- DL manuals

- Samsung

- Air Conditioner

- AG042KSVANH

- Service manual

Samsung AG042KSVANH Service manual

1. Precautions

2. Product Features and Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram and Parts List

6. Wiring Diagram

7. Cycle Diagram

8. Key Options

9. Trial Operation

CONTENTS

DVM CHILLER

DVM CHILLER

AG042KSVANH/AG056KSVANH/AG070KSVANH

AG042KSVGNH/AG056KSVGNH/AG070KSVGNH

SYSTEM AIR CONDITIONER

Summary of AG042KSVANH

Page 1

1. Precautions 2. Product features and specifications 3. Disassembly and reassembly 4. Troubleshooting 5. Pcb diagram and parts list 6. Wiring diagram 7. Cycle diagram 8. Key options 9. Trial operation contents dvm chiller dvm chiller ag042ksvanh/ag056ksvanh/ag070ksvanh ag042ksvgnh/ag056ksvgnh/ag070...

Page 2

Dvm chiller derived model status application division derived models non-built pump ag042ksvanh/eu ag056ksvanh/eu ag070ksvanh/eu built pump ag042ksvgnh/eu ag056ksvgnh/eu ag070ksvgnh/eu.

Page 3

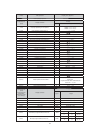

1 contents 1. Precautions ..................................................................................................................................................................................................................................... 1 1-1 precautions for the service .............

Page 4

2 contents 4-3-26. Evi eev opening error .................................................................................................................................................................................. 66 4-3-27. Refrigerant leakage error ..............................................

Page 5: 1. Precautions

1 1. Precautions 1-1 precautions for the service ouse the correct parts when changing the electric parts. – please check the labels and notices for the model name, proper voltage, and proper current for the electric parts. Ofully repair the connection for the types of harness when repairing the prod...

Page 6

2 1-4. Precautions for handling refrigerant of the dvm chiller environmental cautions: air pollution due to gas release osafety cautions if liquid gas is released, then body parts that come into contact with it may experience frostbite/blister/numbness. If a large amount of gas is released, then suf...

Page 7

3 • dual smart inverter: ssc + ssc • bldc inverter motor (14~160 hz) • 3 rd generation vapor injection (maximization of low temperature heating performance) dsi system inverter-based 2. Product features and specifications 2-1 product features 2-1-1 major advantages of product.

Page 8

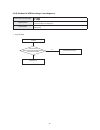

4 ■ control logic 1) simultaneous operation control individual capacity control based on water out sensor equipped inside each unit running the capacity control runs all the units inside the module to control the capacity. K} tg 㾔⤠ k} tg 㾔⤠ start operation when approaching the configured temperature...

Page 9

5 feature (cont.) ■ inverter circuit refrigerant cooling technology ▶ applied high efficiency refrigerant cooling circuit. Secured stable inverter pcb cooling performance. - air cooling method : when natural convection / electric heat performance is low and is high load, efficiency is fallen. - refr...

Page 10

6 2-1-2. Changes in comparison to dvm s changed part changed item and feature basic revision hydro - producing hot water & cold water by using plate type heat exchanger. - control specification for freeze prevention(the application of the water temperature/the pressure sensor). - air purge, drain va...

Page 11

7 changes in comparison to dvm s (cont.) changed part changed item and feature basic revision control box (inverter) inverterpcb (compressor control pcb) pf no. 8 inverter controller. ← pf no. 9 inverter controller. ← communication terminal block communication terminal block mounted on the pcb. ← re...

Page 12

8 2-1-3. Structure of product (h/p) hydro control inverter control control box (hydro side) control box (inverter) receiver accumulator compressor oil separator sub-cooler water outlet water inlet air side heat exchanger water side heat exchanger water temp. Sensor water pressure sensor water outlet...

Page 13

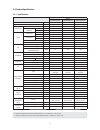

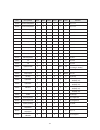

9 2-2. Product specifications 2-2-1. Specifications 1. Cooling capacity rated by: inlet and outlet water temperature 12/7 ° c, outdoor side 35 ° c db, 24 ° c wb. 2. Heating capacity rated by: mouth and hot water outlet temperature 40/45 ° c, outdoor side 7 ° c db, 6 ° c wb. Model ag042ksvanh/eu ag05...

Page 14

10 specifications (cont.) 1. Cooling capacity rated by: inlet and outlet water temperature 12/7 ° c, outdoor side 35 ° c db, 24 ° c wb. 2. Heating capacity rated by: mouth and hot water outlet temperature 40/45 ° c, outdoor side 7 ° c db, 6 ° c wb. Model ag042ksvgnh/eu ag056ksvgnh/eu ag070ksvgnh/eu ...

Page 15

11 3-1 necessary tools 3. Disassembly and reassembly item remark +screw driver monkey spanner -screw driver nipper electric motion driver l-wrench.

Page 16

12 no. Parts procedure remark 1 electrical equipment parts 1) remove 24 screws from the cabinet. (use + screw driver) 2) remove the 8 screws and then separate the left side cover control box of hydro part and right side cover control box of inverter part. (use + screw driver) 3) remove the power, co...

Page 17

13 no. Parts procedure remark 4) when replacing the power terminal block and communication terminal block, remove the 2 screws which is fixed to terminal block cover. 5) remove the 4 screws which is fixed to cabinet for terminal block protection and then remove the 2 screws from the terminal block. ...

