- DL manuals

- Samson

- Valve Positioners

- 3730-4

- Mounting and operating instructions

Samson 3730-4 Mounting and operating instructions

Summary of 3730-4

Page 1

Series 3730 electropneumatic positioner type 3730-4 with profibus-pa communication mounting and operating instructions eb 8384-4 en firmware version k 1.12/r 1.45 edition july 2008 fig. 1 · type 3730-4.

Page 2

2 eb 8384-4 en.

Page 3

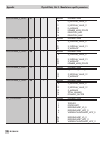

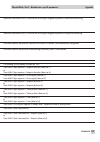

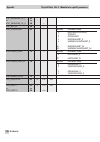

Contents page 1 design and principle of operation . . . . . . . . . . . . . . . . . . . 9 1.1 additional equipment . . . . . . . . . . . . . . . . . . . . . . . . . 10 1.2 communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 1.3 technical data . . . . . . . . . . . . . . . . . . ...

Page 4

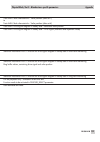

5.5 checking the operating range of the positioner . . . . . . . . . . . . . 50 5.6 initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 5.6.1 initialization modes . . . . . . . . . . . . . . . . . . . . . . . . . . 54 5.7 fault/failure . . . . . . . . . . . . . . . . . . . . ...

Page 5

13.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 13.1.1 system requirements . . . . . . . . . . . . . . . . . . . . . . . . . 99 13.2 installing trovis-view software . . . . . . . . . . . . . . . . . . . 100 13.3 starting trovis-view and performing basic settings . . . ....

Page 6

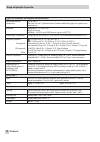

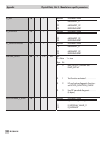

Modifications to positioner firmware compared to the previous version communication old new k 1.00 k 1.01 internal modifications k 1.01 k 1.10 the feature_select parameter allows you to set whether an active diagnostic func- tion is to be reported by a good_function_check or a bad_function_ check (s...

Page 7

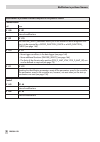

Eb 8384-4 en 7 safety instructions general safety instructions 4 the positioner may only be mounted, started up or operated by trained and experienced personnel familiar with the product. According to these mounting and operating instructions, trained personnel refers to individuals who are able to ...

Page 8

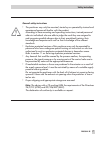

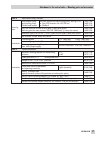

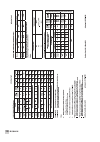

8 eb 8384-4 en article code positioner type 3730-4 x x x 0 x 0 x x 1 x 0 0 x 0 x x with lcd and autotune, profibus-pa explosion protection none ii 2 g eex ia iic t6 and ii 2 d ip 65 t 80 °c (atex) csa/fm intrinsically safe / non incendive ii 3 g eex na ii t6, ii 3 g eex nl iic t6 and ii 3 d ip 65 t ...

Page 9: Design and Principle of

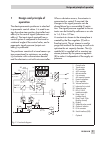

1 design and principle of operation the electropneumatic positioner is attached to pneumatic control valves. It is used to as- sign the valve stem position (controlled vari- able x) to the control signal (reference vari- able w). The input signal received from a control system is compared to the tra...

Page 10: 1.1

The positioner communicates and is pow- ered using iec 61158-2 transmission tech- nology conforming to profibus-pa specifi- cation. As a standard feature, the positioner comes with a binary input for dc voltage signals to signalize process information over the profibus-pa. 1.1 additional equipment v...

Page 11: 1.3

1.3 technical data eb 8384-4 en 11 design and principle of operation type 3730-4 positioner with profibus-pa communication rated travel, adjustable direct attachment to type 3277: 3.6 to 30 mm attachment acc. To iec 60534-6 (namur): 3.6 to 200 mm attachment to rotary actuators (vdi/vde 3865): 24° to...

Page 12

12 eb 8384-4 en design and principle of operation type 3730-4 positioner with profibus-pa communication permissible ambient temperature –40 to +80 °c the limits in the ec type examination certificate additionally apply for explosion-pro- tected devices influences temperature: ≤ 0.15 %/10 k supply ai...

Page 13

Eb 8384-4 en 13 design and principle of operation options for type 3730-4 positioner with profibus-pa communication binary contact 2 for floating contact switching input r Ω , contact load 100 ma, static destruction limit 20 v / 5.8 ma, galvanically isolated solenoid valve approval acc. To iec 61508...

Page 14: Attachment to The Control

2 attachment to the control valve – mounting parts and accessories the positioner can be attached either di- rectly to a samson type 3277 actuator or according to iec 60534-6 (namur) to con- trol valves with cast yokes or rod-type yokes as well as to rotary actuators according to vdi/vde 3845. For a...

Page 15

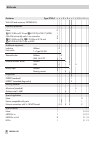

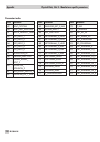

Eb 8384-4 en 15 attachment to the control valve – mounting parts and accessories travel table for direct attachment to type 3277 actuator type 3277-5 and 3277 actuators actuator size cm² rated travel mm adjustment range at positioner min. Travel max. Required lever assigned pin position 120 7.5 5.0 ...

Page 16

16 eb 8384-4 en attachment to the control valve – mounting parts and accessories table 1 direct attachment to type 3277-5 actuator, see fig. 4 order no. Mounting parts for actuators with 120 cm² effective diaphragm area 1400-7452 accessories for the actuator switchover plate (old) for actuator type ...

Page 17

Eb 8384-4 en 17 attachment to the control valve – mounting parts and accessories table 4 attachment to rotary actuators mounting parts with follower clamp and coupling wheel, crnimo steel bracket vdi/vde 3845 for all sizes of fixing level 2, see figs. 8 + 9 for type 3278 actuator with 160/320 cm² fo...

Page 18: 2.1

2.1 direct attachment 2.1.1 type 3277-5 actuator refer to table 1 on page 16 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 15! Actuator with 120 cm² depending on the type of positioner attach- ment, the signal pressure is routed ei...

Page 19

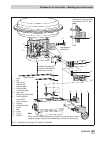

Eb 8384-4 en 19 attachment to the control valve – mounting parts and accessories fig. 4 · direct attachment - signal pressure connection for type 3277-5 actuator with 120 cm 2 9 11 supply 9 output 38 5 6 4 7 6 10 10.1 3 2 1 15 6.1 1.1 1.2 14 8 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 followe...

Page 20: 2.1.2 Type 3277 Actuator

2.1.2 type 3277 actuator refer to table 2 on page 16 or the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 15! Actuators with 240 to 700 cm² the positioner can be mounted either on the left or on the right side of the yoke. The sig- nal pre...

Page 21

Eb 8384-4 en 21 attachment to the control valve – mounting parts and accessories fig. 5 · direct attachment – signal pressure connection for type 3277 actuator with 240, 350 and 700 cm 2 2 10 14 15 1 2 3 11 supply 13 16 b 1.1 1.2 12 12.1 12 12.1 12.2 a 12 16 12.2 supply 1 lever 1.1 nut 1.2 disk spri...

