- DL manuals

- Samson

- Valve Positioners

- 3730-4

- Configuration Manual

Samson 3730-4 Configuration Manual

Summary of 3730-4

Page 1

Series 3730 electropneumatic positioner type 3730-4 configuration and operation over profibus-pa configuration manual kh 8384-4 en firmware version k 2.00/r 1.52 edition may 2012 fig. 1 · configuration and operation over trovis-view (type 3730-4).

Page 2

Note concerning this configuration manual the rotary pushbutton on the positioner allows the type 3730-4 positioner to be operated and configured on site. In addition, the settings can be performed over the profibus-pa network or over the samson ssp interface. The mounting and operating instructions...

Page 3

Revisions of positioner firmware in comparison to previous versions communication firmware revisions k 1.01 internal modifications k 1.10 the feature_select parameter allows you to set whether an active diagnostic func- tion is to be reported by a good_function_check or a bad_function_ check (see pa...

Page 4

4 kh 8384-4 en.

Page 5

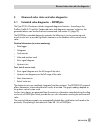

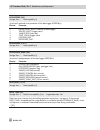

Contents page 1 profibus-pa communication . . . . . . . . . . . . . . . . . . . . . . 6 2 profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3 cyclic data exchange . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3.1 gsd files and automatic id number adaptation . . . . ...

Page 6: Profibus-Pa Communication

1 profibus-pa communication the profibus-pa is a fieldbus version for process automation based on the widely used profibus-dp. The transmission technique conforms with the iec 61158-2 standard and therefore fulfills the requirements for the type of protection, intrinsic safety. Profibus-dp defines t...

Page 7: Cyclic Data Exchange

3 cyclic data exchange cyclically transmitted parameters the following parameters that are transmitted in cyclic data transfer are marked with an as- terisk (*) in the parameter lists on page 38 onwards. 4 pos_d current position of the valve (discrete) 0: not initialized 1: closed (x 2: open (x > 99...

Page 8: 3.1

Status of the device and measured values 4 checkback refer to section 4 for device status. 4 status each process value is assigned a status according to the profibus-pa profile. Status of reference variable (hex): 0-3f 40-7f 80-bf bad uncertain good refer to section 5 for measured value status. 3.1 ...

Page 9

The id number (ident number) of the gsd file must be the same as the id number of the de- vice to ensure successful integration. The automatic ident number adaption function allows a type 3785 positioner to be re- placed by a type 3730-4 positioner without having to replace the gsd file in the host ...

Page 10: 3.2

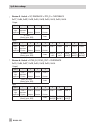

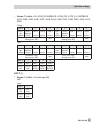

3.2 data exchange the relationship between output and input is based on the control system/master class 1. Slot 1 4 version 1: module = sp 0x4a or 0x82, 0x84, 0x08, 0x05 output byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction sp, valu...

Page 11

4 version 3: module = sp, readback + pos_d 0xc6, 0x84, 0x86, 0x08, 0x05, 0x08, 0x05, 0x05, 0x05 output byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction sp, value (floating point, ieee) status input byte 0 1 2 3 4 5 6 octet 1 sign, exp...

Page 12

4 version 5: module = sp, readback + pos_d + checkback 0xc7, 0x84, 0x89, 0x08, 0x05, 0x08, 0x05, 0x05, 0x05, 0x0a output byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction sp, value (floating point, ieee) status input) byte 0 1 2 3 4 5 ...

Page 13

4 version 7: module = sp + rcas_in, readback + rcas_out + pos_d + checkback 0xcb, 0x89, 0x8e, 0x08, 0x05, 0x08, 0x05, 0x08, 0x05, 0x08, 0x05, 0x05, 0x05, 0x0a output byte 0 1 2 3 4 5 6 7 8 9 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction octet 1 s...

Page 14: 3.3

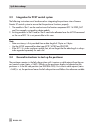

3.3 integration for pcs7 control system the following instructions must be observed on integrating the positioner into a siemens simatic s7 control system to ensure that the positioner functions properly: 1. The module in slot 1 can be read out over the function component sfc 14 dprd_dat and, for ex...

