- DL manuals

- Samsung

- Air Conditioner

- AG042KSVANH

- Installation manual

Samsung AG042KSVANH Installation manual

Summary of AG042KSVANH

Page 1

Dvm chiller installation manual ag042ksv ✴✴✴ / ag056ksv✴✴✴ / ag070ksv✴✴✴ series ŷ thank you for purchasing this samsung product. ŷ before operating this unit, please read this insatallation manual carefully and retain it for future reference..

Page 2

2 english contents installation safety information 3 preparing for installation 8 specifications of the non-pump models 8 specifications of the pump integrated models 9 dvm chiller classification 10 moving the product 10 center location 11 accessories (basic specification) 11 field supply 11 selecti...

Page 3

Ins talla tion 3 english safety information dvm chiller uses r-410a refrigerant. ŷ when moisture or foreign substances enter into the refrigerant pipe using r-410a, it may affect the performance and reliability of the product. Safety precautions must be obeyed when installing the refrigerant pipe. ŷ...

Page 4

Ins talla tion safety information 4 english do not operate the product with power switch or circuit breaker. ŷ potential risk of electric shock or fire. ŷ if automatic blackout restore is set, fan may spin suddenly and it may cause injury. If fuse load switch is used, do not use fuse in incorrect ca...

Page 5

Ins talla tion 5 english when outdoor temperatre drops below zero, take appropriate countermeasures for frozen damage. ŷ freeze protection such as using brine, heater, pump operation, etc. Is necessary. ŷ drain all water and cut-off the power supply when the product is not operated during winter tim...

Page 6

Ins talla tion safety information 6 english check the followings before installation and repair/ maintenance service. ŷ before brazing, remove dangerous and/or flammable things around workplace that may cause an explosion and fire. ŷ before brazing, remove the refrigerant within the pipe or the prod...

Page 7

Ins talla tion 7 english wiring must be connected with the designated wires and it must be fixed securely so that it does not apply any external force to the connection part of the terminals. ŷ if connection or fixation is not properly done, it may cause heat generation or fire. Please connect groun...

Page 8

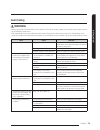

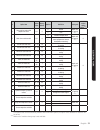

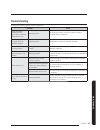

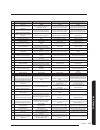

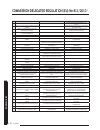

Ins talla tion 8 english preparing for installation specifications of the non-pump models model ag042ksvanh ag056ksvanh ag070ksvanh power supply 3 phase 4 wires 380 ~ 415 v, 50/60 hz capacity cooling (rated) kw 42 56 65 heating (rated) kw 42 56 69.5 power consumption cooling (rated) kw 12.35 18.67 2...

Page 9

Ins talla tion 9 english specifications of the pump integrated models model ag042ksvgnh ag056ksvgnh ag070ksvgnh power supply 3 phase 4 wires 380 ~ 415 v, 50/60 hz capacity cooling (rated) kw 42 56 65 heating (rated) kw 42 56 69.5 power consumption cooling (rated) kw 13.59 20.14 28.26 heating (rated)...

Page 10

Ins talla tion preparing for installation 10 english dvm chiller classification classification dvm chiller appearance applied model ag042/056/070ksv series caution ŷsafely store or dispose the packaging materials. - sharp metals such as nails or wooden material packaging that may break into pieces b...

Page 11

Ins talla tion 11 english caution ŷdo not hang the rope on side of the water pipe. The rope may force the water pipe to deformed or damaged. 2 when moving with a forklift f carefully insert the forklift forks into the forklift holes at the palette. F be careful with the forklift from damaging the pr...

Page 12

Ins talla tion 12 english decide the installation location, with the consideration of the following conditions, under user's approval. F place where hot discharge air or noise from the dvm chiller may not disturb the neighbor (especially in residential areas, keep the operation hours in mind.) f pla...

Page 13

Ins talla tion 13 english caution ŷin regions with heavy snowfall, make sure to install the dvm chiller where there is no concerns of direct snowfall on the dvm chiller. Also, build higher base support so that accumulated snow does not block the air inlet or the heat exchanger. ŷr-410a refrigerant i...

Page 14

Ins talla tion 14 english required space for installation f space requirement was decided based on the following conditions; cooling mode, outdoor temperature of 35 °c. Larger space is required if the outdoor temperature is higher than 35 °c or if the place is heated easily by quantity of solar radi...