Page 22: 2.2

2.2 attachment according to iec 60534-6 the positioner is attached to the control valve with a namur bracket (10). Refer to table 3 on page 16 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 15! 1. Screw the two bolts (14) to the bra...

Page 23

Eb 8384-4 en 23 attachment to the control valve – mounting parts and accessories 10 11 1 1 14.1 3 3.1 16 15 14 1 1.2 1.1 2 9.1 9 6.1 6 7 8 attachment to rod-type yoke rod diameter 20 to 35 mm 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower plate 3.1 follower plate 6 connecting plate 6.1 se...

Page 24: 2.3

2.3 attachment to type 3510 micro-flow valve the positioner is attached to the valve yoke using a bracket. Refer to table 3 on page 16 for the required mounting parts as well as the accessories with their order numbers. Note the travel table on page 15! 1. Place clamp (3) on the valve stem con- nect...

Page 25

Eb 8384-4 en 25 attachment to the control valve – mounting parts and accessories fig. 7 · attachment to type 3510 micro-flow valve 3 10 11 11 6 1 2 1.2 1.1 7 8 6.1 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 clamp 6 connecting plate 6.1 seal rings 7 pressure gauge bracket 8 pressure gauge mount...

Page 26: 2.4

2.4 attachment to rotary actuators the positioner is mounted to the rotary actu- ator using two pairs of double brackets. Refer to table 4 on page 17 for the required mounting parts as well as the accessories with their order numbers. Prior to the attachment of the positioner to the samson type 3278...

Page 27

Eb 8384-4 en 27 attachment to the control valve – mounting parts and accessories fig. 9 · attachment to rotary actuators 10 10.1 6 (7, 8) 1.1 2 4.3 5 6.1 4 1.2 1 note! Always use the connecting plate (6) included in the accessories to connect supply and output. Never screw threaded parts directly in...

Page 28: 2.5

2.5 reversing amplifier for double-acting actuators for the use with double-acting actuators, the positioner must be fitted with a reversing amplifier. The reversing amplifier is listed as an accessory in the table 5 on page 17. The output signal pressure of the positioner is supplied at the output ...

Page 29

Eb 8384-4 en 29 attachment to the control valve – mounting parts and accessories fig. 10 · mounting a reversing amplifier a 1 1.5 1.6 1.3 6.2 6 6.1 1.2 1.1 1 1.6 z a 2 1.4 a 1 a 2 z a 1 output 38 supply 9 output 38 supply 9 1.3 1.2 1.1 from the positioner control signals to the actuator 1 reversing ...

Page 30: 2.6

2.6 attaching an external position sensor refer to table 6 on page 35 for a list of the mounting parts as well as the accessories required for mounting the position sensor. Accessories for the pneumatic connection to the positioner housing can be found in table 7. In the positioner version with an e...

Page 31

Type 3277 actuator with 240 to 700 cm²: the signal pressure is routed to the connec- tion at the side of the actuator yoke for the version "actuator stem extends". For the fail-safe position "actuator stem re- tracts" the connection on the top diaphragm case is used. The connection at the side of th...

Page 32: 2.6.2 Mounting The Position

Place the lever (1) in mid-position and hold it in place . Screw on the nut (1.1). 5. Place the follower clamp (3) on the actu- ator stem, align and fasten it, making sure that the fastening screw rests in the groove of the actuator stem. 6. Place the mounting plate (21) together with the sensor ont...

Page 33: 2.6.3 Mounting The Position

For other actuator sizes or travels, select the lever and pin position from the travel table on page 15. Lever l and xl are included in the mounting kit. 3. Place the lever (1) and disk spring (1.2) on the sensor shaft. Place the lever (1) in mid-position and hold it in place . Screw on the nut (1.1...

Page 34: 2.6.4 Mounting The Position

2.6.4 mounting the position sensor to rotary actuators for the required mounting parts as well as the accessories, refer to the order numbers listed in tables 6 and 7 on page 35. 1. Place the lever (1) in mid-position and hold it in place . Unscrew the nut (1.1) and remove the standard attached leve...

Page 35

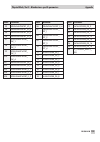

Eb 8384-4 en 35 attachment to the control valve – mounting parts and accessories table 6 mounting parts for position sensor order no. Direct attachment mounting parts for actuators with 120 cm² see fig. 12 left 1400-7472 accessories for actuator 120 cm² connecting plate (9, old) for actuator type 32...

Page 36: 2.7

2.7 attaching positioners with stainless steel housings positioners with stainless steel housings re- quire mounting parts that are completely made of stainless steel or free of aluminum. Note: the pneumatic connecting plate made of stainless steel is available (order number listed below). Pressure ...

Page 37

Should other valve accessories be used which vent the actuator (e.G. Solenoid valve, volume booster, quick exhaust valve), this exhaust air must also be included in the purging function. The connection over the adapter at the positioner must be protected with a check valve (e.G. Check valve g ¼, ord...

Page 38: Connections

3 connections 3.1 pneumatic connections caution! The threads in the positioner housing are not designed for direct air connection! The screw glands must be screwed into the connecting plate, the pressure gauge mount- ing block or the connection block from the accessories. The air connections are opt...

Page 39

D = seat diameter [cm] Δ p = differential pressure across the valve [bar] a = actuator diaphragm area [cm²] f = upper bench range of the actuator [bar] if there are no specifications, calculate as follows: required supply pressure = upper bench range value + 1 bar note! The signal pressure at the ou...

Page 40: 3.2

3.2 electrical connections for electrical installation, you are re- quired to observe the relevant electrotechnical regulations and the accident prevention regulations that apply in the country of use. In ger- many, these are the vde regulations and the accident prevention regula- tions of the emplo...

Page 41

Note: the power supply for the positioner can be supplied either over the connection to the fieldbus segment or over a dc voltage source (9 to 32 v) connected to the bus ter- minals in the positioner. You are required to observe the relevant regulations for use in hazardous areas . Bus line the shie...

Page 42

5. Press the clamping insert into the con- necting screw gland and screw tight the gland nut until the connecting cable is clamped tightly. 6. Route the two-wire bus line to the screw terminals marked "iec 1158-2", whereby no polarity has to be observed. Refer to the profibus-pa user + installation ...

Page 43

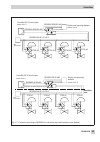

Eb 8384-4 en 43 connections profibus-dp(e) rs 485 3730-40 3730-40 3730-40 3730-40 profibus-pa iec 61158-2 profibus-dp rs 485 3730-41 3730-41 3730-41 3730-41 profibus-pa iec 61158-2 profibus-dp(e) rs 485 profibus-dp rs 485 fig. 17 · connection according to profibus, for safe areas (top) and hazardous...

Page 44: Operation

4 operation note: a summary about operating and start up can be found in section 8 on page 69. 4.1 operator controls and readings rotary pushbutton the positioner is mainly operated with the rotary pushbutton. Turn the button to select and set codes, parameter and values. Press to confirm. Slide swi...