Page 15: Checkback – Device Status

4 checkback – device status each bit can be masked individually for cyclic communication by the class 2 master. This al- lows a targeted selection to be made from the active alarms. Byte bit name description 0 0 cb_fail_safe fail-safe position: the fail-safe position has been trig- gered. This may h...

Page 16

Byte bit name description 1 5 cb_contr_err control loop error: the control valve no longer follows the controlled variable in the tolerable times (see error code 57 in eb 8384-4 en). The error must be reset manually. R 6 cb_contr_inact positioner inactive: this is set when the device is in the out o...

Page 17: 5.1

5 measured value status and valve diagnostics 5.1 extended valve diagnostics – expertplus the type 3730-4 positioner includes integrated diagnostic functions. According to the profibus profile 3.01 and the 'condensed status and diagnostic messages' extension, the generated alarms can be classified a...

Page 18: 5.2

5.2 classification of the status alarms and the condensed state note: the following description only applies to positioners configured corresponding to the profile 3.01 with the 'condensed status and diagnostic messages' extension (set in the cond_status_ diag parameter of the physical block). The a...

Page 19

The condensed state is displayed in the engineering tool and on the positioner display (see table below). Status modification the classification of the status alarms can be assigned as required using the trovis-view software connected to the local ssp interface of the positioner or over the pa param...

Page 20

20 kh 8384-4 en measured value status and valve diagnostics fig. 3 · status and diagnostic alarms event con- densed state? Yes diagnosis status good/no m essage m aintenance required d ia_m aintenance m aintenance demanded d ia_m aintenance_ demanded m aintenanc e alarm dia_m a intenance_alar m proc...

Page 21: 5.3

5.3 status alarm according to profile 3.01 fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 operational errors device not initialized 0x1c bad_out_of_service solenoid valve active 0x80 good_non_specific total travel exceeded 0xa4 good_maint_req control loop error 0x4a good_maint_...

Page 22

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 test calculation 0x0c bad_device_failure program loading error 0x0c bad_device_failure data errors control parameter 0xa4 good_maint_req potentiometer parameter 0xa4 good_maint_req calibration error 0xa4 good_maint_req internal dev...

Page 23

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 friction much higher over whole range 0x80 good_non_specific much lower over whole range 0x80 good_non_specific much higher over partial range 0x80 good_non_specific much lower over partial range 0x80 good_non_specific much higher ...

Page 24

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 observing end position zero point shift monotonously downwards, average value above reference lines 0x80 good_non_specific zero point shift monotonously upwards, average value above reference lines 0x80 good_non_specific zero point...

Page 25: 5.4

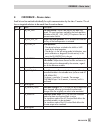

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 function activated initialization active 0x80 good_non_specific diagnostic function activated 0x80 good_non_specific 5.4 status alarms according to profile 3.01 condensed status fault/diagnostic alarm default setting acc. To pro- f...

Page 26

Fault/diagnostic alarm default setting acc. To pro- file 3.01 condensed status classified diagnosis yes no initialization running 0xa4 good_maint_req • – hardware error x signal 0xa8 good_main_demanded • dia_measurement i/p converter 0x24 bad_maint_alarm • dia_hw_electr hardware 0x24 bad_maint_alarm...

Page 27

Fault/diagnostic alarm default setting acc. To pro- file 3.01 condensed status classified diagnosis yes no perhaps bias reduced (test) 0x80 good_non_specific • – perhaps bias increased (test) 0x80 good_non_specific • – working at full capacity 0x80 good_non_specific • – working at full capacity (tes...

Page 28

Fault/diagnostic alarm default setting acc. To pro- file 3.01 condensed status classified diagnosis yes no perhaps larger than in original state (test) 0x80 good_non_specific • – perhaps larger than original state 0x80 good_non_specific • – external leakage perhaps soon expected 0x80 good_non_specif...

