- DL manuals

- Samson

- Valve Positioners

- 3730 Series

- Mounting and operating instructions

Samson 3730 Series Mounting and operating instructions

Summary of 3730 Series

Page 1

Mounting and operating instructions eb 8384-6 en (1300-1623) firmware version 1.11 edition april 2017 series 3730 type 3730-6 electropneumatic positioner with hart ® communication and pressure sensors old design new design.

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8384-6 en 3 1 important safety instructions ..........................................................................7 2 article code ...................................................................................................8 3 design and principle of operation ...................

Page 4

4 eb 8384-6 en contents 5.1.2 supply pressure ...........................................................................................57 5.1.3 signal pressure (output) ................................................................................58 5.2 electrical connections ......................

Page 5

Eb 8384-6 en 5 contents 9.1 retrofittinganinductivelimitcontact ..............................................................89 10 maintenance ...............................................................................................91 11 servicing explosion-protected devices ....................

Page 6

6 eb 8384-6 en note: the functions of the expertplus valve diagnostics are described in the operating in- structions u eb 8389-1. These instructions are included on the enclosed cd-rom and is available on our website. Positioner firmware revisions old new 1.0x 1.10 apositionernotyetinitializedhasthe...

Page 7

Eb 8384-6 en 7 important safety instructions 1 important safety instructions foryourownsafety,followtheseinstructionsconcerningthemounting,start-upandopera- tion of the device: − thedeviceistobemounted,starteduporoperatedonlybytrainedandexperienced personnel familiar with the product. According to t...

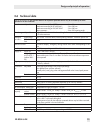

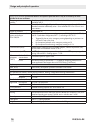

Page 8: 2 Article Code

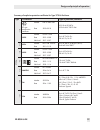

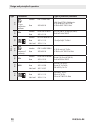

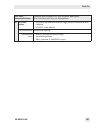

8 eb 8384-6 en article code 2 article code positioner type 3730-6 x x x x x x x 0 x x 0 x 0 0 withhart ® communication and pressure sensors explosion protection without 0 0 0 atex ii2gex iaiic/iibt6;ii2dextbiiict6ip66 1 1 0 iecex ex iaiic/iibt6;exd[ia]iic/iibt6;extda21ip66t80°c 1 1 1 gost 1ex iaiict...

Page 9

Eb 8384-6 en 9 article code positioner type 3730-6 x x x x x x x 0 x x 0 x 0 0 withhart ® communication and pressure sensors housing material aluminum (standard) 1 stainlesssteel1.4581 2 special applications without 0 devicecompatiblewithpaint 1 exhaustairportwith¼-18 nptthread,backofpositionerseale...

Page 10: Ation

10 eb 8384-6 en design and principle of operation 3 design and principle of oper- ation the electropneumatic positioner is mounted on pneumatic control valves and is used to assign the valve position (controlled vari- able x)tothecontrolsignal(referencevari- able w).Thepositionercomparestheelectric ...

Page 11

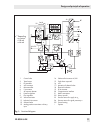

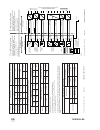

Eb 8384-6 en 11 design and principle of operation pd fsk % s mm % mm w x q g g serial interface 16 13 22 15 a2 a3 be a1 11 2 4 21 20 19 5 3 12 25 6 7 23 8 10 1 14 14 w x y 24 v dc 9 17 18 x 1) >12 v & 24 x 1) depending on version >3.8 ma >4.4 ma 1 control valve 2 travel sensor 3 pd controller 4 a/d ...

Page 12: 3.1 Safety Function (Sil)

12 eb 8384-6 en design and principle of operation 3.1 safety function (sil) thesafetyfunctionisbasedontheshutdown of the i/p converter (6). This causes the pneumaticactuatortobeventedandthe valvetomovetoitsfail-safeposition. Monitoring of the input signal the i/p converter is switched off when the i...

Page 13: 3.3 Communication

Eb 8384-6 en 13 design and principle of operation 3.3 communication the positioner is equipped with an interface for hart ® protocol(highwayaddressable remote transducer) for communication pur- poses. Data are transmitted in a superim- posed frequency (fsk = frequency shift key- ing) on the existing...

Page 14

14 eb 8384-6 en design and principle of operation catedoverasignalcurrentof >21.6 ma. Leakage sensor byupgradingthepositionerwithaleakage sensor,itispossibletodetectseatleakage when the valve is in the closed position. De- tailsonexpertplusvalvediagnosticsinthe operating instructions u eb 8389-1. Bi...

Page 15: 3.6 Technical Data

Eb 8384-6 en 15 design and principle of operation 3.6 technical data type3730-6positioner:the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Travel adjustable directattachmenttotype 3277actuator: 3.6to30 mm attachmentaccordingto...

Page 16

16 eb 8384-6 en design and principle of operation type3730-6positioner:the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Electromagnetic com- patibility complyingwithen61000-6-2,en61000-6-3,en61326-1andnamurrecom- mendation ne ...