Page 45

Eb 8384-4 en 45 operation % mm air to open close init caution valve actuates min side max back min back max side q % s mm % s mm serial interface % mm maintenance alarm/fault manual mode closed-loop operation code readings on the display and their meaning auto automatic mode cl clockwise ccl counter...

Page 46: 4.2

4.2 enabling and selecting parameters the codes which are marked with an aster- isk (*) in section 14.1 on page 110 onwards must be enabled with code 3 before the as- sociated parameters can be configured as described below. Code 3 configuration not enabled configuration enabled 4 from the current d...

Page 47: 4.3

4.3 operating modes 4.3.1 automatic and manual operating modes prior to initialization: if the positioner has not been initialized yet, the automatic operating auto cannot be se- lected. The valve can only be positioned manually with the positioner. To proceed, turn button clockwise until code 1 app...

Page 48: Start-Up and Settings

4.3.2 safe – fail-safe position if you want to move the valve to fail-safe po- sition, proceed as follows: select code 0, press the button, auto or man appears on the display, code 0 blinks. Turn the button until safe appears. Press the button to confirm this setting. Caution! The valve moves to the...

Page 49: 5.1

5.1 determining the fail-safe position to adapt the positioner to the operating di- rection of the actuator, set slide switch to air to open or air to close . Air to open = signal pressure opens the valve, for fail-safe position: actuator stem extends/valve closed air to close = signal pressure clos...

Page 50: 5.3

5.3 adapting the display the data representation on the positioner display can be turned by 180°. If the displayed data appear upside down, proceed as follows: reading direction for right attachment of pneumatic connections reading direction for left attachment of pneumatic connections turn the butt...

Page 51

Ceeded when the displayed angle is higher than 30°, and the outer right or left bar graph element blinks. If this is the case, it is absolutely neces- sary to check lever and pin position as described in section 2. Note: if the selected pin position is smaller than intended for the respective travel...

Page 52: 5.6

5.6 initialization during initialization the positioner adapts it- self optimally to the friction conditions and the signal pressure demand of the control valve. The type and extent of self-adaptation de- pends on the set initialization mode (see section 5.6.1). Max is the default setting for initia...

Page 53

Positioners with expert + diagnostic func- tions start plotting the reference graphs after the initialization process has been com- pleted. See note at the end of this section. Warning! During the initialization, the control valve moves through its entire tra- vel/angle of rotation range. Therefo- r...

Page 54: 5.6.1 Initialization Modes

An unsuccessful plotting of the reference graphs is indicated on the display by code 81 (see error code list). After the initialization has been successfully completed, the positioner still works prop- erly, even though the reference graph plot- ting has not been completed successfully. The plotting...

Page 55

Turn → code 4, press , turn → select pin position determined on attachment, press . If you now switch to code 5, the nominal range appears in mm/°. The lower and upper x-range values for code 8 and 9 are displayed in mm/° and can be adapted accordingly. Nom – initialization based on nominal range in...

Page 56

4 press init key to start initialization! The initialization procedure may take several minutes, depending on the actuator size, as the valve moves through its entire travel/angle of ro- tation range. Positioners with expert + diagnostic func- tions automatically start plotting the refer- ence graph...

Page 57

Turn until the valve reaches its open po- sition, press . 4 press init key to start initialization! The initialization procedure may take several minutes, depending on the actuator size, as the valve moves through its entire travel/angle of ro- tation range. Positioners with expert + diagnostic func...

Page 58

Enable configuration: default off turn → code 3, press , turn → on , press . After enabling: default off turn → code 4, press , press → select pin position determined on attachment, press . Default 15 turn → code 5, press , turn → enter nominal travel/angle, press . Default max turn → code 6, press ...

Page 59

Turn → select k p , press . Default 2 turn → code 18, retain default t v , change only if known. Default ccl turn → code 34, press , turn → select closing direction. Ccl = counterclockwise and cl = clockwise. Direction of rotation which causes the valve to move to the closed position (view onto the ...

Page 60: 5.7

The positioner switches to automatic oper- ating mode! The current valve position is indicated in %. Note: if the positioner shows a tendency to oscillate in automatic operating mode, the parameters k p and t v must be slightly cor- rected. Proceed as follows: set t v to 4 (code 18). If the position...

Page 61: 5.8

Leaves the permissible temperature range af- fect the condensed state and cause a fault alarm to be displayed depending on its clas- sification. The optional expert + diagnostics generates additional diagnostic alarms which are in- cluded in the condensed status with their corresponding status class...

Page 62: (Ssp)

Default off turn → code 36, press , turn → run , press . All control parameters are reset and can be reconfigured. Note: reset the control and identification parameters as well as the bus address with the factory_reset parameter (see page 134). 5.10 start-up via local interface (ssp) the positioner ...

Page 63

Der code 46 in alternating sequence with the current address. The new address is marked with “n“ (new) and the currently used address with “o“ (old). Note: the bus address can only be imple- mented by the profibus command set_adress when the bus address is set to the default setting [126]. Eb 8384-4...

Page 64: Status and Diagnostic

6 status and diagnostic alarms the type 3730-4 positioner contains inte- grated diagnostics to generate classified sta- tus and diagnostic alarms. There are two different types of on-board di- agnostics available: the standard integrated diagnostics (expert) and the optional ex- tended expert + diag...

Page 65: 6.3

The required reference graphs are automati- cally plotted after initialization and saved in the positioner if expert + is activated. The optional diagnostic functions provided by expert + can be selected when ordering the positioner. Additionally, it is possible to activate expert + at a later point...

Page 66

The table below containing the condensed state is reached from the summary of active alarms. Status modification the classification of the status alamrs can be assigned as required using the trovis-view software connected to the lo- cal ssp interface of the positioner or over the pa parameters. Caut...

Page 67

Eb 8384-4 en 67 status and diagnostic alarms fig. 20 · status and diagnostic alarms event con- densed status ? Yes no default settings status diagnostics diagnostics good / n o alarm maintenance required dia_maintenance maint. Demanded dia_maintenance_ demanded maintenance alarm dia_maintenance_alar...

Page 68: Adjusting The Limit Switch

7 adjusting the limit switch the positioner version with an inductive limit switch has one adjustable tag (1) mounted on the shaft which operates the proximity switch (3). For operation of the inductive limit switch, the corresponding switching amplifier (see section 3.2.1) must be connected to the ...

Page 69: Quick Start-Up Guide

For closed position: 1. Initialize positioner. 2. Use the man function to move the positioner to 5 % (see lc display). 3. Adjust the tag using the yellow adjust- ment screw (2) until the tag enters or leaves the field and the switching ampli- fier responds. You can measure the switching voltage as a...

Page 70: 8.2

Pin is in the slot of the follower plate. Make sure the lever can still move. Attachment to rotary actuators 4 lever m pin position 90° 4 put the valve into the closed position, de- termine the opening direction. 4 place the follower plate on the slotted ac- tuator shaft and fasten it to the couplin...