Page 29: 5.5

Fault/diagnostic alarm default setting acc. To pro- file 3.01 condensed status classified diagnosis yes no mostly max. Opening 0x80 good_non_specific • – temperature monitoring lower limit exceeded 0x80 good_non_specific • – higher limit exceeded 0x80 good_non_specific • – reference run reference te...

Page 30

The diagnostic alarm is made up of the standard diagnosis according to profibus-dp protocol and the user-specific diagnosis. The first six octets of the diagnostic alarm are as- signed to the standard diagnosis, essentially providing a statement about the state of the cy- clic connection. Special at...

Page 31

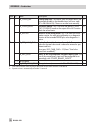

The default setting causes the positioner to provide a manufacturer-specific diagnosis of 26 bytes and a diagnosis of 14 bytes according to profile 3.01. Octet bit explanation note 1 0…7 standard slave diagnostics 2 0…7 3 0…7 4 0…7 5 0…7 6 0…7 7 0…7 definition of manufacturer-specific diagnostic ala...

Page 32

Octet bit explanation note 13 4…7 reserved in profile 3.01 14 0…6 reserved in profile 3.01 7 extension_available (further diagnostic information available) 15 3) 0 device not initialized 1 solenoid valve active 2 total valve travel limit exceeded (see code 24) 3 control loop (see code 57) 4 zero poi...

Page 33

Octet bit explanation note 18 3) 0 no emergency mode (see code 76) 1 program load error (see code 77) 2 options parameter (see code 78) 3 info parameter (see code 75) 4 data memory (see code 66) 5 control calculation (see code 67) 6 pa parameter (see code 74) 7 diagnostic parameter (see code 80) 19 ...

Page 34

Octet bit explanation note 22 3) 0 friction: lower over partial range 2 1 friction: higher whole range (test) 2 2 friction: lower whole range (test) 2 3 friction: higher over partial range (test) 2 4 friction: lower over partial range (test) 2 5 leakage in pneumatics: perhaps existing (test) 2 6 lea...

Page 35

Octet bit explanation note 25 3) 0 zero point shift alternating, average value below reference lines 2 1 attachment between positioner and valve: travel transmission not optimal (test) 2 2 attachment between positioner and valve: perhaps loose 2 3 attachment between positioner and valve: perhaps wor...

Page 36: Acyclic Data Exchange

6 acyclic data exchange note: all parameters in the parameter list on page 38 onwards, which are not marked, are included in the acyclic data exchange. The acyclic data exchange complying to dp-v1 with a master class 2 (ms2) is mainly used for commissioning, parameter settings and for diagnostic pur...

Page 37

7 partial stroke testing over dp-v0 the partial stroke test (pst) can be started in the following ways: operating mode test mode pst start over binary input start with auto test time start over reference variable auto pst man • – • 1) pst auto • • • 1) man pst man • – – pst auto • • – 1) the partial...

Page 38: Parameter Lists

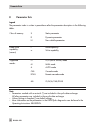

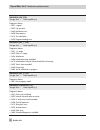

8 parameter lists legend the parameter index is written in parentheses after the parameter description in the following tables. Class of memory: s d n static parameter dynamic parameter non-volatile parameter read/write capability: (access) r w read capability write capability supported modes: o m a...

Page 39: 8.1

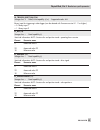

8.1 physical block, slot 0 · profile-specific parameters alert_key (20) storage class: s · read/write capability (r/w) · supported modes: all identification number of the plant section alm_sum (23) storage class: – · read capability (r) current state of process alarms in the physical block. Block_ob...

Page 40

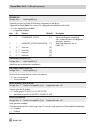

Device_man_id (26) storage class: – · read capability (r) manufacturer of the positioner device_message (37) storage class: s · read/write capability (r/w) · supported modes: all any desired text. The text is saved in the field device. • max. 32 characters, [no text] device_ser_num (28) storage clas...