Page 18

14 no. Parts procedure remark 7) remove the 12 screws from the outside of side refrigerant cooling part. Do not separate heat sink pulling assy piping cooling piping compulsorily. (it can be a cause of parts damage) 8) remove the 2 screws from the inside of side refrigerant cooling part..

Page 19

15 no. Parts procedure remark 3 hydro part control box 9) remove the 4 screws from the front part. 4 hydro part 10) remove the 4 screws which is fixed to bracket tube. 11) remove the 4 screws which is fixed to bracket hydro part. 12) remove the 2 screws securing the coupling points. Loosen bracket p...

Page 20

16 3-3 service work of main parts 3-3-1. Water pump 3-3-1. Water pump (pump built in model only) 1) power off before starting on work. 2) close the valve connected to inlet/outlet of main water pipe. 3) drain all water of water pipe connected to dvm chiller. 4) unscrews the screw of inlet/outlet wat...

Page 21

17 13) separates the fixed screw of pump terminal. (using - screw driver or exclusive tool) 14) connect power wire to terminal as a existing assembly condition. Connection mothod of pump have y-connection & delta connection method. This model must be connected by y-connection method because it uses ...

Page 22

18 3-3-2. Temperature sensor & pressure sensor in the water pipe side - exchange method of the water temperature sensor 1) power off before starting on work. 2) unscrews the fixed screw of cabinet front and c-box. 3) separate the connector from pba 4) separate insu protecting the temperature sensor....

Page 23

19 - exchange method of the pressure sensor 1) power off before starting on work. 2) close the valve connected to inlet/outlet of main water pipe. 3) drain all water of water pipe connected to dvm chiller. 4) unscrews the fixed screw of cabinet front and c-box. 5) separate the connector from pba. 6)...

Page 24

20 3-3-3. Plate type heat exchanger phe 1) power off before starting on work. 2) close the valve connected to inlet/outlet of main water pipe. 3) drain all water of water pipe connected to dvm chiller. 4) unscrews the screw of inlet/outlet water pipe flange connected to dvm chiller. 5) unscrews the ...

Page 25

21 9) unscrew the screw of coupling connecting the two phe in series. 10) separate 6 screws of bracket fixing assy phe. 11) please reassemble in reverse order of disassembly. - bolt torque at time of coupling tightening : 200±10% kgfcm.

Page 26

22 binding wire1 ■ ag042/056/070ksv666 series a b c location specifications used parts a binds a eev, pressure sensor, temperature sensor, water temperature sensor by cable-tie. 6501-001110 (l200) : cable tie b binds a high pressure switch, oil return valve by cable-tie using insu. C binds a high pr...

Page 27

23 binding wire2 ■ ag042/056/070ksv666 series location specifications used parts d binds a vapor injection valve, high-voltage switch, oil return valve, high pressure sensor, evi, hot gas valve by cable-tie using insu. 6501-001110 (l200) : cable tie e binds a low pressure sensor , temperature sensor...

Page 28

24 binding wire3 ■ ag042/056/070ksv666 series location specifications used parts h binds a sub cooler temperature sensor 2 kinds by cable-tie. 6501-001107 (l368) : cable tie i binds a eev coil, cond out temperature sensor, sub cooler temperature sensor 3 kinds, oil return valve by cable-tie. J binds...

Page 29

25 binding wire4 ■ ag042/056/070ksv666 series binds a comp wire-core to bracket beam control box using large size cable- tie(350mm). Binds a comp wire by holder wire. Remove the 3 screws and separate the connector and then separate the double layer structure of control box. 1 no code spec q'ty 1 600...

Page 30

26 [reference sheet] pipe welding position ■ ag042/056/070ksv666 series front welding part 2 no. Welding position q'ty 1 comp + discharge 2 2 comp + suction 2 3 comp + vpaor injection 2 4 oil sepa out + 4way 1 5 oil sepa out + hot gas 1 6 4way + hot gas 1 7 sution + oil return 2 8 vapor injection + ...

Page 31

27 [reference sheet] pipe welding position ■ ag042/056/070ksv666 series front welding part 2 no. Welding position q'ty 1 accum oil retrun valve + suction 1 2 4way + assy phe in 2 3 4way + cond in 2 4 eev + assy phe out 2 all model's pipe welding position is same..

Page 32

28 [reference sheet] pipe welding position ■ ag042/056/070ksv666 series rear welding part no. Welding position q'ty 1 discharge + oip sepa tank 2 2 suction + accum 1 3 receiver tank + receiver tube 2 4 receiver tube + cooling 1 5 cooling + eev 1 6 accum + evi bypass 1 7 evi bypass + subcooler 1 8 su...

Page 33: 4. Troubleshooting

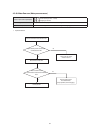

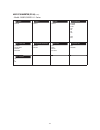

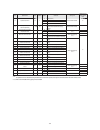

29 4. Troubleshooting 4-1 check-up window description hydro control inverter control ① ⑧ ⑮ ② ⑨ ⑯ ③ ⑩ ⑰ ④ ⑪ ⑱ ⑤ ⑫ ⑲ ⑥ ⑬ ⑳ ⑦ ⑭ ㉑ ㉒ ① ② ③ ⑩ ⑨ ⑧ ⑦ ⑥ ⑤ ④ no. Function no. Function 1 input power 12 input eva1,2 temperature sensor 2 micom download 13 communication between hydro and heat source unit (f1,f2)...