Page 15

Ins talla tion 15 english 2 module installation unit: mm front side 100 or more 200 or more 100 or more 100 or more 300 or mor e (s2) 500 or mor e (s1) 400 or more 400 or more 200 or more front side 300 or more height of the wall is unlimited front side front side 100 or more 100 or more 100 or more...

Page 16

Ins talla tion 16 english warning ŷmake sure to remove the wooden pallet before installing the dvm chiller. If you do not remove the wooden pallet, there is risk of fire during welding the pipes. If the dvm chiller is installed with wooden pallet on, and it was used for long period time, wooden pale...

Page 17

Ins talla tion 17 english product installation unit: mm 200 or more 200 or more 50 or more h beam or vibration-isolation frame supporting base base mount and anchor bolt position a b 54 761 803 54 product - vibration-isolation frame (4 - Ø12) supporting base (h beam or vibraition-isolation frame) ap...

Page 18

Ins talla tion base construction and installation 18 english installation precautions connecting the anchor bolt caution plastic (rubber) washer ŷtighten the rubber washer to prevent the bolt connection part of the dvm chiller from corroding. Anchor specification a b c m ŷuse the anchor bolts and nu...

Page 19

Ins talla tion 19 english installing vibraiton-isolation frame f during installation, make sure there is no gap between the supporting base and the extra structures such as vibration-isolation frame or h beam. F supporting base must be constructed strongly to support the bottom part of the vibration...

Page 20

Ins talla tion 20 english installing the discharge duct around the obstacles ex.) balcony upper floor discharged air ex.) mechanical room discharged air grille/ louver suction air f it is necessary to install a wind/snow prevention duct (field supply) to direct exhaust from the fan horizontally, whe...

Page 21

Ins talla tion 21 english installing the discharge duct in regions with strong wind f in windy regions such as near sea shores, protection wall or wind protection duct must be installed for normal operation of the product. (refer to the illustration of the snow prevention duct, for installing the wi...

Page 22

Ins talla tion 22 english water pipe diagram install the water system according to the diagram. Direction of water flow expansion vessel cleaning and flushing pipe (install when cleaning) load unit ahu or fan coil dvm chiller field scope water side heat exchanger 03 07 04 10 11 09 12 08 01 04 06 05 ...

Page 23

Ins talla tion 23 english warning ŷthe maximum operation water pressure of the product is 1.0 mpa. ŷthe water strainer is not included in the product. You must install 50 mesh stainless strainer (field supply). If the strainer is not installed, it may cause breakdown of the product. ŷthe strainer ne...

Page 24

Ins talla tion water pipe installation 24 english installing strainer f install strainer (field scope: 50 mesh) that cleaning is possible at the inlet of dvm chiller to prevent foreign substances such as bolt and stones from flowing into water side heat exchanger. - if strainer is not installed or t...

Page 25

Ins talla tion 25 english maintaining contamination foreign substances included in chilled/heating water by small particles pass strainers, and they may be stuck or stacked inside plate type heat exchanger. Some parts of water pipes inside the plate type heat exchanger, and the performance may decre...

Page 26

Ins talla tion water pipe installation 26 english securing water storage minimum water storage chilled/ heating water pump buffer tank fan coil f if the length of water pipe is too short, water storage within the system becomes lower and on/off operation of the compressor occurs more often. For stab...

Page 27

Ins talla tion 27 english using the pump note ŷthe description below applies to ag ✴✴✴ksvg series models only. Startup caution ŷdo not start the pump until it has been filled with liquid. Warning ŷpay attention to the direction of the vent hole, and make sure that the escaping hot or cold liquid doe...

Page 28

Ins talla tion using the pump 28 english frost protection pumps which are not being used during periods of frost must be drained to avoid damage. Remove the filling and drain plugs from the pump. Do not refit the plugs until the pump is taken into operation again. Caution ŷbefore startup after a per...

Page 29

Ins talla tion 29 english fault finding warning ŷbefore removing the terminal box cover, switch off the power supply. Make sure that the power supply cannot be accidentally switched on. ŷthe pumped liquid may be scalding hot and under high pressure. Before any removal or dismantling of the pump, the...

Page 30

Ins talla tion using the pump 30 english fault cause remedy 6. The pump runs, but gives no water. A) pump inlet pressure too low. See 5. A). B) the suction pipe is partly clogged by impurities. See 5. B). C) the foot or non-return valve is stuck in its closed position. Remove and clean, repair or re...