Page 41

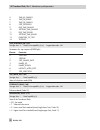

Byte bit according to pa v3.01 description 2 0 dia_maintenance_alarm device error exists 2 1 dia_maintenance_demanded maintenance demanded 2 2 dia_function_check device performing a function check or it is in simulation or in mode_lo 2 3 dia_inv_pro_cond the current process conditions do not allow a...

Page 42

Byte bit description 3 0 emergency mode · no error (code 76) 3 1 program loading error (code 77) 3 2 options parameter (code 78) 3 3 info parameter (code 75) 3 4 data memory (code 66) 3 5 test calculation (code 67) 3 6 pa parameters (code 74) 3 7 diagnostic parameters (code 80) 4 0 reset communicati...

Page 43

• 2712 (0x0a98) · resets the bus address to the default value of 126. The positioner restarts after the reset is performed. The bus address is not reset when the identification parameters are reset. Note: the bus address can only be reset using this command in firmware version k 1.11 and higher. • 3...

Page 44

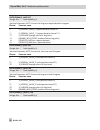

Feature (42) storage class: – · read capability (r) optional existence and state of the feature integrated into the device supported/enabled (note: the structure for supported and enabled are identical!) • 0 = not supported/not enabled • 1 = supported/enabled byte bit element [default] description 0...

Page 45

Mode_blk (22) storage class: – · read capability (r) current mode of the physical block software_revision (24) storage class: – · read capability (r) firmware version (communication ® code 48 f0 /control ® code 43) st_rev (17) storage class: – · read capability (r) revision level of static data stra...

Page 46

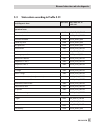

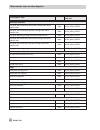

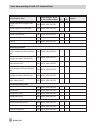

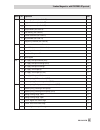

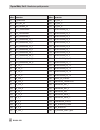

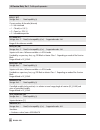

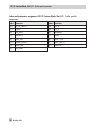

Index and parameter assignment: physical block, slot 0 · profile-specific parameters 46 kh 8384-4 en physical block, slot 0 · profile-specific parameters index parameter 16 block_obj 17 st_rev 18 tag_desc 19 strategy 20 alert_key 21 target_mode 22 mode_blk 23 alm_sum 24 software_revision 25 hardware...

Page 47

8.1.1 physical block, slot 0 · manufacturer-specific parameters active_ident_number (137) storage class: – · read capability (r) gsd file used to run the positioner if the positioner is in the compatibility mode, it can run using the following gsd files: • 3785: 3785 profile 2 • 071d: 3785 profile 3...

Page 48

• 7 · actively closed – diagnosis leakage sensor/cb_add_input solenoid valve – di2 · a leakage sensor is operated at the input as actively closed. This information can be analyzed with function block di2. Additionally, the state of the internal solenoid valve is also transmitted cyclically with chec...

Page 49

Datalogger_ds_15 (125) storage class: – · read capability (r) test function: data logger – data set 1 to 14 element parameter name 0 sollwert_w_1 (reference variable w - data set 1) 1 istwert_x_1 (valve position x - data set 1) 2 stellsignal_y_1 (drive signal y - data set 1) 3 regelabweich_e_1 (setp...

Page 50

Diagnosis_data_1 (131) storage class: – · read capability (r) diagnostic alarms • 0x01 inconsistent data memory • 0x02 potentiometer parameter • 0x04 calibration parameter • 0x08 general parameter • 0x10 interal device error • 0x20 pa parameter • 0x40 info parameter • 0x80 options parameter diagnosi...

Page 51

Kh 8384-4 en 51 physical block, slot 0 · manufacturer-specific parameters byte bit description 2 0 leakage in pneumatics: perhaps too large 2 1 restriction of working range: downwards 2 2 restriction of working range: upwards 2 3 restriction of working range: modification impossible 2 4 dynamic stre...