Page 34

30 4-2. Service operation 4-2-1. Special operation ▶ key input of the outdoor unit when the service enters the operation mode. K1 (number of press) key operation display on 7-segment 1times refrigerant charging in heating mode “ ” “ ” “ ” “ ” 2times trial operation in heating mode “ ” “ ” “ ” “ ” 3t...

Page 35

31 □ trial operation ▶ after initial installation, stable operation for a certain period of time limited to operation conditions. Cooling heating method of entry k2 tact switch 2times k1 tact switch 2times compressor normal operation, but the maximum frequency limit (differ by model) fan and valves ...

Page 36

32 □ forced defrost operation ▶ forced defrost operation : is operation when frost formation occurs in the outdoor. (when carried out the service) □ forced oil recovery operation ▶ forced oil recovery operation : oil recovery in the outdoor unit for the purpose of moving, installation if necessary. ...

Page 37

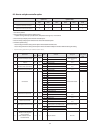

33 4-2-2. Dvm chiller eeprom code table by models 4-2-3. Option code by model classification no. Model eep code 1 ag042ksvanh/eu db82-03347a 2 ag056ksvanh/eu db82-03348a 3 ag070ksvanh/eu db82-03349a 4 ag042ksvgnh/eu db82-03347a 5 ag056ksvgnh/eu db82-03348a 6 ag070ksvgnh/eu db82-03349a sw update tool...

Page 38

34 4-2-4. Number display method Ŷ how to display integrated error code ▶ meanings of first alphabetical character / number of error code ▶ order of error display classification error display method display example display method for error that occurred in indoor unit error number ĺ indoor unit addre...

Page 39

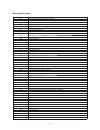

35 □ error display(error code) display description 101 communication error between hydro controller and inverter controller (if not received for 3 minutes from outdoor unit) 108 error due to repeated setting address 109 communication error of hydro controller address not complete 122 error on hydro ...

Page 40

36 □ error display(error code) display description 311 error on double layer pipe sensor (short or open) 321 evi inlet temperature 322 evi outlet temperature 323 error on suction 2 sensor (short or open) 326 error on total suction sensor (short or open) 346 operation failure of fan2 347 unconnected ...

Page 41

37 □ error display(error code) display description 469 inv1 dc link sensor error 471 inv1 data flash error 474 inv1 ipm heat sink error 478 error due to overcurrent of fan1 483 error due to special overcurrent of fan1 485 inv1 input current error 486 error due to over voltage/low voltage of fan1 487...

Page 42

38 4-3. Appropriate measures for symptoms 4-3-1. Reversed phase / no phase check (outdoor unit with 3 phase power) – display 1. When the power is on, check the status of the power from the inverter. Three-phase l1(r)-l2(s)-l3(t) order, regardless of the power connection on the inverter does not phas...

Page 43

39 □ initial tracking (communication check-up) - display 䭓 the outdoor unit micom attempts communication with the inverter control part connected to the communication wire (f1/f2) when the power is turned on. 䭓 basic segment display g seg1 a f g1 g2 b c e d seg2 g seg3 a f g1 g2 b c e d seg4 display...

Page 44

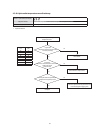

40 4-3-2. Main pcb has no power phenomenon inverter / hydro control part display main pcb has no power phenomenon (7-seg does not blink) judgment method hub pcb power and connection wire to detect. Cause of problem 1) hub pcb connector wire defects and disconnection. 2) main pcb defective. 3) hub pc...

Page 45

41 예 예 아니오 아니오 inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem communication error between indoor and outdoor units. 4-3-3. Communication error between hydro and outdoor unit during tracking 1. Inspection method check the communication cab...

Page 46

42 1. Find a communication ic nearby communication terminal. Ɣ hydro control part 1 - communication ic between hydro control part and inverter control part 2 - commuincation ic between wired remote controller Ɣ inverter control part 3 - communication ic between inverter control part and hydro contro...

Page 47

43 4-3-4. Communication error between indoor and outdoor unit after tracking 1. Inspection method 예 아니오 아니오 예 press the reset key (k3) of the outdoor unit pcb and check the display part. Is the voltage between the 2 cables a square wave with dc±0.7v or more? Is there no hydro response at all from th...

Page 48

44 4-3-5. Internal communication error of the outdoor unit c-box inverter / hydro control part display judgment method communication error between the c-box pcb cause of problem ∙ communication wire inside the c-box is unconnected ∙ main pcb defective 1. Inspection method replace main pcb restart op...

Page 49

45 4-3-6. Internal pcb communication error of the outdoor unit c-box inverter / hydro control part display judgment method pcb does not respond to the invoked main pcb cause of problem c-box internal inverter pcb, fan pcb, hub pcb defective 1. Inspection method replace hub pcb replace fan pcb (fan p...

Page 50

46 internal pcb communication error of the outdoor unit c-box (cont.) replace inv pcb (inv pcb tx part : breakage) check the connection status (cn91 connector) cn32 connector connection no no yes yes lighting of inv pcb ld11 did confirmation? Is inv pcb cn32 connector accurately connected? E206 c003...

