- DL manuals

- SmartPool

- Swimming Pool Cleaners

- NC71AU

- Repair Manual

SmartPool NC71AU Repair Manual

Summary of NC71AU

Page 1

W w w . S m a r t p o o l . C o m smartpool robotic pool cleaner repair manual.

Page 2: Nc71Au

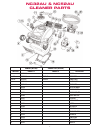

2 nc71au cleaner parts a a a 22 admiral ultra (nc71au) location product # description 1 nc7115 top shell 2 nc7106 lower chassis 3 nc7122au power supply 4 nc7123 cable 5 nc7107 drive motor 6 nc7113 pump motor 7 nc1004 drive brush 8 nc7108 drive wheel tube 9 nc7112 non drive wheel tube 10 nc7104 brush...

Page 3: Nc32Au & Nc52Au

3 nc32au & nc52au cleaner parts admiral (nc32au) admiral plus (nc52au) location product # product # description 1 nc1001:02 chassis 2 and 2a nc1009:02 nc1024:02 pump motor 3 and 3a nc1013au nc1023au power supply 4 nc1012:02 floating cord 5 nc1006:02 drive motor 6 nc1010 drive tube mount 7 nc1011 cha...

Page 4

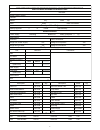

4 ra: received: service center location: customer: phone: email: date of purchase: y n partial authorized by: serial number: used misuse ------------ ------------ water entry motor programming other: part # qty part # qty nc7102 non drive wheel tube nc7112 nc7103 pump motor nc7113 nc7104 top return ...

Page 5

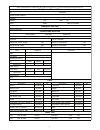

5 ra: received: service center location: customer: phone: email: date of purchase: y n partial authorized by: serial number: used misuse ------------ ------------ water entry motor programming other: part # qty part # qty nc1001:02 foam ring nc1014 nc1003 impeller nc1015 nc1004 bottom lid nc1016 dri...

Page 6

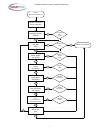

6 nc71au troubleshooting guide model: scrubber/admiral ultra test cable (26-29vdc) test power supply (29-32vdc) replace drive motor replace cable replace pump motor remove any debris from impeller or tracks and check for damage. Test drive motor with test cable (ok) replace power supply water test (...

Page 7

7 smartpool robotic cleaner troubleshooting guide models: nitro/admiral/admiral plus test cable (25-28vdc) test power supply (28-32vdc) self test (ok) filter bag properly installed replace power supply water test (ok) replace cable return to customer test pump motor (25-28vdc) replace pump motor tes...

Page 8: Scrubber Series Evaluation

W w w . S m a r t p o o l . C o m 8 scrubber series evaluation model number: nc71au.

Page 9

W w w . S m a r t p o o l . C o m 9 1) place the cleaner on the bench and examine for physical damage and for any debris caught in the impeller or drive brushes (remove debris if found). 2) place the cleaner upside down on bench and remove the bottom lid by pushing in on the red tabs. 3) perform a s...

Page 10: Results

W w w . S m a r t p o o l . C o m 10 • if the cleaner is “dead in water” or has “no suction/does not pick up debris” then the unit should not move at all during the self test. • if the cleaner is “spinning in circles” or “does not move” then the impeller should operate during the self test. Results.

Page 11: Test The Power Supply

W w w . S m a r t p o o l . C o m 11 test the power supply nc7122au.

Page 12: Results

W w w . S m a r t p o o l . C o m 12 4) test the voltage through the power supply: insert the prongs of the voltmeter into the (2) copper plugs of the power supply socket and turning the unit to the on position (29-32vdc). Picture does not reflect new style power supply design but voltage output is ...

Page 13: Test The Cable

W w w . S m a r t p o o l . C o m 13 test the cable nc7123.

Page 14: Results

W w w . S m a r t p o o l . C o m 14 6) place the prongs of meter into the back of the cable harness, connect the other end of the cable to the power supply and turn the power supply to the on position. Important: leave the cable plugged into the pump motor for an accurate reading. • if the voltage ...

Page 15: Test The Drive Motor

W w w . S m a r t p o o l . C o m 15 test the drive motor nc7107.

Page 16: Results

W w w . S m a r t p o o l . C o m 16 8) carefully remove the heat shrink covering the drive motor connection. 9) connect one end of the test cable to the drive motor and the other end to the power supply. Turn the power supply to the on position. Important: this is a quick on/off test. Do not run th...