Page 71: 8.3

Operation selecting the parameters or values each parameter has a code number which is shown in the display. Turn the button to select parameters or values and then push to confirm. Select and confirm esc to prevent an en- tered value from being accepted. Enabling parameters parameters that have a c...

Page 72: 8.3.3 Manual Method (Man)

Turn → code 4, ↵ turn → select pin position, ↵ turn → code 5, ↵ turn → enter nominal travel/range, ↵ turn → code 6, ↵ select nom, ↵ press init key! 8.3.3 manual method (man) initialization mode same as nom, but for start-up of control valves with unknown nominal ranges. The final position of travel/...

Page 73: Retrofitting An Inductive

9 retrofitting an inductive limit switch required retrofit kit: limit switch order no. 1400-7460 note! For explosion-protected devices, the requirements in section 11 need to be kept. 1. Take off the rotary pushbutton (3) and cap (1), unthread the five fixing screws (2) and lift off the plastic cove...

Page 74: Maintenance

10 maintenance the positioner does not require any mainte- nance. There are filters with a 100 μ m mesh size in the pneumatic connections for supply and output which can be removed and cleaned, if required. The maintenance instructions of any up- stream supply air pressure reducing stations must be ...

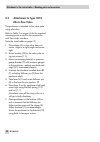

Page 75: Profibus-Pa Communication

12 profibus-pa communication the profibus-pa is a version for process automation based on the widely used profibus-dp. The transmission technique conforms with the iec 61158-2 standard and the- refore fulfills the requirements for the type of protection, intrinsic safety. Profibus-dp defines two typ...

Page 76: 12.2.1 Gsd Files

4 readback current position of the valve and status controlled variable x in relation to travel range/angle of rotation (out_scale) range of values defined in pv_scale 4 sp the setpoint sp is transmitted to the positioner. Defines the position of the valve between open and closed. Range of values de...

Page 77: 12.2.2 Data Exchange

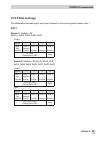

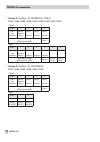

12.2.2 data exchange the relationship between output and input is based on the control system/master class 1. Slot 1 version 1: module = sp 0x4a or 0x82, 0x84, 0x08, 0x05 output byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction sp, val...

Page 78

4 version 3: module = sp, readback + pos_d 0xc6, 0x84, 0x86, 0x08, 0x05, 0x08, 0x05, 0x05, 0x05 output byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction sp, value (floating point, ieee) status input byte 0 1 2 3 4 5 6 octet 1 sign, exp...

Page 79

4 version 5: module = sp, readback + pos_d + checkback 0xc7, 0x84, 0x89, 0x08, 0x05, 0x08, 0x05, 0x05, 0x05, 0x0a output byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction sp, value (floating point, ieee) status input byte 0 1 2 3 4 5 6...

Page 80

4 version 7: module = sp + rcas_in, readback + rcas_out + pos_d + checkback 0xcb, 0x89, 0x8e, 0x08, 0x05, 0x08, 0x05, 0x08, 0x05, 0x08, 0x05, 0x05, 0x05, 0x0a output byte 0 1 2 3 4 5 6 7 8 9 octet 1 sign, exponent octet 2 exponent fraction octet 3 fraction octet 4 fraction octet 5 fraction octet 1 s...

Page 81

12.2.3 integration for pcs7 control system the following steps must be observed on integrating the positioner into a simatic s7 control system to ensure that the positioner functions properly: 1. The module in slot 1 can be read out over the function component sfc 14 “dprd_dat“ and, for example, ass...

Page 82

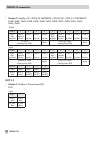

Byte bit name description 3 cb_override operating voltage for the optional built-in solenoid valve failed: the positioner cannot function and moves to the fail-safe position determined by the actuator, regardless of the reference variable. R 0 4…6 not assigned 0 7 cb_trave_time control loop error: t...

Page 83

Byte bit name description 2 0 cb_tot_valve_trav limit value for total valve travel exceeded: the current value for the total valve travel is above the entered or predetermined limit. Reset over self_calib_cmd = 10 (reset total valve travel limit exceeded). R 1 cb_add_input status of the second optio...

Page 84

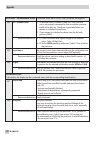

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 initialization errors x > range 0x80 good_non_specific delta x 0x80 good_non_specific incorrect attachment (mechanics/pneumatics) 0x80 good_non_specific initialization time exceeded 0x80 good_non_specific initialization/solenoid va...

Page 85

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 extended diagnostics – expert + air supply perhaps modified test 0x80 good_non_specific perhaps not enough test 0x80 good_non_specific perhaps not enough 0x80 good_non_specific working at full capacity 0x80 good_non_specific workin...

Page 86

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 perhaps too large 0x80 good_non_specific limit range down 0x80 good_non_specific up 0x80 good_non_specific modification impossible 0x80 good_non_specific dynamic stress factor load factor > 90 % 0x80 good_non_specific inner leakage...

Page 87

Fault/diagnostic alarm value (hex) status alarm acc. To profile 3.01 range mostly near closing position 0x80 good_non_specific mostly near max. Opening 0x80 good_non_specific mostly closing position 0x80 good_non_specific mostly max. Opening 0x80 good_non_specific temperature monitoring lower limit ...

Page 88

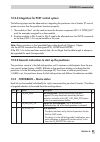

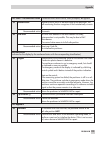

Fault/diagnostic alarm default setting acc. To profile 3.01 condensed status classified diagnosis yes no extended diagnostics available 0x80 good_non_specific • dia_maintenance extension_available no emergency mode 0xa4 good_maint_req • dia_mem_checksum temperature 0x80 good_non_specific • – tempera...

Page 89

Fault/diagnostic alarm default setting acc. To profile 3.01 condensed status classified diagnosis yes no pa parameter 0xa4 good_maint_req • dia_mem_checksum diagnostic parameter 0xa4 good_maint_req • dia_mem_checksum extended diagnostics expert + air supply perhaps modified test 0x80 good_non_specif...

Page 90

Fault/diagnostic alarm default setting acc. To profile 3.01 condensed status classified diagnosis yes no leakage pneumatics perhaps existing test 0x80 good_non_specific • – perhaps existing 0x80 good_non_specific • – perhaps too large test 0x80 good_non_specific • – perhaps too large 0x80 good_non_s...

Page 91

Fault/diagnostic alarm default setting acc. To profile 3.01 condensed status classified diagnosis yes no zero point alternating, average value below reference lines 0x80 good_non_specific • – connection positioner/valve no opt. Travel transm. Test 0x80 good_non_specific • – perhaps loose 0x80 good_n...

Page 92

12.5 diagnostics with profibus-dp protocol generated alarms are classified and summarized in the profibus profile 3.01 and “con- densed status and diagnostic messages“ extension. The diagnostic approach complying with profibus-dp includes the following types of diag- nostic transfer: 4 the dp master...