Page 17

Eb 8384-6 en 17 design and principle of operation type3730-6positioner:the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Conformity · options for type 3730-6 positioner electronic forced venting·approvalacc.Toiec 61508/sil inpu...

Page 18

18 eb 8384-6 en design and principle of operation external position sensor travel same as positioner cable 10m·flexibleanddurable·withm12x1connector·flame-retardantacc.To vde 0472·resistanttooils,lubricantsandcoolantsaswellasotheraggressivemedia permissibleambient temperature –40to+90 °cwithafixedco...

Page 19

Eb 8384-6 en 19 design and principle of operation summary of explosion protection certificates for type 3730-6 positioner type certification type of protection/comments 3730-6- -110 ec type examination certificate number ptb 10atex2007 ii2gex iaiic/iibt6; ii2dextbiiict80°cip66 date 2010-08-18 nepsi ...

Page 20

20 eb 8384-6 en design and principle of operation type certification type of protection/comments 3730-6- -210 ec type examination certificate number ptb 10atex2007 withtype 3770-1fieldbarrier: ii2gex d[ia]iic/iibt6gb; ii2dextbiiict80°cip66 date 2010-08-18 -211 iecex number iecexptb 10.0057 ex iaiic/...

Page 21: Valve – Mounting Parts and

Eb 8384-6 en 21 attachment to the control valve – mounting parts and accessories 4 attachment to the control valve – mounting parts and accessories notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1.Remove the protective film f...

Page 22

22 eb 8384-6 en attachment to the control valve – mounting parts and accessories travel tables note: the m lever is included in the scope of delivery. S, l, xl levers for attachment according to iec 60534-6 (namur) are available as accessories (see table 3). Direct attachment to type 3277-5 and type...

Page 23: 4.1 Direct Attachment

Eb 8384-6 en 23 attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 2 on page 53 − observe the travel table on page 22. Actuator with 120 cm² (seefig. 3) the signal pressure from the posi...

Page 24

24 eb 8384-6 en attachment to the control valve – mounting parts and accessories.

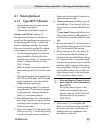

Page 25: 4.1.2 Type 3277 Actuator

Eb 8384-6 en 25 attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 on page 53 − observe the travel table on page 22. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mountthepositionerontheyoke.Th...

Page 26

26 eb 8384-6 en attachment to the control valve – mounting parts and accessories marking.

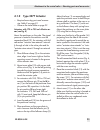

Page 27: Iec 60534-6

Eb 8384-6 en 27 attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 on page 54 − observe the travel table on page 22. Fig. 5 the positioner is attached to the control valve usinganamurbracket(10...

Page 28

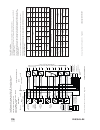

28 eb 8384-6 en attachment to the control valve – mounting parts and accessories attachmenttorod-typeyoke rodswith20to35 mmdiameter attachmenttonamurrib additionalbracketfor actuatorswith2800 cm² andtravel≥60 mm xlandllever 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower plate 3.1 follower ...

Page 29: Vdi/vde 3847

Eb 8384-6 en 29 attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 type3730-6-xxxxxxx0xx0600and type3730-6-xxxxxxx0xx0700positioners with air purging of the actuator's spring chambercanbeattachedaccordingtovdi/ vde 3847. Type 3730-6xxxxxxx0xx000...

Page 30

30 eb 8384-6 en attachment to the control valve – mounting parts and accessories.

Page 31

Eb 8384-6 en 31 attachment to the control valve – mounting parts and accessories 7. Insert the screws (13.1) through the mid- dleholesoftheadapterblock(13). 8. Place the connecting plate (12) together with the seal (12.1) onto the screws (13.1)correspondingtothefail-safeac- tion "actuator stem exten...

Page 32

32 eb 8384-6 en attachment to the control valve – mounting parts and accessories attachment to namur rib (see fig. 8) − required mounting parts and accesso- ries:table 4onpage 54 − observethetraveltableonpage 22. 1. Series 240 valves, actuator size up to 1400-60 cm²:screwthetwobolts(14) tothebracket...

Page 33

Eb 8384-6 en 33 attachment to the control valve – mounting parts and accessories 6. Insert the formed seal (17.1) into the turnboard(17)andmounttheturnboard totheadapterblock(13)usingthe screws (17.2). 7. Mounttheblankplate(18)totheturn- boardusingthescrews(18.1).Make sure that the seals are correct...

Page 34

34 eb 8384-6 en attachment to the control valve – mounting parts and accessories 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower plate 3.1 follower plate 4 blankingplug 5 sealing plug 6 adapterbracket 6.1 screw 6.2 moldedseal 6.3 screw 10 namur connectionblock 11 screw with toothed lockwash...