Page 17: Replacing The Cable

W w w . S m a r t p o o l . C o m 17 replacing the cable nc7123.

Page 18

W w w . S m a r t p o o l . C o m 18 1) loosen the pressure fitting to the cable and gently pull on the wires to expose the connection. 2) carefully remove the heat shrink covering the drive motor connection. 3) remove the (2) screws that hold the strain relief to the shell of the cleaner..

Page 19

W w w . S m a r t p o o l . C o m 19 4) pull up on the cable to gain access to the strain relief. 5) remove the (2) screws that hold the two halves of the strain relief together. 6) remove the defective cable from the cleaner and feed the new cable through the shell..

Page 20

W w w . S m a r t p o o l . C o m 20 note: there should be at least 14’’ (~35cm) of cable inside the cleaner: that is the distance from the strain relief to the pump motor. 7) find the 14’’ (~35cm) mark and make a loop in the cable that intersects with that line. 8) take that loop and fold/rotate it...

Page 21

W w w . S m a r t p o o l . C o m 21 steps 7 and 8 9) insert the looped cable into the strain relief. 10) reinstall the (2) screws that hold the two halves of the strain relief together..

Page 22

W w w . S m a r t p o o l . C o m 22 11) pull the cable from the back of cleaner so that the strain relief is resting against the shell. 12) reinstall the (2) screws that hold the strain relief to the shell of the cleaner by aligning the threads of the cable collar. 13) reconnect the cable harness (...

Page 23: Replacing The Drive Motor

W w w . S m a r t p o o l . C o m 23 replacing the drive motor nc7107.

Page 24

W w w . S m a r t p o o l . C o m 24 1) loosen the pressure fitting to the drive motor and gently pull on the wires to expose the connection. 2) carefully remove the heat shrink covering the drive motor connection. 3) remove the tracks by gently pulling outward on the track while rotating the drive ...

Page 25

W w w . S m a r t p o o l . C o m 25 4) with a phillips head screwdriver, remove the (5) screws from each side-plate . 5) remove both side-plates. 6) remove the (2) drive pulleys on the drive motor side using a phillips head screwdriver..

Page 26

W w w . S m a r t p o o l . C o m 26 7) remove the (3) motor mount screws using a phillips head screwdriver on the drive motor side. 8) gently pull on the drive motor to remove it from the shell and slide the drive tubes from the drive motor. 9) pull the cable to the drive motor through the hole in ...

Page 27

W w w . S m a r t p o o l . C o m 27 the cleaner is fully disassembled and ready to be reassembled with the new drive motor. 10) feed the cable of the new drive motor through the hole in the shell. Make sure the fitting is in a vertical position to pass it through the shell. 11) slide the new drive ...

Page 28

W w w . S m a r t p o o l . C o m 28 12) reinsert the motor mount screws. 13) reinstall the (2) drive pulleys and tighten the screws using a phillips head screwdriver..

Page 29

W w w . S m a r t p o o l . C o m 29 14) reinstall the side-plates and tighten the screws using a phillips head screwdriver. (note: the curve of the side-plate should face the pool’s surface or the up direction in this example. The (3) center screws are machine threaded the (2) outside screws are se...

Page 30: Replacing The Pump Motor

W w w . S m a r t p o o l . C o m 30 replacing the pump motor nc7113.

Page 31

W w w . S m a r t p o o l . C o m 31 1) remove the impeller cover by unscrewing the (1) mounting screw. 2) remove the (4) motor mount screws. 3) place cleaner upside-down on bench and remove the bottom lid..

Page 32

W w w . S m a r t p o o l . C o m 32 4) loosen the pressure fitting to the drive motor and gently pull on the wires to expose the connection. 5) carefully remove the heat shrink covering the drive motor connection. 6) loosen the pressure fitting to the cable and gently pull on the wires to expose th...

Page 33

W w w . S m a r t p o o l . C o m 33 7) carefully remove the heat shrink covering the cable connection. 8) remove the pump motor from the shell. 9) install the new pump motor into the shell; making sure that drive motor and cable connections are on the correct side..

Page 34

W w w . S m a r t p o o l . C o m 34 10) connect the drive motor clip, feed it into the pump motor and tighten the pressure fitting. 11) connect the cable clip, feed it into the pump motor and tighten the pressure fitting. 12) reinstall the (4) motor mount screws..