Page 51

47 4-3-7. Outdoor temperature sensor error 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem outdoor temperature sensor open / short is defective. Did the outside temperature sensor connector break away from the pcb? Did...

Page 52

48 4-3-8. Cond out temperature sensor error (open / short) 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. Yes did the outdoor cond out sensor connector break away from th...

Page 53

49 4-3-9. Outdoor unit cond out sensor breakaway error inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem outdoor unit cond out sensor breakaway / defective / relevant path blocked. 1. Judgment method 1) no inspection for cooling operation. 2...

Page 54

50 4-3-10. Compressor discharge or top 1/2 temperature sensor error 1. Inspection method inverter / hydro control part display (compressor 1 discharge) (compressor 2 discharge) (compressor 1 top) (compressor 2 top) judgment method refer to the inspection method below. Cause of problem compressor dis...

Page 55

51 4-3-11. Compressor discharge or top temperature sensor breakaway error 1. Inspection method inverter / hydro control part display (compressor 1 discharge) (compressor 2 discharge) (compressor 1 top) (compressor 2 top) judgment method 1) relevant compressor frequency of 60hz or higher. 2) suction ...

Page 56

52 4-3-12. : suction temperature sensor breakaway error 1. Inspection method inverter / hydro control part display judgment method difference of suction temperature of compressor starting verge and suction temperature that is on present operation : if less than 2 & for 30 minutes to keep. (judgment...

Page 57

53 4-3-13. High pressure sensor error (open / short) inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. 1. High pressure sensor open/short error determination method 1) identifies from when power...

Page 58

54 4-3-14. Low pressure sensor error (open / short) inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. 1. Low pressure sensor open/short error determination method 1) identifies from when power i...

Page 59

55 4-3-15. Suction temperature sensor error (open / short) 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. Temperature (°c) 70 60 50 40 30 20 10 0 -10 resistance (kΩ) 2.2 ...

Page 60

56 4-3-16. Liquid pipe temperature sensor error (open / short) 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. No no temperature (°c) 70 60 50 40 30 20 10 0 -10 resistance...

Page 61

57 4-3-17. Evi in temperature sensor error (open / short) 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. Did the connector for the evi in temperature sensor break away fr...

Page 62

58 4-3-18. Evi out temperature sensor error (open / short) 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. Did the connector for the evi out temperature sensor break away ...

Page 63

59 4-3-19. Suction-2 temperature sensor error (open / short) 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem disconnection or breakdown of relevant sensor. Yes did the connector for the suction-2 sensor break away from...

Page 64

60 4-3-20. Measures of other outdoor unit error inverter / hydro control part display fan2 wire unconnected error fan2 pba ipm temperature sensor error fan1 wire unconnected error fan1 pba ipm temperature sensor error comp.2 wire unconnected error inverter pba2 igbt tempera- ture sensor error comp.1...

Page 65

61 4-3-21. : comp down due to high pressure protection control 예 예 예 아니오 예 아니오 아니오 예 아니오 is the s-net estimated value and the manifold gauge value in range? Are the hydro and outdoor unit eev normally operating? Are there any blockage inside the pipe? (filter etc.) are the outdoor fan operating norm...

Page 66

62 4-3-22. : comp down due to low pressure protection control inverter / hydro control part display judgment method inspection when the value of low pressure sensor is 1.8kgf/cm², or less for air conditioning and 0.8kgf/cm² for heating. Cause of problem ∙ refrigerant shortage ∙ electronic expansion ...

Page 67

63 4-3-23. : suspension of starting due to compressor discharge temperature sensor / top temperature sensor 1. Inspection method inverter / hydro control part display judgment method when value of compressor discharge temperature sensor / top temperature sensor is checked at 120&or more cause of pr...

Page 68

64 4-3-24. 3-phase input wiring error 1. Inspection method inverter / hydro control part display judgment method when turn on the power and check the status of the power from the inverter. If the phase does not connect the power(no phase) : e425 or e466 (e366) is displayed (air conditioner to mainta...

Page 69

65 4-3-25. : suspension of starting by abnormal compression ratio 1. Inspection method inverter / hydro control part display judgment method ∙ compression ratio [(high pressure+1.03)/(low pressure+1.03)] less than 1.5 and lasts for 10 minutes or more ∙ differential pressure (high pressure - low pres...

Page 70

66 4-3-26. Evi eev opening error 1. Inspection method check the refrigerant amount no reconnect connector is evi eev connector accurately connected to pcb? Yes no reassemble the coil is eev coil accurately installed? Yes breakdown replace intercooler check the intercooler leakage normal breakdown re...

Page 71

67 4-3-27 refrigerant leakage error 1. Pressure sensor open/short error determination method 1) identifies from when power is supplied or 2 minutes after reset, and only when set is stopped. 2) an open/short error will occur if the input voltage standard range of 0.5v ~ 4.95v is exceeded. 2. Inspect...

Page 72

68 4-3-28. Prevention of heating operation due to outdoor temperature inverter / hydro control part display (prevention of cooling operation due to low temperature of outdoor) judgment method ∙ cooling operation : when the outdoor temperature is less than -25 °c cause of problem ∙ system protection ...

Page 73

69 4-3-29 fan starting error outdoor unit display (fan pcb(fan1)) (fan pcb(fan2)) judgment method ∙ startup, and then if the speed increase is not normally. ∙ detected by h/w or s/w cause of problem ∙ compressor connection error ∙ defective compressor ∙ defective pcb power off and then restart repla...

