- DL manuals

- Samson

- Valve Positioners

- 4763

- Mounting And Operating Instructions

Samson 4763 Mounting And Operating Instructions

Summary of 4763

Page 1

Mounting and operating instructions eb 8359-2 en edition april 2014 type 4763 electropneumatic positioner type 4763 electropneumatic positioner.

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8359-2 en 3 1 general safety instructions .............................................................................5 2 article code ...................................................................................................6 3 technical data .....................................

Page 5

Eb 8359-2 en 5 general safety instructions 1 general safety instructions foryourownsafety,followtheseinstructionsconcerningthemounting,startupandopera- tionofthepositioner: − thepositioneristobemounted,starteduporoperatedonlybytrainedandexperienced personnelfamiliarwiththeproduct. Accordingtothesemo...

Page 6: 2 Article Code

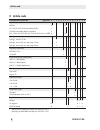

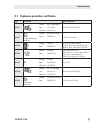

6 eb 8359-2 en article code 2 article code electropneumatic positioners type 4763- x 1 x 0 0 x x x x 0 x 0 x x 0 explosion protection without 0 2/7 exii2gexiaiict6gbaccordingtoatex 1 csa/fmintrinsicallysafe/nonincendive 3 exii3gexnaiit6gc/exiciict6gcforzone2acc.Toatex 8 2/7 spring spring1,travel=15m...

Page 7: 3 Technical Data

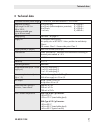

Eb 8359-2 en 7 technical data 3 technical data controlledvariable(travelrange) 7.5to60 mm,withleverextension:7.5to90 mm referencevariable 1) split-range0to50 %or 50to100 % referencevariablespan (upto50 mmtravel) 4to20 ma(ex), r i =250 Ω 2) 4to20 ma(withoutexplosionprotection), r i =200 Ω 2) 0to20 ma...

Page 8

8 eb 8359-2 en technical data influences temperature: supplyair: vibrations: variablepositionwhenturnedby180°: degreeofprotection ip54·ventingovercheckvalve(1790-7408):ip65 compliance · electromagneticcompatibility complyingwithen61000-6-2,en61000-6-3anden61326-1 weight approx.1.2kg materials housin...

Page 9

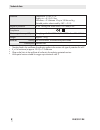

Eb 8359-2 en 9 technical data 3.1 explosion protection certificates type certification type of protection 4763-1 number rucde.08.00697 1ex iaiict6/t5/t4gbx date 15.12.2014 validuntil 2019-12-14 4763-1 number ptb 02atex2078 ii2gex iaiict6gb datum 2002-07-19 ectypeexamination certificate 4763-3 ® numb...

Page 10: Ation

10 eb 8359-2 en design and principle of operation 4 design and principle of oper- ation theelectropneumaticpositionerisusedto assignthevalveposition(controlledvariable) totheinputsignal(referencevariable).The positionercomparesthecontrolsignalofa controlsystemtothetravelofthecontrol valveandissuesas...

Page 11

Eb 8359-2 en 11 design and principle of operation 4 21 14 13 10.2 7 1 15 8 5 6.1 6 3 fig. 1: positioner with cover removed p st output 38 p e supply 9 21 1.1 4 5 6 8 9 9.1 10.2 10 10.1 6 8 9 9.1 10.2 10.1 10 11 i i p 12 14 13 1 2 2.1 20 travel arrangementofnozzle/flapperplate forreverseoperatingdire...

Page 12: 5 Attachment

12 eb 8359-2 en attachment 5 attachment toattachthepositionertovalveswithcast yokesaccordingtoiec 60534-6(namur rib),mountingparts(orderno.1400-5745) areused.Forvalveswithrod-typeyokes,the mountingkit(orderno.1400-5745)andad- ditionallythemountingkit(orderno.1400- 5342)arenecessary(seealsoaccessorie...

Page 13

Eb 8359-2 en 13 attachment 15 1 20 2 2.1 21 22 23 fig. 3: attachment to valves with cast yokes (namur rib) 15 1 28 27 26 20 2.1 2 21 24 23 fig. 4: attachment to valves with rod-type yokes.

Page 14: 6 Connections

14 eb 8359-2 en connections 6 connections 6.1 electrical connections danger! For electrical installation, observe the relevant electrotechnical regulations and the accident prevention regula- tions that apply in the country of use. In germany, these are the vde regu- lations and the accident prevent...

Page 15: 6.2 Pneumatic Connections

Eb 8359-2 en 15 connections equipment for use in zone 2/zone 22: inequipmentoperatedaccordingtotypeof protectionex naii(non-sparkingequipment) accordingtoen 60079-15: 2003,circuits maybeconnected,interruptedorswitched whileenergizedonlyduringinstallation, maintenanceorrepair. Guidethewiresfortherefe...

Page 16: 6.4 Supply Pressure

16 eb 8359-2 en connections 6.4 supply pressure therequiredsupplyairpressuredependson thebenchrangeandtheactuator'soperating direction(fail-safeaction). Thebenchrangeiswrittenonthenameplate eitherasthespringrangeorsignalpressure range.Theoperatingdirectionismarkedfa or fe,orbyasymbol. Actuator stem ...

Page 17: 7 Operation

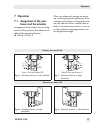

Eb 8359-2 en 17 operation 7 operation 7.1 assignment of the posi- tioner and the actuator arrangementoftheactuator,themounting positionofthepositioner,thereferencevari- ableandtheoperatingdirection: Î seefig. 6tofig. 9 whenanysubsequentchangesaremade, e.G.Reversingtheoperatingdirectionofthe position...