Page 35

W w w . S m a r t p o o l . C o m 35 13) reinstall the impeller cover by replacing the (1) mounting screw..

Page 36: Model Numbers:

W w w . S m a r t p o o l . C o m 36 smartpool cleaner evaluation model numbers: nc32au, nc52au.

Page 37

W w w . S m a r t p o o l . C o m 37 1) place the cleaner on the bench and examine for physical damage and if there is any debris caught in the impeller or drive brush (remove debris if found). 2) remove bottom lid. 3) check filter bag for proper installation. The “push in” sign should be covered by...

Page 38: Results

W w w . S m a r t p o o l . C o m 38 4) perform a self test: place the unit upside down on the bench, plug in the power supply and the cable. Turn power supply to the on position: the pump motor should run and then the drive motor should turn on. Shut the unit down after the drive motor starts to ru...

Page 39: Test The Power Supply

W w w . S m a r t p o o l . C o m 39 test the power supply nc1013au and nc1023au.

Page 40: Results

W w w . S m a r t p o o l . C o m 40 • if power supply is found to be defective, replace with a new power supply and perform another self test. • if power supply is found to be ok, proceed with the following steps. Results 5) test the voltage through the power supply by inserting the prongs of the v...

Page 41: Nc1012:02

W w w . S m a r t p o o l . C o m 41 test voltage through cable nc1012:02 (version 2 cable).

Page 42: Results

W w w . S m a r t p o o l . C o m 42 6) loosen the pressure fitting to the cable and pull on the plug to expose the connection. 7) place the prongs of the voltmeter into the back of the connection (do not disconnect the cable harness) and turn the power supply on to read the voltage through the cabl...

Page 43: Drive Motor

W w w . S m a r t p o o l . C o m 43 test the voltage to the drive motor drive motor nc1006:02 (version 2).

Page 44

W w w . S m a r t p o o l . C o m 44 8) unscrew pump motor from unit by removing the (4) mounting screws 9) cut the zip tie: this will give easier access to the pump motor. Important: be careful not to cut the wires. 10) pull up on the pump motor to remove it from the shell..

Page 45: Results

W w w . S m a r t p o o l . C o m 45 11) turn cleaner on its side and place the pump motor on bench (impeller up) 12) loosen the pressure fitting to the drive motor and pull on wire to expose the connection. 13) disconnect the harness and read the voltage off the plug (wire coming from the pump moto...

Page 46: Testing Sensor Wheels

W w w . S m a r t p o o l . C o m 46 testing sensor wheels.

Page 47: Results

W w w . S m a r t p o o l . C o m 47 14) loosen the pressure fitting to the sensor wheels, pull on the wires to expose the connection and separate the connection. 15) while reading resistance/checking for continuity, place the prongs of the voltmeter on the two metal contacts on 1 of the 2 sensor wh...

Page 48: Replacing The Cable

W w w . S m a r t p o o l . C o m 48 replacing the cable nc1012:02 (version 2 cable).

Page 49

W w w . S m a r t p o o l . C o m 49 1) loosen the pressure fitting to the cable and pull on the plug to expose the connection. Release the connections by separating the harness. 2) turn the red tabs inward to release the cage and gain access to the cable strain relief. 3) remove the (6) screws of t...

Page 50

W w w . S m a r t p o o l . C o m 50 4) pull the cable through the cleaner shell. Note: the hole alignment of the inner screws (2 holes are offset). 5) insert new cable into shell..

Page 51

W w w . S m a r t p o o l . C o m 51 6) pull enough cable into the cleaner to reach the pump motor by feeding it around the cable channel. 8) reconnect the cable harness, insert the connection into the pump motor and tighten the pressure fitting. 7) align the holes of the strain relief and the cable...

Page 52: Replacing The Drive Motor

W w w . S m a r t p o o l . C o m 52 replacing the drive motor nc1006:02 (version 2).

Page 53

W w w . S m a r t p o o l . C o m 53 1) unscrew the pump motor from the unit by removing the (4) mounting screws. 2) loosen the pressure fitting to the drive motor, pull on wire to expose connection and disconnect the harness. 3) remove the large rubber cap on the drive motor side and remove the (3)...

Page 54

W w w . S m a r t p o o l . C o m 54 5) feed the new cable through the shell. 6) reconnect the plug, feed the wires into the pump motor and tighten the pressure fitting. 7) feed the motor into the tube, reinstall the (3) screws and replace the rubber cap..