Page 74

70 ipm breakdown diagnostics (fan pcb) 1. Preparations before checking 1) power off 2) ipm failure, discharge mode may not work properly. Therefore, wait more than 15 minutes after the power off. 3) remove all of the fan pcb connectors. (comp connector included) 4) prepare the digital multi tester. ...

Page 75

71 4-3-30. Fan lock error inverter / hydro control part display (fan pcb(fan1)) (fan pcb(fan2)) judgment method ∙ is checked symptoms by phase current of fan motor. Cause of problem ∙ fan motor connection error. ∙ defective fan ∙ defective pcb 1. Inspection method power on and then trial operation p...

Page 76

72 4-3-31. Momentary blackout error 1. Measures : replace hub pcb or main, hub connection wire. Inverter / hydro control part display (prevention of heating operation due to high temperature of outdoor) judgment method ∙ momentary stop of compressor due to momentary blackout. Cause of problem ∙ mome...

Page 77

73 4-3-32. Outdoor fan motor overheating inverter / hydro control part display (fan pcb(fan1)) (fan pcb(fan2)) judgment method ∙ overheating due to the internal sensor of the fan motor. Cause of problem ∙ defective connection wire ∙ defective fan motor ∙ defective pcb ∙ defective installation condit...

Page 78

74 4-3-33. Fan ipm overheat error inverter / hydro control part display (fan1 pcb) (fan2 pcb) judgment method ∙ ipm internal temperature more than 85°c (e455, e355) cause of problem ∙ heat sink and ipm assembly defective. ∙ defective heat sink cooling 1. Inspection method power off yes did check the...

Page 79

75 4-3-34. Compressor starting error inverter / hydro control part display (inverter1 pcb) (inverter2 pcb) judgment method ∙ startup, and then if the speed increase is not normally. ∙ detected by h/w or s/w. Cause of problem ∙ compressor connection error ∙ defective compressor ∙ defective pcb 1. Ins...

Page 80

76 starting error (cont.) ■ compressor applied 2 before change after change measure error of no.1 compressor error of no.1 compressor replace no.1 compressor error of no.1 compressor error of no.2 compressor replace no.1 inverter pcb error of no.2 compressor error of no.2 compressor replace no.2 com...

Page 81

77 4-3-35. Inverter overcurrent error 1. Inspection method inverter / hydro control part display (inverter1 pcb) (inverter2 pcb) judgment method ∙ will occur if the overcurrent flowing in the ipm. ∙ detected by h/w or s/w cause of problem ∙ installation defective ∙ comp. Defective ∙ pcb defective ∙ ...

Page 82

78 compressor applied 2 before change after change measure error of no.1 compressor error of no.1 compressor replace no.1 compressor error of no.1 compressor error of no.2 compressor replace no.1 inverter pcb error of no.2 compressor error of no.2 compressor replace no.2 compressor error of no.2 com...

Page 83

79 ipm [igbt] breakdown diagnostics (inverter pcb) 1. Preparations before checking 1) power off. 2) ipm failure, discharge mode may not work properly. Therefore, wait more than 15 minutes after the power off. 3) remove all of the inverter pcb connectors and wire that is fixed as screw. (include wire...

Page 84

80 4-3-36. Overvoltage / low voltage error inverter / hydro control part display (inverter1 pcb) (inverter2 pcb) judgment method ∙ n-phase wiring error and emi fuse short. ∙ dc-link overvoltage / low voltage occurs. Cause of problem ∙ check the input wiring ∙ emi fuse short 1. Inspection method powe...

Page 85

81 4-3-37. Dc link voltage sensor error outdoor unit display (inverter1 pcb) (inverter2 pcb) (outdoor fan 1 pcb) judgment method ∙ dc voltage detection : error judgment where the voltage value is more than 4.8v or less than 0.2v. Cause of problem ∙ dc link connector disconnected ∙ pcb voltage sensin...

Page 86

82 4-3-38. Fan motor overcurrent error outdoor unit display (fan pcb(fan1)) (fan pcb(fan2)) judgment method ∙ occurs when overcurrent flows in the ipm. ∙ detected by h/w or s/w cause of problem ∙ defective fan pcb ∙ connector error ∙ defective motor 1. Inspection method replace fan pcb yes replace o...

Page 87

83 fan motor overcurrent error (cont.) outdoor unit display (fan pcb(fan1)) (fan pcb(fan2)) judgment method ∙ occurs when overcurrent flows in the ipm. ∙ detected by h/w or s/w cause of problem ∙ defective fan motor 1. Inspection method yes power off e489 replace no1 fan motor e389 replace no2 fan m...

Page 88

84 4-3-39. Input / output current sensor error outdoor unit display inverter1 pcb(input current sensor) inverter2 pcb(input current sensor) inverter1 pcb(output current sensor) inverter 2 pcb(output current sensor) outdoor fan pcb (fan1 output current sensor) outdoor fan pcb (fan2 output current sen...

Page 89

85 4-3-40. Outdoor fan pcb overvoltage / low voltage error inverter / hydro control part display judgment method ∙ n-phase wiring error and emi fuse short. ∙ dc-link overvoltage / low voltage occurs. Cause of problem ∙ check the input wiring ∙ emi fuse short 1. Inspection method power off yes is inv...