Page 35: Micro-Flow Valve

Eb 8384-6 en 35 attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 on page 54 − observe the travel table on page 22. Thepositionerisattachedtothevalveyoke usingabracket. 1. Fastenth...

Page 36

36 eb 8384-6 en attachment to the control valve – mounting parts and accessories s lever notice only use the connecting plate (6) included in the accessories to connect supply and output! Never screw threaded parts directly into housing! 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower plate...

Page 37: 4.5.1 Heavy-Duty Version

Eb 8384-6 en 37 attachment to the control valve – mounting parts and accessories 2. Placecouplingwheel(4)withflatside facing the actuator on the follower clamp (3).Refertofig. 11toalignslotsothatit matches the direction of rotation when the valve is in its closed position. 3. Fasten the coupling whe...

Page 38

38 eb 8384-6 en attachment to the control valve – mounting parts and accessories.

Page 39: Double-Acting Actuators

Eb 8384-6 en 39 attachment to the control valve – mounting parts and accessories place spacers (11) underneath, if neces- sary. 2. For samson type 3278 and vetec s160 rotary actuators, screw the adapt- er (5) onto the free end of the shaft or place adapter (5.1) onto the shaft of the vetec r actuato...

Page 40

40 eb 8384-6 en attachment to the control valve – mounting parts and accessories.

Page 41: 4.6.1 Reversing Amplifier

Eb 8384-6 en 41 attachment to the control valve – mounting parts and accessories the following applies to all reversing am- plifiers: the signal pressure of the positioner is sup- pliedattheoutput1ofthereversingamplifi- er. An opposing pressure, which equals the required supply pressure (z) when add...

Page 42

42 eb 8384-6 en attachment to the control valve – mounting parts and accessories.

Page 43: Position Sensor

Eb 8384-6 en 43 attachment to the control valve – mounting parts and accessories 4.7 attachment of external position sensor positioner unit with sensor mounted on a micro- flow valve − required mounting parts and accessories: table 7 on page 57 in the positioner version with an external po- sition s...

Page 44

44 eb 8384-6 en attachment to the control valve – mounting parts and accessories type 3277 actuator with 175 to 750 cm²: the signal pressure is routed to the connec- tionatthesideoftheactuatoryokeforthe versionwithfail-safeaction"actuatorstem extends".Forthefail-safeaction"actuator stem retracts" th...

Page 45: Sensor With Attachment

Eb 8384-6 en 45 attachment to the control valve – mounting parts and accessories 4. Placethelever(1)anddiskspring(1.2) on the sensor shaft. Place the lever in mid-position and hold it in place. Screw on the nut (1.1). 5. Place follower clamp (3) on the actuator stem, align it and screw tight so that...

Page 46: Sensor to Type 3510

46 eb 8384-6 en attachment to the control valve – mounting parts and accessories 2. Screw the position sensor (20) onto the bracket(21). The standard attached m lever with the fol- lower pin (2) at position 35 is designed for 120to350 cm²actuatorswith15 mmrated travel. For other actuator sizes or tr...

Page 47: 4.7.4 Mounting On Rotary

Eb 8384-6 en 47 attachment to the control valve – mounting parts and accessories withthediskspring(1.2)fromthesen- sor shaft. 2. Screw the position sensor (20) onto the bracket(21). 3. Select the s lever (1) from the accessories and screw the follower pin (2) into the hole for pin position 17. Place...

Page 48

48 eb 8384-6 en attachment to the control valve – mounting parts and accessories 4. Placethelever(1)anddiskspring(1.2) on the sensor shaft. Place the lever in mid-position and hold it in place. Screw on the nut (1.1). Followtheinstructionsdescribingattachment tothestandardpositionerinsection 4.5. In...

Page 49: 4.8 Mounting The Leakage

Eb 8384-6 en 49 attachment to the control valve – mounting parts and accessories 4.8 mounting the leakage sensor fig. 19 normally, the control valve is delivered with positionerandleakagesensoralready mounted. Iftheleakagesensorismountedafterthe valvehasbeeninstalledoritismountedon- to another contr...

Page 50: Stainless Steel Housings

50 eb 8384-6 en attachment to the control valve – mounting parts and accessories 4.9 attaching positioners with stainless steel housings positioners with stainless steel housings re- quire mounting parts that are completely made of stainless steel or free of aluminum. Note: the pneumatic connecting ...

Page 51

Eb 8384-6 en 51 attachment to the control valve – mounting parts and accessories attachment according to iec 60534-6 (namur rib or attachment to rod-type yokes) and to rotary actuators the positioner requires an additional port for theexhaustairthatcanbeconnectedover piping.Anadapteravailableasan ac...

