type 3277 actuator refer to table 2 on page 10 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 9! Actuators with 240 to 700 cm 2 the positioner can be mounted either on the left or on the right side of the yoke. The sig- nal pr...

Page 15

Eb 8384-1 en 15 attachment to the control valve – mounting parts and accessories fig. 4 · direct attachment – signal pressure connection for type 3277 actuator with 240, 350 and 700 cm 2 2 10 14 15 1 2 3 11 supply 13 16 b 1.1 1.2 12 12.1 12 12.1 12.2 a 12 16 12.2 supply 1 lever 1.1 nut 1.2 disk spri...

Page 16: 2.2

2.2 attachment according to iec 60534-6 the positioner is attached to the control valve with a namur bracket (10). Refer to table 3 on page 11 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 9! 1. Screw the two bolts (14) to the brac...

Page 17

Eb 8384-1 en 17 attachment to the control valve – mounting parts and accessories fig. 5 · attachment according to iec 60534-6 (namur) 10 11 6.1 6 7 8 1 1 14.1 3 3.1 16 15 14 1 1.2 1.1 2 9.1 9 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower plate 3.1 follower plate 6 connecting plate 6.1 se...

Page 18: 2.3

2.3 attachment to type 3510 micro-flow valve the positioner is attached to the valve yoke using a bracket. Refer to table 3 on page 11 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 9! 1. Place clamp (3) on the valve stem con- necto...

Page 19

Eb 8384-1 en 19 attachment to the control valve – mounting parts and accessories fig. 6 · attachment to type 3510 micro-flow valve 3 10 11 11 6 1 2 1.2 1.1 7 8 6.1 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 clamp 6 connecting plate 6.1 seal rings 7 pressure gauge bracket 8 pressure gauge mount...

Page 20: 2.4

2.4 attachment to rotary actuators the positioner is mounted to the rotary actu- ator using two pairs of double brackets. Refer to table 4 on page 11 for the required mounting parts as well as the accessories with their order numbers. Prior mounting the positioner to the samson type 3278 rotary actu...

Page 21

Eb 8384-1 en 21 attachment to the control valve – mounting parts and accessories fig. 8 · attachment to rotary actuators 10 10.1 6 (7, 8) 1.1 2 4.3 5 6.1 4 1.2 1 note! Always use the connecting plate (6) included in the accessories to connect supply and output. Never screw threaded parts directly in...

Page 22: 2.5

2.5 reversing amplifier for double-acting actuators for the use with double-acting actuators, the positioner must be fitted with a reversing amplifier. The reversing amplifier is listed as an accessory in the table 5 on page 11. The output signal pressure of the positioner is supplied at the output ...

Page 23

Eb 8384-1 en 23 attachment to the control valve – mounting parts and accessories fig. 9 · mounting a reversing amplifier a 1 1.5 1.6 1.3 6.2 6 6.1 1.2 1.1 1 1.6 z a 2 1.4 a 1 a 2 z a 1 output 38 supply 9 output 38 supply 9 1.3 1.2 1.1 1 reversing amplifier 1.1 special screws 1.2 gasket 1.3 special n...

Page 24: Connections

3 connections 3.1 pneumatic connections caution! The threads in the positioner housing are not designed for direct air connection! The screw glands must be screwed into the connecting plate, the pressure gauge mount- ing block or the connection block from the accessories. The air connections are opt...

Page 25

D = seat diameter [cm] Δ p = differential pressure across the valve [bar] a = actuator diaphragm area [cm 2 ] f = upper bench range of the actuator [bar] if there are no specifications, calculate as follows: required supply pressure = upper bench range value + 1 bar note! The signal pressure at the ...

Page 26: 3.2

3.2 electrical connections for electrical installation, you are re- quired to observe the relevant elec- trotechnical regulations and the acci- dent prevention regulations that ap- ply in the country of use. In germa- ny, these are the vde regulations and the accident prevention regula- tions of the...

Page 27

Caution! The erroneous connection of a voltage source of just around 7 v (or around 2 v when connected to the wrong pole) can damage the positioner. In general, it is not necessary to connect the positioner to a bonding conductor. Should this be required, however, this conductor can be connected ins...

Page 28: Operation

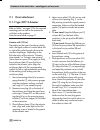

4 operation the positioner is mainly operated with the rotary pushbutton. The volume restriction must be set first to adapt the air delivery. 4.1 operator controls rotary pushbutton turn the button to select a parameter code (p0 to p16) and then press it to con- firm the parameter code selected. If ...

Page 29: Start-Up

Volume restriction q the volume restriction is used to adapt the air delivery to the actuator size. Two fixed settings are possible depending on how the air is routed at the actuator. See section 5.1 for more details. Display the lc display indicates symbols that are assigned to codes and functions....