Page 90

86 4-3-41. Hall ic (fan) error inverter / hydro control part display (fan pcb(fan1)) (fan pcb(fan2)) judgment method ∙ fan rotation defective or vibration and noise of the defective operation. ∙ hall ic there is no signal input. Cause of problem ∙ connection status error. ∙ hall ic wire disconnectio...

Page 91

87 4-3-42. Inverter overheat error inverter / hydro control part display (inverter1 pcb) (inverter2 pcb) judgment method ∙ igbt module internal temperature : 105°c more than (e500, e400) cause of problem ∙ cooling pin and the igbt junction part assembly defective. ∙ refrigerant cooling heat sink and...

Page 92

88 4-3-43. Option setting error of outdoor unit 1. Inspection method inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem ∙ option setting error of outdoor unit. (e2p option use of other model or set of the relevant outdoor unit, compressor bre...

Page 93

89 4-3-44. Hydro inlet temperature sensor (tw1) short/open 1. Inspection method restart operation after connecting the connector to pcb. Replace this part as it is the defective of hydro in temperature sensor itself. Restart operation after replace the pcb. No no yes yes did the connector for water ...

Page 94

90 1. Inspection method 4-3-45. Hydro outlet temperature sensor (tw2) short/open inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem hydro unit water out temperature sensor open/short error. Restart operation after connecting the connector to ...

Page 95

91 4-3-46. Frozen damage error inverter / hydro control part display judgment method water outlet temperature dose not change more than 3&. Eva in/out maintains the temperature below zero. Cause of problem indoor temperature of hydro heat exchanger is low.(flow/temperature is low) 1. Inspection met...

Page 96

92 4-3-47. Error when freeze prevention comp off inverter / hydro control part display (possibility of restarting in once ~ 3 times) (stopping on 4 times) judgment method water outlet temperature dose not change more than 3& eva in/out maintains the temperature below zero. During the cooling operat...

Page 97

93 4-3-48. Hydro outlet temperature sensor breakaway inverter / hydro control part display judgment method water outlet temperature before and after the operation : temperature difference is less than 2& cause of problem breakaway of hydro outlet temperature sensor 1. Inspection method check the mo...

Page 98

94 4-3-49. Water flow error (water pressure sensor) inverter / hydro control part display (auto-restarting in once ~ 5 times) (stopping on 6 times) judgment method output status from pump signal : does not detect the signal of flow sensor, more than 5 seconds. Cause of problem does not detect the si...

Page 99

95 4-3-50. Error on pump magnetic switch malfunction inverter / hydro control part display judgment method refer to the inspection method below. Cause of problem pump magnetic switch malfunction pump interlock input contact connection status. During pump operation the on signal to the contact does n...

Page 100

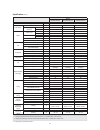

96 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 5. Pcb diagram and parts list 5-1. Assy pcb main-hydro - model : all models name is commonness.

Page 101

97 ① #1 : earth ② #1 : live #2 : #3 : neutral ③ #1 : neutral #2 : #3 : live signal ④ #1 : cooling_heating_dp signal #2 : #3 : cooling_heating_dp signal #4 : #5 : operation_dp signal #6 : #7 : operation_dp signal ⑤ #1 : com1_rxd #2 : com1_txd #3 : ntrst #4 : tdo #5 : tck #6 : tdi #7 : tms #8 : trace_...

Page 102

98 1 2 3 4 5 6 8 9 10 11 13 12 14 7 assy pcb main-hydro (cont.) - model : all models name is commonness.

Page 103

99 ① #1 : #2 : phe_out signal #3 : gnd #4 : 5v ② #1 : flow switch signal #2 : gnd ③ #1: n/a #2 : n/a #3: n/a #4 : n/a #5 : set temp #6 : gnd #7 : ext_water_out temp #8 : gnd ④ #1 : pump_protection temp #2 : gnd ⑤ #1 : night_low_noise_op signal #2 : gnd #3 : demand_op signal #4 : gnd #5 : fan_force_o...

Page 104

100 3 2 1 5 4 6 7 8 9 10 11 12 13 14 15 16 5-2. Assy pcb main - model : all models name is commonness.

Page 105

101 ① #1 : 5v #2 : rxd_inverter signal #3 : inv_comm signal #4 : gnd ② #1 : rxd_in #2 : txd_in #3 : ntrst #4 : tdo #5 : tck #6 : tdi #7 : tms #8 : trace_clk#9 : gnd #10 : 5v #11 : 5v #12 : mode0 #13 : reset_main #14 : trace 3 #15 : #16 : #17 : gnd #18 : trace 2#19 : trace 1 #20 : trace 0 ③ #1 : gnd ...

Page 106

102 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 5-3. Assy pcb sub-fan - model : all models name is commonness.

Page 107

103 ① #1 : rxd_debug1 #2 : txd_debug1 #3 : boot1 #4 : tdo1 #5 : tck1 #6 : tdi1 #7 : tms1 #8 : #9 : gnd #10 : 5v #11 : #12 : #13 : #14 : #15 : #16 : #17 : #18 : #19 : #20 : ② #1 : 5v #2 : viewer1_dac1 #3 : viewer2_dac1 #4 : viewer3_dac1 #5 : data_dac1 #6 : cs_dac1 #7 : clk_dac1 #8 : gnd ③ #1 : u ④ #1...