Page 52

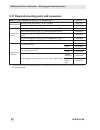

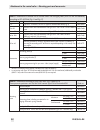

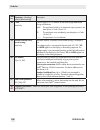

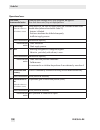

52 eb 8384-6 en attachment to the control valve – mounting parts and accessories 4.11 required mounting parts and accessories table 1: direct attachment to type 3277-5 actuator (fig. 3) order no. Mountingparts standardversionforactuators120 cm²orsmaller 1400-7452 versioncompatiblewithpaintforactuato...

Page 53

Eb 8384-6 en 53 attachment to the control valve – mounting parts and accessories table 2: direct attachment to type 3277 actuator (fig. 4) order no. Mounting parts standardversionforactuators175,240,350,355,700,750 cm² 1400-7453 versioncompatiblewithpaintforactuators175,240,350,355,700,750 cm² 1402-...

Page 54

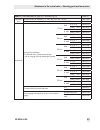

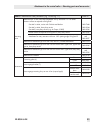

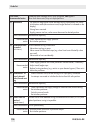

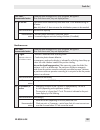

54 eb 8384-6 en attachment to the control valve – mounting parts and accessories table 3: attachment to namur ribs or control valves with rod-type yokes (20 to 35 mm rod diameter) according to iec 60534-6 (fig. 5 and fig. 9) travel in mm lever for actuator order no. 7.5 s type3271-5with60/120cm²onty...

Page 55

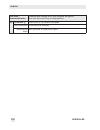

Eb 8384-6 en 55 attachment to the control valve – mounting parts and accessories table 5: attachment to rotary actuators (fig. 10 and fig. 11) order no. Mounting parts attachmentacc.Tovdi/vde3845(september2010),seesection 15.1fordetails actuatorsurfacecorrespondstofixinglevel1 sizeaa1toaa4,versionwi...

Page 56

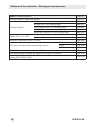

56 eb 8384-6 en attachment to the control valve – mounting parts and accessories table 6: general accessories order no. Reversingamplifierfordouble-actingactuators type 3710 cableglandm20x1.5, blackplastic(6to12 mmclampingrange) 8808-1011 blueplastic(6to12 mmclampingrange) 8808-1012 nickel-platedbra...

Page 57

Eb 8384-6 en 57 attachment to the control valve – mounting parts and accessories table 7: attachment of external position sensor order no. Templateformountingpositionsensoronoldermountingparts.Seenoteonpage 43 1060-0784 direct attachment mountingpartsforactuatorswith120cm².Seefig. 15(left). 1400-747...

Page 58: 5 Connections

58 eb 8384-6 en connections 5 connections warning! Risk of injury due to the actuator stem extending or retracting! Do not touch or block the actuator stem! Notice malfunction due to incorrect se- quence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protective fi...

Page 59

Eb 8384-6 en 59 connections thebenchrangeiswrittenonthenameplate either as the spring range or signal pressure range depending on the actuator. The direc- tionofactionismarkedfaorfe,orbya symbol. Note: plow is indicated under code 0 if the supply pressure p s is lower than the upper spring range val...

Page 60

60 eb 8384-6 en connections selecting cables and wires observeclause 12 of en 60079-14 (vde 0165,part 1)forinstallationofthein- trinsically safe circuits. Clause 12.2.2.7applieswhenrunningmulti- corecablesandwireswithmorethanone intrinsically safe circuit. Theradialthicknessoftheinsulationofa conduc...

Page 61: 5.2.1 Switching Amplifier

Eb 8384-6 en 61 connections equipment with energy-limited circuits in type of protection ex nl iic. Cable entry cableentrywithm20 x 1.5cablegland. See section on accessories for clamping range. Thereisasecondm20x1.5threadedhole inthehousingthatcanbeusedforaddition- al connection, when required. The ...

Page 62: Tion

62 eb 8384-6 en connections observetherelevantregulationsforinstalla- tion in hazardous areas. 5.2.2 establishing communica- tion communicationbetweenpcandpositioner using an fsk modem or handheld communi- cator (if necessary, using an isolation ampli- fier)isbasedonthehart ® protocol. Viator fsk mo...

Page 63

Eb 8384-6 en 63 connections standard bus (multidrop): inthestandardbus(multidrop)mode,the positioner follows the analog current signal (referencevariable)inthesamemanneras forpoint-to-pointcommunication.Thisoper- atingmodeis,forexample,suitableforsplit- range operation of positioners (series con- ne...

Page 64: Ings

64 eb 8384-6 en operating controls and readings 6 operating controls and read- ings rotary pushbutton therotarypushbuttonislocatedunderneath the front protective cover. The positioner is operatedonsiteusingtherotarypushbutton: turn : select codes and values press :confirmsetting air to open/air to c...

Page 65

Eb 8384-6 en 65 operating controls and readings readings icons assigned to certain codes, parameters and functions are indicated on the display. Operating modes: − manualmode(seesection 8.2.1) the positioner follows the manual set point(code 1)insteadofthemasignal. Blinks:thepositionerisnotinitializ...