Page 52

Diagnosis_hw (130) storage class: – · read capability (r) diagnostic alarms • 0x01 x signal • 0x02 i/p converter • 0x04 hardware error • 0x08 data memory • 0x10 test calculation • 0x20 program loading error diagnosis_init_1 (128) storage class: – · read capability (r) diagnostic alarms • 0x01 x > ra...

Page 53

Dl_trigger_select_bin (136) storage class: s · read/write capability (r/w) · supported modes: all binary input for triggerung in data logger (can be selected with firmware version k 1.11 or higher) • 0 · binary input 1 • 1 · binary input 2 et_bsz (78) storage class: – · read capability (r) statistic...

Page 54

Feature_select (64) storage class: s · read/write capability (r/w) · supported modes: all coded bitwise, therefore more than one alarm possible at one time bit: 0 = false · 1 = true byte bit description 0 0 bad_device_failure sets diag_ext-bit · by using the 'condensed status and di- agnostic messag...

Page 55

Kh 8384-4 en 55 physical block, slot 0 · manufacturer-specific parameters fst_sw_1 (142) to fst_sw_4 (145) storage class: – · read capability (r) tests man: full stroke test (fst) – reference variable data set 1 to 4 • fst_sw_1: data set 1 (measured points 1 to 25) • fst_sw_2: data set 2 (measured p...

Page 56

Histogramm_e_lang (67) storage class: – · read capability (r) statistical information auto: structure for long-term setpoint deviation histogram element parameter name 0 e_interval_value_0 (setpoint deviation interval 0) … 11 e_interval_value_11 (setpoint deviation interval 11) 12 e_average (average...

Page 57

Kh 8384-4 en 57 physical block, slot 0 · manufacturer-specific parameters histogramm_z_kurz (71) storage class: – · read capability (r) statistical information auto: structure for short-term cycle counter histogram element parameter name 0 z_interval_value_0 (cycle counter interval 0) … 12 z_interva...

Page 58

Hysterese_kurz (76) storage class: – · read capability (r) statistical information auto: structure for drive signal diagram hysteresis in short-term monitoring element parameter name 0 stellsignal_0 (drive signal 0) 0 ventilstellung_0 (valve position 0) … 9 stellsignal_9 (drive signal 9) 9 ventilste...

Page 59

Kh 8384-4 en 59 physical block, slot 0 · manufacturer-specific parameters pst_ss_1 (101) and pst_ss_2 (102) storage class: – · read capability (r) tests man: partial stroke test (pst) – drive signal data set 1 and 2 pst_sw_1 (97) to pst_sw_4 (100) storage class: – · read capability (r) tests man: pa...

Page 60

Stat_kennlinie_vs_1 (85) to stat_kennlinie_vs_4 (88) storage class: – · read capability (r) tests man: static characteristic – valve position data set 1 to 4 • stat_kennlinie_vs_1: data set 1 (measuring points 1 to 25) • stat_kennlinie_vs_2: data set 2 (measuring points 26 to 50) • stat_kennlinie_vs...

Page 61

Stationaer_kurz_rp (74) storage class: – · read capability (r) statistical information auto: structure for drive signal diagram steady-state in short-term monitoring. Ring buffer values, containing drive signal and valve position element parameter 0 stellsignal_0 (drive signal 0) 0 ventilstellung_0 ...

Page 62

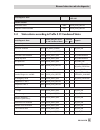

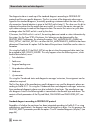

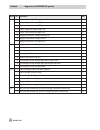

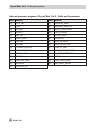

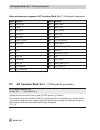

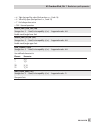

62 kh 8384-4 en physical block, slot 0 · manufacturer-specific parameters index parameter 79 et_endlage 80 stat_ref_vs 81 stat_again_vs 82 stat_stellsignal 83 hys_stellsignal 84 stat_kennlinie_r 85 stat_kennlinie_vs_1 86 stat_kennlinie_vs_2 87 stat_kennlinie_vs_3 88 stat_kennlinie_vs_4 89 stat_kennl...