Page 55

W w w . S m a r t p o o l . C o m 55 8) place the pump motor in the shell and secure it with the (4) motor mount screws. Important: make sure the drive motor cable is around the motor support..

Page 56: Replacing The Pump Motor

W w w . S m a r t p o o l . C o m 56 replacing the pump motor nc1009:02 or nc1024:02 (version 2).

Page 57

W w w . S m a r t p o o l . C o m 57 1) unscrew the pump motor from the unit by removing the (4) mounting screws. 2) cut the zip tie: this will give easier access to the pump motor. Important: be careful not to cut the wires. 3) pull up on the pump motor to remove it from the shell..

Page 58

W w w . S m a r t p o o l . C o m 58 4) turn cleaner on its side and place the pump motor on bench (impeller up) 5) loosen all the pressure fittings and disconnect all the connections. 6) connect all the components to their proper harness, feed wires into the pump motor and tighten pressure fittings...

Page 59

W w w . S m a r t p o o l . C o m 59 7) place pump motor into shell. 8) place the pump motor in the shell and secure it with the (4) motor mount screws. Important: make sure the drive motor cable is around the motor support..

Page 60: Nc1004

W w w . S m a r t p o o l . C o m 60 replacing the drive brushes nc1004.

Page 61

W w w . S m a r t p o o l . C o m 61 1) lift the support tab over the post to remove the brush from the wheel tube. 2) wrap the new brush around the wheel tube and pull the post through the hole in the center of the support tab..

Page 62: Replacing The Foam Ring

W w w . S m a r t p o o l . C o m 62 replacing the foam ring nc1014.

Page 63

W w w . S m a r t p o o l . C o m 63 1) remove the large rubber cap on the non-drive motor side and remove the (3) motor mount screws. 2) remove the drive tube mount and slide wheel tube assembly off the drive motor. 3) lift the support tab over the post to remove the brush from the wheel tube. 4) s...

Page 64

W w w . S m a r t p o o l . C o m 64 5) install the new foam ring and reinstall drive brush. 6) slide the wheel tube onto the drive motor and reinstall the drive tube mount. 7) reinstall the (3) screws and replace the rubber cap..

Page 65: Scrubber Series

W w w . S m a r t p o o l . C o m b1 scrubber series cleaners will have the serial number located on the side on the inner shell. The number will ei- ther be printed on the shell or on a sticker. How to locate the serial number scrubber series.

Page 66

W w w . S m a r t p o o l . C o m b2 wall to wall and wall climbing model cleaners will have the serial number located on either the side or back (behind the cage) of the inner shell. The number will be printed on the shell or on a sticker. How to locate the serial number wall to wall & climber seri...

Page 67

687 prospect st lakewood, nj 08701 732-‐730-‐9880 installation of cleaner weights 1) remove the protective cover to the adhesive backing. Admiral ultra admiral and admiral plus 2) press the weight on the inside of the shell, ensuring there is enough clearance for the installation of the bottom lid...

Page 68

Replacing the bottom lid support clips 687 prospect st lakewood, nj 08701 732-730-9880 1) use a cutting tool to cut the tab on the underside of the support. 2) use a flat-head screwdriver to remove the clip from the casing. 3) replace the old clip with the new material provided. Fit the washer onto ...

Page 69

Replacing the bottom lid support clips 687 prospect st lakewood, nj 08701 732-730-9880 4) place the red clip in the shell of the unit and begin to fasten the screw to the clip. 5) while holding the screw with a phillips-head screwdriver, rotate the red clip until it is firmly in place..

Page 70

Error reason(s) suggestion(s) dead in water outlet/gfi check outlet/reset the gfi or try another outlet cleaner reset unplug the cleaner and allow it to rest for 30 seconds extension cord try plugging the power supply directly into an outlet not moving debris caught in tracks/brushes/impeller check ...

Page 71

Covered in this chart nc32au and nc52au test and results chart component working range symptom(s)/result(s) of defective component additional information power supply 28‐32vdc cleaner will be dead in water cable 25‐28vdc cleaner will be dead in water cleaner may go back and forth in one spot pump mo...

Page 72

In this chart nc71au test and results chart component working range symptom(s)/result(s) of defective component additional information power supply 29‐32 vdc cleaner will be dead in water cable 26‐29 vdc cleaner will be dead in water make sure to test the cable while pump motor is running pump motor...