Page 31

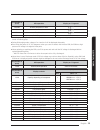

Ele ctric al w ork 31 english circuit breaker and power cable specification classification capacity (hp) model mca mfa non-pump models 15 ag042ksvanh 32 40 20 ag056ksvanh 46 60 25 ag070ksvanh 58 75 pump integrated models 15 ag042ksvgnh 39 50 20 ag056ksvgnh 53 60 25 ag070ksvgnh 65 75 ŷpower supply co...

Page 32

Ele ctric al w ork electrical wiring work 32 english example of exposed core wire insulator (inner cover) exposed wire core sheath (outer cover) ŷdo not use the power cable with the core wire exposed due to insulator damage occurred during removal of the sheath. When the core wire is exposed, it may...

Page 33

Ele ctric al w ork 33 english connecting the power cable power cable power cable power cable unit 1 unit 2 unit 3 communication cable 3rzhuŷjurxqgfdeoh power cable elcb or mccb+elb elcb or mccb+elb elcb or mccb+elb 3rzhuŷjurxqg cable 3rzhuŷ ground cable 3rzhuŷ ground cable power cable protection tub...

Page 34

Ele ctric al w ork electrical wiring work 34 english connecting the communication cable unit 1 module control f1 f2 v1 v2 f3 f4 unit2 unit 3 protection tube communication cable communication cable single connection module/group connection hydro controller communication part module control f1 f2 v1 v...

Page 35

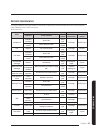

Ele ctric al w ork 35 english no. Name signal function contact on (short) contact off (open) a-t/b 1-2 cooling/heating display zero voltage contact display when operates in heating mode heat cool 3-4 operation display display when operates operate stop 5-6 warning display display when error occurs e...

Page 36

Ele ctric al w ork electrical wiring work 36 english input contact 1 3 5 7 9 11 13 15 17 19 2 4 6 8 10 12 14 16 18 20 b-t/b no. Name signal function contact on (short) contact off (open) signal recognition setting unit b-t/b 1-2 disuse - - - - - - 3-4 disuse - - - - - - 5-6 disuse - - - - - - 7-8 pu...

Page 37

Ele ctric al w ork 37 english ŷusual input: operate by current status of contact instant input: operate when contact signal changes from off to on / from on to off. Note1) operates when input method of opearation on/off is set as external contact note2) operates when input method of operation mode i...

Page 38

Ele ctric al w ork electrical wiring work 38 english no. Name signal function contact on (short) contact off (open) signal recognition setting unit c-t/b 17-18 set temperature/ room temperature sensor analog current recognize water outlet set temperature by external input (4 ~ 20 ma) note1) recogniz...

Page 39

Ele ctric al w ork 39 english note ŷroom temperature sensor and external water outlet temperature sensor is not supplied. Purchase and install the appropriate sensor according to the usage. - room temperature sensor: 4 ~ 20 ma (4 ma : -50 ˚c, 20 ma : 50 ˚c) - external water outlet temperature sensor...

Page 40

Ele ctric al w ork electrical wiring work 40 english selecting solderless ring terminal f select the solderless ring terminal depending on the nominal dimension of the power cable. F cover and insulate the solderless ring terminal and connection part of the power cable. Soldering unit: mm nominal di...

Page 41

Ele ctric al w ork 41 english connecting the power terminal f connect the cables to the terminal board with solderless ring terminals. F properly connect the cables by using certified and rated cables and make sure to fix them properly so that external force is not applied to the terminal. F use a d...

Page 42

Ele ctric al w ork electrical wiring work 42 english examples of using the cable striper cable striper 1 adjust the blade position by coin. (controller is at the bottom side of the tool.) fix the blade position according to the outer sheath thickness of the power cable. 2 fix the power cable and too...

Page 43

Ele ctric al w ork 43 english fixing the power cable caution ŷdo not let the power cable come into contact with the pipes inside the dvm chiller. If the power supply cable touches the pipes, the vibration of the compressor is transferred to the pipes and can damage the power supply cables or pipes, ...

Page 44

Ele ctric al w ork electrical wiring work 44 english withdrawing the power cable connect the power cable protection tube into the power supply box. Be sure that the power supply cable is not damaged by burr on the knock-out hole. Installing the solution device f1 f2 of1 of2 r1 r2 f1 terminal block w...

Page 45

Ele ctric al w ork 45 english performing the grounding work use a rated grounding cable by referring to the specification of the electric cable for the product. F when using the exclusive grounding terminal (when the exclusive grounding terminal is already built in the house) exclusive grounding ter...