Page 63

8.1.2 ao function block, slot 1 · profile-specific parameters alert_key (20) storage class: s · read/write capability (r/w) · supported modes: all id number of the plant unit alm_sum (23) storage class: – · read capability (r) current states of the process alarms in the ao function block batch (24) ...

Page 64

Check_back_mask (50) storage class: – · read capability (r) defines the supported status bits in check_back bit = 0: status not supported bit = 1: status supported check_back_opt (65) storage class: s · read/write capability (r/w) · supported modes: all this alarm does not apply for acyclic access d...

Page 65

In_channel (37) storage class: s · read/write capability (r/w) · supported modes: all assignment between the transducer block and the function block • 0 · not active • 0x013a · active (feedback_value is written to readback) increase_close (52) storage class: s · read/write capability (r/w) · support...

Page 66

Pos_d* (47) storage class: – · read capability (r) current position of the valve (discrete) • 0 · not initialized • 1 · closed (x • 2 · open (x > 99.5 %) • 3 · intermediate position pv_scale (27) storage class: s · read/write capability (r/w) · supported modes: all range of the reference variable rc...

Page 67

Sp (25) storage class: s · read/write capability (r/w) · supported modes: all upper limit of the reference variable • value and range from pv_scale ±10 %, [100 %] note: this value must be adapted correspondingly if the scale end setting is changed in pv_scale parameter. St_rev (17) storage class: – ...

Page 68: 8.2

Index and parameter assignment: ao transducer block, slot 1 · profile-specific parameters 8.2 ao transducer block, slot 1 · profile-specific parameters act_stroke_time_dec (89) storage class: – · read capability (r) specifies the minimum transit time to reach closed position [s] (code 41) the minimu...

Page 69

Act_stroke_time_inc (90) storage class: – · read capability (r) specifies the minimum transit time to reach open position [s] (code 40) the minimum transit time to reach open (100 % position) position is the actual time in seconds that the system (consisting of positioner, actuator and valve) needs ...

Page 70

Alarm_sum (87) storage class: – · read capability (r) current state of process alarms in the ao transducer block • [0] alarm_key (84) storage class: s · read/write capability (r/w) · supported modes: all id number of the plant unit • [0] block_obj (80) storage class: – · read capability (r) device_c...

Page 71

Mode_blk (86) storage class: – · read capability (r) current mode of positioner positioning_value (137) storage class: – · read capability (r) current positioning value unit of out_scale rated_travel (112) storage class: s · read/write capability (r/w) · supported modes: all specifies the rated trav...

Page 72

• 35 to 39 · – • 40 · reset “x signal“ • 41 · reset “i/p converter“ • 42 · reset “hardware“ • 43 · reset “control parameter“ • 44 · reset “potentiometer parameter“ • 45 · reset “calibration“ • 46 · reset “general parameters“ • 47 · reset “internal device error 1“ • 48 · reset “no emergency mode“ • 4...

Page 73

• 7 · calibration sequence mixed up • 8 to10 · – • 11 · timeout • 12 · proportional range restricted too much • 13 · rated travel or transmission incorrectly selected • 14 · mechanics system stuck (during initialization) • 15 · pneumatics system leaks (during initialization) • 16 · action interrupte...

Page 74

Setp_cutoff_inc (119) storage class: s · read/write capability (r/w) · supported modes: all final position w > (code 15) if the reference variable exceeds the entered value, the valve moves towards the final position which corresponds to 100 % reference variable. Electropneumatic actuators are compl...

Page 75

Kh 8384-4 en 75 ao transducer block, slot 1 · profile-specific parameters travel_limit_low (127) storage class: s · read/write capability (r/w) · supported modes: all travel/angle lower limit [% of pv_scale] (code 10) limitation of the travel/angle of rotation downwards to the entered value. The cha...