Page 108

104 5-4. Assy pcb sub-emi (pf#8 h power model only) - model : ag042/056ksv666 series ① cn23- inverter 220v ② cn21-fan a ③ cn22-main 220 ④ rst- rst input #1 : ac #2 : #3 : ac #1 : r #2 : s #3 : t #1 : ac #2 : ac t-in s-in r-in 1 3 2 4.

Page 109

105 1 2 4 3 5 6 7 8 9 10 11 5-5. Assy pcb sub-emi (pf #9 h power model only) (cont.) - model : ag070ksv666 series.

Page 110

106 ① cn23-inverter 220v ② cncn108-hub 220v ③ cn42-earth ④ cn105-r out #1 : ac live #2 : #3 : ac neutral #4 : #5 : ac neutral #1 : ac live #2 : #3 : ac neutral #1 : earth (pe) #1 : r-out ⑤ cn106-s out ⑥ cn107-t out ⑦ cn41-earth ⑧ cn101-r in #1 : s-out #1 : t-out #1 : earth (pe) #1 : r-in ⑨ cn102-s i...

Page 111

107 5-6. Assy pcb main-hub - model : all models name is commonness □ dc 1 2 3 4 5 6 7 8 9 10 11 12.

Page 112

108 assy pcb main-hub (cont.) - model : all models name is commonness □ dc ① cn83-evi eev ② cn81-eev1 ③ cn82-eev2 ④ cn43-temp. Sensor #1 : eev3_a_out #2 : eev3_b_out #3 : eev3_a'_out #4 : eev3_b'_out #5 : 12v #1 : eev1_b'_out #2 : eev1_a'_out #3 : eev1_b_out #4 : eev1_a_out #5 : 12v #6 : 12v #1 : ee...

Page 113

109 assy pcb main-hub (cont.) - model : all models name is commonness □ ac 1 1 2 3 4 5 6 7 8 9 10 11.

Page 114

110 assy pcb main-hub (cont.) - model : all models name is commonness □ ac (cont.) ① cn714-cch1 ② cn715-main-cooling ③ cn713-cch2 ④ cn704-hotgas-valve1 #1 : cch1 #2 : cch1 #1: main-cooling #2: main-cooling #1 : cch2 #2 : cch2 #1 : hotgas bypass1 #2 : hotgas bypass1 ⑤ cn705-hotgas-bypass2 ⑥ cn703-evi...

Page 115

111 5-7. Assy pcb inverter (pf #8) - model : ag042/056ksv666 series 4 2 3 5 1 8 9 7 6.

Page 116

112 assy pcb inverter (pf #8) (cont.) - model : ag042/056ksv666 series ① w- comp w ② u-comp u ③ v-comp v ④ cn22-download #1 : comp w #1 : comp u #1 : comp v #1 : rx-down #2 : tx-down #3 : n-trst #4 : tdo #5 : tck #6 : tdi #7 : tms #8 : #9 : gnd #10 : vcc ⑤ cn32 – main comm ⑥ reactor (wire connection...

Page 117

113 assy pcb inverter (pf #9) (cont.) - model : ag070ksv666 series 10 8 4 9 7 6 11 12 13 1 2 3 5.

Page 118

114 assy pcb inverter (pf #9) (cont.) - model : ag070ksv666 series ① w-comp w ② u-comp u ③ v-comp v ④ cn22-download #1 : comp w #1 : comp u #1 : comp v #1: rx-down #2: tx-down #3: boot #4: tdo #5: tck #6: tdi #7: tms #9: gnd #10: vcc ⑤ cn32 – main comm ⑥ cn702-reactor1 ⑦ cn701-reactor2 ⑧ cn91-fan dc...

Page 119

115 ① cn44 ② cn36 ③ cn#44 ④ cn45 ⑤ cn55 #1 : f1 #2 : f2 #1 : of1 #2 : of2 #1 : r1 #2 : r2 gnd #1 :f1 #2 :f2 #3 :of1 #4 :of2 #5 :r1 #6 :r2 1 2 3 4 5 5-8. Assy pcb sub-comm - model : all models name is commonness.

Page 120

116 117 this document can not be used without samsung’s authorization. 6-1. Dvm chiller hydro part wiring diagram - model : ag042/056/070ksvanh/eu 6. Wiring diagram.

Page 121

118 119 this document can not be used without samsung’s authorization. Dvm chiller hydro part wiring diagram (cont.) - model : ag042/056/070ksvgnh/eu.

Page 122

120 121 this document can not be used without samsung’s authorization. 6-2. Dvm chiller inverter control part wiring diagram - model : ag042/056ksvanh/eu.

Page 123

122 123 this document can not be used without samsung’s authorization. 6-3. Dvm chiller inverter control part wiring diagram - model : ag070ksvanh/eu.

Page 124

124 125 this document can not be used without samsung’s authorization. 6-4. Dvm chiller inverter control part wiring diagram - model : ag042/056ksvgnh/eu.

Page 125

126 127 this document can not be used without samsung’s authorization. 6-5. Dvm chiller inverter control part wiring diagram - model : ag070ksvgnh/eu.