Page 46

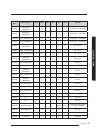

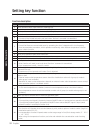

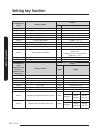

Ele ctric al w ork 46 english setting key function setting hydro controller option basic segment display seg1 seg2 seg3 seg4 seg5 seg6 remarks water in 0 1 - 0 5 0 ex) -5 °c view mode display f press and hold k3 and k4 for 3 seconds to enter the view mode. F press k3 to change view mode in order of ...

Page 47

Ele ctric al w ork 47 english number of press key operation seg1 seg2 seg3 seg4 seg5 seg6 remarks 8 times discharge 1 temperature 0 8 1 0 1 ex) 101.8 °c 101 (drop) 9 times discharge 2 temperature 0 9 1 0 1 ex) 101.8 °c 101 (drop) 10 times top 1 temperature 1 0 1 0 1 ex) 101.8 °c 101 (drop) 11 times ...

Page 48

Ele ctric al w ork setting key function 48 english number of press key operation seg1 seg2 seg3 seg4 seg5 seg6 remarks 31 times hydro eev 1 3 1 1 0 0 ex) 1007 step 100 (drop "/10") 32 times hydro eev 2 3 2 1 0 0 ex) 1007 step 100 (drop "/10") 33 times main eev 1 3 3 1 0 0 ex) 1007 step 100 (drop "/1...

Page 49

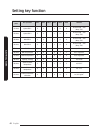

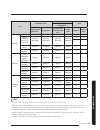

Ele ctric al w ork 49 english how to set hydro controller option option no. Option value seg1 seg2 seg3 seg4 seg5 seg6 operation on/off input method 0 1 - - - 0 temperature setting input method 0 2 - - - 0 1 turn on the product. 2 press and hold the k2 to enter the option setting. F in option settin...

Page 50

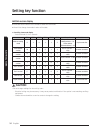

Ele ctric al w ork setting key function 50 english no. Option item option value factory default option definition setting unit module control setting option note1) 5 demand level 0 ~ 11 3 0 default (100 %) main unit of module o 1 95 % 2 90 % 3 85 % 4 80 % 5 75 % 6 70 % 7 65 % 8 60 % 9 55 % 10 50 % 1...

Page 51

Ele ctric al w ork 51 english no. Option item option value factory default option definition setting unit module control setting option note1) 14 using exterior water outlet temperature sensor 0/1 0 0 disuse main unit of group note2) 1 use 15 water law control standard 0/1 0 0 outdoor temperature ma...

Page 52

Ele ctric al w ork setting key function 52 english function description no. Description 1 select operation on/off input method of module/group 2 select temperature setting input method of module/group 3 select operation mode (cool/heat, hot water/cool storage) input method of module/group 4 select d...

Page 53

Ele ctric al w ork 53 english water law this function allows water outlet temperature to change regarding damand load changes depending on outdoor temperature and room temperature. It can be set to increase energy efficiency and comfort. F outdoor temparture standard w at er ou tle t se t t emp . Ou...

Page 54

Ele ctric al w ork setting key function 54 english micom version display f press and hold k3 and k5 for 3 seconds to enter the view mode. F press k3 to change view mode in order of the table. F cancelling view mode display - press and hold k3 for 3 seconds. Seg1 seg2 seg3 seg4 seg5 seg6 remarks data...

Page 55

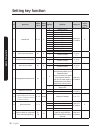

Ele ctric al w ork 55 english setting inverter controller option basic segment display step display contents display seg1 seg2 seg3 seg4 at initial power supply checking segment display 8 8 8 8 setting communication (addressing) - a d 0 1 after communication setting (usual occasion) transmit/recepti...

Page 56

Ele ctric al w ork setting key function 56 english installing and setting the option with tact switch and functions 1 press and hold k2 for 3 seconds. (only available when the operation is stopped) f the display will show the following. F if you have set the emergency operation for compressor malfun...

Page 57

Ele ctric al w ork 57 english option item input unit seg1 seg2 seg3 seg4 function of the option remarks outdoor unit fan speed correction individual 0 6 0 0 factory default 0 1 increase fan speed increase the outdoor unit fan speed to maximum value unused option main 0 7 0 0 unused option unused opt...

Page 58

Ele ctric al w ork setting key function 58 english setting key operation and checking the view mode with tact switch k1 k2 k3 k4 k1 k2 k3 k4 k1 (number of press) key operation display on 7-segment 1 time refrigerant charging in heating mode 2 times trial operation in heating mode 3 times refrigerant...

Page 59

Ele ctric al w ork 59 english k2 (number of press) key operation display on 7-segment 10 times inverter compressor 2 check 11 times fan 1 check 12 times fan 2 check 13 times end key operation - f to use key operating function for service and maintenance when installing module/group, set as main cont...