Page 66

66 eb 8384-6 en operating controls and readings malfunction/fault manualmode closed-loopoperation code bar graph for set point deviation or lever position units fail-safepositionactive maintenancedemanded/ maintenancerequired blinks:outofspecification configurationenabled designation position parame...

Page 67: 6.1 Serial Interface

Eb 8384-6 en 67 operating controls and readings 6.1 serial interface thepositionermustbesuppliedwithatleast 3.8 ma. Thepositionercanbeconnecteddirectlyto the pc over the local serial interface and the serial interface adapter. The operator soft- wareistrovis-view(version4)within- stalleddevicemodule...

Page 68

68 eb 8384-6 en operating controls and readings table 8: dynamic hart ® variables assignment variable meaning unit set point set point % direction of action set point direction of action set point % set point after transit time specification setpointaftertransittimespecification % valve position act...

Page 69: 7 Start-Up and Settings

Eb 8384-6 en 69 start-up and settings 7 start-up and settings notice malfunction due to incorrect se- quence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protective film from the pneumatic connections. 2.Mount the positioner on the control valve. 3. Connect the ...

Page 70: Striction Q

70 eb 8384-6 en start-up and settings note: the switch position is prompted prior to an initialization. After an initial- ization has been completed, chang- ing the switch position does not have any effect on the operation of the po- sitioner. 7.2 adjusting the volume re- striction q max back min si...

Page 71: Range of The Positioner

Eb 8384-6 en 71 start-up and settings note: if no settings are entered within 120 seconds, the enabled configuration function becomes invalid. Enableconfiguration default: no turn g code 3, display: no press , code 3blinks. Turn yes press , display: limit the signal pressure: pressure limit defaul...

Page 72: 7.6 Initialization

72 eb 8384-6 en start-up and settings the permissible range has been exceed- ed when the displayed angle is more than30°andtheouterrightorleftbar elementblinks.Thepositionergoestothe fail-safeposition(safe). Aftercancelingthefail-safeposition (safe)(seesection 8.2.2)itisabsolutely essentialthatyouch...

Page 73

Eb 8384-6 en 73 start-up and settings − substitute calibration (sub) thismodeallowsapositionertobere- placed while the plant is running, with the least amount of disruption to the plant (see section 7.6.5). Note: for normal operation, simply start initialization by pressing the init key after mounti...

Page 74: Based On Maximum

74 eb 8384-6 en start-up and settings fail-safe position direction of action referencevariablew valve closed at open at air to open 0 % 100 % air to close 100 % 0 % thetight-closingfunctionhasbeenactivated. Set code15(finalpositionw>)to99% for three-way valves. Canceling an initialization process an...

Page 75: Based On Nominal Range

Eb 8384-6 en 75 start-up and settings after initialization, the maximum travel/an- gleofrotation(code 5)whichwasdetected during initialization is indicated. 7.6.2 nom – initialization based on nominal range thecalibratedsensorallowstheexactvalve traveltobemeasuredveryaccurately. Duringinitialization...

Page 76: Based On A Manually

76 eb 8384-6 en start-up and settings note: if the nominal range determined during initialization is smaller than the range entered in code 5, initial- ization is canceled and an error mes- sage (code 52) is generated. Î afterinitialization,checkthedirectionof action(code 7)and,ifnecessary, change i...

Page 77: Based On Manually Se-

Eb 8384-6 en 77 start-up and settings press . Turn code 1 press , code 1blinks. Turn clockwiseinsmallstepsuntilthere- quired valve position is reached. The valve mustbemovedwithamonotonicallyin- creasing signal pressure. Press toconfirmtheopenposition. Start initialization: Î pressinitkey! After i...

Page 78: Tion

78 eb 8384-6 en start-up and settings pos1 (end position 1) pos2 (end position 2) turn code 6 press , code 6blinks. Turn man2 press toconfirmthe man2 as the initial- ization mode. pos1 and the current an- gle position of the lever are indicated on the display in alternating sequence. Turn cloc...

Page 79

Eb 8384-6 en 79 start-up and settings enableconfiguration default: no turn g code 3, display: no press , code 3blinks. Turn yes press , display: enter the pin position and nominal range: mm pin position default: no mm nominal range (lockedwhencode 4=no) turn code 4 press , code 4blinks. Turn p...

Page 80

80 eb 8384-6 en start-up and settings change pressure limit and control parame- ters: note: do not change the pressure limit (code 16). Only change the control parameters k p (code 17) and t v (code 18) if the settings of the the re- placed positioner are known. Pressure limit default: no k p level ...

Page 81: 7.7 Zero Calibration

Eb 8384-6 en 81 start-up and settings note: − since initialization has not been completed, the error code 76 (no emergency mode) and possibly al- so error code 57 (control loop) may appear on the display. These alarms do not influence the posi- tioner’s readiness for operation. − if the positioner s...