Page 18: 7.1.1 Determining and

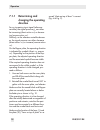

18 eb 8359-2 en operation 7.1.1 determining and changing the operating direction foranincreasinginputsignal(reference variable),thesignalpressurep st caneither beincreasing(directaction ing(reverseaction). Similarly,asthereferencevariabledecreas- es,thesignalpressurecaneitherdecrease (directaction )...

Page 19

Eb 8359-2 en 19 operation operatingdirectionincreasing/increasing (direct feelerpinontopofflapperplate operatingdirectionincreasing/decreasing (reverse) flapperplateontopoffeelerpin rangespring feeler pin coverplate nozzleblock marking flapper fig. 10: position of nozzle block, cover plate removed 1...

Page 20: Ence Variable

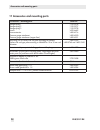

20 eb 8359-2 en operation 7.2 starting point and refer- ence variable theattachedleverandtheinstalledrange springofthepositionerareassignedtothe valuesofratedvalvetravelandthereference variableasintable1. Innormaloperation,thereferencevariable spanis100 %=16 ma.Asmallerspanof, forexample,50 %=8 mais...

Page 21

Eb 8359-2 en 21 operation table 1: range springs rated travel [mm] min./max. Travel [mm] reference variable (input signal) range spring standardtravelsforsamsonvalveswithleverl(40to127 mminlength) 15 7.5 to 15 100 % 50 % 1 2 30 14 to 32 100 % 50 % 2 3 60 30 to 70 100 % 3 furthertravelrangeswithlever...

Page 22: Tends”

22 eb 8359-2 en operation 7.3.2 setting for actuator with fail-safe action “stem ex- tends” toensurethatthetotalclosingforceofthe actuatoractsonthevalve,proceedasfol- lows: Î withdirectoperatingdirection juststartingpointto4.5 ma(slightly raised). Î withreverseoperatingdirection:ad- juststartingpoin...

Page 23: 7.4 Exchanging The Range

Eb 8359-2 en 23 operation wisecausestheplugstemtomovefrom itsendpositionearlier;turningitclock- wisecausesittomovefromitsendposi- tionlater. Upper range value (span) e.G. 4 ma 3. Oncethestartingpointhasbeenset,in- creasetheinputsignalto4 maatthe ammeter. Atexactly4 ma,theplugstemmust standstill,havi...

Page 24: Matic Into A Pneumatic Posi-

24 eb 8359-2 en converting the electropneumatic into a pneumatic positioner 8 converting the electropneu- matic into a pneumatic posi- tioner theelectropneumaticpositionercanbecon- vertedintoatype 4765pneumaticposition- erwithaconversionkit. Note: the version suitable for oxygen of the type 4763 pne...

Page 25

Eb 8359-2 en 25 converting the electropneumatic into a pneumatic positioner 1 3 2 4 5 7 6 38 fig. 14: converting the positioner table 2: conversion kits requiredconversionkituptodeviceindex.02. Forconnectionwithgthread orderno.1400-6724 forconnectionwithnptthread orderno.1400-6725 requiredconversion...

Page 26

26 eb 8359-2 en servicing explosion-protected devices 9 servicing explosion-protected devices ifapartofthedeviceonwhichtheexplosionprotectionisbasedneedstobeserviced,the devicemustnotbeputbackintooperationuntilaqualifiedinspectorhasassesseditaccord- ingtoexplosionprotectionrequirements,hasissuedanin...

Page 27

Eb 8359-2 en 27 maintenance, calibration and work on equipment 10 maintenance, calibration and work on equipment interconnectionwithintrinsicallysafecircuitstocheckorcalibratetheequipmentinsideor outsidehazardousareasistobeperformedonlywithintrinsicallysafecurrent/voltagecali- bratorsandmeasuringins...

Page 28

28 eb 8359-2 en accessories and mounting parts 11 accessories and mounting parts accessories – mounting parts order no. Rangespring1 rangespring2 rangespring3 leveri leverextension pressuregaugeattachment pressuregaugeattachment(copper-free) 1190-0736 1190-0737 1190-0738 1690-6469 1400-6716 1400-695...

Page 29: 12 Dimensions In Mm

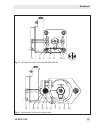

Eb 8359-2 en 29 dimensions in mm 12 dimensions in mm 157 49.5 15 2.5 38 . . . Useableleverlengthi: 40to127 mm (withleverextension 40to200 mm) pneumaticconnections: iso-228/1-g¼ cablegland: deviceindex.02and lower:pg13.5 deviceindex.03and higher:m20x1.5 g 1 / 8 connection forhousingwith gthread or 1 ...

Page 30

30 eb 8359-2 en.

Page 31

Eb 8359-2 en 31.

Page 32

32 eb 8359-2 en.

Page 33

Eb 8359-2 en 33.

Page 34

34 eb 8359-2 en.

Page 35

Eb 8359-2 en 35.

Page 36

36 eb 8359-2 en.

Page 37

Eb 8359-2 en 37.

Page 38

38 eb 8359-2 en.

Page 39

Eb 8359-2 en 39.

Page 40: Eb 8359-2 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8359-2 en 2017-05-03 · engl ish.