Page 60

Ele ctric al w ork setting key function 60 english k4 (number of press) display contents display seg1 seg2, 3, 4 19 times evi outlet temperature j -42 °c -, 4, 2 20 times main eev 1 step k 2000 steps 2, 0, 0 21 times main eev 2 step l 2000 steps 2, 0, 0 22 times evi eev step m 300 steps 3, 0, 0 23 t...

Page 61

Bef ore opera tion 61 english check points after installation 1 before supplying the power, use dc 500 v insulation resistance tester to measure the power terminal and the product grounding. F 3 phase 4 wires 380 ~ 415 v: r, s, t, n / single phase: l, n f measurement should be over 30 mΩ. 2 before s...

Page 62

Bef ore opera tion check points after installation 62 english trial operation before the trial operation, check the following list to protect the product. Precautions before trial operation ŷwhen the outdoor temperature is low, turn on the main power 6 hours before starting the operation. - if you s...

Page 63

Bef ore opera tion 63 english f is the strainer in water pipe contaminated after the trial operation? - clean the strainer if contaminated. F is minimum amount of circulating water (over 50 % of rated flow rate) acquired? Trial operation for each chiller unit hydro-unit_module_chiller k1 k2 k3 k4 k5...

Page 64

Bef ore opera tion check points after installation 64 english 7 change the set temperature if necessary in main control. Default value cooling heating 7 °c 45 °c f temperature can be adjusted by k3 and k4. Set temperature k3 k4 0.1 °c up 0.1 °c down f set temperature range set temperature range cool...

Page 65

Maintenance 65 english maintenance name of the parts hydro controller control box air side heat exchanger water side heat exchanger inverter controller control box compressor plate type heat exchanger hydro air vent valve water inlet temperature sensor water inlet pressure sensor water inlet flange ...

Page 66

Maintenance maintenance 66 english water pipe installation cleaning and flushing pipe (install when cleaning) 03 04 10 09 08 direction of water flow expansion vessel water side heat exchanger field scope 07 09 06 05 12 11 dvm chiller 02 08 01 note ŷthe part shown in the dotted line is an installatio...

Page 67

Maintenance 67 english f connect water (brine) pipes to the nearest place of the product by flange, and make the pipe and the product to be separated. Install valve at inlet/outlet of pipes, drain valve at inlet, and air purge valve at outlet of water (brine) pipe. F maintain the water or brine stor...

Page 68

Maintenance maintenance 68 english caution regarding drainage during winter time drain valve f when dvm chiller is not operated during winter time, drain all water by opening drain valves in chiller shown in figure and drain valves in the pipes. Filling hole drain hole f if the dvm chiller has an in...

Page 69

Maintenance 69 english item chilled water system heating water system effect low level medium temperature heating gauge circulation water (below 20 °c ) supply water circulation water (over 20 °c below 60 °c) supply water corrosion forming scale basic item ph (25 °c) 6.8 ~ 8.0 6.8 ~ 8.0 7.0 ~ 8.0 7....

Page 70

Maintenance maintenance 70 english maintaining plate type heat exchanger f when the product was not operated for long period of time, check the followings: - check the water to see if the water quality is meets the standard. - clean the strainer. - check to see if there is enough amount of flow rate...

Page 71

Maintenance 71 english stopping during winter time f do not cut-off the power supply. - this may result in water leakage or pipe damage because pump will not operate to prevent freezing. Do not cut-off the power supply for the pump. F stop the operation with water pipe valve opened. - stop the opera...

Page 72

Maintenance maintenance 72 english inspection for normal operation item standard number of inspection side effects when inadequate forced drainage have you set the electric conductivity value properly? Once a week corrosion, water scale or slime may occur is electric conductivity sensor working prop...

Page 73

Maintenance 73 english chilled water management if the chilled water storage exceeds optimal range, stop the operation until cause is taken care before re-start the operation. F range: 50 ~ 200 % of rated flow rate 0 50 100 150 200 250 300 20 40 60 80 100 120 140 160 180 200 220 240 pr essur e loss ...

Page 74

Maintenance maintenance 74 english water temperature range operate the product within the following range. For product protection, compressor operation may be limited. Classification rated condition (inlet/ outlet) range (water outlet) water brine cooling 12/7 °c 5 °c ~ 25 °c -10 °c ~ 25 °c heating ...