Page 82

82 eb 8384-6 en start-up and settings enable configuration: turn g code 3, display: no press , code 3blinks. Turn yes press , display: perform zero calibration: init mode default max turn code 6 press , code 6blinks. Turn zp Î pressinitkey! Zerocalibrationstarts.Thepositioner moves the valve t...

Page 83

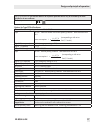

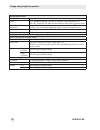

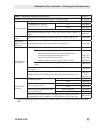

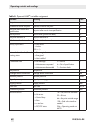

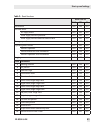

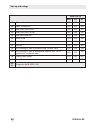

Eb 8384-6 en 83 start-up and settings table 9: reset functions reset code 36 diag std ds initialization no yes yes fail-safeaction air supply failure no no yes power supply failure of positioner no no yes power supply failure of external solenoid valve no no yes emergency mode no no no operating hou...

Page 84

84 eb 8384-6 en start-up and settings reset code 36 diag std ds 19 toleranceband no yes yes 20 select characteristic no yes yes 21 enter transit time open no yes yes 22 enter transit time closed no yes yes 24 total valve travel limit no yes yes 25 alarm mode no yes yes 26 limit a1 no yes yes 27 limi...

Page 85: 8 Operation

Eb 8384-6 en 85 operation 8 operation warning! Risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. 8.1 enabling and selecting pa- rameters all codes and their meaning and default set- tingsarelistedinthecodelistinsection 14. Codeswhicharemarkedwi...

Page 86

86 eb 8384-6 en operation % automatic mode switching to manual mode (man) turn code 0 press , display: auto, code 0blinks. Turn man press . The positioner changes to the man- ual mode ( ). The manual mode starts using the last set point of the automatic mode, ensuring a bumplesschangeover.Thecur...

Page 87: 8.3 Fault/malfunction

Eb 8384-6 en 87 operation exit the fail-safe position turn code 0 press , code 0blinks. Turn and select the required operating mode (auto or man). Press . The positioner switches to the operating mode selected. 8.3 fault/malfunction astatusclassificationisassignedtoallstatus and fault alarms in th...

Page 88: Sages

88 eb 8384-6 en operation the message with the highest priority deter- mines the condensed state in the positioner. Iffaultalarmsexist,thepossiblesourceof errorisdisplayedincode49onwards.In this case, err appears on the display. S example: errorcausedbypinposition refertothecodelist(section 14)forpo...

Page 89

Eb 8384-6 en 89 adjusting the limit contact 9 adjusting the limit contact the positioner version with an inductive limit contacthasanadjustabletag(1)mounted on the axis of rotation, which operates the proximity switch (3). For operation of the inductive limit contact, thecorrespondingswitchingamplif...

Page 90: Limit Contact

90 eb 8384-6 en adjusting the limit contact adjusting the switching point: note: during adjustment or testing, the switching point must always be ap- proached from mid-position (50 %). Toguaranteetheswitchingunderallambient conditions, adjust the switching point ap- prox.5 %beforethemechanicalstop(o...

Page 91

Eb 8384-6 en 91 adjusting the limit contact imity switch (7) on the cover with a dot of glue. 4. Removethejumper(8801-2267)atthe socketx7ofthetopboardandinsertthe cableconnector(11). 5. Guidethecableinsuchamannerthatthe plasticcovercanbeplacedbackontothe positioner.Insertthefixingscrews(2)and screwt...

Page 92: 10 Maintenance

92 eb 8384-6 en maintenance 10 maintenance the positioner does not require any mainte- nance. Therearefilterswitha100 µmmeshsizein the pneumatic connections for supply and outputwhichcanberemovedandcleaned, if required. The maintenance instructions of any up- stream supply air pressure reducing stat...

Page 93: Work On Equipment

Eb 8384-6 en 93 maintenance, calibration and work on equipment b) updates on site: updates on site are only permitted after the plant operator presented a signedhotworkpermit. Afterupdatinghasbeencompleted,addthe currentfirmwaretothenameplate;thiscan bedoneusinglabels. 13 maintenance, calibration an...

Page 94: 14 Code List

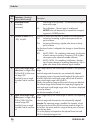

94 eb 8384-6 en code list 14 code list code no. Parameter–readings/ values[defaultsetting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 0 operating mode [man] manualmode auto automatic mode safe fail-safeposition esc cancel switchoverfr...

Page 95

Eb 8384-6 en 95 code list code no. Parameter–readings/ values[defaultsetting] description 4* pin position (continued) if you select a pin position in code 4 that is too small, the positioner switches to safe mode for reasons of safety. Pin position standard adjustment range code 4 code 5 code 5 17 7...

