- DL manuals

- Samson

- Valve Positioners

- 4763

- Mounting And Operating Instructions

Samson 4763 Mounting And Operating Instructions

Summary of 4763

Page 1

Electropneumatic positioner type 4763 fig. 1 · type 4763 mounting and operating instructions eb 8359-2 en edition september 2010

Page 2

Contents 1 design and principle of operation. . . . . . . . . . . . . . . . . . . . 6 2 attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.1 attachment to valves with cast yokes . . . . . . . . . . . . . . . . . . . 8 2.2 attachment to valves with rod-type yokes . . . . . ....

Page 3

Eb 8359-2 en 3 safety instructions general safety instructions 4 the positioner is to be mounted, started up or operated only by trained and experienced personnel familiar with the product. According to these mounting and operating instructions, trained personnel refers to individuals who are able t...

Page 4

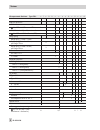

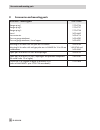

4 eb 8359-2 en versions electropneumatic positioner type 4763- x 1 x 0 0 x x x x 0 x 0 x x 0 explosion protection without 0 2/7 ii 2 g eex ia iic t6 acc. To atex 1 csa/fm intrinsically safe/non incendive 3 ii 3 g eex na ii t6 for zone 2 (atex) 8 2/7 range spring range spring 1, travel = 15 mm 1 rang...

Page 5

Eb 8359-2 en 5 technical data type 4736 positioner travel range 7.5 to 60 mm, with 90 mm lever extension reference variable split-range 0 to 50 % and 50 to 100 % reference variable span (up to 50 mm travel) 4 to 20 ma (ex) internal resistance r i at 20 °c approx. 250 w ± 7 % 4 to 20 ma (not ex) inte...

Page 6: Design and Principle of

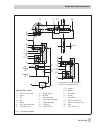

1 design and principle of operation the electropneumatic positioner is used for the correlation between the valve stem posi- tion (controlled variable x) and the input sig- nal (reference variable w) received from the controller. In this case, the input signal ac- cepted from the control device is c...

Page 7

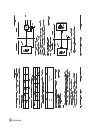

Eb 8359-2 en 7 design and principle of operation p st output 36 p e supply 9 21 1.1 4 5 6 8 9 9.1 10.2 10 10.1 6 8 9 9.1 10.2 10.1 10 11 i i p 12 14 13 1 2 2.1 20 fig. 3 · functional diagram legend for figs. 2 and 3 1 lever for valve travel 1.1 shaft 2 pin 2.1 nut 3 sleeve 4 zero adjustment screw 5 ...

Page 8: Attachment

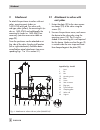

2 attachment to attach the positioner to valves with cast yokes, mounting parts (order no. 1400-5745) are used. For valves with rod-type yokes (pillars), the mounting kit (or- der no. 1400-5745) and additionally the mounting kit (order no. 1400-5342) are necessary (see also accessories table on page...

Page 9: Rod-Type Yokes

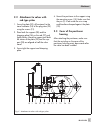

2.2 attachment to valves with rod-type yokes 1. Screw the plate (20), off-centered, to the travel indicator (24) of the plug stem (23) using the screws (21). 2. Place both the support (28) and the clamping plate (26) on the rod (27) and lightly fasten. Move the support until both the center of the p...

Page 10: Connections

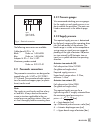

3 connections 3.1 electrical connections danger! Risk of electric shock and/or the formation of an explosive atmo- sphere! – for electrical installation, observe the rel- evant electrotechnical regulations and the accident prevention regulations that apply in the country of use. – the following regu...

Page 11: 3.2 Pneumatic Connections

The following accessories are available: cable gland m 20 x 1.5 black order no. 1400-6985 blue order no. 1400-6986 adapter m 20 x 1.5 to ½ npt: aluminum, powder-coated order no. 0310-2149 3.2 pneumatic connections the pneumatic connections are designed as tapped holes with ¼ npt or iso 2228/1- g ¼ t...

Page 12: Operation

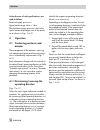

In the absence of such specifications, pro- ceed as follows: required supply pressure = upper bench range value + 1 bar the positioner output pressure is led to the top or bottom diaphragm case of the actua- tor as shown in figs. 7 to 10. 4 operation 4.1 combining positioner and actuator the arrange...