Page 93

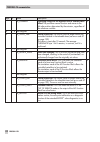

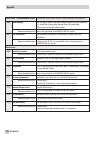

The first four bytes of the manufacturer-specific diagnosis are used for diagnostic alarms ac- cording to profile 3.01. On using the “condensed status and diagnostic messages“ exten- sion, these condensed diagnostic alarms are also included in these bytes. The manufac- turer-specific diagnosis liste...

Page 94

Octet bit explanation note 12 0 dia_zero_err (zero point error, final position) 1 – 2 dia_conf_inval (configuration invalid/invalid address) 12 3 dia_warmstart (restart-up/warm start performed) 4 dia_coldstart (new start-up/cold start performed) 5 dia_maintenance (maintenance required) 1 6 dia_chara...

Page 95

Octet bit explanation note 16 3) 7 test or calibration running 17 3) 0 x signal (see code 62) 1 i/p converter (see code 64) 2 hardware (see code 65) 3 control parameter (see code 68) 4 poti parameter (see code 69) 5 adjustment parameter (see code 70) 6 internal device error 1 (see code 73) 7 general...

Page 96

Octet bit explanation note 21 3) 0 actuator spring: perhaps pretensioning increased (test) 2 1 actuator spring: working at full capacity 2 2 actuator spring: working at full capacity (test) 2 3 shifting working range: close 2 4 shifting working range: open 2 5 friction: higher over whole range 2 6 f...

Page 97

Octet bit explanation note 24 3) 6 zero point shift monotonously downwards, average value below reference lines 2 7 zero point shift monotonously upwards, average value below reference lines 2 25 3) 0 zero point shift alternating, average value below reference lines 2 1 attachment between positioner...

Page 98: 12.6 Acyclic Data Exchange

12.6 acyclic data exchange note: all parameters in the parameter list on page 130 onwards, which are not marked, are included in the acyclic data exchange. The acyclic data exchange complying to dp-v1 with a master class 2 (ms2) is mainly used for commissioning, parameter configuration and for diagn...

Page 99: 13.1 General

13 settings in trovis-view software 13.1 general the trovis-view software allows various smart samson devices to be configured over a common operator interface. It consists of the operator interface, communication server, and the device-specific module. The software has a windows ® explorer look and...

Page 100

13.2 installing trovis-view software 1. Insert the installation cd-rom to start the installation program. Once inserted, the cd-rom usually starts the installation program automatically, depen- ding on the configuration of the operating system. If the program does not start automati- cally, double-c...

Page 101

13.3 starting trovis-view and performing basic settings you can perform the settings in trovis-view either when the positioner is connected (onli- ne) to the computer or not connected (offline). Note: when the positioner is not connected, the default settings appear on the operator in- terface or, a...

Page 102

5. Set the communications port for data communication. Proceed as follows: 4 connect the serial port of the compu- ter using the serial interface adapter (order no. 1400-7700) to the serial interface connection of the positio- ner. In case the computer does not have a serial port, a usb/rs-232 adapt...

Page 103: 13.4 Data Transmission

Converting the software version the trovis-view software version must match the firmware of the positioner. On exchanging data between the positioner and trovis-view, the software automatically checks whether the versions are compatible and, if necessary, converts the data. If you want to adapt the ...

Page 104

Important! Perform the electrical connection as described in section 3.2 first before downloading any data to the positioner. 13.4.1 offline operation (indirect data transmission) in offline mode, there is no constant data communication between the computer and positio- ner. Communication must first...

Page 105: 13.4.3 Setting Parameters

Operational data graphs (trend viewer) in online mode, process data (positioning value trd, actual valve position and set point de- viation [e]) are plotted in a graph over time. Select trend viewer in the view menu. You can modify the graphs, for example, by adding data points that should be record...

Page 106

1. Click on one of the folders in the left tree directory to view the parameter settings on the right. Place the cursor over a data point to open a tool tip providing more information on the parameter. 2. Double-click the required parameter to open a pop-up window to modify parameter set- ting. Righ...

Page 107

13.5 initializing the positioner initializing the positioner is only possible in trovis-view when the positioner has been at- tached properly to the control valve and has been connected (see sections 2 and 3). The po- sitioner must be connected to the computer over the serial interface adapter. The ...

Page 108

2. Select the initialization type under initialization (maximum range, nominal range, manu- al adjustment, substitute) in the positioner folder in the start-up subfolder. 3. Start initialization by right-clicking initialization and selecting execute. How long the initialization procedure lasts depen...

Page 109

Eb 8384-4 en 109 settings in trovis-view software.

Page 110: Appendix

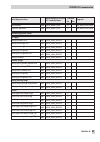

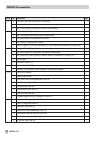

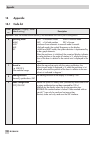

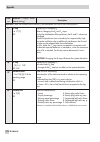

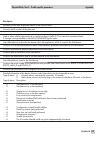

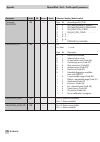

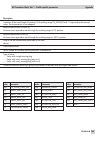

14 appendix 14.1 code list code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 0 operating mode [man] auto safe esc auto = automatic mode man = manual mode safe = fail-safe position ...

Page 111

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 4* pin position 17, 25, 35, 50, 70, 100, 200 mm 90° with rotary actuators [off], esc note! If you select a pin position in code 4 ...

Page 112

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 7* w/x [ ää] increasing/increasing äæ increasing/decreasing esc direction of action of the reference variable w in relation to the...

Page 113

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 11* upper x-limit 50.0 to 120.0 [100] % of the operating range off, esc limitation of the travel/angle of rotation upwards to the ...

Page 114

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 17* kp step 0 to 17 [7] esc displaying or changing k p note on changing the k p and t v steps: during the initialization of the po...

Page 115

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 21* w-ramp open 0 to 240 s [0] esc the time required to pass through the operating range when the valve opens. Limitation of the t...

Page 116

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 36* reset [off], run, esc resets all parameters to default (factory setting). Note: after setting run, the positioner must be re-i...

Page 117

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 46* bus address esc in delivered state, the standard bus address is 126. The address can only be changed with the profibus command...

Page 118

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48* d8 expert + activation enter the activation code for expert + . After the activation procedure has been successfully completed...

Page 119

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48* transducer blocks a0, di1, di2 t t0 target mode ao trd required operating mode t1 actual mode ao trd actual operating mode t2 ...

Page 120

Code no. Parameter – display, values [default setting] description important ! Codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48* i8 di1 fsafe_val_d default value when the sensor reports an error i9 simulate simulation d2 function block l l0 target mode di...

Page 121

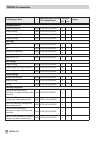

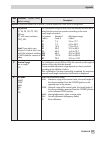

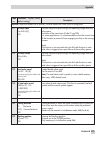

Error codes – recommended action condensed status alarm active, when prompted, err appears. Initialization errors (indicated on the display by the condensed status with the corresponding classification) 50 x the value supplied by the measuring signal is either too high or too low, the measuring sens...

Page 122

Error codes – recommended action condensed status alarm active, when prompted, err appears. 54 init – solenoid valve 1) a solenoid valve is installed (code 45 = yes) and was not or not properly connected so that an actuator pressure could not be built up. The alarm is generated when you attempt to i...