Page 76

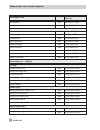

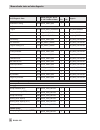

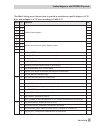

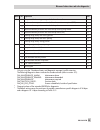

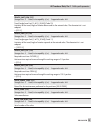

Valve_type (141) storage class: s · read/write capability (r/w) · supported modes: all type of valve • 0 · valve with straight-moving plug • 1 · valve with rotary moving plug (part-turn) • 2 · valve with rotary moving plug (multi-turn) index and parameter assignment: ao transducer block, slot 1 · pr...

Page 77: 8.3

8.3 ao transducer block, slot 1 · manufacturer-specific parameters active_ident_number (205) storage class: – · read capability (r) gsd file in the positioner if the positioner is in the compatibility mode, it can run using the following gsd files: • 3785: 3785 profile 2 • 071d: 3785 profile 3 • 068...

Page 78

Datalogger (185) storage class: – · read capability (r) structure of read and write parameters of the data logger (expertplus) element parameter 0 datalogger_select (selection for data logger) 1 trigger_select (trigger status) 2 sample_rate (scan rate) 3 start_value (trigger value) 4 logging_limit 5...

Page 79

Device_charact (202) and device_charact_2 (231) storage class: s · read/write capability (r/w) · supported modes: all structure of the device properties element parameter 0 actuator effective area 1 type of actuator 2 attachment 3 lower signal pressure range 4 upper signal pressure range 5 supply pr...

Page 80

Diag_testinfo (201) storage class: – · read capability (r) info parameter concerning an active diagnostic test running (expertplus) 0 · d1 drive signal diagram steady-state 2 · d2 drive signal diagram hysteresis 4 · d3 static characteristic 8 · d4 partial stroke test 16 · d5 drive signal diagram hys...

Page 81

• 5 · start partial stroke test • 6 · stop partial stroke test • 7 · start all tests automatically in sequence • 8 · stop tests • 9 · start drive signal test steady-state • 10 · stop drive signal test steady-state • 11 · start drive signal test hysteresis • 12 · stop drive signal test hysteresis • 1...

Page 82

Event_logging_1 (190) and event_logging_2 (191) storage class: – · read capability (r) data sets 1/2 of the event logging (expertplus) element parameter 0 messages_0…15 (alarms 0…15) 1 elapsed_hours_meter_0…15 (time stamp of recorded alarms 0…15) … 29 message_14…29 (alarms 14…29) 30 elapsed_hours_me...

Page 83

• fst_meas_data1…3_dead_ti_fall • fst_meas_data1…3_t63_falling • fst_meas_data1…3_t98_falling • fst_meas_data1…3_rise_ti_falling • fst_meas_data1…3_settl_ti_falling fst_cancel_conditions (226) storage class: s · read/write capability (r/w) · supported modes: all cancelation conditions of the full st...

Page 84

Fst_test_status_1 (228) to fst_test_status_3 (230) storage class: – · read capability (r) status of performed full stroke tests (fst) histogramm_e_abtastrate (200) storage class: s · read/write capability (r/w) · supported modes: all scan rate for setpoint deviation histogram for short-term monitori...

Page 85

Pressure_limit (177) storage class: s · read/write capability (r/w) · supported modes: all pressure limit (code 16) • 1 · off • 2 · 3.7 bar • 3 · 2.4 bar • 4 · 1.4 bar pst_analysis_1 (213) to pst_analysis_3 (215) storage class: – · read capability (r) settings for partial stroke test (pst) • pst_mea...

Page 86

• pst_cancel_cond_activ_max_time (activation 'max. Breakaway time') • pst_cancel_cond_max_break_time (max. Breakaway time) • pst_cancel_cond_active_time_reach (activation 'allowed time to reach pst target') • pst_cancel_cond_time_reach (allowed time to reach pst target) pst_display (218) storage cla...

Page 87

Pst_test_status_1 (219) to pst_test_status_3 (221) storage class: – · read capability (r) status of partial stroke tests (pst) • pst_test_stat1...3_test_start (test start) • pst_test_stat1...3_no_test_avail (no test available) • pst_test_stat1...3_x_cancel (x cancellation) • pst_test_stat1...3_y_can...