Page 96

96 eb 8384-6 en code list code no. Parameter–readings/ values[defaultsetting] description 6* initialization mode (init mode) (continued) kp: finetuningoftheinputfilter·thevalvemovesthroughits entire valve range. Np: zerocalibration·thezeropointisrecalibrated. Notice valve will temporarily be moved f...

Page 97

Eb 8384-6 en 97 code list code no. Parameter–readings/ values[defaultsetting] description 10* lower travel/angle limit (lowerx-limit) 0.0to49.9 %oftheoperat- ingrange,[no],esc lower limitation of the travel/angle of rotation to the entered val- ue. The characteristic is not adapted. 11* upper travel...

Page 98

98 eb 8384-6 en code list code no. Parameter–readings/ values[defaultsetting] description 14* closed end position (end position w 0.0to49.9 %,[1.0 %]ofthe span adjusted in code 12/13,no,esc limit of the set point w actuatorswithfail-safeactionatoarecompletelyventedand actuatorswithfail-safeactionatc...

Page 99

Eb 8384-6 en 99 code list code no. Parameter–readings/ values[defaultsetting] description 19* tolerance band 0.1to10.0 %,[5.0 %]ofthe operating range, esc used for error monitoring. Ifthesetpointdeviationisgreaterthanselectedtolerancebandfor atimelongerthanthelagtime[30 s],thiscausestheerrorcode 57(...

Page 100

100 eb 8384-6 en code list code no. Parameter–readings/ values[defaultsetting] description 23* absolute total valve travel [0]to99·10 7 , yes, esc exponential reading from 9999travelcyclesonwards totaled full valve travel cycle canberesetto0incode 36–stdandcode 36–ds. Note: the total valve travel is...

Page 101

Eb 8384-6 en 101 code list code no. Parameter–readings/ values[defaultsetting] description 26* limit a1 (alarm limit 1) 0.0to100.0[2.0]%ofthe operating range, no, esc the setting has no effect when an inductive limit con- tact is installed. The valve position limit relating to the operating range. A...

Page 102

102 eb 8384-6 en code list code no. Parameter–readings/ values[defaultsetting] description 31* position transmitter test 3) –10.0to110.0 %oftheop- eratingrange·esc,[default value is last indicated value ofthepositiontransmitter] testingthepositiontransmitter.Valuescanbeenteredinrelationto the operat...

Page 103

Eb 8384-6 en 103 code list code no. Parameter–readings/ values[defaultsetting] description 36* reset (continued) dag: reset diagnostics assessment − parameter settings, reference values and logs remain unchanged. − thepositionerdoesnotneedtobere-initialized. Ds: resets positioner to default settings...

Page 104

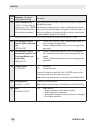

104 eb 8384-6 en code list code no. Parameter–readings/ values[defaultsetting] description 44 y info read only controlsignalyin%inrelationtothetravelrangedetermined during initialization max: thepositionerbuildsupitsmaximumoutputpressure,see descriptionincode 14and15. 0p: the positioner vents comple...

Page 105

Eb 8384-6 en 105 code list note: the error codes listed in following appear in the display corresponding to their status classification set over the condensed state (maintenance required/maintenance de- manded: , out of specification: blinking, failure: ). If “no message” is as- signed to the error ...

Page 106

106 eb 8384-6 en code list error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 52 attachment • thenominalrangecouldnotbeachievedduringinitializationwithnom initialization mode (the maximum travel/angle reached is ind...

Page 107

Eb 8384-6 en 107 code list error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 56 pin/switch position 1) pinpositionnotenteredfornominalrange(nom)orsubstitute(sub)ini- tialization. 2) ato/atc switch defective. Status...

Page 108

108 eb 8384-6 en code list operational error error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 57 control loop additional indication at thefaultalarmcontact! Controllooperror,thevalvenolongerfollowsthecontrolledvar...

Page 109

Eb 8384-6 en 109 code list error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 61 kp too low proportional-actioncoefficientkplevellowerthan3wasdetectedduringini- tialization. Note: a kp level statusclassification [ma...

Page 110

110 eb 8384-6 en code list error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 64 i/p converter (y) current circuit of i/p converter interrupted. Statusclassification failure(cannotbeclassified) recommended action re...

Page 111

Eb 8384-6 en 111 code list error appendix error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 65 hardware additional indication at the faultalarmcontact! • initializationkeyjammed. • ahardwareerrorhasoccurred.Theposi...

Page 112

112 eb 8384-6 en code list diagnosis errors error codes – recommended action condensed state message active, when prompted, err appears. Whenfaultalarmsexist,theyaredisplayedhere. 77 unassigned 78 unassigned 79 collective error messagesgeneratedinexpertplus the error does not have any direct effect ...

Page 113: 15 Dimensions In Mm

Eb 8384-6 en 113 dimensions in mm 15 dimensions in mm 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 70 70 28 schild 58 58 pressure gauge bracket or connecting plate attachmentaccordingtoiec 60534-6 lever(seefig. 31) external position sensor direct attachment m20 x 1.5 fig. 28: namur a...