Page 123

Error codes – recommended action condensed status alarm active, when prompted, err appears. 59 autocorrection should an error occur in the data range of the positioner, the self-monitoring function recognizes it and automatically corrects it. Recommended action automatic 60 fatal error an error was ...

Page 124

Error codes – recommended action condensed status alarm active, when prompted, err appears. 66 data memory the writing of data to the data memory does not work anymore, e.G. When the written data deviate from the read data. Valve moves to the fail-safe position. Recommended action return the positio...

Page 125

Error codes – recommended action condensed status alarm active, when prompted, err appears. 76 no emergency mode the travel measuring system of the positioner has a self-monitoring function (see code 62). A controlled emergency mode is not available on certain actuators, such as double-acting actuat...

Page 126

126 eb 8384-4 en appendix.

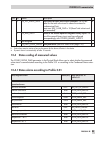

Page 127: 14.2 Parameter Lists

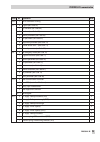

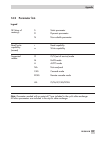

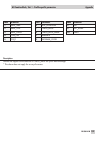

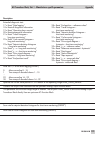

14.2 parameter lists legend sk (class of memory): s d n static parameter dynamic parameter non-volatile parameter read/write capability: (access) r w read capability write capability supported modes: o m a na cas rcas all o/s (out of service) mode man mode auto mode not analyzed cascade mode remote ...

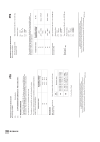

Page 128: Trd

128 eb 8384-4 en appendix os out-scale out positioning_ value feedback_ value increase_close moving_direction block mode code 7 pv-scale readback auto man lo ao trd.

Page 129

Eb 8384-4 en 129 appendix final_value final_ position_ value pd-controller k p , t v out_scale final_value_range final_value_range pressure_limit actuator moving_direction clear fail safe set fail safe code 8/9 code 8/9 travel sensor code 7 code 0 code 20 code 16 code 10/11 code 14/15 tight-closing ...

Page 130

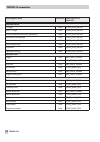

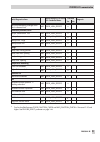

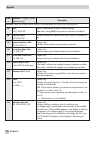

Physical block, slot 0 · profile-specific parameters 130 eb 8384-4 en appendix physical block, slot 0 · profile-specific parameters parameter index sk access mode selection/display [default value] alarm_sum 23 r [0] alert_key 20 s r/w all [0] block_object 16 r cond_status_diag 43 s r/w all descripto...

Page 131

Eb 8384-4 en 131 physical block, slot 0 · profile-specific parameters appendix description indicates current state of process alarms in the physical block. Contains the id number of the plant unit. Used to select whether the positioner is used according to profile 3.01 or used with condensed states....

Page 132

132 eb 8384-4 en appendix physical block, slot 0 · profile-specific parameters parameter index sk access mode selection/display [default value] continued: diagnosis 29 r byte bit according to pa v3.01 2 0 dia_maintenance_alarm . . . . 2 1 dia_maintenance_demanded 2 2 dia_function_check. . . . . . . ...

Page 133

Eb 8384-4 en 133 physical block, slot 0 · profile-specific parameters appendix description type of alarm description . . . R a device error exists . . . R maintenance demanded . . . R device performing a function check or it is in simulation or in mode_lo . . . R the current process conditions do no...

Page 134

134 eb 8384-4 en appendix physical block, slot 0 · profile-specific parameters parameter index sk access mode selection/display [default value] factory_reset 35 s r/w all 1 (0x0001) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2506 (0x09ca) . . . . . . . . . . . . . . . . . . . . . . . . 27...

Page 135

Eb 8384-4 en 135 physical block, slot 0 · profile-specific parameters appendix description command to reset the positioner to default values resets the start-up, identification and function block parameters as well as the status classification note: after performing a reset, the positioner needs to ...

Page 136

136 eb 8384-4 en appendix physical block, slot 0 · profile-specific parameters parameter index sk access mode selection/display [default value] feature 42 r supported / enabled 0 = not supported / not enabled 1 = supported / enabled byte bit element 0 0 condensed_status. . . . . . . . . . . . . 0 1 ...

Page 137

Eb 8384-4 en 137 physical block, slot 0 · profile-specific parameters appendix description describes the optional features integrated into the device as well as the existence and state of the features. Note! The structure for supported and enabled are identical! Default description . . . 1 status an...

Page 138

Parameter index 138 eb 8384-4 en appendix physical block, slot 0 · profile-specific parameters index parameter 16 block_object 17 st_rev 18 tag_desc 19 strategy 20 alert_key index parameter 21 target_mode 22 mode_blk 23 alarm_sum 24 software_revision 25 hardware_revision index parameter 26 device_ma...

Page 139

Eb 8384-4 en 139 physical block, slot 0 · profile-specific parameters appendix index parameter 31 diagnosis_mask 32 diagnosis_mask_ext 33 device_certification 34 write_locking 35 factory_reset index parameter 36 descriptor 37 device_message 38 device_instal_date 39 local_op_ena 40 ident_number_ sele...

Page 140

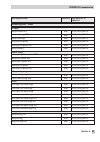

Physical block, slot 0 · manufacturer-specific parameters 140 eb 8384-4 en appendix physical block, slot 0 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] config_binary_ input_2 59 s r/w all 0 floating contact – di2 . . . . . . . . . . . . . . . . ...

Page 141

Eb 8384-4 en 141 physical block, slot 0 · manufacturer-specific parameters appendix description configuration of the second binary input . . . The input is analyzed with the second di function block. . . . A leakage sensor is operated at the input as actively open. This information is passed on by t...

Page 142

142 eb 8384-4 en appendix physical block, slot 0 · manufacturer-specific parameters datalogger_ds_15 125 r element parameter name 0 sollwert_w_1 1 istwert_x_1 2 stellsignal_y_1 3 regelabweich_e_1 4 zeit_t_1 5 sollwert_w_2 6 istwert_x_2 7 stellsignal_y_2 8 regelabweich_e_2 9 zeit_t_2 device_product_n...

Page 143

Eb 8384-4 en 143 physical block, slot 0 · manufacturer-specific parameters appendix test function auto: data logger – data set 15 data set 15 consisting of 2 packages (one package consisting of w, x, y, e and t variables) indicates the product number of the positioner. Further detailed information o...

Page 144

144 eb 8384-4 en appendix physical block, slot 0 · manufacturer-specific parameters et_bsz 78 r element parameter name 0 messwert_0 … 29 messwert_29 30 referenzwert et_endlage 79 r element parameter name 0 messwert_0 … 29 messwert_29 30 referenzwert et_ventilstellung 77 r element parameter name 0 me...

Page 145

Eb 8384-4 en 145 physical block, slot 0 · manufacturer-specific parameters appendix statistical information auto: structure for end position trend – operating hours counter statistical information auto: structure for end position trend – drive signal statistical information auto: structure for end p...