Page 30: 5.2

4 the “side“ position applies for actuators with a loading pressure connection at the side, e.G. Type 3271-5. 4 the “back“ position applies for actua- tors with a loading pressure connection at the back, e.G. In type 3277-5. The “side” restriction position always applies for actuators from other man...

Page 31: 5.5

5.5 initialization during initialization the positioner adapts it- self optimally to the friction conditions and the signal pressure demand of the control valve. The type and extent of self-adaptation de- pends on the preset parameters. Max is the default setting for the nominal range (code p4). Dur...

Page 32: 5.6

Note! The time required for the initialization procedure depends on the actuator transit time and can take a few minutes. Initialization successfully completed, positioner runs in control operation after a successful initialization, the positioner runs in control operation indi- cated by the control...

Page 33: 5.7

Reset error codes the error codes e0, e1, e8 and e9 can be reset as follows: turn button until the error code appears, press button, esc appears, turn button, rst appears, press button to reset error. The resetting procedure can be canceled by pressing button when esc appears. Canceling the fail-saf...

Page 34: Code List

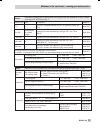

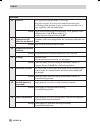

6 code list code display, values [default setting] description parameter codes * the positioner must be re-initialized when the setting is changed p0 status indication showing basic information. Canceling the fail-safe position with rst is possible. P1 reading direction the reading direction of the ...

Page 35

P7 w/x >> / [>>] direction of action of the reference variable w to the travel/rotational angle x (increasing/increasing or increasing/decreasing). P8 * gain k p 30/[50] on initializing the positioner, the gain is set to the selected value. P9 pressure limit on/[off] the signal pressure can take on ...

Page 36

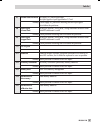

Error codes e0 zero error with tight-closing function p10 w zero point incorrect. Error may arise when the mounting posi- tion/linkage of the positioner moves or when the valve seat trim is worn, especially with soft-sealed plugs. Remedy check valve and mounting of the positioner. If ok, perform a z...

Page 37

E7 actuator does not move no supply air, mounting blocked. No input signal or input signal below 3.7 ma remedy check supply air, positioner mounting and ma input signal. Re-initialize the positioner. E8 travel signal at lower limit wrong pin position, wrong lever, wrong attachment direction when nam...

Page 38: Maintenance

7 maintenance the positioner does not require any mainte- nance. There are filters with a 100 μ m mesh size in the pneumatic connections for supply and output which can be removed and cleaned, if required. The maintenance instructions of any up- stream supply air pressure reducing stations must be o...

Page 39: Dimensions In Mm

9 dimensions in mm eb 8384-1 en 39 dimensions in mm a 1 z a 2 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 output a1 output a2 supply (9) 50 80 130 49 59 79 76 50 58 58 58 attachment to rotary actuators vdi/vde 3845 for all sizes of fixing level 2 or connecting plate direct attachmen...

Page 40

40 eb 8384-1 en.

Page 41

Eb 8384-1 en 41.

Page 42

42 eb 8384-1 en.

Page 43

Eb 8384-1 en 43.

Page 44

44 eb 8384-1 en.

Page 45

Eb 8384-1 en 45 $gghqgxp3djh 5hylv lrq&rqwur o1x p ehu0d\ $gghqgx pwr(% (1 ,qwulqvlfdoo\ vdih lilqv wdooh gdv vshf lilhg lq p dqxidfwxuhu·vlqvwdoo d wlrqpdqxdo &6$fhuwlilhgirukd]dugrxvorfdwlrqv ([ld,,&7&odvv ,=rqh &odvv,*urxsv$%& ' &odvv,,*urxsv()*&odvv,,, 7\sh(qf orvxuh 1rwhv 7khdss dudwx vpd \e hl...

Page 46

46 eb 8384-1 en $gghqgxp3djh 5hylv lrq&rqwur o1x p ehu0d\ $gghqgx pwr(% (1 &6$fhuwlilhgirukd]dugrxvorfdwlrqv ([q$&odvv ,=rqh &odvv,,'ly*urxsv$ % & ' &odvv,,'ly*urxsv()*&od vv,,, 7\sh(qf orvxuh hs sr vlwlrqhu zlwk vriwz duholplw v zlwfk hv + $=$5'286 6$)( /2&$7,21'ly=rqh /2&$7,21 1rwhv 7khlqvwdoo dwl...

Page 47

Eb 8384-1 en 47.

Page 48

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8384-1 en s/z 2006-05.