Page 88

• 29 reset 'travel histogram x - short-term monitoring' • 30 reset 'setpoint deviation histogram e - short-term monitoring' • 31 reset 'cycle counter histogram - short-term monitoring' • 32 reset 'drive signal diagram hysteresis - short-term monitoring' • 38 reset 'drive signal diagram steady-state ...

Page 89

Startup_para (207) storage class: s · read/write capability (r/w) · supported modes: all start-up parameters • trans1_init_method (initialization method (max, nom, man, sub) • trans1_moving_direction (direction of action) • trans1_lin_type (type of characteristic) • trans1_init_with_ref_test (initia...

Page 90

5 time_63_falling 6 time_98_rising 7 time_98_falling 8 step_progress 9 rise_time_falling 10 settling_time_falling 11 rise_time_rising 12 settling_time_rising 13 duration_of_test 14 testinfo step_response_rw (189) storage class: s · read/write capability (r/w) · supported modes: all parameters for st...

Page 91

Kh 8384-4 en 91 ao transducer block, slot 1 · manufacturer-specific parameters • 4 · tight-closing of the valve (final position w • 5 · valve fully open (final position w >, code 15) • 7 · fail-safe position active • 255 · normal operation travel_limit_low_on (168) storage class: s · read/write capa...

Page 92

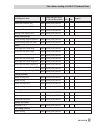

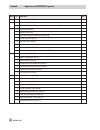

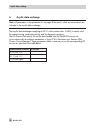

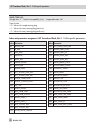

Index and parameter assignment: ao transducer block, slot 1 · manufacturer-specific parameters 92 kh 8384-4 en ao transducer block, slot 1 · manufacturer-specific parameters index parameter 160 pin_position 161 init_method 162 sub_mode_init 163 device_init_state 164 moving_direction 165 closing_dire...

Page 93

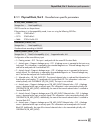

8.3.1 di1/2 function block, slot 2/3 · profile-specific parameters alert_key (20) storage class: s · read/write capability (r/w) · supported modes: all identification number of the plant section • [0] alm_sum (23) storage class: – · read capability (r) current states of the process alarms in di func...

Page 94

Channel (30) storage class: s · read/write capability (r/w) · supported modes: all connection of the function block with the transducer block di1: 0 · not active 780 · active di2: 0 · not active 524 · active fsafe_type (36) storage class: s · read/write capability (r/w) · supported modes: all fail-s...

Page 95

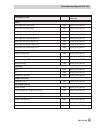

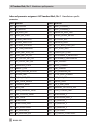

St_rev (17) storage class: – · read capability (r) revision level of static data strategy (19) storage class: s · read/write capability (r/w) · supported modes: all grouping to allow faster processing of blocks • [0] blocks are grouped by entering the same value in the strategy parameter of each blo...

Page 96

Index and parameter assignment: di1/2 function block, slot 2/3 · profile-specific parameters 96 kh 8384-4 en di1/2 function block, slot 2/3 · profile-specific parameters index parameter 16 block_object 17 st_rev 18 tag_desc 19 strategy 20 alert_key 21 target_mode 22 mode_blk 23 alm_sum index paramet...

Page 97

8.3.2 di1/2 transducer block, slot 2/3 · profile-specific parameters alert_key (64) storage class: s · read/write capability (r/w) · supported modes: all identification number of the plant section • [0] alm_sum (67) storage class: – · read capability (r) current states of the process alarms in di tr...

Page 98

St_rev (61) storage class: s · read capability (r) revision level of static data strategy (63) storage class: s · read/write capability (r/w) · supported modes: all grouping to allow faster processing of blocks • [0] blocks are grouped by entering the same value in the strategy parameter of each blo...

Page 99

Kh 8384-4 en 99.

Page 100

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De kh 8384-4 en 2012-06.