Page 146

146 eb 8384-4 en appendix physical block, slot 0 · manufacturer-specific parameters histogramm_e_lang 67 r element parameter name 0 e_interval_value_0 … 11 e_interval_value_11 12 e_average 13 number_mess_points 14 deviation_min 15 deviation_max histogramm_x_kurz 69 r element parameter name 0 x_inter...

Page 147

Eb 8384-4 en 147 physical block, slot 0 · manufacturer-specific parameters appendix statistical information auto: structure for long-term histogram plotting e 0 setpoint deviation interval 0 … 11 setpoint deviation interval 11 12 average value e for long-term 13 number of measuring points 14 min. Se...

Page 148

148 eb 8384-4 en physical block, slot 0 · manufacturer-specific parameters appendix hysterese_kurz 76 r element parameter name 0 stellsignal_0 0 ventilstellung_0 … 9 stellsignal_9 9 ventilstellung_9 hysterese_lang 75 r element parameter name 0 mittelwert_0 … 18 mittelwert_18 ident_limit_switches 50 ...

Page 149

Eb 8384-4 en 149 physical block, slot 0 · manufacturer-specific parameters appendix statistical information auto: structure for drive signal diagram hysteresis in short-term monitoring statistical information auto: structure for drive signal diagram hysteresis in long-term monitoring describes wheth...

Page 150

150 eb 8384-4 en appendix physical block, slot 0 · manufacturer-specific parameters stat_kennlinie_vs_1 to stat_kennlinie_vs_4 85 to 88 r r stat_ref_vs 80 r stat_stellsignal 82 r element parameter name 0 referenzzeitstempel 1 testinfo 2 fortschritt 3 referenzwert_0 4 wiederholungswert_0 … 51 referen...

Page 151

Eb 8384-4 en 151 physical block, slot 0 · manufacturer-specific parameters appendix tests man: static characteristic – valve position (data set 1) to tests man: static characteristic – valve position (data set 4) tests man: drive signal diagram in steady-state – reference valve position tests man: d...

Page 152

Parameter index 152 eb 8384-4 en appendix physical block, slot 0 · manufacturer-specific parameters index parameter 49 ident_options 50 ident_limit_switches 51 device_product_num 52 text_input_1 53 text_input_2 54 text_input_3 55 text_input_4 56 text_input_5 57 production_id 58 reading_direction 59 ...

Page 153

Eb 8384-4 en 153 physical block, slot 0 · manufacturer-specific parameters appendix index parameter 93 sprungantwort_vs_1 94 sprungantwort_vs_2 95 sprungantwort_vs_3 96 sprungantwort_vs_4 97 sprungantwort_ sw_1 98 sprungantwort_ sw_2 99 sprungantwort_ sw_3 100 sprungantwort_ sw_4 101 sprungantwort_s...

Page 154

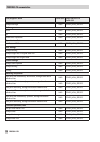

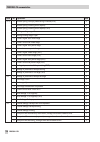

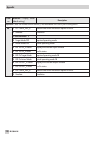

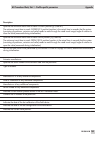

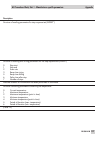

Ao function block, slot 1 · profile-specific parameters 154 eb 8384-4 en appendix ao function block, slot 1 · profile-specific parameters parameter index sk access mode selection/display [default value] alarm_sum 23 r alert_key 20 s r/w all batch 24 s r/w all block_object 16 r check_back * 37 r chec...

Page 155

Eb 8384-4 en 155 ao function block, slot 1 · profile-specific parameters appendix description indicates the current states of the process alarms in the ao function block. Contains the id number of the plant unit. Contains the identification of the batch process. Detailed information of the device, c...

Page 156

156 eb 8384-4 en appendix ao function block, slot 1 · profile-specific parameters parameter index sk access mode selection/display [default value] pos_d * 35 r 0. . Not initialized 1. . Closed (x 2. . Opened (x > 99.5 %) 3. . Intermediate position pv_scale 26 s r/w all rcas_in * 28 s r/w all range d...

Page 157

Eb 8384-4 en 157 ao function block, slot 1 · profile-specific parameters appendix description current position of the valve (discrete) range of the reference variable setpoint with status: reference variable w in rcas mode provided by a supervisory host, e.G. Pid block or master class1. Depending on...

Page 158

Parameter index ao function block, slot 1 · manufacturer-specific parameters 158 eb 8384-4 en appendix ao function block, slot 1 · profile-specific parameters index parameter 16 block_object 17 st_rev 18 tag_desc 19 strategy 20 alert_key index parameter 21 target_mode 22 mode_blk 23 alarm_sum 24 bat...

Page 159

Eb 8384-4 en 159 ao function block, slot 1 · profile-specific parameters appendix index parameter 31 fsafe_time 32 fsafe_type 33 fsafe_value 34 rcas_out 35 pos_d index parameter 36 setp_deviation 37 check_back 38 check_back_mask 39 simulate 40 increase_close index parameter 41 out 42 out_scale 240 v...

Page 160

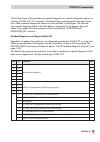

Ao transducer block, slot 1 · profile-specific parameters 160 eb 8384-4 en appendix ao transducer block, slot 1 · profile-specific parameters parameter index sk access mode selection/display [default value] act_stroke_time_dec 89 r [1.0 s] act_stroke_time_inc 90 r [1.0 s] actuator_action 143 s r/w a...

Page 161

Eb 8384-4 en 161 ao transducer block, slot 1 · profile-specific parameters appendix description specifies the minimum transit time to reach closed position [s] (code 41) the minimum transit time to reach closed (0 % position) position is the actual time in seconds that the system (consisting of posi...

Page 162

162 eb 8384-4 en appendix ao transducer block, slot 1 · profile-specific parameters parameter index sk access mode selection/display [default value] lin_type 105 s r/w all 0 = linear 1 = equal percentage 2 = equal percentage reverse 3 = user defined (currently not supported) 4 = samson control butte...

Page 163

Eb 8384-4 en 163 ao transducer block, slot 1 · profile-specific parameters appendix description type of characteristic (code 20) mode of operation of the positioner indicates the current positioning value. Specifies the rated travel [mm] or rotational angle [degrees] of the valve. Command to start t...

Page 164

164 eb 8384-4 en appendix ao transducer block, slot 1 · profile-specific parameters parameter index sk access mode selection/display [default value] self_calib_status 114 r [0] 0 = undetermined 1 = in progress 2 = canceled 3 = range incorrect 4 = error in mechanics/pneumatics 5 = gain error 6 = offs...

Page 165

Eb 8384-4 en 165 ao transducer block, slot 1 · profile-specific parameters appendix description manufacturer-specific status of the sequence started with self_calib_cmd parameter note: during the zero point key test, this parameter gets the switching state of the zero point key. 11 = time out 12 = p...