Page 75

Maintenance 75 english freeze prevention of water pipe follow the list if draining water inside the pump and water pipe is difficult. Using brine f use ethylene glycol, propylene glycol, etc. For brine. Ethylene glycol is inexpensive, and used for general industry, and propylene glycol is used for f...

Page 76

Maintenance maintenance 76 english standard data for status of anti-freeze (based on temperature of anti-freeze at 15 °c) type of anti- freeze (based on 15 °c ) concentration [% wt.] freezing point (°c) brine freezing point graph ethylene glycol 10 -3.2 0 10 -60 -50 -40 -30 -20 -10 0 20 30 40 50 60 ...

Page 77

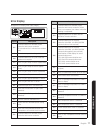

Maintenance 77 english error display f segment will display error code (4 digit). Hydro-unit_module_chiller k1 k2 k3 k4 k5 k6 88-seg display display description 101 communication error between hydro controller and inverter controller (if not received for 3 minutes from outdoor unit) 108 error due to...

Page 78

Maintenance maintenance 78 english display description 277 error on top 2 temperature sensor (short or open) 291 error on high pressure sensor (short or open) 296 error on low pressure sensor (short or open) 308 error on suction sensor (short or open) 311 error on double layer pipe sensor (short or ...

Page 79

Maintenance 79 english display description 452 instant blackout error 453 overheated motor of fan1 455 error due to overheated ipm of fan1 461 inv1 comp starting error 462 compressor stop due to full current control or error due to low current on ct2 464 inv1 dc peak error 465 inv1 comp vlimit error...

Page 80

Maintenance maintenance 80 english error history display f press and hold k3 and k6 for 3 seconds to enter the view mode. F press k3 to change view mode in order of the table. F cancelling view mode display - press and hold k3 for 3 seconds. Seg1 seg2 seg3 seg4 seg5 seg6 remarks currently occurred e...

Page 81

Maintenance 81 english important information regulation regarding the refrigerant used this product contains fluorinated greenhouse gases. Do not vent gases into the atmosphere. Caution ŷinform user if system contains 5 tco 2 e or more of fluorinated greenhouse gases. In this case, it has to be chec...

Page 82

Maintenance maintenance 82 english vacuuming the pipes f use tools for r-410a to prevent the inflow of foreign substances and resist against the internal pressure. F use vacuum pump that allows vacuuming under -100.7 kpa (5 torr). F use the vacuum pump with the check valve to prevent pump oil from f...

Page 83

Maintenance 83 english troubleshooting f following situations are not product breakdown. Problem cause when only pump operates during winter time or outdoor temperature is low supplying power forced pump function to prevent water freezing is available. (refer to page 63.) when compressor is heated w...

Page 84

Maintenance maintenance 84 english f before you report the problem of the product, check the following table. Problem monitor cause solution when pump and compressor is not starting off check if there is power failure. Operate again when the power is on again. Check if circuit breaker is closed. Ope...

Page 85

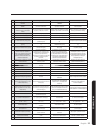

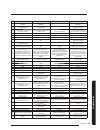

Maintenance 85 english periodic maintenance for proper operation, check and record the following list periodically. Recommended values are normal operation range. Operation time is 3650 hours/year. F common items name periodic maintenance preventive maintenance checklist check standard check period ...

Page 86

Maintenance maintenance 86 english name periodic maintenance preventive maintenance checklist check standard check period preventive description preventive period pressure sensor resistance value should be rated resistance value every year exchange 5 years visual check no deformation structural part...

Page 87

Maintenance 87 english maintaining water system f check and clean water strainer. - if strainer is blocked, water side heat exchanger may freeze due to lack of water storage. F check if air is not mixed in inlet/outlet of chilled/heating water pipe system. - air may be mixed in the system even if fi...

Page 88

Maintenance 88 english caution ŷto change functions of the product, electrical wiring and changing setting are also mandatory. Contact the merchandise or service center for electrical wiring work and changing settings. Automatic function f cooling/heating - the product contains function that cool/he...

Page 89

Maintenance 89 english forced fan function f this function operates fan of chiller to remove accumulated snow on the fan. F snow accumulation prevention, which operates occasionally when outdoor temperature is below 5 °c, is basic function use this function by module control or external contact when...

Page 90

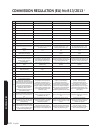

Maintenance 90 english commission regulation (eu) no 813/2013 i) a model(s) : ag042ksvanh b air-to-water heat pump : yes c water-to-water heat pump : no d brine-to-water heat pump : no e low-temperature heat pump : no f equipped with a supplementary heater : no g heat pump combination heater : no h ...