Page 126: 7. Cycle Diagram

128 abbreviation name inv inverter compressor ofm outdoor fan motor ohx outdoor heat exchanger ac accumulator os oil separator ic intercooler ipmc ipm cooler hps high pressure sensor lps low pressure sensor wips water inlet temperature sensor wops water outlet temperature sensor hpsw high pressure s...

Page 127

129 ∙ cycle diagram function explanation 1. Accumulator : separating the incoming liquid refrigerant to the compressor in order to prevent liquid refrigerant. 2. Oil separator : separating the oil from the refrigerant discharged from the compressor, and the separated oil is returned to the compresso...

Page 128: 8. Key Options

130 view mode display Ź press and hold k3 and k4 for 3 seconds to enter the view mode. Ź press k3 to change view mode in order of the table. Ź press k4 to change view mode in reverse order of the table. Ź cancelling view mode display - press and hold k3 for 3 seconds. Basic segment display seg1 seg2...

Page 129

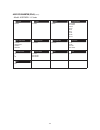

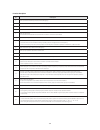

131 number of press key operation seg1 seg2 seg3 seg4 seg5 seg6 remarks 13 times suction1 temperature 1 3 - 1 1 2 ex) -11.2 °c 14 times suction2 temperature 1 4 - 1 1 2 ex) -11.2 °c 15 times cond out temperature 1 5 - 1 1 2 ex) -11.2 °c 16 times liquid temperature 1 6 3 5 0 ex) 35 °c 17 times eva in...

Page 130

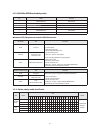

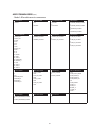

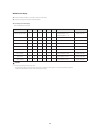

132 option no. Option value seg1 seg2 seg3 seg4 seg5 seg6 operation on/off input method 0 1 - - - 0 temperature setting input method 0 2 - - - 0 no. Option item option value factory default option definition setting unit module control setting option note1) 1 operation on/off input method 0.1 0 0 mo...

Page 131

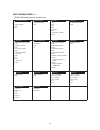

133 note1) for options that can be selected by module control and main option, the option value selected for last time will be saved. Note2) main unit of module when group is not available no. Option item option value factory default option definition setting unit module control setting option note1...

Page 132

134 no. Description 1 select operation on/off input method of module/group 2 select temperature setting input method of module/group 3 select operation mode (cool/heat, hot water/cool storage) input method of module/group 4 select demand control input method of module/group 5 select demand level • c...

Page 133

135 water law this function allows water outlet temperature to change regarding damand load changes depending on outdoor temperature and room temperature. It can be set to increase energy efficiency and comfort. Note refer to page 133 for set values of water outlet set temperature (tcool1, tcool2, t...

Page 134

136 micom version display Ź press and hold k3 and k5 for 3 seconds to enter the view mode. Ź press k3 to change view mode in order of the table. Ź cancelling view mode display - press and hold k3 for 3 seconds. Seg1 seg2 seg3 seg4 seg5 seg6 remarks data source address setting mode 0 1 0 1 1 2 group ...

Page 135

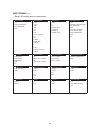

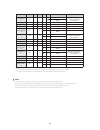

137 8-3. Setting inverter controller option basic segment display setting inverter controller option switch k1 k2 k3 k4 k1 k2 k3 k4 step display content display seg1 seg2 seg3 seg4 at initial power input checking segment display 8 8 8 8 chiller units communicating setting (addressing) - seg1 seg2 se...

Page 136

138 installing and setting the option with tact switch and functions 1. Press and hold k2 for 3 seconds. (only available when the operation is stopped) - the display will show the following. - if you have set the emergency operation for compressor malfunction, 1 or 2 will be displayed on seg 4. - se...

Page 137

139 note1) forced fan function: operates fan periodically to prevent show compiling on the fan while the product is stopped note2) maximum cooling capacity restriction: limits operation capacity of compressor according to indoor load note • during option setting, you may press and hold the k1 for 3 ...

Page 138

140 how to set a special operation using tact switch and check the view mode - to use key operating function for service and maintenance when installing module/group, set as main control or cancel in module/group. - during discharging mode, voltage of inv1 and inv2 will be displayed alternately. - e...

Page 139

141 k3 (number of press) key operation display on 7-segment 1 time intialize (reset) operation same as initial state k4 (number of press) display contents display seg1 seg2, 3, 4 1 time capacity depending on horsepower 1 ag042k ✴✴✴ 0, 1, 5 ag056k ✴✴✴ 0, 2, 0 ag070k ✴✴✴ 0, 2, 5 2 times order frequenc...

Page 140: 9. Trial Operation

142 note before a test run, check whether the power wire is disconnected or misconnected. If the power wire is disconnected or misconnected, error code displays or power is not supplied or major part is not operated. The pump built-in model is able not to operate or to be occurred trip of ocr or to ...

Page 141

143 6. Operation mode in main control is selected be cooling/heating switch. Dip s/w no.2 on off cool mode heat mode - operation mode can be changed only when operation is off. 7. Change the set temperature if necessary in main control. Default value cooling heating 7 °c 45 °c - temperature can be a...

Page 142

This service manual is a property of samsung electronics co., ltd. Any unauthorized use of manual can be punished under applicable international and/or domestic law. © samsung electronics co., ltd. May. 2016. Printed in korea. Code no. Ac-00148e_2 gspn (global service partner network) area web site ...