Page 13

Eb 8359-2 en 13 operation fig. 11 · position of nozzle block, cover plate removed actuator: stem extends (fa) actuator: stem retracts (fe) 1 20 pst w fig. 7 · operating direction 1 20 pst w fig. 8 · operating direction right attachment pst w fig. 9 · operating direction pst w fig. 10 · operating dir...

Page 14: Signal (Reference Variable)

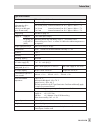

4.2 starting point and input signal (reference variable) the attached lever and the installed range spring of the positioner are assigned to the values of rated valve travel (mm) and the in- put signal (% reference variable) as in the table below. In standard operation, the reference vari- able span...

Page 15: Valve

With a 4 to 20 ma input signal, for exam- ple, the valve must also move through the entire range (0 to 100 % ). The starting point then is 4 ma and the upper range value 20 ma. In split-range operation, the controller output signal used to control two control valves is divided in such a way that the...

Page 16: “Stem Extends”

4.3.2 setting actuator version “stem extends” note: to ensure that the total closing force of the actuator can be effective in the control valve, the diaphragm chamber must be completely vented at the lower range value of the refer- ence variable (operating direction at the upper range value (operat...

Page 17

Check if the valve begins to move at ex- actly 20 ma. Correct deviation using the zero adjust- ment screw (4); turning it counterclock- wise moves the control valve earlier from its final position and clockwise later. Upper range value (span) e.G. 4 ma 3. After adjusting the starting point, adjust t...

Page 18: Converting An

5 converting an electropneumatic into a pneumatic positioner the appropriate conversion kit allows the electropneumatic positioner to be converted into a type 4765 pneumatic positioner. Note: eb 8359-1 en then applies for the converted type 4765 pneumatic positioner. Required conversion kit for mode...

Page 19: Devices

4. Push the free end of the hose onto the connecting plate (6). 6 servicing explosion-protected devices if a part of the device on which the explo- sion protection is based needs to be ser- viced, the device must not be put back into operation until a qualified inspector has as- sessed it according ...

Page 20

8 accessories and mounting parts 20 eb 8359-2 en accessories and mounting parts accessories – mounting parts order number range spring 1 range spring 2 range spring 3 lever i lever extension pressure gauge attachment pressure gauge attachment, free of copper 1190-0736 1190-0737 1190-0738 1690-6469 1...

Page 21: Dimensions In Mm

9 dimensions in mm eb 8359-2 en 21 dimensions in mm 157 49.5 15 2.5 38 . . . Useable lever length i: 40 to 127 mm (with 40 to 200 mm lever extension) pneum. Connection: iso-228/1-g ¼ cable gland model index .02 or lower: pg 13.5 model index .03 or higher: m 20 x 1.5 tapped hole g 1 8 for g threaded ...

Page 22

22 eb 8359-2 en.

Page 23

Eb 8359-2 en 23.

Page 24

24 eb 8359-2 en.

Page 25

Eb 8359-2 en 25.

Page 26

26 eb 8359-2 en $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu0d\ $gghqgxpwr(%(1 ,qvwdoodwlrq0dqxdo irudssdudwxvfhuwli lhg e\&6$iruxvhlqkd] dugrxvorfdwlrqv (ohfwulfdou dwlqjril qwulqvlf doo\ vdi hds sdu dwxv d qgds sdudwx virul qvwdoo dwlrqlqk d]d ugrx v orfdwlrqv 7deoh0d[lpxpydoxhv 8 l ru9 pd[ , l ru, pd[ 3 l...

Page 27

Eb 8359-2 en 27 $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu$xjxvw $gghqgxpwr(%(1 ,qvwdoodwlrq0dqxdo irudssdudwxv dssuryhge\ )0iruxvhlqkd]dugrxvorfdwlrqv (ohfwulfdou dwlqjril qwulqvlf doo\ vdi hds sdu dwxv d qgds sdudwx virul qvwdoo dwlrqlqk d]d ugrx v orfdwlrqv 7deoh0d[lpxpydoxhv 8 l ru9 pd[ , l ru, pd[ 3 l...

Page 28

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone +49 69 4009-0 · fax +49 69 4009-1507 internet: http://www.Samson.De eb 8359-2 en s/ z 2012-04.