Page 91

Maintenance 91 english a model(s) : ag056ksvanh b air-to-water heat pump : yes c water-to-water heat pump : no d brine-to-water heat pump : no e low-temperature heat pump : no f equipped with a supplementary heater : no g heat pump combination heater : no h parameters shall be declared for medium-te...

Page 92

Maintenance 92 english a model(s) : ag070ksvanh b air-to-water heat pump : yes c water-to-water heat pump : no d brine-to-water heat pump : no e low-temperature heat pump : no f equipped with a supplementary heater : no g heat pump combination heater : no h parameters shall be declared for medium-te...

Page 93

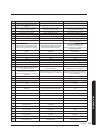

Maintenance 93 english no english(en) bulgarian(bg) spanish(es) czech(cs) i commission regulation (eu) no 813/2013 РЕГЛАМЕНТ (ЕС) № 813/2013 НА КОМИСИЯТА reglamento (ue) no 813/2013 de la comisiÓn naŘÍzenÍ komise (eu) č. 813/2013 ii ecodesign requirements for space heater Изискванията за екопроектир...

Page 94

Maintenance 94 english no english(en) bulgarian(bg) spanish(es) czech(cs) ab degradation co-efficient(**) Коефициент на влошаване на ефективността(**) coeficiente de degradación (**) koeficient ztráty energie (**) ac heating water operating limit temperature Гранична температура на загряваната вода ...

Page 95

Maintenance 95 english no danish(da) german(de) estonian(et) greek(el) i kommissionens forordning (eu) nr. 813/2013 verordnung (eu) nr. 813/2013 der kommission komisjoni mÄÄrus (el) nr 813/2013, ΚΑΝΟΝΙΣΜΌΣ (ΕΕ) αριθ. 813/2013 ΤΗΣ ΕΠΙΤΡΟΠΉΣ ii kravene til miljøvenligt design af anlæg til rumopvarmnin...

Page 96

Maintenance 96 english no danish(da) german(de) estonian(et) greek(el) ae supplerende forsyningsanlæg zusatzheizgerät lisakütteseade Συμπληρωματικός θερμαντήρας af slukket tilstand aus-zustand väljalülitatud seisund Κατάσταση εκτός λειτουργίας ag termostat fra-tilstand thermostat-aus-zustand termost...

Page 97

Maintenance 97 english no french(fr) croatian(hr) italian(it) latvian(lv) i rÈglement (ue) no 813/2013 de la commission uredba komisije (eu) br. 813/2013 regolamento (ue) n. 813/2013 della commissione komisijas regula (es) nr. 813/2013 ii les exigences d’écoconception applicables aux dispositif de c...

Page 98

Maintenance 98 english no french(fr) croatian(hr) italian(it) latvian(lv) aa copcyc ou percyc copcyc ili percyc copcyc oppure percyc copcyc vai percyc ab coefficient de dégradation (**) koeficijent degradacije (**) coefficiente di degradazione (**) pazeminājuma koeficients (**) ac température maxima...

Page 99

Maintenance 99 english no lithuanian(lt) hungarian(hu) maltese(mt) dutch(nl) i komisijos reglamentas (es) nr. 813/2013 a bizottsÁg 813/2013/eu rendelete regolament tal-kummissjoni (ue) nru 813/2013 verordening (eu) nr. 813/2013 van de commissie ii ekologinio projektavimo reikalavimai už patalpų šild...

Page 100

Maintenance 100 english no lithuanian(lt) hungarian(hu) maltese(mt) dutch(nl) ad vartojamoji galia ne aktyviąja veiksena energiafogyasztás a főfunkción kívüli üzemmódokban konsum tal-enerġija fil-modalitajiet minbarra dik attiva elektriciteitsverbruik in andere standen dan de actieve modus ae papild...

Page 101

Maintenance 101 english no polish(pl) portuguese(pt) romanian(ro) slovak(sk) i rozporzĄdzenie komisji (ue) nr 813/2013 regulamento (ue) n.O 813/2013 da comissÃo nariadenie komisie (eÚ) č. 813/2013 nariadenie komisie (eÚ) č. 813/2013 ii wymogi dotyczące ekoprojektu dla ogrzewaczy pomieszczeń os requi...

Page 102

Maintenance 102 english no polish(pl) portuguese(pt) romanian(ro) slovak(sk) ae ogrzewacz dodatkowy aquecedor suplementar dodatočný tepelný zdroj dodatočný tepelný zdroj af tryb wyłączenia modo desligado režim vypnutia režim vypnutia ag tryb wyłączonego termostatu modo termóstato desligado režim vyp...