Page 114

114 eb 8384-6 en dimensions in mm attachment according to vdi/vde 3847totype 3277 attachment according to vdi/vde 3847toanamur rib 62 164 38 200 16 4 164 13 62 24 fig. 29: attachment according to vdi/vde 3847 lever(seefig. 31).

Page 115

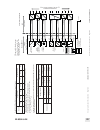

Eb 8384-6 en 115 dimensions in mm 56 86 130 80 166 30 86 Ø 101 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 reversing amplifier (optional)* heavy-duty version a 1 z a 2 output a1 output a2 supply (9) 50 80 58 130 49 59 79 76 50 150 reversing amplifier (optional)* connecting plate g ¼...

Page 116

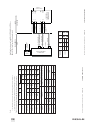

116 eb 8384-6 en dimensions in mm x z y 16 10...17 lever x y z s 17 mm 25 mm 33 mm m 25 mm 50 mm 66 mm l 70 mm 100 mm 116 mm xl 100 mm 200 mm 216 mm fig. 31: lever 15.1 fixing levels according to vdi/vde 3845 (september 2010) a m6 c b 25 m min Ød Ød fixinglevel2(bracketsurface) fixing level 1 (actua...

Page 117

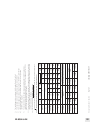

Eb 8384-6 en 117 valve characteristic selection linear (select characteristic: 0) 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] equal percentage (select characteristic: 1) reverse equal percentage (select characteristic: 2) 0 50 100 0 50 100 travel/ angle of rotation [%] ref...

Page 118

Samson butterfly valve linear (select charac- teristic: 3) samson butterfly valve equal percentage (select characteristic: 4) 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] vetec rotary plug valve linear (...

Page 119

Eb 8384-6 en 119.

Page 120

120 eb 8384-6 en.

Page 121

Eb 8384-6 en 121.

Page 122

122 eb 8384-6 en.

Page 123

Eb 8384-6 en 123.

Page 124

124 eb 8384-6 en.

Page 125

Eb 8384-6 en 125.

Page 126

126 eb 8384-6 en r ev is ion c on trol n um be r: 01/ n ov em be r 2014 page 1 of 6 a dde ndum to e b 8 38 4- 6 e n in st al la tio n m an ua l f or eq ui pm en t c ert ifi ed b y f m f or us e i n ha za rd ou s a rea s in tri ns ic al ly saf e i f i nst al le d as sp ec ifi ed in m an uf ac tu re r...

Page 127

Eb 8384-6 en 127 r ev is ion c on trol n um be r: 01/ n ov em be r 2014 page 3 of 6 a dde ndum to e b 8 38 4- 6 e n ta bl e 2 : c sa /f m -ce rt ifi ed b arri er p ara m et ers o f c ir cu it 1, 2 an d 6 b arr ier suppl y ba rr ie r ev al ua tio n ba rr ie r v 0c r mi n. I sc p ma x. V 0c r mi n. I ...

Page 128

128 eb 8384-6 en r ev is ion c on trol n um be r: 01/ n ov em be r 2014 page 5 of 6 a dde ndum to e b 8 38 4- 6 e n n ot e! 1.) fo r th e m ax im um v alu es o f th e in div id ua l e ne rg y lim ited ci rcu its se e tab le 4 . 2.) c abl e ent ry : onl y r ig id m et al c ondui t a cc or di ng to dr...

Page 129

Eb 8384-6 en 129 r ev is ion c on trol n um be r: 0 / m ay 2012 page 1 of 5 a dde ndum to e b 8 38 4- 6 e n ins ta lla tio n m anu al fo r a ppa ra tus c er tif ie d by c sa / f m for u se in h az ar do us loc at ion s. In tri nsi cal ly saf e i f i nst al le d as sp ec ifi ed in m an uf ac tu re r’...

Page 130

130 eb 8384-6 en r ev is ion c on trol n um be r: 0 / m ay 2012 page 3 of 5 a dde ndum to e b 8 38 4- 6 e n c ircu it seri al in terf ace b u ex tern al p os iti on sen so r ( r i ≥ 10k Ω p assi ve ) te rmi na l c on ne ct or a na lo g p cb . Pi n p9 , p1 0, p 11 / e xt er na l c on nect or u i or v...

Page 131

Eb 8384-6 en 131 r ev is ion c on trol n um be r: 0 / m ay 2012 page 5 of 5 a dde ndum to e b 8 38 4- 6 e n 1.) th e i ns ta llat io n m ust b e i n acco rd an ce w ith th e c an ad ian e le ct rical c od e, p ar t 1 2.) fo r t he m ax im um va lu es for the in di vi du al e ne rgy l im ited c ircu ...

Page 132: Eb 8384-6 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8384-6 en 2017-04-19 · engl ish.