Page 166

Parameter index 166 eb 8384-4 en appendix ao transducer block, slot 1 · profile-specific parameters index parameter 80 block_object 81 st_rev 82 tag_desc 83 strategy 84 alert_key 85 target_mode 86 mode_blk index parameter 87 alarm_sum 89 act_stroke_time_dec 90 act_stroke_time_inc 103 device_calib_da...

Page 167

Eb 8384-4 en 167 ao transducer block, slot 1 · profile-specific parameters appendix index parameter 126 tot_valve_trav_lim 127 travel_limit_low 128 travel_limit_up 129 travel_rate_dec 130 travel_rate_inc 131 valve_maint_date 137 positioning_value index parameter 138 feedback_value 139 valve_man 140 ...

Page 168

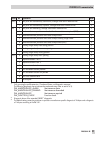

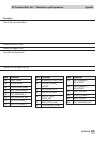

Ao transducer block, slot 1 · manufacturer-specific parameters 168 eb 8384-4 en appendix ao transducer block, slot 1 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] autostart_hyst 194 s r/w all blocking_position 166 s r/w all charact_type 173 s r/w...

Page 169

Eb 8384-4 en 169 ao transducer block, slot 1 · manufacturer-specific parameters appendix description indicates the minimum interval to perform the hysteresis test (expert + ). Indicates and modifies the blocking position. Type of characteristic. Text field (32 characters) to describe the characteris...

Page 170

170 eb 8384-4 en appendix ao transducer block, slot 1 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] device_charact 202 s r/w all element parameter name 0 actuator_size 1 actuator_version 2 attachment 3 pressure_range_start 4 pressure_range_end 5 ...

Page 171

Eb 8384-4 en 171 ao transducer block, slot 1 · manufacturer-specific parameters appendix description structure of the device properties 0 actuator effective area 1 type of actuator 2 attachment 3 lower signal pressure range value 4 upper signal pressure range value 5 supply pressure 6 booster 7 stem...

Page 172

172 eb 8384-4 en appendix ao transducer block, slot 1 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] enhanced_diag_cmd 192 s r/w all 0 = no function 1 = start data logging 2 = stop data logging 3 = start hysteresis online test 4 = stop hysteresis ...

Page 173

Eb 8384-4 en 173 ao transducer block, slot 1 · manufacturer-specific parameters appendix description extended diagnostic tests 17 = reset “data logging“ 18 = reset all diagnostic information 19 = reset “operating hours counter” 20 = reset temperature information 21 = reset “travel histogram – long-t...

Page 174

174 eb 8384-4 en appendix ao transducer block, slot 1 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] init_method 161 s r/w all 0 = maximum range 1 = nominal range 2 = manual adjustment 3 = substitute 4 = zero point moving_direction 164 s r/w all n...

Page 175

Eb 8384-4 en 175 ao transducer block, slot 1 · manufacturer-specific parameters appendix description used to select the type of initilization direction of operation, i.E. How the reference variable w is assigned to the controlled variable x indicates the number of zero point calibrations since the l...

Page 176

176 eb 8384-4 en appendix ao transducer block, slot 1 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] step_response_r 188 r element parameter name 0 overshoot_rising 1 overshoot_falling 2 dead_time_rising 3 dead_time_falling 4 time_63_rising 5 time...

Page 177

Eb 8384-4 en 177 ao transducer block, slot 1 · manufacturer-specific parameters appendix description structure of reading parameters for step response test (expert + ) structure of reading and writing parameters for the step response test (expert + ) 0 step start 1 step end 2 scan rate 3 ramp time r...

Page 178

Parameter index 178 eb 8384-4 en appendix ao transducer block, slot 1 · manufacturer-specific parameters parameter index sk access mode selection/display [default value] transducer_state 172 r [0] = see operating mode 1 = solenoid valve active 2 = lower travel limit active (code 10) 3 = upper travel...

Page 179

Eb 8384-4 en 179 ao transducer block, slot 1 · manufacturer-specific parameters appendix description state of the transducer block enables the lower x-limit. Enables the upper x-limit. User-defined characteristic indicates the zero point limit [%]. Index parameter 184 final_value 185 datalogger 186 ...

Page 180

Di1/2 function block, slot 2/3 · profile-specific parameters parameter index 180 eb 8384-4 en appendix di1/2 function block, slot 2/3 · profile-specific parameters index parameter 16 block_object 17 st_rev 18 tag_desc index parameter 19 strategy 20 alert_key 21 target_mode index parameter 22 mode_bl...

Page 181

Eb 8384-4 en 181 di1/2 function block, slot 2/3 · profile-specific parameters appendix index parameter 26 out_d 30 channel 31 invert index parameter 36 fsafe_type 37 fsafe_val_d 40 simulate index parameter 240 view1 description indicates the current states of the process alarms in the di function bl...

Page 182

Di1 transducer block, slot 2 · profile-specific parameters di2 transducer block, slot 3 · profile-specific parameters parameter index 182 eb 8384-4 en appendix di1/2 transducer block, slot 2/3 · profile-specific parameters parameter index sk access mode selection/display [default value] alarm_sum 67...

Page 183

Eb 8384-4 en 183 di1/2 function block, slot 2/3 · profile-specific parameters appendix description this parameter contains the measured logical value and its status which are available to the function block. Identification of the sensor (type) manufacturer of the sensor serial number of the sensor e...

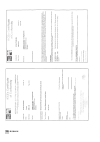

Page 184: Dimensions In Mm

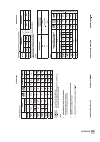

15 dimensions in mm 184 eb 8384-4 en dimensions in mm a 1 z a 2 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 70 70 28 schild output a1 output a2 supply (9) 50 80 58 58 58 130 49 59 79 76 50 150 direct attachment attachment acc. To iec 60534-6 lever mm s = 17 m = 50 l = 100 xl = 200 a...

Page 185

Eb 8384-4 en 185.

Page 186

186 eb 8384-4 en.

Page 187

Eb 8384-4 en 187.

Page 188

188 eb 8384-4 en.

Page 189

Eb 8384-4 en 189.

Page 190

190 eb 8384-4 en.

Page 191

Eb 8384-4 en 191.

Page 192

192 eb 8384-4 en.

Page 193

Eb 8384-4 en 193.

Page 194

194 eb 8384-4 en.

Page 195

Eb 8384-4 en 195.

Page 196

196 eb 8384-4 en.

Page 197

Eb 8384-4 en 197 addendum p a g e 1 revi si ons con tro l no. 1 : march. 2006 addendum t o eb 8384 -5 en insta ll a ti on manu al for a pparatus cer ti fi ed by cs a f o r us e i n haz a rdou s loc a ti on s. C o m m unication is o p ti ona ll y eith er a cco rdi n g to th e fo undati o n tm f ie ld...

Page 198

198 eb 8384-4 en.

Page 199

Eb 8384-4 en 199.

Page 200

200 eb 8384-4 en.

Page 201

Eb 8384-4 en 201.

Page 202

202 eb 8384-4 en.

Page 203

Eb 8384-4 en 203.

Page 204: Eb 8384-4 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8384-4 en s/z 2008-08.