Page 103

Maintenance 103 english no slovenian(sl) finnish(fi) swedish(sv) i uredba komisije (eu) št. 813/2013 komission asetus (eu) n:o 813/2013, kommissionens fÖrordning (eu) nr 813/2013 ii okoljsko primerno zasnovo zahteve za grelnik prostorov ekosuunnitteluvaatimukset varten tilalämmittimellä ekodesignkra...

Page 104

Maintenance 104 english no slovenian(sl) finnish(fi) swedish(sv) ak druge postavke muut kohdat andra poster al upravljanje zmogljivosti tehonsäätö kapacitetsreglering am stalna/spremenljiva kiinteä/muuttuva fast/variabel an za toplotne črpalke zrak–voda: nazivna stopnja pretoka zraka, zunanja ilma-v...

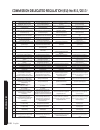

Page 105

Maintenance 105 english product fiche (energy labelling of space heaters) ii) a supplier's name or trademark samsung electronics co., ltd. Samsung electronics co., ltd. Samsung electronics co., ltd. B supplier's model identifier ag042ksvanh/eu ag056ksvanh/eu ag070ksvanh/eu c seasonal space heating e...

Page 106

Maintenance 106 english commission delegated regulation (eu) no 811/2013 i) product fiche (energy labelling of space heaters) ii) a supplier's name or trademark samsung electronics co., ltd. Samsung electronics co., ltd. Samsung electronics co., ltd. B supplier's model identifier ag042ksvgnh/eu ag05...

Page 107

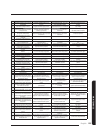

Maintenance 107 english no english(en) bulgarian(bg) spanish(es) czech(cs) i commission delegated regulation (eu) no 811/2013 ДЕЛЕГИРАН РЕГЛАМЕНТ (ЕС) № 811/2013 НА КОМИСИЯТА reglamento delegado (ue) no 811/2013 de la comisiÓn naŘÍzenÍ komise v pŘenesenÉ pravomoci (eu) č. 811/2013 ii product fiche (...

Page 108

Maintenance 108 english no danish(da) german(de) estonian(et) greek(el) i kommissionens delegerede forordning (eu) nr. 811/2013 delegierte verordnung (eu) nr. 811/2013 der kommission komisjoni delegeeritud mÄÄrus (el) nr 811/2013 ΚΑΤ' ΕΞΟΥΣΙΟΔΌΤΗΣΗ ΚΑΝΟΝΙΣΜΌΣ (ΕΕ) αριθ. 811/2013 ΤΗΣ ΕΠΙΤΡΟΠΉΣ ii pro...

Page 109

Maintenance 109 english no french(fr) croatian(hr) italian(it) latvian(lv) i rÈglement dÉlÉguÉ (ue) no 811/2013 de la commission delegirana uredba komisije (eu) br. 811/2013 regolamento delegato n. 811/2013 della commissione europea komisijas deleĢĒtĀ regula (es) nr. 811/2013 ii fiche de produit (l’...

Page 110

Maintenance 110 english commission delegated regulation (eu) no 811/2013 i) no lithuanian(lt) hungarian(hu) maltese(mt) dutch(nl) i komisijos deleguotasis reglamentas (es) nr. 811/2013 a bizottsÁg 811/2013/eu felhatalmazÁson alapulÓ rendelete regolament ta’ delega tal- kummissjoni (ue) nru 811/2013 ...

Page 111

Maintenance 111 english no polish(pl) portuguese(pt) romanian(ro) slovak(sk) i rozporzĄdzenie delegowane komisji (ue) nr 811/2013 regulamento delegado (ue) nº 811/2013 da comissÃo regulamentul delegat al comisiei (ue) nr. 811/2013 delegovanÉ nariadenie komisie (eÚ) č. 811/2013 ii karta produktu (w o...

Page 112

Maintenance 112 english commission delegated regulation (eu) no 811/2013 i) no slovenian(sl) finnish(fi) swedish(sv) i delegirana uredba komisije (eu) št. 811/2013 komission delegoitu asetus (eu) n:o 811/2013 kommissionens delegerade fÖrordning (eu) nr 811/2013 ii podatkovni list izdelka (energijske...

Page 113

Maintenance 113 english memo.

Page 114

Db68-05916a-02 samsung electronics co., ltd. 107, hanamsandan 6beon-ro, gwangsan-gu, gwangju-si, korea 62218 samsung electronics (uk) ltd, euro qa lab. Blackbushe business park. Saxony way, yateley, hampshire. Gu46 6gg united kingdom.